Komatsu D41E-6, D41P-6 Bull Dozer Operation and Maintenance Manual EEAM007405

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: EEAM007405

- Format: PDF

- Size: 5.6MB

- Number of Pages: 210

-

Model List:

- D41E-6 Bull Dozer

- D41P-6 Bull Dozer

- 1. FOREWORD

- 1.1. FOREWORD

- 1.2. SAFETY INFORMATION

- 1.2.1. NOISE

- 1.2.2. VIBRATION

- 1.3. INTRODUCTION

- 1.3.1. FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

- 1.4. NECESSARY INFORMATION

- 1.4.1. MACHINE SERIAL NO. PLATE AND POSITION

- 1.4.2. ENGINE SERIAL NO. PLATE AND POSITION

- 1.4.3. POSITION OF SERVICE METER

- 1.4.4. TABLE OF ENTER SERIAL NO. AND DISTRIBUTORN

- 1.4.5. MACHINE SERIAL PLATE

- 2. SAFETY

- 2.1. SAFETY

- 2.2. SAFETY LABELS

- 2.2.1. POSITIONS OF SAFETY PICTOGRAMS

- 2.2.1.1. SAFETY DECALS

- 2.3. GENERAL PRECAUTIONS

- 2.4. PRECAUTIONS FOR OPERATION

- 2.4.1. STARTING ENGINE

- 2.4.2. AFTER STARTING ENGINE

- 2.4.3. TRANSPORTATION

- 2.4.4. BATTERY

- 2.4.5. TOWING

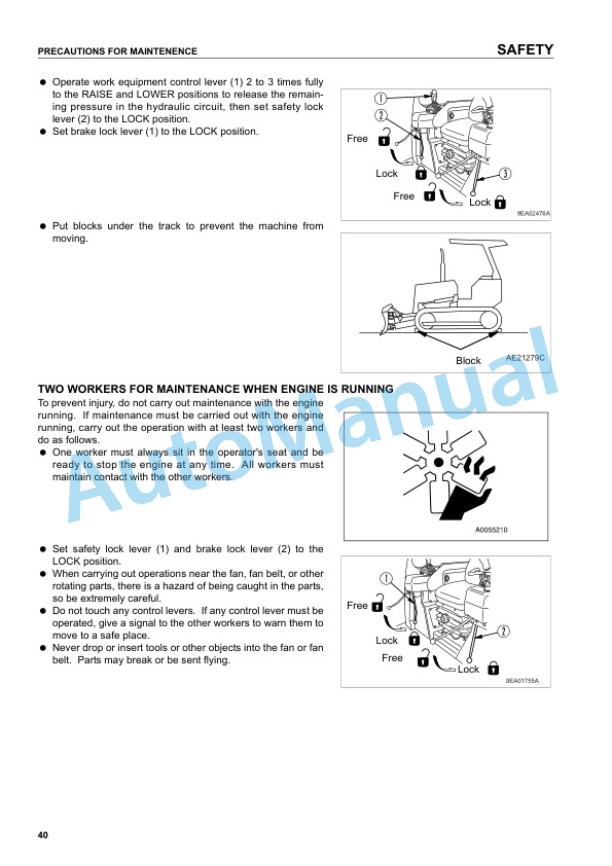

- 2.5. PRECAUTIONS FOR MAINTENENCE

- 3. OPERATION

- 3.1. GENERAL VIEW

- 3.1.1. GENERAL VIEW OF MACHINE

- 3.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 3.2. EXPLANATION OF COMPONENTS

- 3.2.1. MONITOR PANEL

- 3.2.2. SWITCHES

- 3.2.3. LAMP

- 3.2.4. CONTROL LEVERS AND PEDALS

- 3.2.5. FUSE

- 3.2.6. ELECTRIC POWER TAKEOUT ADAPTER

- 3.2.7. DOOR OPEN LOCK

- 3.2.8. SASH GLASS INTERMEDIATE LOCK

- 3.2.9. CAP, COVER WITH LOCK

- 3.2.9.1. METHOD OF OPENING AND CLOSING CAP WITH LOCK

- 3.2.9.2. METHOD OF OPENING AND CLOSING COVER WITH LOCK

- 3.2.10. HOT AND COOL BOX

- 3.2.11. DOOR POCKET

- 3.2.12. ASHTRAY

- 3.2.13. TOOL BOX

- 3.2.14. CAR STEREO, HANDLING

- 3.2.14.1. EXPRANATION OF COMPONENTS

- 3.2.14.2. PRECAUTION WHEN USING

- 3.2.15. AIR CONDITIONER, HANDLING

- 3.2.15.1. EXPLANATION OF PARTS

- 3.2.15.2. COOLING OPERATION

- 3.2.15.3. HEATING OPERATION

- 3.2.15.4. PREVENTION METHOD OF ENTRY OF DUST

- 3.2.15.5. PRECAUTION WHEN USING AIR CONDITIONER

- 3.2.15.6. INSPECTION DURING OFFSEASON

- 3.2.15.7. PROCEDURE FOR REPLACING RECEIVER

- 3.2.15.8. CLEANING AIR FILTER

- 3.3. OPERATION

- 3.3.1. CHECK BEFORE STARTING ENGINE, ADJUST

- 3.3.1.1. WALKAROUND CHECK

- 3.3.1.2. CHECK BEFORE STARTING

- 3.3.1.3. ADJUSTMENT

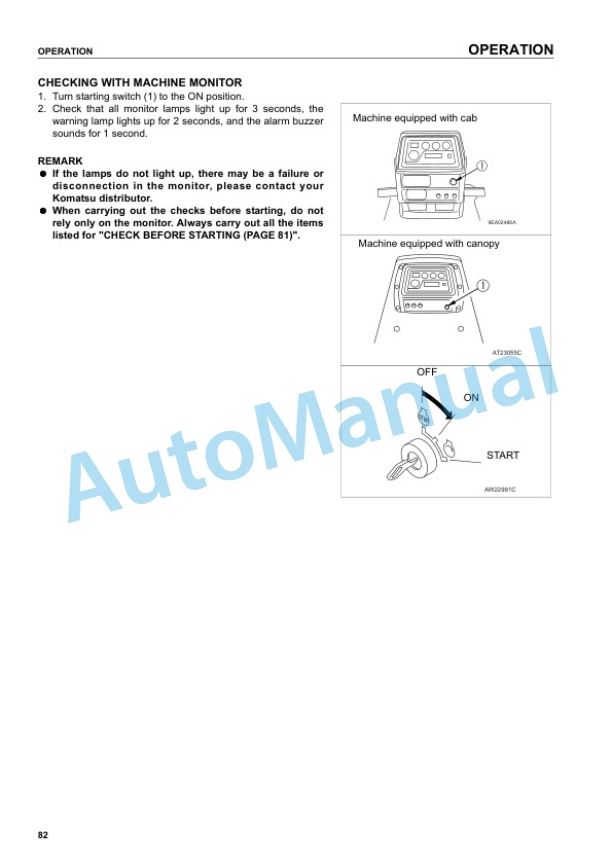

- 3.3.1.4. OPERATION AND CHECK BEFORE STARTING ENGINE

- 3.3.2. STARTING ENGINE

- 3.3.2.1. NORMAL STARTING

- 3.3.2.2. STARTING IN COLD WEATHER

- 3.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 3.3.3.1. BREAKING IN THE NEW MACHINE

- 3.3.3.2. NORMAL OPERATION

- 3.3.3.3. STARTING IN COLD WEATHER

- 3.3.4. STOPPING ENGINE

- 3.3.5. CHECK AFTER STOPPING ENGINE

- 3.3.6. MACHINE OPERATION

- 3.3.6.1. MOVING MACHINE OFF

- 3.3.6.2. STOPPING MACHINE

- 3.3.7. SHIFTING GEAR

- 3.3.8. SHIFTING BETWEEN FORWARD AND REVERSE

- 3.3.9. STEERING MACHINE

- 3.3.9.1. NORMAL TURNING

- 3.3.9.2. TURNING WHILE DESCENDING A SLOPE

- 3.3.10. PRECAUTIONS FOR OPERATION

- 3.3.10.1. METHOD OF USING STEERING CLUTCH

- 3.3.10.2. PERMISSIBLE WATER DEPTH

- 3.3.10.3. PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS

- 3.3.10.4. PRECAUTIONS ON SLOPES

- 3.3.10.5. IT IS PROHIBITED TO KEEP THE DOOR OPEN DURING OPERATIONS

- 3.3.10.6. IT IS PROHIBITED TO MODIFY THE CAB GLASS IN ANY WAY THAT WILL OBSTRUCT THE VIEW

- 3.3.10.7. PRECAUTIONS FOR BLIND SPOTS CAUSED BY CAB STAY

- 3.3.11. WORK POSSIBLE USING BULLDOZER

- 3.3.11.1. DOZING

- 3.3.11.2. SMOOTHING

- 3.3.11.3. CUTTING INTO HARD OR FROZEN GROUND OR DITCHING

- 3.3.11.4. FELLING TREES, REMOVING STUMPS

- 3.3.12. PARKING MACHINE

- 3.3.13. CHECK AFTER FINISHING WORK

- 3.3.14. LOCKING

- 3.3.15. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 3.3.15.1. OPERATION METHOD

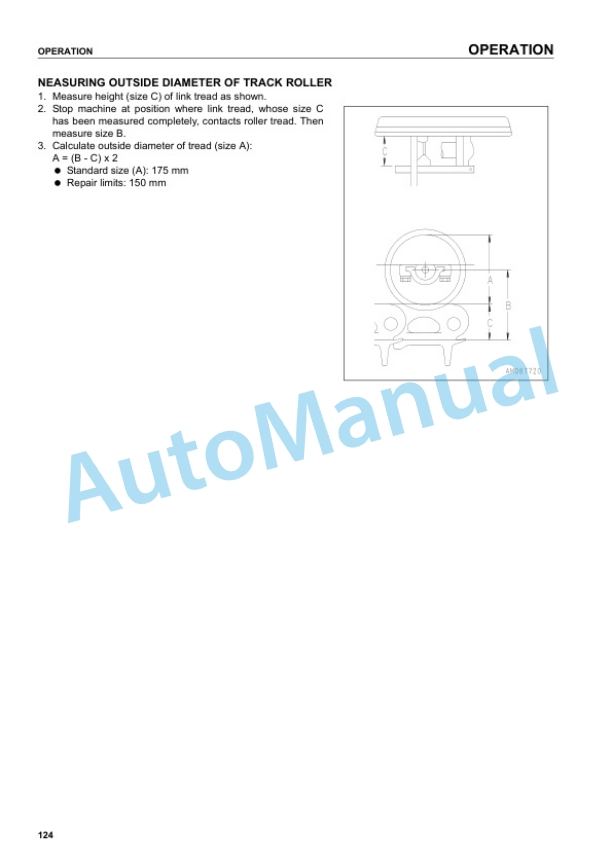

- 3.3.15.2. INSPECTION AND ADJUSTMENT

- 3.3.15.3. INSPECTION AND REPAIR

- 3.4. TRANSPORTATION

- 3.4.1. TRANSPORTATION MEANS

- 3.4.2. REMOVING CAB

- 3.4.3. LOADING, UNLOADING WORK

- 3.4.4. LIFTING MACHINE

- 3.5. COLD WEATHER OPERATION

- 3.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 3.5.2. AFTER COMPLETION OF WORK

- 3.5.3. AFTER COLD WEATHER

- 3.6. LONGTERM STORAGE

- 3.6.1. BEFORE STORAGE

- 3.6.2. DURING STORAGE

- 3.6.3. AFTER STORAGE

- 3.7. TROUBLESHOOTING

- 3.7.1. AFTER RUNNING OUT OF FUEL

- 3.7.2. MACHINE TOWING METHOD

- 3.7.3. IF BATTERY IS DISCHARGED

- 3.7.3.1. REMOVE AND INSTALL BATTERY

- 3.7.3.2. PRECAUTIONS FOR CHARGING BATTERY

- 3.7.3.3. STARTING ENGINE WITH BOOSTER CABLE

- 3.7.4. OTHER TROUBLE

- 3.7.4.1. ELECTRICAL SYSTEM

- 3.7.4.2. CHASSIS

- 3.7.4.3. ENGINE

- 4. MAINTENANCE

- 4.1. GUIDE TO MAINTENANCE

- 4.2. OUTLINE OF SERVICE

- 4.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 4.2.1.2. FUEL

- 4.2.1.3. COOLANT

- 4.2.1.4. GREASE

- 4.2.1.5. CARRYING OUT KOWA (Komatsu Oil Wear Analysis)

- 4.2.1.6. STORING OIL AND FUEL

- 4.2.1.7. FILTERS

- 4.2.2. RELATING TO ELECTRIC SYSTEM

- 4.3. WEAR PARTS LIST

- 4.3.1. WEAR PARTS LIST

- 4.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 4.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 4.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 4.5.1. TORQUE LIST

- 4.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 4.6.1. SAFETY CRITICAL PARTS

- 4.7. MAINTENANCE SCHEDULE CHART

- 4.7.1. MAINTENANCE SCHEDULE CHART

- 4.7.1.1. WHEN REQUIRED

- 4.7.1.2. CHECK BEFORE STARTING

- 4.7.1.3. EVERY 50 HOURS SERVICE

- 4.7.1.4. EVERY 250 HOURS SERVICE

- 4.7.1.5. EVERY 500 HOURS SERVICE

- 4.7.1.6. EVERY 1000 HOURS SERVICE

- 4.7.1.7. EVERY 2000 HOURS SERVICE

- 4.7.1.8. EVERY 4000 HOURS SERVICE

- 4.8. SERVICE PROCEDURE

- 4.8.1. WHEN REQUIRED

- 4.8.1.1. CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT

- 4.8.1.2. CLEAN INSIDE OF COOLING SYSTEM

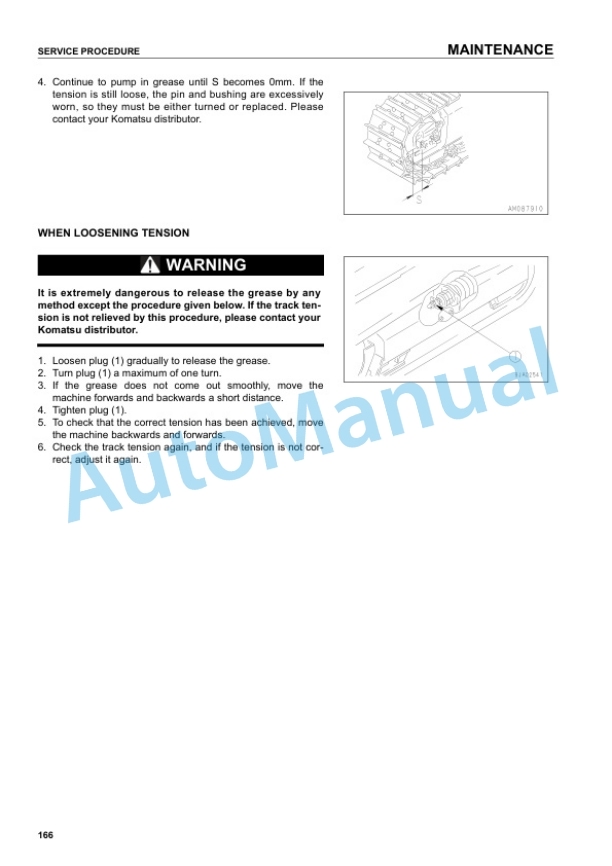

- 4.8.1.3. CHECK TRACK TENSION

- 4.8.1.4. CHECK AND TIGHTEN TRACK SHOE BOLTS

- 4.8.1.5. CHECK ELECTRICAL INTAKE AIR HEATER

- 4.8.1.6. REVERSE AND REPLACE END BITS AND CUTTING EDGES

- 4.8.1.7. CLEAN, CHECK RADIATOR FINS

- 4.8.1.8. ADJUST PLAY IN CENTER BALL

- 4.8.1.9. CHECK, ADJUST AIR CONDITIONER

- 4.8.1.10. GREASE DOOR HINGE

- 4.8.1.11. CHECK DOOR LOCK STRIKER

- 4.8.1.12. REPLACE DOOR DAMPER

- 4.8.1.13. CHECK DOOR LATCH

- 4.8.1.14. CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID

- 4.8.1.15. REPLACE WIPER BLADE

- 4.8.1.16. CHECK IDLER OIL LEVEL, ADD OIL

- 4.8.1.17. ADJUST IDLER CLEARANCE

- 4.8.1.18. PROCEDURE FOR BLEEDING AIR IN HYDRAULIC SYSTEM

- 4.8.1.19. PROCEDURE FOR RELEASING INTERNAL PRESSURE OF HYDRAULIC SYSTEM

- 4.8.2. CHECK BEFORE STARTING

- 4.8.3. EVERY 50 HOURS SERVICE

- 4.8.3.1. DRAIN WATER, SEDIMENT FROM FUEL TANK

- 4.8.4. EVERY 250 HOURS SERVICE

- 4.8.4.1. LUBRICATING

- 4.8.4.2. CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL

- 4.8.4.3. CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

- 4.8.4.4. CHECK LEVEL OF BATTERY ELECTROLYTE

- 4.8.4.5. CHECK, CLEAN FUEL STRAINER

- 4.8.4.6. CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE

- 4.8.4.7. CHECK BRAKE PERFORMANCE

- 4.8.4.8. CLEAN AIR CONDITIONER AIR FILTER (FRESH/RECIRC FILTER)

- 4.8.5. EVERY 500 HOURS SERVICE

- 4.8.5.1. REPLACE FUEL FILTER CARTRIDGE

- 4.8.6. EVERY 1000 HOURS SERVICE

- 4.8.6.1. CHANGE OIL IN TRANSMISSION CASE, CLEAN STRAINER (POWER TRAIN STRAINER)

- 4.8.6.2. REPLACE TRANSMISSION OIL FILTER CARTRIDGE

- 4.8.6.3. CLEAN BREATHER

- 4.8.6.4. GREASE UNIVERSAL JOINT

- 4.8.6.5. CHANGE OIL IN STEERING CLUTCH CASE

- 4.8.6.6. CHECK OIL LEVEL IN DAMPER CASE, ADD OIL

- 4.8.6.7. CHECK FAN BELT TENSION, REPLACE

- 4.8.6.8. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 4.8.6.9. CHECK ALL TIGHTENING PARTS OF TURBOCHARGER

- 4.8.6.10. CHECK PLAY OF TURBOCHARGER ROTOR

- 4.8.6.11. CHECK FOR LOOSE ROPS MOUNT BOLTS

- 4.8.7. EVERY 2000 HOURS SERVICE

- 4.8.7.1. CHANGE OIL IN HYDRAULIC TANK, REPLACE HYDRAULIC OIL FILTER ELEMENT

- 4.8.7.2. REPLACE HYDRAULIC TANK BREATHER ELEMENT

- 4.8.7.3. CHANGE OIL IN DAMPER CASE

- 4.8.7.4. CHANGE OIL IN FINAL DRIVE CASE

- 4.8.7.5. CHECK VIBRATION DAMPER

- 4.8.7.6. CHECK ALTERNATOR, STARTING MOTOR

- 4.8.7.7. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 4.8.8. EVERY 4000 HOURS SERVICE

- 4.8.8.1. CHECK WATER PUMP

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS

- 6. ATTACHMENTS, OPTIONS

- 6.1. GENERAL PRECAUTIONS

- 6.1.1. PRECAUTIONS RELATED TO SAFETY

- 6.2. SUSPENSION SEAT

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901