Komatsu D375A-5 Bull Dozer Shop Manual SEBM036104

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM036104

- Format: PDF

- Size: 50.5MB

- Number of Pages: 1066

Category: Komatsu Shop Manual PDF

-

Model List:

- D375A-5 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL, COOLANT AND LUBRICANT

- 4. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 4.1. POWER TRAIN

- 4.2. OVERALL DRAWING OF POWER TRAIN UNIT

- 4.3. POWER TRAIN HYDRAULIC PIPING DRAWING

- 4.4. DAMPER, UNIVERSAL JOINT

- 4.5. TORQUE CONVERTER, PTO

- 4.6. TORQUE CONVERTER VALVE

- 4.7. SCAVENGING PUMP

- 4.8. TRANSMISSION CONTROL

- 4.9. TRANSMISSION

- 4.10. TRANSMISSION ECMV

- 4.11. TRANSMISSION LUBRICATION RELIEF VALVE

- 4.12. POWER TRAIN PUMP LUBRICATION PUMP

- 4.13. STEERING, BRAKE CONTROL

- 4.14. TRANSFER, BEVEL GEAR SHAFT, STEERING

- 4.15. STEERING ECMV

- 4.16. STEERING CLUTCH, STEERING BRAKE ECMV

- 4.17. PARKING BRAKE VALVE

- 4.18. SUDDEN STOPS PREVENTION VALVE

- 4.19. CARRIER ROLLERUnit

- 4.20. TRACK ROLLER BOGIE

- 4.21. TRACK SHOE

- 4.22. MAIN FRAME

- 4.23. SUSPENSION

- 4.24. WORK EQUIPMENT HYDRAULIC PIPING DIAGRAM

- 4.25. PPC CONTROL PIPING DIAGRAM

- 4.26. WORK EQUIPMENT CONTROL

- 4.27. HYDRAULIC TANK

- 4.28. PPC CHARGE VALVE

- 4.29. ACCUMULATOR

- 4.30. PPC LOCK VALVE

- 4.31. PPC VALVE

- 4.32. WORK EQUIPMENT CYLINDER

- 4.33. PISTON VALVE

- 4.34. QUICK DROP VALVE

- 4.35. PIN PULLER SWITCH

- 4.36. PIN PULLER SOLENOID VALV

- 4.37. BLADE CONTROL KNOB

- 4.38. PITCH, DUAL TILT SOLENOID VALVE

- 4.39. WORK EQUIPMENT PPC CHARGE PUMP

- 4.40. MAIN CONTROL VALVE

- 4.41. CYLINDER STAY

- 4.42. BLADE

- 4.43. RIPPER EQUIPMENT

- 4.44. CAB MOUNT

- 4.46. AIR CONDITIONER

- 4.47. ENGINE CONTROL

- 4.48. ENGINE CONTROL SYSTEM

- 4.49. DECELERATOR POTENTIOMETER

- 4.50. HPI ENGINE CONTROL SYSTEM

- 4.51. MONITOR SYSTEM

- 4.52. MONITOR PANEL

- 4.53. MODE SELECTION SYSTEM

- 4.54. ELECTRICAL DEVICE

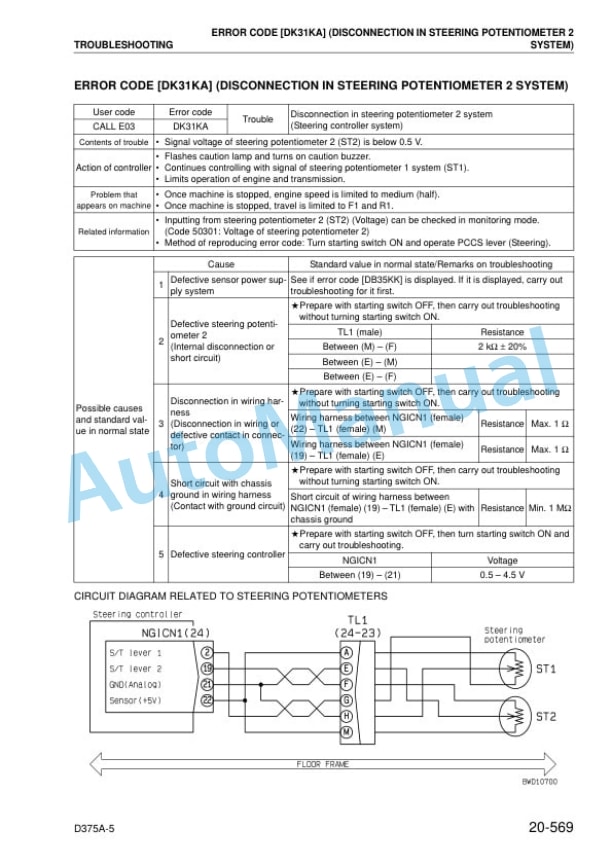

- 4.55. STEERING ELECTRONIC CONTROL

- 4.56. VHMS CONTROLLER

- 4.57. COMMUNICATION (ORB ORBCOMM) CONTROLLER/ANTENNA

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 5.2. STANDARD VALUE TABLE FOR MACHINE RELATED PARTS

- 5.3. TESTING AND ADJUSTING

- 5.4. TROUBLESHOOTING

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. HOW TO READ THIS MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCHES OF SPECIAL TOOLS

- 6.5. REMOVAL AND INSTALLATION OF FUEL PUMP ASSEMBLY

- 6.6. REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL

- 6.7. REMOVAL AND INSTALLATION OF ENGINE REAR SEAL

- 6.8. REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 6.9. REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY

- 6.10. REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY

- 6.11. REMOVAL AND INSTALLATION OF RADIATOR GUARD ASSEMBLY

- 6.12. REMOVAL AND INSTALLATION OF ENGINE ASSEMBLY

- 6.13. REMOVAL AND INSTALLATION OF DAMPER ASSEMBLY

- 6.14. DISASSEMBLY AND ASSEMBLY OF DAMPER

- 6.15. REMOVAL AND INSTALLATION OF POWER TRAIN UNIT ASSEMBLY

- 6.16. DISCONNECTION OF POWER TRAIN UNIT ASSEMBLY

- 6.17. CONNECTION OF POWER TRAIN UNIT ASSEMBLY

- 6.18. DISASSEMBLY ANDASSEMBLY OFPTO ASSEMBLY

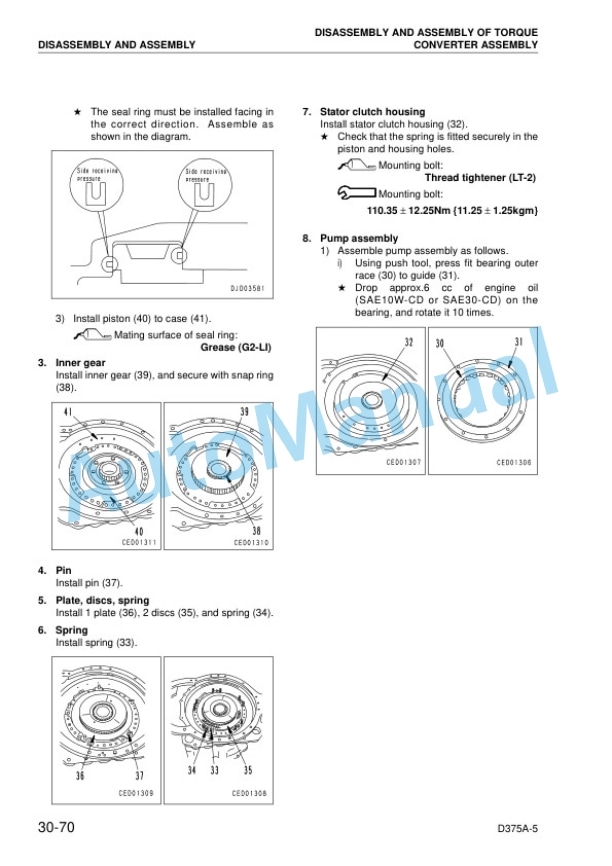

- 6.19. DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY

- 6.20. DISASSEMBLY AND ASSEMBLY OF TORQFLOW TRANSMISSION ASSEMBLY

- 6.21. DISASSEMBLY AND ASSEMBLY OF STEERING CASE ASSEMBLY

- 6.22. REMOVAL AND INSTALLATION OF POWER TRAIN, LUBRICATION PUMP ASSEMBLY

- 6.23. REMOVAL AND INSTALLATIONOF SCAVENGING PUMP ASSEMBLY

- 6.24. REMOVAL AND INSTALLATION OF FINAL DRIVE ASSEMBLY

- 6.25. DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY

- 6.26. REMOVAL AND INSTALLATION OF TRACK FRAME ASSEMBLY

- 6.27. REMOVAL AND INSTALLATION OF IDLER ASSEMBLY

- 6.28. DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY

- 6.29. REMOVAL AND INSTALLATION OF RECOIL SPRING ASSEMBLY

- 6.30. DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY

- 6.31. REMOVAL AND INSTALLATION TRACK ROLLER ASSEMBLY

- 6.32. DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 6.33. REMOVAL AND INSTALLATION OF BOGIE ASSEMBLY

- 6.34. DISASSEMBLY AND ASSEMBLY OF BOGIE ASSEMBLY

- 6.35. REMOVAL AND INSTALLATION OF 1ST BOGIE ASSEMBLY

- 6.36. EXPANDING AND ASSEMBLY TRACK SHOE INSTALLATION

- 6.37. WHOLE DISASSEMBLY AND ASSEMBLY OF TRACK SHOE

- 6.38. DIMENSIONS TABLE OF FITTING JIG OF LINK PRESS

- 6.39. DISASSEMBLY AND ASSEMBLY OF 1 LINK IN THE FIELD

- 6.40. DISASSEMBLY AND ASSEMBLY OF MASTER LINK

- 6.41. REMOVAL AND INSTALLATION OF PIVOT SHAFT ASSEMBLY

- 6.42. REMOVAL AND INSTALLATION OF EQUALIZER BAR

- 6.43. DISASSEMBLY AND ASSEMBLY OF EQUALIZER BAR BUSHING

- 6.44. REMOVAL AND INSTALLATION OF SEGMENT TOOTH

- 6.45. REMOVAL AND INSTALLATION OF HYDRAULICTANK ASSEMBLY

- 6.46. REMOVAL AND INSTALLATION OF WORK EQUIPMENT AND PPC PUMP ASSEMBLY

- 6.47. REMOVAL AND INSTALLATION OF BLADE LIFT VALVE ASSEMBLY

- 6.48. DISASSEMBLY AND ASSEMBLY OF BLADE LIFT VALVE ASSEMBLY

- 6.49. DISASSEMBLY AND ASSEMBLY OF BLADE TILT AND RIPPER LOW VALVE ASSEMBLY

- 6.50. DISASSEMBLY AND ASSEMBLY OF RIPPER HIGH VALVE ASSEMBLY

- 6.51. DISASSEMBLY AND ASSEMBLY OF PPC CHARGE VALVE ASSEMBLY

- 6.52. DISASSEMBLY AND ASSEMBLY OF BLADE PPC VALVE ASSEMBLY

- 6.53. DISASSEMBLY AND ASSEMBLY OF RIPPER PPC VALVE ASSEMBLY

- 6.54. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 6.55. DISASSEMBLY AND ASSEMBLY OF RIPPER PIN PULLER CYLINDER ASSEMBLY

- 6.56. REMOVAL AND INSTALLATION OF BLADE ASSEMBLY

- 6.57. DISASSEMBLY AND ASSEMBLY OF BLADE ASSEMBLY

- 6.58. DISASSEMBLY AND ASSEMBLY OF GIANT RIPPER ASSEMBLY

- 6.59. REMOVAL AND INSTALLATION OF ROPS GUARD

- 6.60. REMOVAL AND INSTALLATION OF OPERATORS CABASSEMBLY

- 6.61. REMOVAL AND INSTALLATION OF FLOOR FRAME

- 6.62. REMOVAL AND INSTALLATION OF DASHBOARD ASSEMBLY

- 6.63. REMOVAL AND INSTALLATION OF MONITOR PANEL ASSEMBLY

- 6.64. REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY

- 7. OTHERS

- 7.1. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 7.2. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 7.3. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (TILTDOZER)

- 7.4. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (TILTDOZER)

- 7.5. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (DUAL TILTDOZER)

- 7.6. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM (DUAL TILTDOZER)

- 7.7. ELECTRICAL CIRCUIT DIAGRAM (1/7)

- 7.8. ELECTRICAL CIRCUIT DIAGRAM (2/7)

- 7.9. ELECTRICAL CIRCUIT DIAGRAM (3/7)

- 7.10. ELECTRICAL CIRCUIT DIAGRAM (4/7)

- 7.11. ELECTRICAL CIRCUIT DIAGRAM (5/7)

- 7.12. ELECTRICAL CIRCUIT DIAGRAM (6/7)

- 7.13. ELECTRICAL CIRCUIT DIAGRAM (7/7)

- 7.14. DIAGRAM FOR ELECTRICAL CIRCUIT OF AIR CONDITIONER

- 7.15. ELECTRIC CIRCUIT DIAGRAM OF INSIDE CAB

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00