Komatsu D40A-3, D40P-3, D41A-3, D41E-3, D41P-3, D41A-3A Bull Dozer Shop Manual SEBM0120C07

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM0120C07

- Format: PDF

- Size: 96.9MB

- Number of Pages: 556

Category: Komatsu Shop Manual PDF

-

Model List:

- D40A-3 Bull Dozer

- D40P-3 Bull Dozer

- D41A-3 Bull Dozer

- D41E-3 Bull Dozer

- D41P-3 Bull Dozer

- D41A-3A Bull Dozer

- 0.0.1. ASSEMBLY DRAWING

- 0.0.2. SPECIFICATIONS

- 0.0.3. ENGINE ASSEMBLY DRAWING

- 0.0.4. ENGINE SPECIFICATIONS

- 0.0.5. WEIGHT TABLE

- 0.0.6. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 1. ENGINE

- 1.1. STRUCTURE AND FUNCTION

- 1.1.1. STRUCTURE AND FUNCTION

- 1.1.1.1. RADIATOR AND OIL COOLER

- 1.1.1.3. ENGINE CONTROL

- 1.1.1.4. FUEL TANK

- 1.1.1.5. ENGINE MOUNT

- 1.2. TESTING AND ADJUSTING

- 1.2.1. TESTING AND ADJUSTING

- 1.2.1.1. STANDARD FOR INSPECTION, ADJUSTMENT AND TROUBLESHOOTING

- 1.2.1.2. TOOLS FOR INSPECTION AND ADJUSTMENT

- 1.2.1.3. TESTING AND ADJUSTING ENGINE

- 1.2.1.4. INTAKE AND EXHAUST ENGINE SYSTEM

- 1.2.1.5. ADJUSTING VALVE CLEARANCE

- 1.2.1.6. ENGINE

- 1.2.1.7. MEASURING COMPRESSION PRESSURE

- 1.2.1.8. LUBRICATION SYSTEM

- 1.2.1.9. FUEL SYSTEM

- 1.2.1.10. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 1.2.1.11. COOLING SYSTEM

- 1.2.1.12. CHECKING AND ADJUSTING FAN BELT TENSION

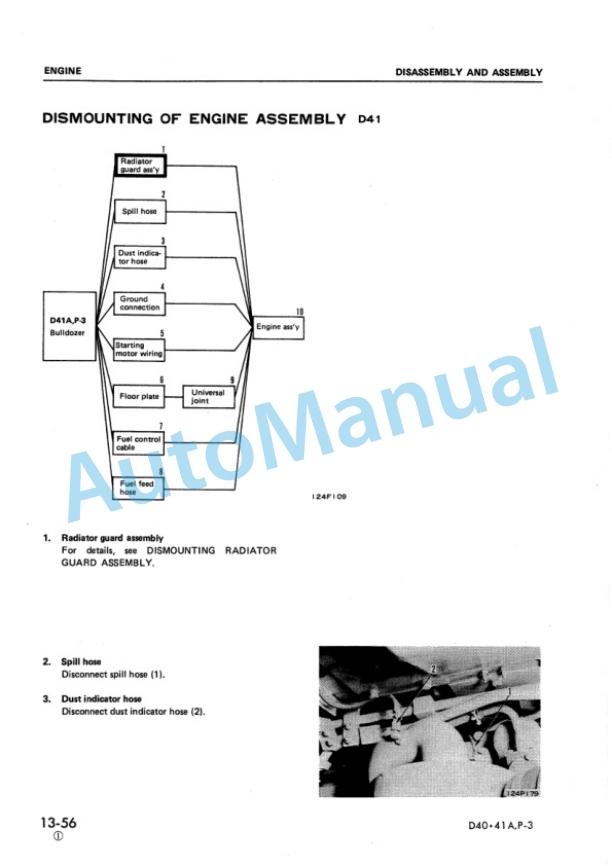

- 1.3. DISASSEMBLY AND ASSEMBLY

- 1.3.1. DISASSEMBLY AND ASSEMBLY

- 1.3.1.1. ENGINE OIL COOLER

- 1.3.1.2. FUEL INJECTION PUMP

- 1.4. STRUCTURE AND FUNCTION

- 1.4.1. STRUCTURE AND FUNCTION

- 1.4.1.1. GENERAL

- 1.4.1.2. POWER TRAIN HYDRAULIC SYSTEM (D413)

- 1.4.1.3. MAIN CLUTCH (D403)

- 1.4.1.4. MAIN CLUTCH CONTROL (D403)

- 1.4.1.5. MAIN CLUTCH LUBRICATION (D403)

- 1.4.1.6. INERTIA BRAKE (D403)

- 1.4.1.7. TRANSMISSION (D403)

- 1.4.1.8. INTERLOCK MECHANISM (D403)

- 1.4.1.9. DOUBLE MESH PREVENTIVE DEVICE (D403)

- 1.4.1.10. TRANSMISSION CONTROL (D403)

- 1.4.1.11. DAMPER (D413)

- 1.4.1.12. HYDROSHIFT TRANSMISSION (D413)

- 1.4.1.13. TRANSMISSION LUBRICATION SYSTEM (D413)

- 1.4.1.14. HYDROSHIFT TRANSMISSION CONTROL (D413)

- 1.4.1.15. TRANSMISSION CONTROL VALVE (D413)

- 1.4.1.16. INCHING VALVE AND CONTROL (D413)

- 1.4.1.17. TRANSMISSION OIL FILTER

- 1.4.1.18. OIL COOLER BYPASS VALVE

- 1.4.1.19. STEERING HYDRAULIC OIL SYSTEM AND OIL CIRCUIT DIAGRAM

- 1.4.1.20. STEERING PUMP

- 1.4.1.21. STEERING CLUTCH AND BEVEL GEAR

- 1.4.1.22. STEERING CONTROL VALVE

- 1.4.1.23. STEERING MAIN RELIEF VALVE

- 1.4.1.24. TRANSMISSION AND STEERING CLUTCH PIPING

- 1.4.1.25. STEERING BRAKE

- 1.4.1.26. STEERING CONTROL

- 1.4.1.27. STEERING CLUTCH AND BRAKE CONTROL LINKAGE

- 1.4.1.28. FINAL DRIVE

- 1.5. TESTING AND ADJUSTING

- 1.5.1. TESTING AND ADJUSTING

- 1.5.1.1. MEASURING OIL PRESSURE AND TEMPERATURE

- 1.5.1.2. TESTING AND ADJUSTING TRAVEL

- 1.5.1.3. MEASURING OPERATING FORCE

- 1.5.1.4. TESTING AND ADJUSTING MAIN CLUTCH

- 1.5.1.5. STANDARD VALVE FOR TESTING AND ADJUSTING

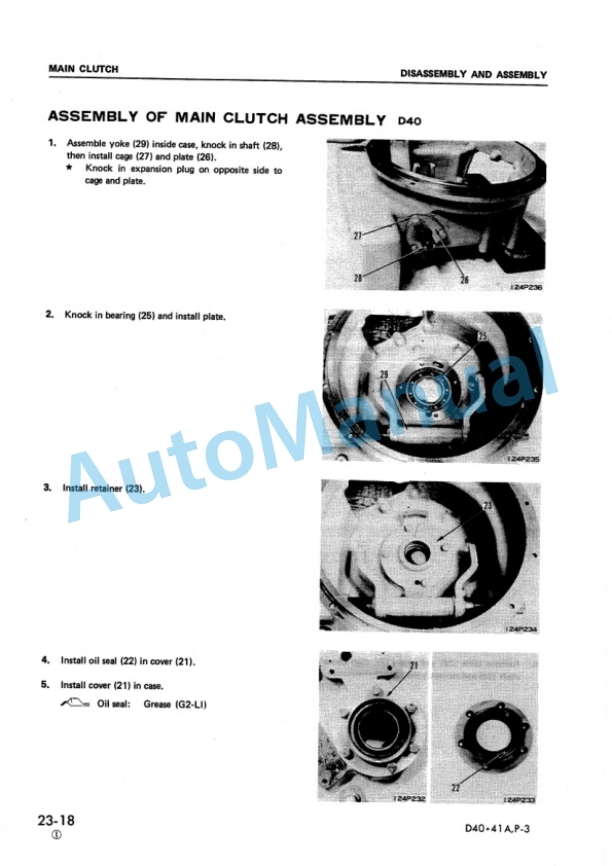

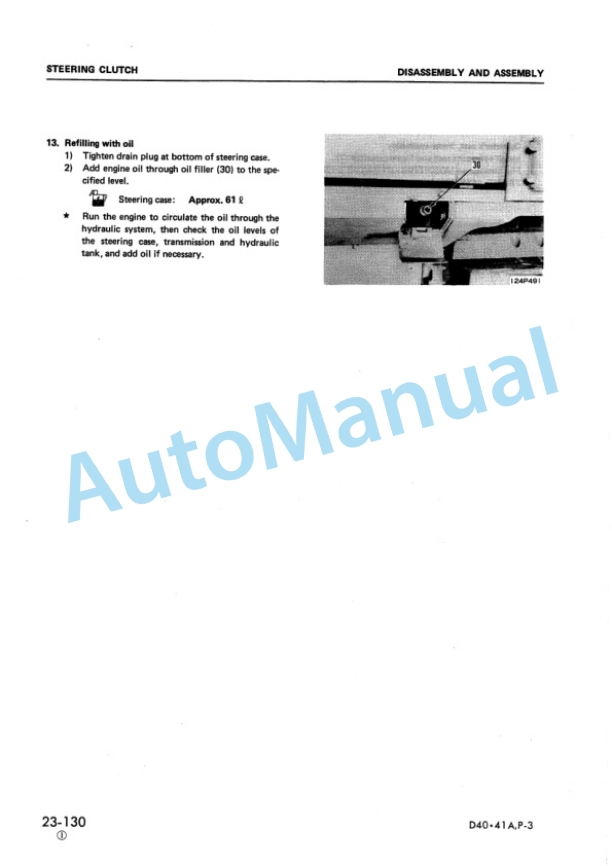

- 1.6. DISASSEMBLY AND ASSEMBLY

- 1.6.1. DISASSEMBLY AND ASSEMBLY

- 1.6.1.1. MAIN CLUTCH (D40)

- 1.6.1.2. TRANSMISSION (D40)

- 1.6.1.3. HYDROSHIFT TRANSMISSION (D41)

- 1.6.1.4. TRANSMISSION CONTROL VALVE (D41)

- 1.6.1.5. OIL COOLER BYPASS VALVE (D41)

- 1.6.1.6. STEERING, WORK EQUIPMENT PUMP (D40)

- 1.6.1.7. STEERING PUMP (D41)

- 1.6.1.8. BEVEL GEAR AND SHAFT

- 1.6.1.9. STEERING CLUTCH

- 1.6.1.10. OIL COOLER RELIEF VALVE (D40)

- 1.6.1.11. STEERING CONTROL VALVE

- 1.6.1.12. FINAL DRIVE

- 1.6.1.13. OPERATORS SEAT AND FRAME (D40)

- 1.6.1.14. OPERATORS SEAT AND FRAME (D41)

- 1.6.1.15. DASHBOARD (D40)

- 1.7. MAINTENANCE STANDARD

- 1.7.1. MAINTENANCE STANDARD

- 1.7.1.1. MAIN CLUTCH

- 1.7.1.2. INERCIA BRAKE

- 1.7.1.3. TRANSMISSION

- 1.7.1.4. DAMPER

- 1.7.1.5. HYDROSHIFT TRANSMISSION

- 1.7.1.6. TRANSMISSION CONTROL VALVE

- 1.7.1.7. OIL COOLER BYPASS VALVE

- 1.7.1.8. BEVEL GEAR SHAFT

- 1.7.1.9. STEERING CLUTCH

- 1.7.1.10. STEERING BRAKE

- 1.7.1.11. STEERING MAIN RELIEF VALVE

- 1.7.1.12. STEERING CONTROL VALVE

- 1.7.1.13. STEERING PUMP

- 1.7.1.14. FINAL DRIVE

- 1.7.1.15. SPROCKET

- 2. UNDERCARRIAGE

- 2.1. STRUCTURE AND FUNCTION

- 2.1.1. STRUCTURE AND FUNCTION

- 2.1.1.1. TRACK (SWANP SHOE)

- 2.1.1.2. SUSPENSION

- 2.2. DISASSEMBLY AND ASSEMBLY

- 2.2.1. DISASSEMBLY AND ASSEMBLY

- 2.2.1.1. TRACK FRAME

- 2.2.1.2. RECOIL SPRING

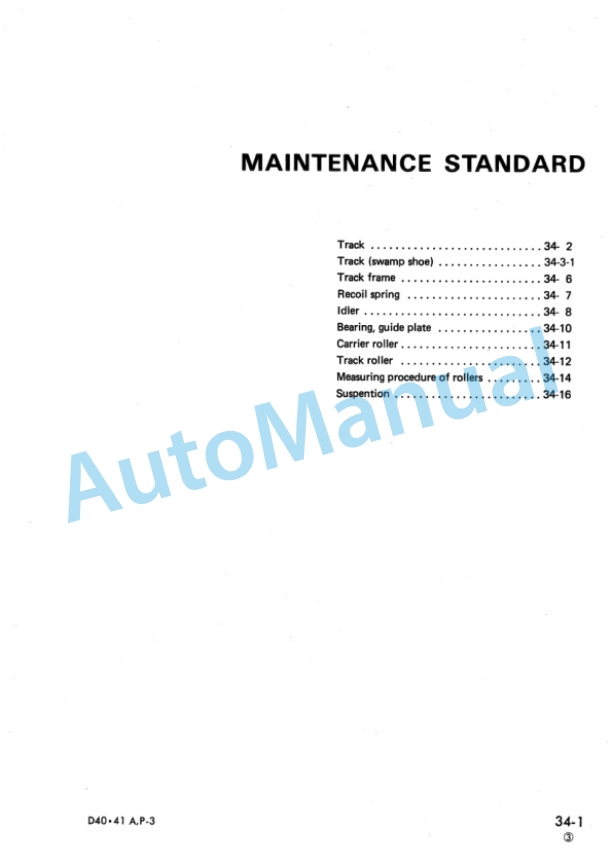

- 2.3. MAINTENANCE STANDARD

- 2.3.1. MAINTENANCE STANDARD

- 2.3.1.1. TRACK

- 2.3.1.2. TRACK (SWANP SHOE)

- 2.3.1.3. TRACK FRAME

- 2.3.1.4. RECOIL SPRING

- 2.3.1.5. IDLER

- 2.3.1.6. BEARING, GUIDE PLATE

- 2.3.1.7. CARRIER ROLLER

- 2.3.1.8. TRACK ROLLER

- 2.3.1.9. MEASURING PROCEDURE OF ROLLERS

- 2.3.1.10. SUSPENTION

- 3. HYDRAULIC SYSTEM

- 3.1. STRUCTURE AND FUNCTION

- 3.1.1. STRUCTURE AND FUNCTION

- 3.1.1.1. GENERAL

- 3.1.1.2. HYDRAULIC CONTROL SYSTEM (D40P3,D41E,P3)

- 3.1.1.3. HYDRAULIC CIRCUIT DIAGRAM (D40P3,D41E,P3)

- 3.1.1.4. HYDRAULIC CONTROL SYSTEM (D41A3A)

- 3.1.1.5. HYDRAULIC CIRCUIT DIAGRAM (D41A3A)

- 3.1.1.6. HYDRAULIC TANK AND FILTER

- 3.1.1.7. HYDRAULIC CONTROL

- 3.1.1.8. HYDRAULIC PUMP

- 3.1.1.9. BLADE CONTROL VALVE

- 3.1.1.10. BLADE LIFT CONTROL

- 3.1.1.11. BLADE TILT CONTROL

- 3.1.1.12. BLADE LIFT CYLINDER

- 3.1.1.13. BLADE TILT CYLINDER

- 3.1.1.14. BLADE ANGLING CYLINDER

- 3.1.1.15. HYDRAULIC CYLINDER

- 3.2. TESTING AND ADJUSTING

- 3.2.1. TESTING AND ADJUSTING

- 3.2.1.1. PERFORMANCE OF HYDRAULIC PUMP

- 3.2.1.2. TESTING AND ADJUSTING HYDRAULIC PRESSURE OF WORK EQUIPMENT

- 3.2.1.3. MEASURING TEMPERATURE OF HYDRAULIC OIL

- 3.2.1.4. TESTING AND ADJUSTING TRAVEL AND OPERATING FORCE OF WORK EQUIPMENT CONTROL LEVERS

- 3.2.1.5. MEASURING HYDRAULIC DRIFT

- 3.2.1.6. STANDARD VALUE FOR TESTING AND ADJUSTING

- 3.3. DISASSEMBLY AND ASSEMBLY

- 3.3.1. DISASSEMBLY AND ASSEMBLY

- 3.3.1.1. HYDRAULIC PUMP (D41)

- 3.3.1.2. WORK EQUIPMENT CONTROL VALVE

- 3.3.1.3. BLADE LIFT CYLINDER

- 3.3.1.4. BLADE TILT CYLINDER (D40,41P)

- 3.3.1.5. BLADE LIFT CYLINDER

- 3.3.1.6. BLADE TILT CYLINDER (D40,41P)

- 3.4. MAINTENANCE STANDARD

- 3.4.1. MAINTENANCE STANDARD

- 3.4.1.1. CONTROL VALVE

- 3.4.1.2. BLADE CONTROL VALVE

- 3.4.1.3. LIFT CYLINDER

- 3.4.1.4. TILT CYLINDER

- 3.4.1.5. ANGLING CYLINDER

- 3.4.1.6. HYDRAULIC PUMP

- 4. WORK EQUIPMENT

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. STRUCTURE AND FUNCTION

- 4.1.1.1. ANGLEDOZER

- 4.1.1.2. STRAIGHTTILTDOZER

- 4.1.1.3. POWER ANGLE TILTDOZER

- 4.2. DISASSEMBLY AND ASSEMBLY

- 4.2.1. DISASSEMBLY AND ASSEMBLY

- 4.2.1.1. ANGLE DOZER (D40,41A)

- 4.2.1.2. STRAIGHTTILTDOZER (D40,41P)

- 4.3. MAINTENANCE STANDARD

- 4.3.1. MAINTENANCE STANDARD

- 4.3.1.1. WORK EQUIPMENT

- 5. OTHERS

- 5.1. ELECTRICAL SYSTEM

- 5.1.1. ELECTRICAL SYSTEM

- 5.1.1.1. ELECTRICAL CIRCUIT DIAGRAM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00