Komatsu D375Ai-8 Bull Dozer Operation and Maintenance Manual TEN00798-01

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: TEN00798-01

- Format: PDF

- Size: 10.1MB

- Number of Pages: 206

-

Model List:

- D375Ai-8 Bull Dozer

- 1. COVER

- 2. FOREWORD

- 2.1. CONTENTS

- 2.2. READ THIS MANUAL

- 2.3. SAFETY INFORMATION

- 2.4. INTRODUCTION

- 2.4.1. intelligent Machine Control

- 2.4.2. MACHINE FEATURES

- 2.5. ABBREVIATION LIST

- 3. SAFETY

- 3.1. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 3.1.1. PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

- 3.1.1.1. PRECAUTIONS WHEN STANDING UP FROM OPERATORS SEAT

- 3.1.1.2. PRECAUTIONS WHEN LEAVING MACHINE

- 3.1.2. PRECAUTIONS FOR BLADE AUTOMATIC CONTROL

- 3.2. PRECAUTIONS FOR OPERATION

- 3.2.1. START ENGINE

- 3.2.1.1. IN COLD WEATHER

- 3.3. PRECAUTIONS FOR MAINTENANCE

- 3.3.1. PRECAUTIONS FOR CHECK AND MAINTENANCE

- 3.3.1.1. PRECAUTIONS FOR AUX BOX

- 4. OPERATION

- 4.1. GENERAL VIEW

- 4.1.1. MACHINE EQUIPMENT NAME

- 4.1.2. CONTROLS AND GAUGES NAMES

- 4.1.2.1. CONTROL BOX NAME

- 4.2. EXPLANATION OF COMPONENTS

- 4.2.1. intelligent Machine Control SYSTEM

- 4.2.1.1. CONTROL BOX

- 4.2.1.2. AUTO/MANUAL SWITCH

- 4.2.1.3. CUT/FILL OFFSETS SWITCH

- 4.2.1.4. BACK GRADE MODE SWITCH

- 4.2.1.5. AUX BOX

- 4.2.1.6. AUTOPITCH ADJUSTMENT

- 4.3. MACHINE OPERATIONS AND CONTROLS

- 4.3.1. CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE

- 4.3.2. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 4.3.2.1. RESET CYLINDER STROKE END

- 4.3.2.2. SET STANDARD ANGLE OF BLADE EDGE

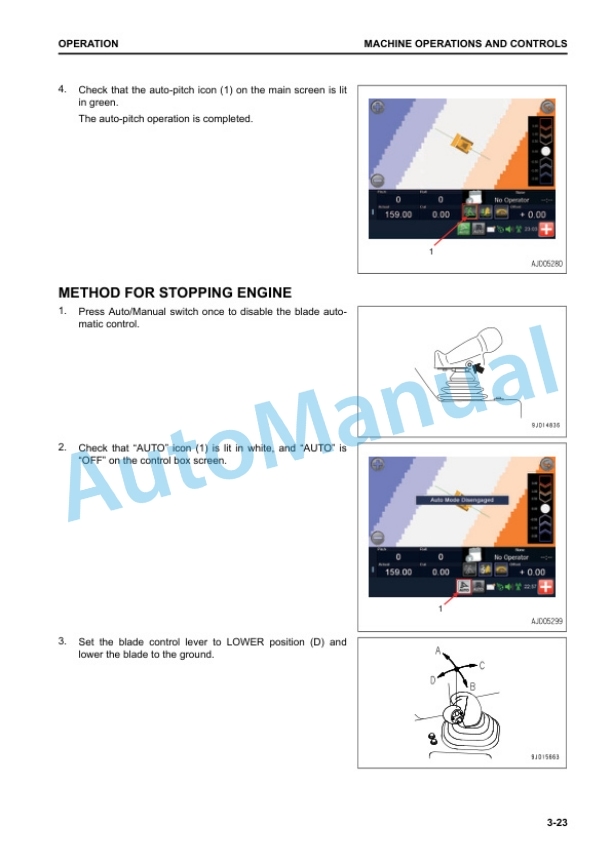

- 4.3.3. METHOD FOR STOPPING ENGINE

- 4.3.4. METHOD FOR USING AUTOMATIC BLADE CONTROL

- 4.3.4.1. PREPARATIONS FOR BLADE AUTOMATIC CONTROL

- 4.3.4.2. HANDLE AUTOMATIC BLADE CONTROL

- 4.3.4.3. MODE SETTINGS

- 4.3.4.4. FUNCTION RELATED WITH MACHINE MONITOR BLADE AUTOMATIC CONTROL

- 4.3.4.5. PRECAUTIONS WHEN USING BLADE AUTOMATIC CONTROL

- 4.3.4.6. RECOMMENDED APPLICATIONS AND MODES

- 4.4. TRANSPORTATION

- 4.4.1. HANDLE CYLINDERS WHEN BLADE IS NOT INSTALLED OR REMOVING AND INSTALLING BLADE

- 4.4.2. REMOVE AUX BOX

- 4.5. PRECAUTIONS FOR LONGTERM STORAGE

- 4.5.1. TURN BATTERY DISCONNECT SWITCH TO OFF POSITION BEFORE LONGTERM STORAGE

- 4.6. TROUBLES AND ACTIONS

- 4.6.1. OTHER TROUBLE

- 4.6.1.1. PHENOMENA AND ACTIONS FOR CONTROL BOX

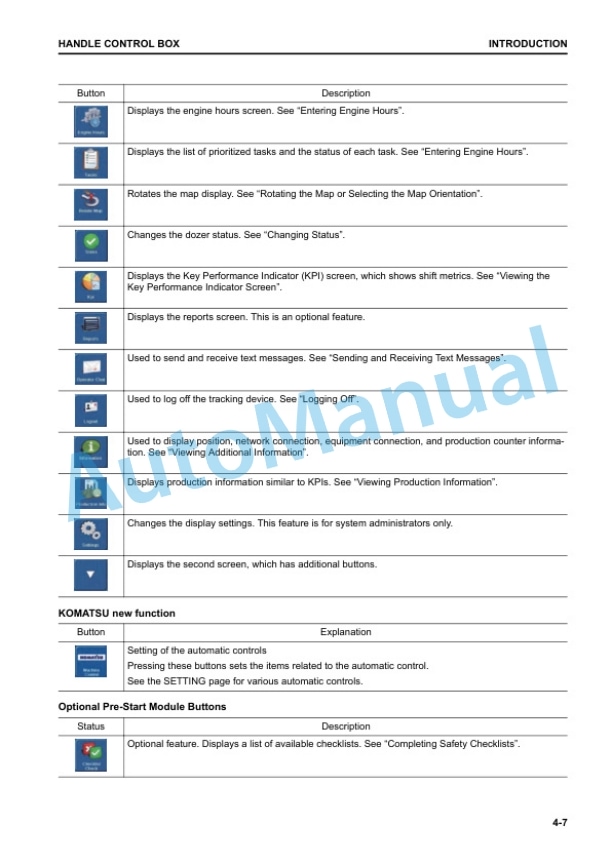

- 5. HANDLE CONTROL BOX

- 5.1. TABLE OF CONTENTS

- 5.2. INTRODUCTION

- 5.2.1. PROVISION SYSTEM OVERVIEW

- 5.2.2. MAIN COMPONENTS

- 5.2.2.1. TRACKING DEVICES

- 5.2.2.2. GPS AND WIFI ANTENNAS

- 5.2.2.3. CENTRAL SERVER

- 5.2.2.4. DESKTOP CLIENT COMPUTERS

- 5.2.2.5. WiFi NETWORK

- 5.2.3. DOZER GUIDANCE

- 5.2.3.1. TOP VIEW

- 5.2.3.2. SIDE VIEW

- 5.2.4. BENCH ELEVATION CONTROL

- 5.2.5. PRODUCTION TRACKING

- 5.2.6. SAFETY

- 5.2.6.1. EMERGENCY MESSAGES

- 5.2.6.2. MAYDAY MESSAGES

- 5.2.6.3. OPERATOR CHAT

- 5.2.6.4. PROXIMITY DETECTION

- 5.2.6.5. SAFETY INSPECTIONS

- 5.3. GENERAL PROCEDURES

- 5.3.1. LOGGING ON

- 5.3.2. COMPLETING SAFETY CHECKLISTS

- 5.3.2.1. ENTERING COMMENTS

- 5.3.2.2. VIEWING PRESTART CHECK REPORTS

- 5.3.3. LOGGING OFF

- 5.3.4. CHANGING STATUS

- 5.3.5. CHANGING THE VOLUME

- 5.3.6. CHANGING THE DISPLAY COLOR SCHEME

- 5.3.7. SENDING AND RECEIVING TEXT MESSAGES

- 5.3.7.1. SENDING CUSTOM MESSAGES

- 5.3.7.2. VIEWING INCOMING MESSAGES

- 5.3.8. SENDING A QUICK MESSAGE

- 5.3.9. SENDING AN EMERGENCY MESSAGE

- 5.4. DOZER ACTIVITIES

- 5.4.1. OVERVIEW

- 5.4.2. INDICATING THE SIDE FOR TRUCKS TO LOAD ON

- 5.4.3. TRACKING TIME AND VOLUME

- 5.4.3.1. SELECTING AN ACTIVITY

- 5.4.3.2. SUSPENDING AN ACTIVITY

- 5.4.3.3. RESUMING AN ACTIVITY

- 5.4.3.4. STOPPING AN ACTIVITY

- 5.4.4. WORKING ON PREDEFINED DESIGN SURFACES

- 5.4.5. CREATING FLAT AREAS, DRAINAGE SURFACES, AND RAMPS

- 5.4.5.1. CREATING FLAT AREAS

- 5.4.5.2. CREATING DRAINAGE SURFACES

- 5.4.5.3. CREATING A ONEPOINT RAMP

- 5.4.5.4. CREATING A TWOPOINT RAMP

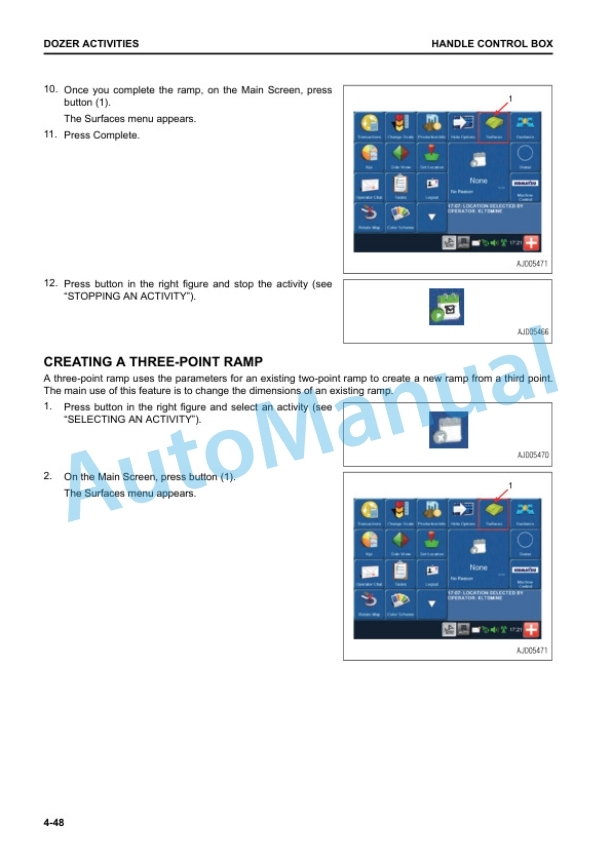

- 5.4.5.5. CREATING A THREEPOINT RAMP

- 5.4.6. ROTATING THE MAP OR SELECTING THE MAP ORIENTATION

- 5.4.6.1. ROTATING THE MAP

- 5.4.6.2. SELECTING THE MAP ORIENTATION

- 5.4.7. ENTERING ENGINE HOURS

- 5.4.8. ENTERING FUELING INFORMATION

- 5.4.9. WORKING ON TASKS

- 5.5. DOZER INFORMATION

- 5.5.1. OVERVIEW

- 5.5.2. VIEWING TRANSACTIONS

- 5.5.3. VIEWING THE KEY PERFORMANCE INDICATOR SCREEN

- 5.5.4. VIEWING PRODUCTION INFORMATION

- 5.5.5. VIEWING ADDITIONAL INFORMATION

- 5.5.5.1. VIEWING POSITION INFORMATION

- 5.5.5.2. VIEWING THE ABOUT SCREEN

- 5.6. KOMATSU MACHINE CONTROL MENU

- 5.6.1. MAIN SCREEN

- 5.6.2. MAIN MENU DISPLAY

- 5.6.3. KOMATSU MACHINE CONTROL MENU

- 5.6.3.1. METHOD FOR INPUTTING WEAR AMOUNT OF BLADE EDGE AND TRACK SHOE

- 5.6.3.2. METHOD FOR CHECKING AND ADJUSTING BLADE ELEVATION

- 5.6.3.3. INPUT WEAR AMOUNT OF GROUSER

- 5.6.3.4. BLADE CONTROL

- 5.6.3.5. DOZING MODE SETTINGS

- 5.6.3.6. ADJUST CUT/FILL OFFSETS

- 5.6.3.7. MATCH FUNCTION

- 5.6.3.8. MACHINE CONTROL OPTION MENU SETTING

- 5.6.4. TROUBLES AND ACTIONS

- 5.6.4.1. OTHER TROUBLE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 6.1.1. SPECIFICATIONS D375AI8

- 7. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100