Komatsu D51EX-22, D51PX-22 Crawler Dozer Shop Manual CEBM019110

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM019110

- Format: PDF

- Size: 77.6MB

- Number of Pages: 1268

Category: Komatsu Shop Manual PDF

-

Model List:

- D51EX-22 Crawler Dozer

- D51PX-22 Crawler Dozer

- 1. FOREWORD

- 1.1. CONTENTS

- 1.2. SAFETY

- 1.3. GENERAL

- 1.4. HOW TO READ THE SHOP MANUAL

- 1.5. HOISTING INSTRUCTIONS

- 1.6. PUSH PULL COUPLER

- 1.7. EXPLANATION OF MAINTENANCE STANDARD TERMS

- 1.8. STANDARD TIGHTENING TORQUE

- 1.9. ELECTRIC WIRE CODE

- 1.10. CONVERSION TABLES

- 1.11. COATING MATERIALS

- 2. GENERAL

- 2.1. SPECIFICATION DRAWING

- 2.2. SPECIFICATION

- 2.3. WEIGHT TABLE

- 2.4. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 3. STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD

- 3.1. ENGINE AND COOLING SYSTEM

- 3.2. POWER TRAIN

- 3.3. UNDER CARRIAGE AND FRAME

- 3.4. HYDRAULIC SYSTEM 1 (HST)

- 3.5. HYDRAULIC SYSTEM 2 (WORK EQUIPMENT)

- 3.6. WORK EQUIPMENT

- 3.7. CAB AND ITS ATTACHMENTS

- 3.8. ELECTRICAL SYSTEM

- 4. STANDARD VALUE TABLES

- 4.1. STANDARD VALUE TABLE FOR ENGINE

- 4.2. STANDARD VALUE TABLE FOR CHASSIS

- 4.3. PERFORMANCE MEASURING POSTURE AND METHOD

- 5. TESTING AND ADJUSTING

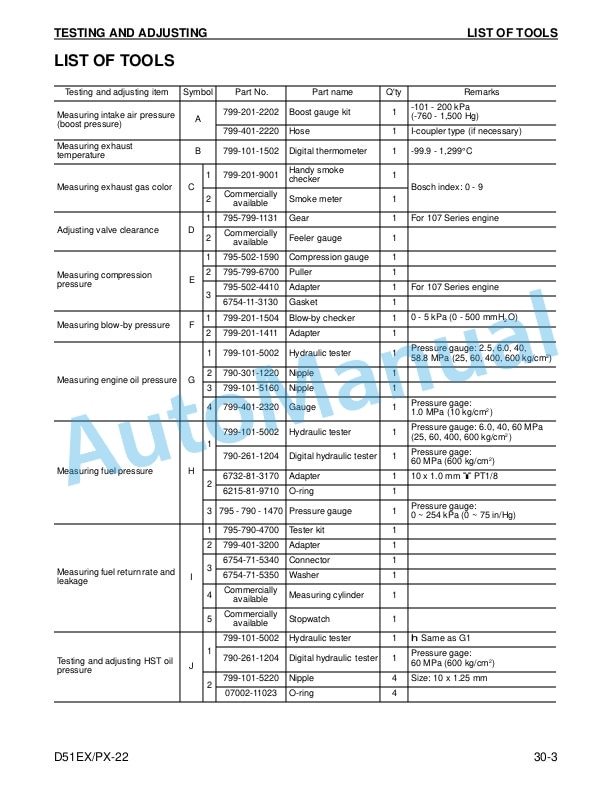

- 5.1. LIST OF TOOLS

- 5.2. ENGINE

- 5.3. HANDLING CONTROLLER HIGHVOLTAGE CIRCUIT

- 5.4. FUEL SYSTEM

- 5.5. FAN (WORK EQUIPMENT) PUMP PRESSURE

- 5.6. FAN SPEED

- 5.7. DECELERATOR PEDAL

- 5.8. HST OIL PRESSURE

- 5.9. MOTOR CONTROL VALVE OUTLET PRESSURE

- 5.10. PARKING BRAKE LEVER

- 5.11. BRAKE PERFORMANCE

- 5.12. BRAKE PEDAL LINKAGE

- 5.13. EMERGENCY RELEASE OF PARKING BRAKE

- 5.14. IDLER CLEARANCE

- 5.15. TRACK SHOE TENSION

- 5.16. WORK EQUIPMENT

- 5.17. WORK EQUIPMENT PPC VALVE

- 5.18. LOCK LEVER ADJUSTMENT

- 5.19. CYLINDER LEAKAGE

- 5.20. HYDRAULIC CIRCUIT

- 5.21. BLADE CENTER BALL ADJUSTMENT

- 5.22. BLADE PITCH BALL ADJUSTMENT

- 5.23. DIODES

- 5.24. MONITOR PANEL (EMMS) SPECIAL FUNCTIONS

- 5.25. PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRICAL SYSTEM

- 5.26. ELECTRIC/HYDRAULIC DEVICES ARE ADJUSTED/REPLACED

- 5.27. PMCLINIC

- 6. TROUBLESHOOTING

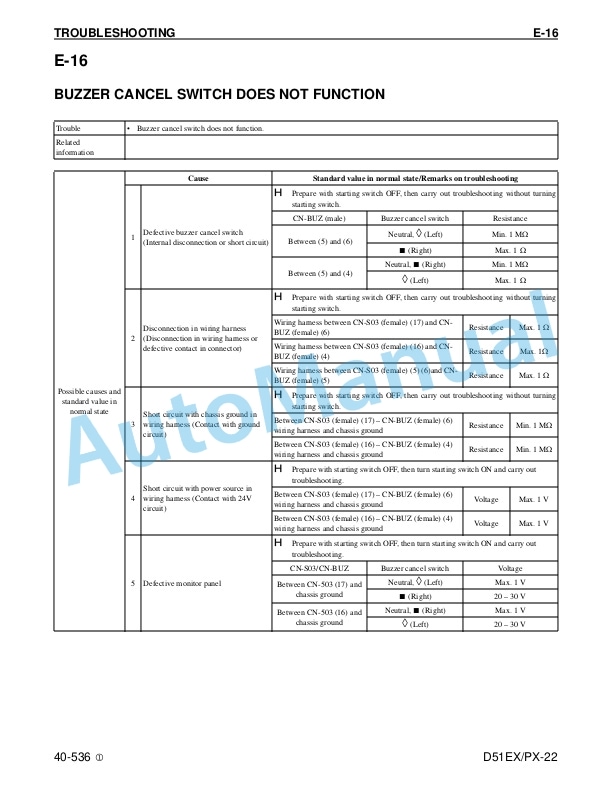

- 6.1. TROUBLESHOOTING (GENERAL)

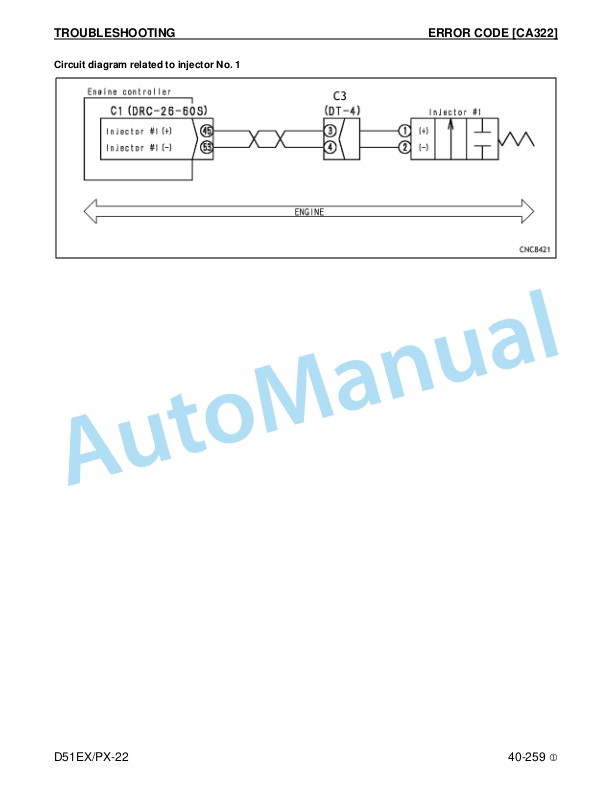

- 6.2. TROUBLESHOOTING (BY ERROR CODE)

- 6.3. TROUBLESHOOTING (EMODE)

- 6.4. TROUBLESHOOTING (HMODE)

- 6.5. TROUBLESHOOTING (SMODE)

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. HOW TO USE THIS MANUAL

- 7.2. PRECAUTIONS WHEN CARRYING OUT AN OPERATION

- 7.3. SPECIAL TOOL LIST

- 7.4. CONNECTOR REPAIR PROCEDURES

- 7.5. NOSE GUARD (HOOD)

- 7.6. MUFFLER AND EXHAUST STACK

- 7.8. MONITOR PANEL AND HST CONTROLLER

- 7.9. KOMTRAX CONTROLLER

- 7.10. SEAT

- 7.11. AIR CONDITIONER/HEATER

- 7.12. FOOT HEATER

- 7.13. FOOT HEATER OVERHAUL PROCEDURES

- 7.14. ENGINE AND HST PUMP

- 7.15. DRIVE DAMPENER

- 7.16. HST PUMP OVERHAUL PROCEDURES

- 7.17. WORK EQUIPMENT PUMP OVERHAUL PROCEDURES

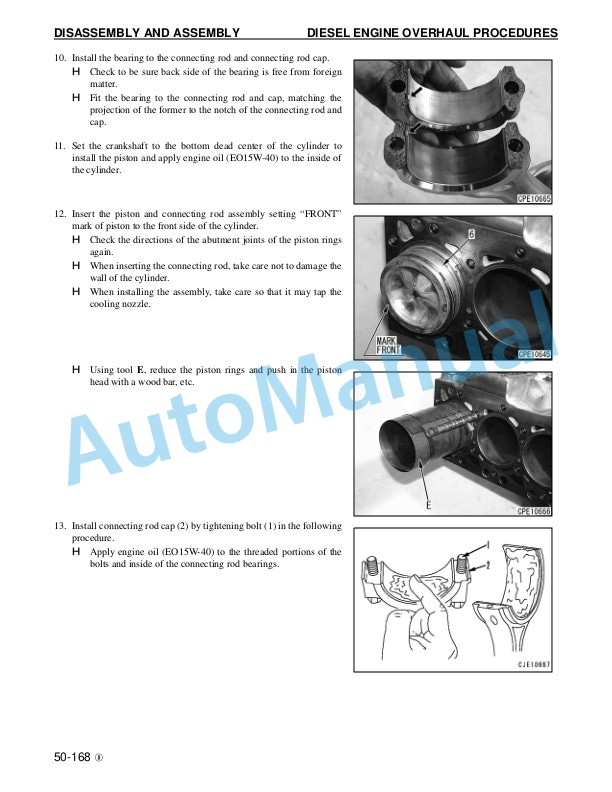

- 7.18. DIESEL ENGINE OVERHAUL PROCEDURES

- 7.19. TRACK SYSTEM

- 7.20. WHOLE DISASSEMBLY AND ASSEMBLY OF TRACK SHOE (PLUS TYPE TRACK SHOE)

- 7.21. FIELD DISASSEMBLY AND ASSEMBLY OF ONE LINK (CONVENTIONAL TYPE TRACK SHOE)

- 7.22. FIELD DISASSEMBLY AND ASSEMBLY OF ONE LINK (PLUS TYPE TRACK SHOE)

- 7.23. TRACK FRAME

- 7.24. FRONT TRACK IDLER

- 7.25. TRACK ROLLER

- 7.26. FINAL DRIVE

- 7.27. FINAL DRIVE OVERHAUL PROCEDURES

- 7.28. TRAVEL MOTOR OVERHAUL PROCEDURES

- 7.29. FAN MOTOR

- 7.30. FAN MOTOR OVERHAUL PROCEDURES

- 7.31. DB 12 VALVE

- 7.32. COOLING PACKAGE

- 7.33. FUEL TANK

- 7.34. HYDRAULIC TANK

- 7.35. WORK EQUIPMENT

- 7.36. CYLINDER OVERHAUL PROCEDURES

- 8. OTHERS

- 8.1. CONNECTOR ARRANGEMENT DRAWING AND ELECTRICAL CIRCUIT DIAGRAM

- 8.2. CONNECTOR LOCATION VIEW

- 8.3. CAB ELECTRICAL ACCESSORIES

- 8.4. AIR CONDITIONER AND HEATER UNIT

- 8.5. HYDRAULIC SYSTEM

- 8.6. ELECTRICAL DIAGRAMS

- 9. Blank Page

Rate this product

You may also like