Komatsu D575A-3 Super Dozer Shop Manual SEBM022003

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM022003

- Format: PDF

- Size: 31.0MB

- Number of Pages: 866

Category: Komatsu Shop Manual PDF

-

Model List:

- D575A-3 Super Dozer

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULLTYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. GENERAL

- 1.1. SPECIFICATION DRAWING

- 1.2. SPECIFICATIONS

- 1.3. WEIGHT TABLE

- 1.4. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 2. STRUCTURE AND FUNCTION, MAINTENANCE STANDARD

- 2.1. RADIATOR, OIL COOLER

- 2.2. ENGINE CONTROL

- 2.3. POWER TRAIN SYSTEM

- 2.4. POWER TRAIN SKELTON

- 2.5. POWER TRAIN HYDRAULIC PIPING

- 2.6. DAMPER

- 2.7. TORQUE CONVERTER, PTO

- 2.8. TORQUE CONVERTER VALVE

- 2.9. TORQUE CONVERTER LOCKUP CONTROL SYSTEM

- 2.10. TORQUE CONVERTER FILTER

- 2.11. TRANSMISSION CONTROL

- 2.12. TRANSMISSION

- 2.13. TRANSMISSION CONTROL VALVE

- 2.14. LUBRICATION RELIEF VALVE

- 2.15. STEERING CLUTCH, BRAKE CONTROL

- 2.16. STEERING CONTROL VALVE

- 2.17. STEERING CLUTCH, STEERING BRAKE

- 2.18. TRACK ROLLER BOGIE

- 2.19. SUSPENSION

- 2.20. HYDRAULIC PIPING DIAGRAM FOR WORK EQUIPMENT

- 2.21. CENTRALIZED OIL PRESSURE DETECTION PIPING DIAGRAM

- 2.22. HYDRAULIC TANK

- 2.23. PITCH, TILT SELECTOR SOLENOID VALVE ASSEMBLY

- 2.24. PPC VALVE

- 2.25. SAFETY LOCK VALVE, PPC ACCUMULATOR

- 2.26. PPC RELIEF VALVE

- 2.27. MAIN CONTROL VALVE

- 2.28. PITCH SELECTOR SOLENOID VALVE

- 2.29. PITCH PRIORITY SOLENOID VALVE

- 2.30. PITCH ASSIST SOLENOID VALVE

- 2.31. BLADE CONTROL KNOB

- 2.32. PISTON VALVE

- 2.33. QUICK DROP VALVE

- 2.34. WORK EQUIPMENT CYLINDER

- 2.35. CYLINDER STAY, YOKE

- 2.36. WORK EQUIPMENT

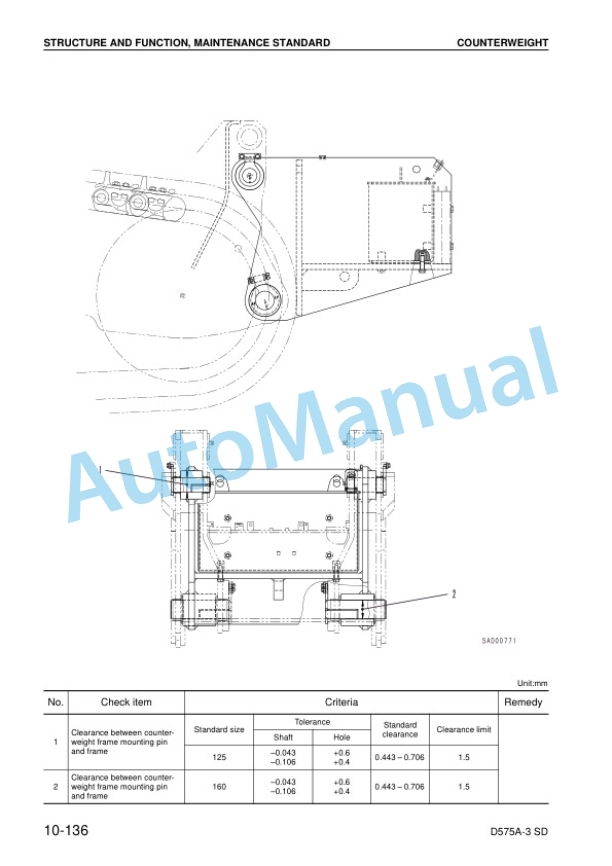

- 2.37. COUNTERWEIGHT

- 2.38. AIR CONDITIONER

- 2.39. ENGINE CONTROL SYSTEM

- 2.40. ENGINE CONTROL SYSTEM WITH ELECTRONIC ENGINE THROTTLE CONTROLLER

- 2.41. MONITOR SYSTEM

- 2.42. SENSOR

- 2.43. MODE SELECTION SYSTEM

- 2.44. BLADE CONTROL SYSTEM

- 2.45. ACTUAL ELECTRICAL WIRING DIAGRAM

- 3. TESTING AND ADJUSTING

- 3.1. STANDARD VALUE TABLE FOR ENGINE

- 3.2. STANDARD VALUE TABLE FOR CHASSIS

- 3.3. STANDARD VALUE TABLE FOR ELECTRICAL RELATED PARTS

- 3.4. TESTING AND ADJUSTING

- 3.4.1. TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING

- 3.4.2. MEASURING ENGINE SPEED

- 3.4.3. MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)

- 3.4.4. MEASURING EXHAUST TEMPERATURE

- 3.4.5. MEASURING EXHAUST COLOR

- 3.4.6. ADJUSTING VALVE CLEARENCE

- 3.4.7. MEASURING COMPRESSION PRESSURE

- 3.4.8. MEASURING BLOWBYPRESSURE

- 3.4.9. MEASURING ENGINE OIL PRESSURE

- 3.4.10. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.4.11. TESTING AND ADJUSTING FAN BELT TENSION

- 3.4.12. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 3.4.13. TESTING AND ADJUSTING BELT TENTENSION FOR AIR CONDITIONER COMPRESSOR

- 3.4.14. ADJUSTING ENGINE SPEED SENSOR

- 3.4.15. MEASURING COOLING FAN SPEED

- 3.4.16. ADJUSTING FUEL CONTROL DIAL AND DECELERATOR PEDAL

- 3.4.17. MEASURING TORQUE CONVERTER STALL SPEED

- 3.4.18. MEASURING TORQUE CONVERTER STALL HYDRAULIC PUMP RELIEF (FULL STALL ) SPEED

- 3.4.19. MEASURING POWER TRAIN OIL PRESSURE

- 3.4.20. PROCEDURE FOR RELEASING STEERING BRAKE

- 3.4.21. SIMPLE PROCEURE FOR TESTING BRAKE PERFORMANCE

- 3.4.22. ADJUSTING BRAKE PEDAL LINKAGE

- 3.4.23. ADJUSTING CLEARENCE OF IDLER

- 3.4.24. TESTING AND ADJUSTING TRACK SHOE TENSION

- 3.4.25. TESTING AND ADJUSTING WORK EQUIPMENT CIRCUIT PRESSURE (MAIN RELIEF AND PPC CIRCUIT)

- 3.4.26. MEASURING PPC VALVE OUTPUT PRESSURE

- 3.4.27. ADJUSTING PPC VALVE

- 3.4.28. CHECKING LOCATION OF CAUSE OF HYDRAULIC DRIFT OF BLADE

- 3.4.29. MEASURING LEAKAGE INSIDE CYLINDER

- 3.4.30. RELEASING AIR REMAINING IN HYDRAULIC CIRCUIT ON PPC VALUE

- 3.4.31. BLEEDING AIR FROM HYDRAULIC CYLINDER

- 3.4.32. ADJUSTING WORK EQUIPMENT SAFETY LEVER

- 3.4.33. PROCEDURE FOR ADJUSTING BLADE TILT LIMIT ANGLE

- 3.5. TROUBLESHOOTING

- 3.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 3.5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 3.5.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 3.5.4. CHECKS BEFORE TROUBLESHOOTING

- 3.5.5. CONNECTOR ARRANGEMENT DIAGRAM

- 3.5.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 3.5.7. TBRANCH BOX AND TBRANCH ADAPTER TABLE

- 3.5.8. EXPLANATION OF FUNCTIONS OF CONTROL MECHANISM OF ELECTRICAL SYSTEM

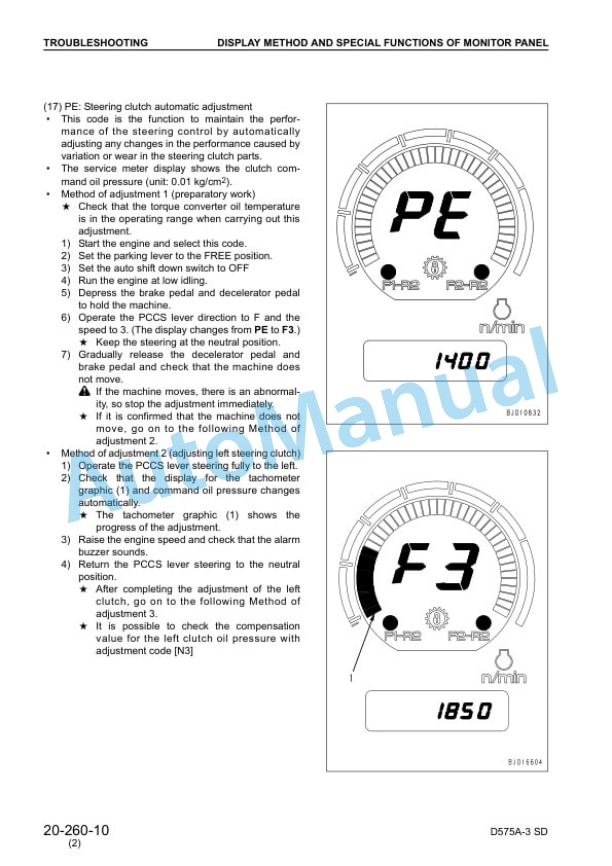

- 3.5.9. DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

- 3.5.10. METHOD OF USING TROUBLESHOOTING CHARTS

- 3.5.11. TROUBLESHOOTING OF NETWORK SYSTEM (N MODE)

- 3.5.12. TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM (E MODE)

- 3.5.13. TROUBLESHOOTING OF STEERING CONTROLLER SYSTEM (ST MODE)

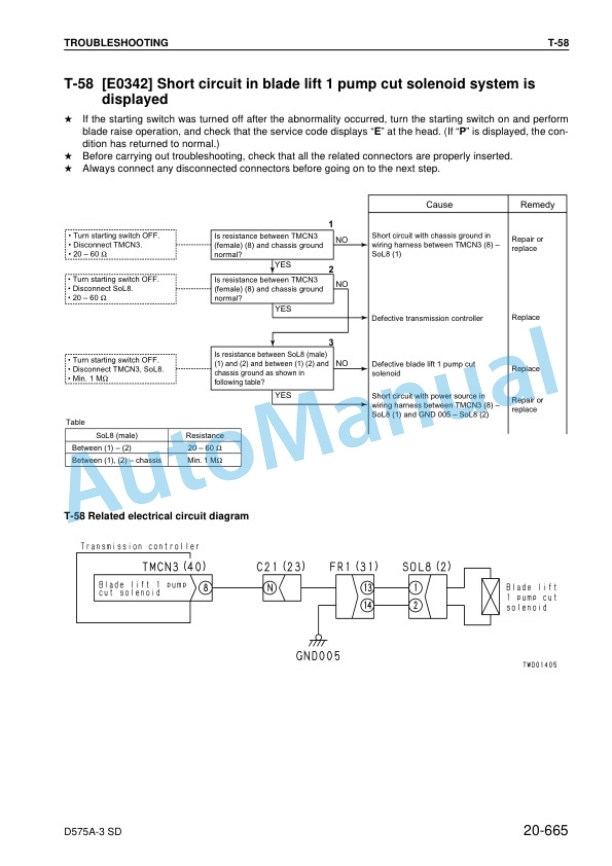

- 3.5.14. TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM (T MODE)

- 3.5.15. TROUBLESHOOTING OF HYDRAULIC MECHANICAL SYSTEM (H MODE)

- 3.5.16. TROUBLESHOOTING OF MONITOR PANEL AND ELECTRICAL SYSTEM (M MODE)

- 3.5.17. TROUBLESHOOTING OF ENGINE (S MODE)

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. METHOD OF USING MANUAL

- 4.2. PRECATIONS WHEN CARRYING OUT OPERATION

- 4.3. SPECIAL TOOL LIST

- 4.4. ENGINE OIL COOLER

- 4.4.1. REMOVAL

- 4.4.2. INSTALLATION

- 4.5. FUEL INJECTION PUMP

- 4.5.1. REMOVAL

- 4.5.2. INSTALLATION

- 4.6. AFTERCOOLER CORE

- 4.6.1. REMOVAL AND INSTALLATION

- 4.7. NOZZLER HOLDER

- 4.7.1. REMOVAL AND INSTALLATION

- 4.8. CYLINDER HEAD

- 4.8.1. REMOVAL

- 4.8.2. INSTALLATION

- 4.9. HYDRAULIC COOLER

- 4.9.1. REMOVAL AND INSTALLATION

- 4.10. RADIATOR

- 4.10.1. REMOVAL

- 4.10.2. INSTALLATION

- 4.11. FAN DRIVE SUPPORT

- 4.11.1. REMOVAL

- 4.11.2. INSTALLATION

- 4.12. FAN DRIVE PULLEY (FAN END)

- 4.12.1. REMOVAL AND INSTALLATION

- 4.12.2. DISASSEMBLY

- 4.12.3. ASSEMBLY

- 4.13. FAN DRIVE PULLEY (ENGINE END)

- 4.14. PTO, TORQUE CONVERTER

- 4.15. TORQUE CONVERTER

- 4.15.1. DISASSEMBLY

- 4.15.2. ASSEMBLY

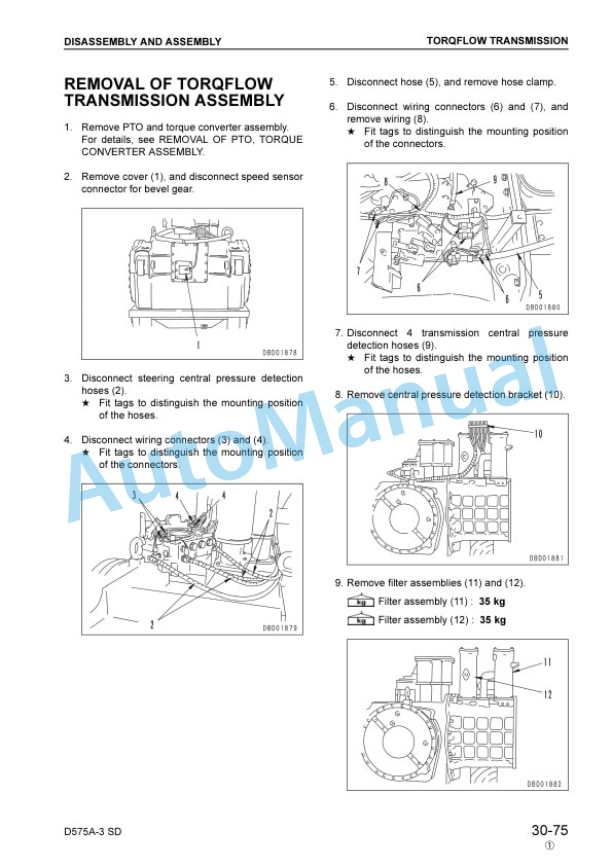

- 4.16. TORQFLOW TRANSMISSION

- 4.17. STEERING CLUTCH

- 4.18. TORQUE CONVERTER VALVE

- 4.18.1. REMOVAL

- 4.18.2. INSTALLATION

- 4.18.3. DISASSEMBLY

- 4.18.4. ASSEMBLY

- 4.19. TRANSMISSION CONTROL VALVE

- 4.19.1. REMOVAL AND INSTALLATION

- 4.19.2. DISASSEMBLY

- 4.19.3. ASSEMBLY

- 4.20. POWER TRAIN PUMP

- 4.20.1. REMOVAL AND INSTALLATION

- 4.21. TRANSMISSION LUBRICATION PUMP

- 4.21.1. REMOVAL AND INSTALLATION

- 4.22. SCAVENGING PUMP

- 4.22.1. REMOVAL AND INSTALLATION

- 4.23. RECOIL SPRING, TUBE

- 4.23.1. REMOVAL AND INSTALLATION

- 4.23.2. DISASSEMBLY

- 4.23.3. ASSEMBLY

- 4.24. IDLER YOKE CYLINDER

- 4.24.1. CHECKING BEFORE REMOVAL

- 4.24.2. REMOVAL

- 4.24.3. REMOVAL (WHEN THERE IS ABNORMALITY INSIDE TRACK FRAME)

- 4.24.4. INSTALLATION

- 4.24.5. DISASSEMBLY

- 4.24.6. ASSEMBLY

- 4.25. PRESSFITTING JIG DIMENSION TABLE FOR LINK PRESS

- 4.26. FIELD DISASSEMBLY OF ONE LINK

- 4.27. ADJUSTING TRACK SHOE TENSION

- 4.28. PIVOT SHAFT

- 4.28.1. REMOVAL AND INSTALLATION

- 4.29. EQUALIZER BAR

- 4.29.1. REMOVAL

- 4.29.2. INSTALLATION

- 4.30. REPLACING EQUALIZER BAR BUSHING

- 4.31. SEGMENT TEETH

- 4.31.1. REMOVAL AND INSTALLATION

- 4.32. WORK EQIPMENT PUMP

- 4.32.1. REMOVAL AND INSTALLATION

- 4.33. WORK EQUIPMENT ASSIST, CONTROL PUMP

- 4.33.1. REMOVAL AND INSTALLATION

- 4.34. BLADE VALVE

- 4.34.1. REMOVAL AND INSTALLATION

- 4.34.2. DISASSEMBLY

- 4.34.3. ASSEMBLY

- 4.35. MAIN RELIEF VALVE

- 4.35.1. DISASSEMBLY AND ASSEMBLY

- 4.36. BLADE LIFT CYLINDER

- 4.36.1. REMOVAL AND INSTALLATION

- 4.37. BLADE PITCH CYLINDER

- 4.37.1. REMOVAL AND INSTALLATION

- 4.38. HYDRAULIC CYLINDER

- 4.38.1. DISASSEMBLY

- 4.38.2. ASSEMBLY

- 4.39. BLADE PPC VALUE

- 4.40. OPERATORS COMPARTMENT FRAME

- 4.41. COUNTERWEIGHT FRAME

- 4.41.1. REMOVAL AND INSTALLATION

- 4.42. BLADE CYLINDER SUPPORT

- 4.42.1. REMOVAL

- 4.42.2. INSTALLATION

- 5. OTHERS

- 5.1. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 5.2. HYDRAULIC CIRCUIT DIAGRAM FOR WORK EQUIPMENT

- 5.3. ELECTRICAL CIRCUIT DIAGRAM (1/7)

- 5.4. ELECTRICAL CIRCUIT DIAGRAM (2/7)

- 5.5. ELECTRICAL CIRCUIT DIAGRAM (3/7)

- 5.6. ELECTRICAL CIRCUIT DIAGRAM (4/7)

- 5.7. ELECTRICAL CIRCUIT DIAGRAM (5/7)

- 5.8. ELECTRICAL CIRCUIT DIAGRAM (6/7)

- 5.9. ELECTRICAL CIRCUIT DIAGRAM (7/7)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00