Komatsu D475A-2 Bull Dozer Shop Manual SEBM019M0207

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM019M0207

- Format: PDF

- Size: 40.8MB

- Number of Pages: 621

Category: Komatsu Shop Manual PDF

-

Model List:

- D475A-2 Bull Dozer

- 1. MAIN MENU

- 2. CONTENTS

- 3. STRUCTURE AND FUNCTION

- 3.1. ENGINE

- 3.1.1. ENGINE MOUNT

- 3.1.2. RADIATOR, OIL COOLER

- 3.1.3. FAN DRIVE HYDRAULIC PIPING DIAGRAM

- 3.1.4. FAN DRIVE HYDRAULIC SYSTEM DIAGRAM

- 3.1.5. FAN DRIVE HYDRAULIC CIRCUIT DIAGRAM

- 3.1.6. FAN DRIVE PUMP (SAR63 40)

- 3.1.7. FAN DRIVE MOTOR (SAL140)

- 3.1.8. FAN HIGHLOW SPEED SELECTOR SOLENOID VALVE, CHECK VALVE

- 3.1.9. FAN DRIVE CIRCUIT MAIN RELIEF VALVE

- 3.1.10. INLINE SERVO VALVE

- 3.1.11. ENGINE CONTROL

- 3.2. POWER TRAIN

- 3.2.1. POWER TRAIN

- 3.2.2. POWER TRAIN UNIT

- 3.2.3. POWER TRAIN PIPING

- 3.2.4. POWER TRAIN HYDRAULIC SYSTEM

- 3.2.5. POWER TRAIN HYDRAULIC CIRCUIT

- 3.2.6. DAMPER AND UNIVERSAL JOINT

- 3.2.7. TORQUE CONVERTER AND PTO

- 3.2.8. TORQUE CONVERTER VALVE

- 3.2.9. TRANSMISSION

- 3.2.10. SCAVENGING PUMP

- 3.2.11. POWER TRAIN PUMP AND LUBRICATION PUMP

- 3.2.12. STRAINERS

- 3.2.13. POWER TRAIN OIL FILTER AND LUBRICATION OIL FILTER

- 3.2.14. TRANSFER, BEVEL PINION, BEVEL GEAR SHAFT, STEERING CLUTCH, STEERING BRAKE

- 3.2.15. TRANSFER, BEVEL PINION

- 3.2.16. BEVEL GEAR, STEERING CLUTCH AND STEERING BRAKE

- 3.2.17. STEERING CLUTCH AND STEERING BRAKE CONTROL

- 3.2.18. STEERING CLUTCH, BRAKE HYDRCUALIC CIRCUIT DIAGRAM

- 3.2.19. STEERING CONTROL VALVE

- 3.2.20. FINAL DRIVE

- 3.2.21. POWER TRAIN UNIT MOUNT

- 3.3. UNDERCARRIAGE

- 3.3.1. TRACK (LUBRICATED TRACK LINK)

- 3.3.2. TRACK FRAME AND RECOIL SPRING

- 3.3.3. IDLER

- 3.3.4. TRACK ROLLER

- 3.3.5. CARRIER ROLLER

- 3.3.6. SUSPENSION

- 3.4. HYDRAULIC SYSTEM

- 3.4.1. HYDRAULIC PIPING DIAGRAM

- 3.4.2. HYDRAULIC CONTROL

- 3.4.3. HYDRAULIC CIRCUIT SYSTEM

- 3.4.4. HYDRAULIC CIRCUIT DIAGRAM

- 3.4.5. HYDRAULIC TANK

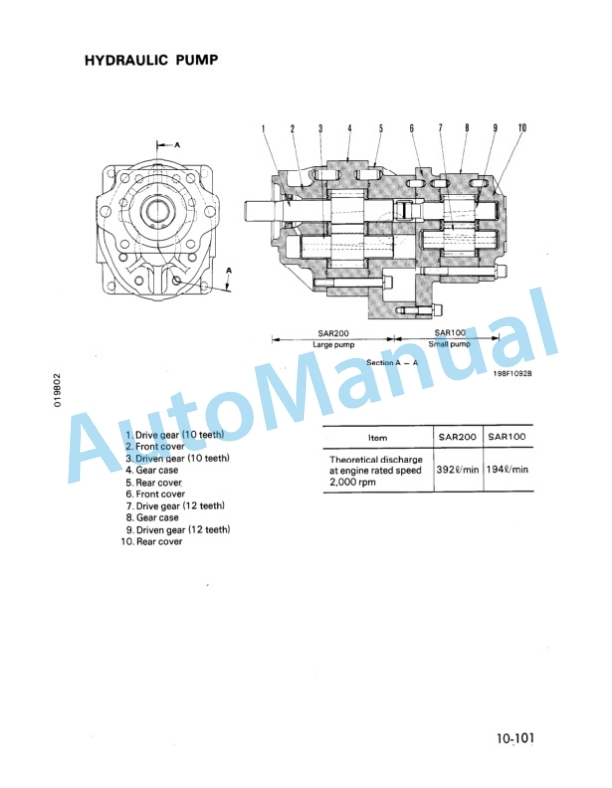

- 3.4.6. HYDRAULIC PUMP

- 3.4.7. BLADE LIFT VALVE

- 3.4.8. MAIN RELIEF, SHUTTLE VALVE

- 3.4.9. BLADE TILT, RIPPER LOW VALVE

- 3.4.10. RIPPER HIGH VALVE

- 3.4.11. HYDRAULIC LEVER OPERATION

- 3.4.12. CYLINDER

- 3.4.13. RIPPER CYLINDER

- 3.4.14. PINPULLER HYDRAULIC SYSTEM DRAWING

- 3.4.15. PINPULLER HYDRAULIC CIRCUIT DRAWING

- 3.4.16. PINPULLER SOLENOID VALVE

- 3.5. WORK EQUIPMENT

- 3.5.1. DOZER EQUIPMENT

- 3.5.2. RIPPER EQUIPMENT

- 3.5.3. CYLINDER STAY

- 3.6. ELECTRIC AND ELECTRONIC SYSTEM

- 3.6.1. ELECTRICAL WIRING DIAGRAM

- 3.6.2. CAB WIRING DIAGRAM

- 3.6.3. AIR CONDITIONER CIRCUIT DIAGRAM

- 3.6.4. EVMS (ELECTRONIC VEHICLE MONITORING SYSTEM)

- 3.6.5. ELECTRICAL CONTROL

- 3.6.6. SENSOR

- 3.6.7. PINPULLER CONTROL

- 3.7. OTHERS

- 3.7.1. ROPS CANOPY

- 3.7.3. AIR CONDITIONER

- 4. TESTING AND ADJUSTING

- 4.1. TABLE OF STANDARD VALUES FOR ENGINE

- 4.2. TABLE OF STANDARD VALUES FOR CHASSIS

- 4.3. TABLE OF ELECTRICAL JUDGEMENT STANDARD VALUE

- 4.4. TESTING AND ADJUSTING

- 4.4.1. TESTING AND ADJUSTING TOOL LIST

- 4.4.2. ADJUSTING VALVE CLEARANCE

- 4.4.3. MEASURING COMPRESSION PRESSURE

- 4.4.4. CHECKING AND ADJUSTING FUEL INJECTION TIMING

- 4.4.5. MEASURING TORQUE CONVERTER STALL SPEED

- 4.4.6. BLEEDING AIR FROM HYDRAULIC CYLINDER

- 4.4.7. MEASURING OIL PRESSURE

- 4.4.8. ADJUSTING FUEL CONTROL LINKAGE

- 4.4.9. ADJUSTING GEAR SHIFT LEVER LINKAGE

- 4.4.10. ADJUSTING STEERING CLUTCH LINKAGE

- 4.4.11. ADJUSTING BRAKE PEDAL LINKAGE

- 4.4.12. ADJUSTING BLADE CONTROL LINKAGE

- 4.4.13. ADJUSTING RIPPER CONTROL LINKAGE

- 4.5. TROUBLESHOOTING

- 4.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 4.5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 4.5.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

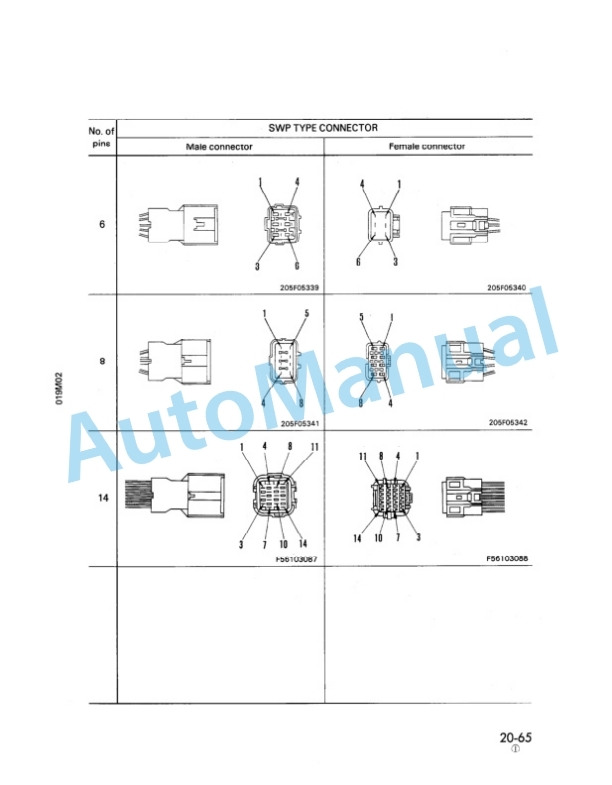

- 4.5.4. HANDLING CONNECTORS

- 4.5.5. PREVENTING RECURRENCE OF THE SAME TROUBLE

- 4.5.6. CHECKS BEFORE TROUBLESHOOTING

- 4.5.7. METHOD OF USING TROUBLESHOOTING CHARTS

- 4.5.8. RELATED ELECTRICAL CIRCUIT

- 4.5.9. LOCATION OF CONNECTORS FOR TROUBLESHOOTING

- 4.5.10. LOCATION OF CONNECTORS

- 4.5.11. CONNECTION TABLE FOR CONNECTOR

- 4.5.12. TABLE OF FAILURE MODES AND CAUSES (ELECTRICAL, HYDRAULIC, MECHANICAL SYSTEMS)

- 4.5.13. TABLE OF FAILURE MODES AND CAUSES (MACHINE MONITOR)

- 4.5.14. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM

- 4.5.15. TROUBLESHOOTING OF ELECTRICAL SYSTEM

- 4.5.16. TROUBLESHOTING OF MONITOR SYSTEM

- 5. DISASSEMBLY AND ASSEMBLY

- 5.1. METHOD OF USING MANUAL

- 5.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 5.3. SPECIAL TOOL LIST

- 5.4. WEIGHT TABLE

- 5.5. LUBRICANT AND COOLANT TABLE

- 5.6. TIGHTENING TORQUES AND STANDARD VALUES TABLE

- 5.7. ENGINE

- 5.7.1. STARTING MOTOR

- 5.7.2. ALTERNATOR

- 5.7.3. ENGINE OIL COOLER

- 5.7.4. TORQUE CONVERTER COOLER

- 5.7.5. FUEL INJECTION PUMP

- 5.7.6. WATER PUMP

- 5.7.7. TURBOCHARGER

- 5.7.8. AFTERCOOLER CORE

- 5.7.9. POWER TRAIN UNIT

- 5.7.10. PTO, TORQUE CONVERTER

- 5.7.11. TORQUE CONVERTER

- 5.7.13. TORQFLOW TRANSMISSION

- 5.7.14. STEERING CASE

- 5.7.15. STEERING CLUTCH, BRAKE

- 5.7.16. TRANSFER GEAR HOUSING

- 5.7.17. TORQUE CONVERTER VALVE

- 5.7.18. TRANSMISSION CONTROL VALVE

- 5.7.19. STEERING CONTROL VALVE

- 5.7.20. POWER TRAIN PUMP

- 5.7.21. SCAVENGING PUMP

- 5.7.22. FINAL DRIVE

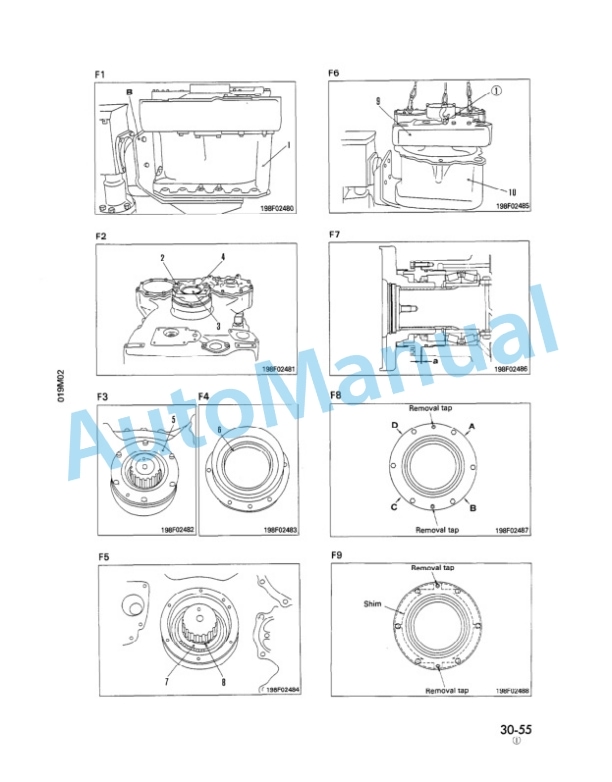

- 5.7.23. IDLER

- 5.7.24. TRACK ROLLER

- 5.7.25. CARRIER ROLLER

- 5.7.26. TRACK SHOE

- 5.7.27. PIVOT SHAFT

- 5.7.28. EQUALIZER BAR

- 5.7.29. EQUALIZER BAR BUSHING

- 5.7.30. IDLER YOKE CARTRIDGE

- 5.7.31. IDLER PAD

- 5.8. HYDRAULIC SYSTEM

- 5.8.1. HYDRAULIC PUMP

- 5.8.2. BLADE LIFT VALVE

- 5.8.3. BLADE TILT, RIPPER Lo VALVE

- 5.8.4. RIPPER Hi VALVE

- 5.8.5. BLADE LIFT CYLINDER

- 5.8.6. BLADE TILT CYLINDER

- 5.8.7. RIPPER LIFT CYLINDER

- 5.8.8. RIPPER TILT CYLINDER

- 5.8.9. HYDRAULIC CYLINDER

- 5.8.10. PIN PULLER CYLINDER

- 5.9. WORK EQUIPMENT

- 5.9.1. WORK EQUIPMENT

- 5.9.2. RIPPER

- 5.9.3. ROPS CAB

- 6. MAINTENANCE STANDARD

- 6.1. ENGINE

- 6.1.1. ENGINE MOUNT

- 6.1.2. FAN DRIVE PUMP (SAR63 40)

- 6.1.3. FAN DRIVE MOTOR (SAL140)

- 6.1.4. INLINE SERVO VALVE

- 6.2. POWER TRAIN

- 6.2.1. DAMPER

- 6.2.2. TORQUE CONVERTER (TCS521 D)

- 6.2.3. TORQUE CONVERTER VALVE

- 6.2.4. TORQFLOW TRANSMISSION

- 6.2.5. TRANSMISSION CONTROL VALVE

- 6.2.6. POWER TRAIN LUBRICATION PUMP (BAL 160 224)

- 6.2.7. TRANSFER, BEVEL PINION

- 6.2.8. BEVEL GEAR, STEERING CLUTCH, BRAKE

- 6.2.9. STEERING CONTROL VALVE

- 6.2.10. CARRIER ROLLER

- 6.2.11. TRACK (LUBRICATED TRACK LINK)

- 6.2.12. EQUALIZER BAR

- 6.2.13. PIVOT SHAFT

- 6.3. HYDRAULIC SYSTEM

- 6.3.1. WORK EQUIPMENT PUMP (SARZOO 100)

- 6.3.2. BLADE LIFT VALVE

- 6.3.3. MAIN RELIEF, SHUTTLE VALVE

- 6.3.4. BLADE TILT, RIPPER LOW VALVE

- 6.3.5. RIPPER HIGH VALVE

- 6.3.6. HYDRAULIC CYLINDER

- 6.3.7. CYLINDER STAY

- 6.4. WORK EQUIPMENT

- 6.4.1. DOZER EQUIPMENT

- 6.4.2. CUTTING EDGES AND END BITS

- 6.4.3. RIPPER EQUIPMENT

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00