Komatsu D475A-3 Bull Dozer Shop Manual SEBM027502

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM027502

- Format: PDF

- Size: 28.4MB

- Number of Pages: 738

Category: Komatsu Shop Manual PDF

-

Model List:

- D475A-3 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DIMENSION DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE AND FUNCTION

- 4.1. ENGINE, POWER TRAIN COOLING SYSTEM DRAWING

- 4.2. POWER TRAIN

- 4.3. POWER TRAIN SKELETON

- 4.4. POWER TRAIN HYDRAULIC PIPING DIAGRAM

- 4.5. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 4.6. TORQUE CONVERTER AND PTO

- 4.7. TORQUE CONVERTER VALVE

- 4.8. TRANSMISSION

- 4.9. TRANSMISSION CONTROL

- 4.10. TRANSMISSION ECMV

- 4.11. TRANSMISSION CLUTCH ECMV

- 4.12. TRANSMISSION LUBRICATION RELIEF VALVE

- 4.13. PRIORITY VALVE

- 4.14. STEERING, BRAKE CONTROL

- 4.15. TRANSFER, BEVEL GEAR SHAFT, STEERING

- 4.16. TRANSFER, BEVEL PINION

- 4.17. STEERING ECMV

- 4.18. STEERING CLUTCH, STEERING BRAKE ECMV

- 4.19. SUDDEN STOP PREVENTION VALVE

- 4.20. FINAL DRIVE

- 4.21. TRACK FRAME

- 4.22. HYDRAULIC TANK

- 4.23. PPC VALVE

- 4.24. MAIN CONTROL VALVE

- 4.25. PINPULLER HYDRAULIC SYSTEM DRAWING

- 4.26. PINPULLER HYDRAULIC CIRCUIT DRAWING

- 4.27. PINPULLER SOLENOID VALVE

- 4.28. AIR CONDITIONER

- 4.29. ENGINE CONTROL

- 4.30. ENGINE CONTROL SYSTEM

- 4.31. DECELERATION POTENTIOMETER

- 4.32. ENGINE CONTROL SYSTEM WITH ELECTRONIC ENGINE THROTTLE CONTROLLER

- 4.33. MONITOR SYSTEM

- 4.34. MONITOR PANEL

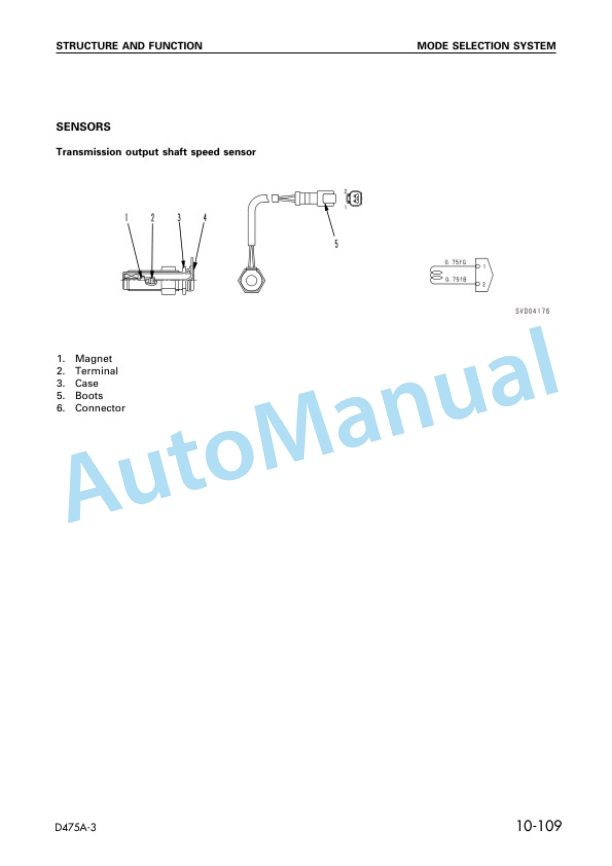

- 4.35. MODE SELECTION SYSTEM

- 4.36. ELECTRICAL EQUIPMENT

- 4.37. STEERING ELECTRONIC CONTROL

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 5.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 5.3. TESTING AND ADJUSTING

- 5.3.1. TABLE OF TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.3.2. MEASURING ENGINE SPEED

- 5.3.3. MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)

- 5.3.4. MEASURING EXHAUST TEMPERATURE

- 5.3.5. MEASURING EXHAUST COLOR

- 5.3.6. ADJUSTING VALVE CLEARANCE

- 5.3.7. MEASURING COMPRESSION PRESSURE

- 5.3.8. MEASURING BLOWBY PRESSURE

- 5.3.9. MEASURING ENGINE OIL PRESSURE

- 5.3.10. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.3.11. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.3.12. TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR

- 5.3.13. ADJUSTING ENGINE SPEED SENSOR

- 5.3.14. ADJUSTING FUEL CONTROL DIAL AND DECELERATOR PEDAL

- 5.3.15. MEASURING POWER TRAIN OIL PRESSURE

- 5.3.16. SIMPLE METHOD FOR TESTING BRAKE PERFORMANCE

- 5.3.17. ADJUSTING BRAKE PEDAL AND PARKING BRAKE LEVER

- 5.3.18. ADJUSTING PCCS LEVER CONSOLE POSITION

- 5.3.19. EMERGENCY ESCAPE METHOD WHEN POWER TRAIN HAS TROUBLE

- 5.3.20. ADJUSTING CLEARANCE OF IDLER

- 5.3.21. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.3.22. MEASURING AND ADJUSTING WORK EQUIPMENT OIL PRESSURE

- 5.3.23. TESTING AND ADJUSTING WORK EQUIPMENT CONTROL CIRCUIT PRESSURE

- 5.3.24. MEASURING PPC VALVE AND PITCH, TILT CONTROL VALVE OUTPUT PRESSURE

- 5.3.25. ADJUSTING PPC VALVE

- 5.3.26. MEASURING OUTPUT PRESSURE OF DEMAND SOLENOID VALVE

- 5.3.27. MEASURING OUTPUT PRESSURE OF RIPPER PINPULLER SOLENOID VALVE

- 5.3.28. CHECKING LOCATION OF CAUSE OF HYDRAULIC DRIFT OF BLADE AND RIPPER

- 5.3.29. MEASURING LEAKAGE INSIDE HYDRAULIC CYLINDER

- 5.3.30. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.3.31. BLEEDING AIR FROM HYDRAULIC CYLINDERS

- 5.3.32. ADJUSTING WORK EQUIPMENT SAFETY LEVER

- 5.3.33. ADJUSTING RIPPER LEVER POSITION

- 5.3.34. PROCEDURE FOR ADJUSTING BLADE TILT LIMIT ANGLE (DUAL TILT DOZER SPECIFICATION)

- 5.3.35. SPECIAL FUNCTIONS OF MONITOR PANEL (EMMS)

- 5.3.36. ADJUSTING METHOD OF REPLACED CONTROLLER

- 5.3.37. PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRIC SYSTEM

- 5.3.38. HANDLING OF OPTIONAL DEVICES

- 5.3.39. PM CLINIC SERVICE

- 5.3.40. UNDERCARRIAGE TROUBLESHOOTING REPORT

- 5.4. TROUBLESHOOTING

- 5.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.4.4. CHECKS BEFORE TROUBLESHOOTING

- 5.4.5. CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING

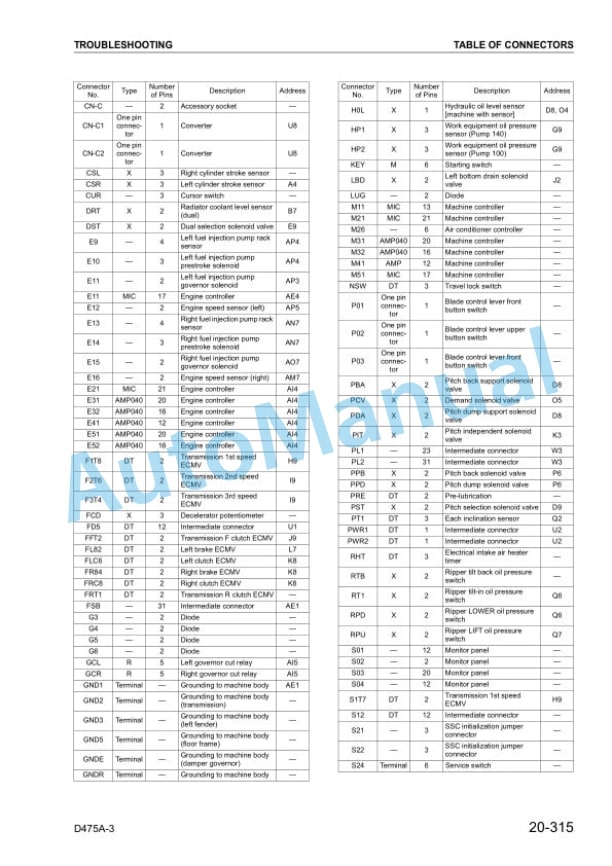

- 5.4.6. TABLE OF CONNECTORS

- 5.4.7. CONNECTOR ARRANGEMENT DRAWING

- 5.4.8. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.4.9. TBRANCH BOX AND TBRANCH TABLE

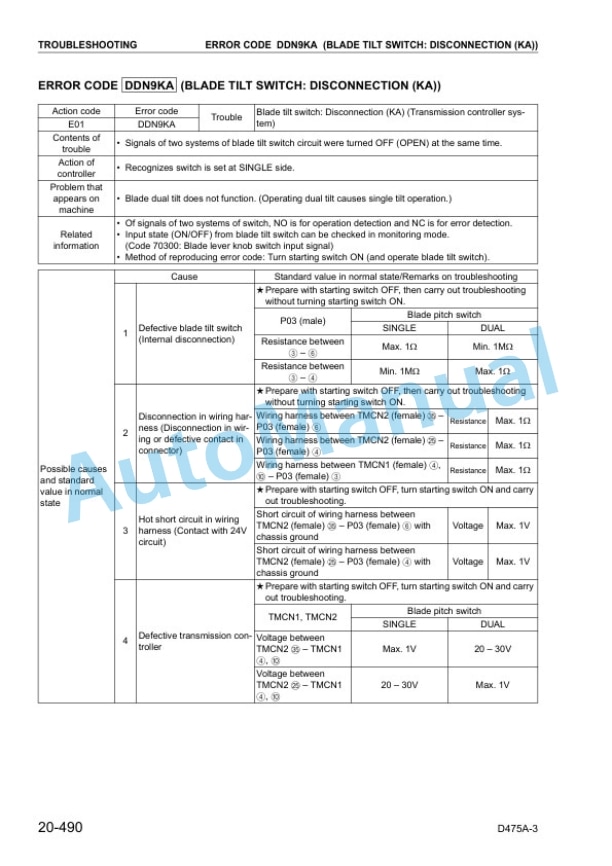

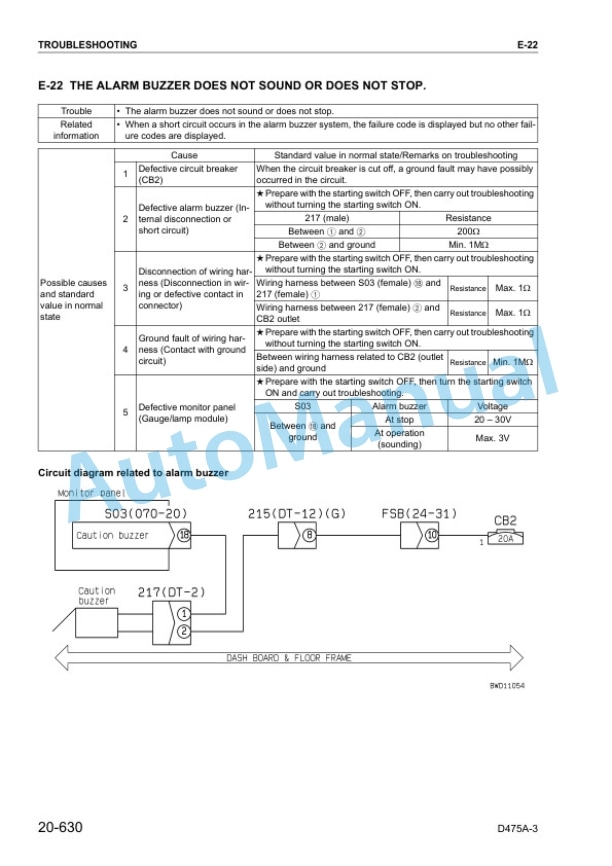

- 5.4.10. TROUBLESHOOTING WHEN ERROR CODE IS DISPLAYED (ERROR CODE)

- 5.4.11. TROUBLESHOOTING OF ELECTRICAL SYSTEM (EMODE)

- 5.4.12. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. POWER TRAIN UNIT ASSEMBLY

- 6.1.1. REMOVAL AND INSTALLATION

- 6.2. PTO,TORQUE CONVERTER ASSEMBLY

- 6.2.1. REMOVAL AND INSTALLATION

- 6.3. TORQFLOW TRANSMISSION ASSEMBLY

- 6.3.1. DISASSEMBLY AND ASSEMBLY

- 6.4. STEERING CASE ASSEMBLY

- 6.4.1. DISASSEMBLY AND ASSEMBLY

- 6.5. TRANSMISSION CONTROL VALVE ASSEMBLY

- 6.5.1. REMOVAL AND INSTALLATION

- 6.6. STEERING CONTROL VALVE ASSEMBLY

- 6.6.1. REMOVAL AND INSTALLATION

- 6.7. FLOOR FRAME ASSEMBLY

- 6.7.1. REMOVAL AND INSTALLATION

- 6.8. DASHBOARD ASSEMBLY

- 6.8.1. REMOVAL AND INSTALLATION

- 6.9. CONTROLLER ASSEMBLY

- 6.9.1. REMOVAL AND INSTALLATION

- 6.10. AIR CONDITIONER UNIT ASSEMBLY

- 6.10.1. REMOVAL AND INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT

- 7.2. DAMPER, UNIVERSAL JOINT

- 7.3. TORQUE CONVERTER

- 7.4. TORQUE CONVERTER VALVE

- 7.5. TORQFLOW TRANSMISSION

- 7.6. POWER TRAIN, HYDRAULIC, LUBRICATION PUMP

- 7.7. TRANSFER, BEVEL PINION

- 7.8. BEVEL GEAR SHAFT, STEERING CLUTCH, BRAKE

- 7.9. PARKING BRAKE VALVE

- 7.10. WORK EQUIPMENT CONTROL PUMP

- 7.11. MAIN CONTROL VALVE

- 7.12. PPC VALVE

- 7.13. WORK EQUIPMENT CYLINDER

- 7.14. CYLINDER STAY

- 7.15. BLADE

- 7.16. RIPPER EQUIPMENT

- 8. OTHERS

- 8.1. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 8.1.1. SINGLE TILT SPECIFICATION

- 8.1.2. DUAL TILT SPECIFICATION

- 8.1.3. SUPER DOZER SPECIFICATION

- 8.2. ELECTRICAL CIRCUIT DIAGRAM

- 8.2.1. SINGLE TILT AND DUAL TILT SPECIFICATIONS

- 8.2.2. SUPER DOZER SPECIFICATION

- 8.2.3. ELECTRICAL CIRCUIT DIAGRAM FOR INSIDE CAB

Rate this product

You may also like