Komatsu D61EX-15, D61PX-15 Bull Dozer Shop Manual WE051Z0002

$40.00

- Type Of Manual: Shop Manual

- Manual ID: WE051Z0002

- Format: PDF

- Size: 149.0MB

- Number of Pages: 988

Category: Komatsu Shop Manual PDF

-

Model List:

- D61EX-15 Bull Dozer

- D61PX-15 Bull Dozer

- 1. MAIN MENU

- 2. COVER

- 3. TABLE OF GENERAL CONTENTS

- 4. GENERAL FOREWARD

- 4.1. SAFETY

- 4.2. FOREWARD

- 5. GENERAL

- 5.1. Specification dimension drawing

- 5.2. Specifications

- 5.3. Weight table

- 5.4. Oil and coolant table

- 6. GENERAL STRUCTURE AND FUNCTION, MAINTENANCE STANDARD

- 6.1. Engine and cooling related components

- 6.1.1. Cooling system

- 6.2. Power transmitting system

- 6.2.1. Power train

- 6.2.2. Power train skeleton

- 6.2.3. Overall drawing of power train unit

- 6.2.4. Hydraulic piping diagram of power train

- 6.2.5. Damper and universal joint

- 6.2.6. Transmission, steering, and brake control

- 6.3. Power transmitting system

- 6.3.1. Torque converter and PTO

- 6.3.2. Transmission

- 6.3.3. Transmission ECMV

- 6.3.4. Main relief valve

- 6.3.5. Lubricating oil relief valve

- 6.4. Power transmitting system

- 6.4.1. Scavenging pump

- 6.4.2. Power train and lubrication pump

- 6.4.3. HSS system

- 6.5. Power transmitting system

- 6.5.1. HSS pump

- 6.5.2. HSS motor

- 6.6. Power transmitting system

- 6.6.1. Bevel gear shaft, HSS, and brake

- 6.6.2. Brake valve

- 6.6.3. Final drive

- 6.7. Undercarriage and frame

- 6.7.1. Frame assembly

- 6.7.2. Suspension

- 6.7.3. Track frame and recoil spring

- 6.8. Hydraulic system

- 6.8.1. Layout of hydraulic devices for work equipment

- 6.8.2. Work equipment control

- 6.8.3. Hydraulic tank and filter

- 6.8.4. Solenoid valve

- 6.8.5. Accumulator

- 6.8.6. Hydraulic cylinder

- 6.8.7. Piston valve

- 6.8.8. Quick drop valve

- 6.9. Hydraulic system

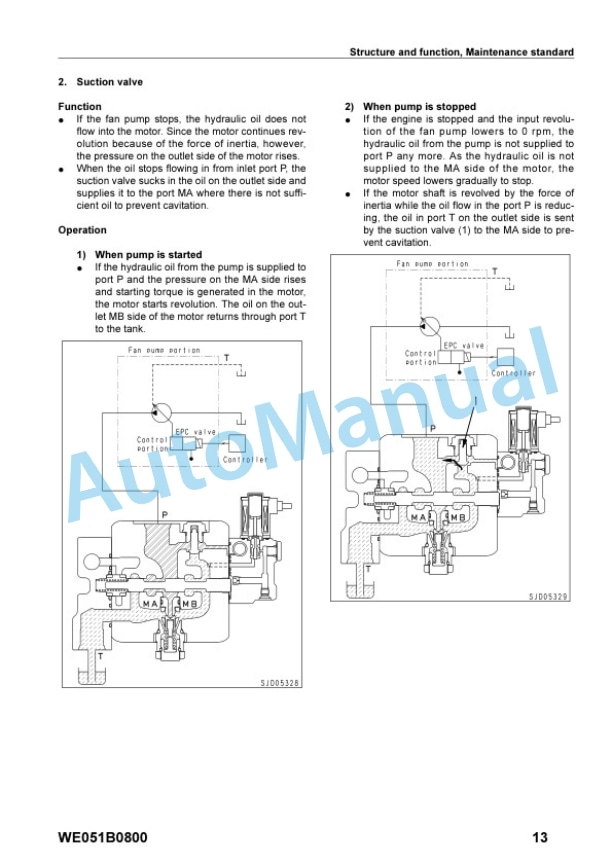

- 6.9.1. Cooling fan pump

- 6.9.2. Cooling fan motor

- 6.9.3. PPC valve

- 6.9.4. Electric lever (Steering)

- 6.10. Hydraulic system

- 6.10.1. Control valve

- 6.10.2. CLSS

- 6.10.3. Selfpressure reducing valve

- 6.11. Work equipment

- 6.11.1. Work equipment

- 6.11.2. Cutting edge and end bit

- 6.11.3. Ripper

- 6.12. Cab and its attachments

- 6.12.1. Cab mount

- 6.12.3. Air conditioner piping

- 6.13. Electric system

- 6.13.1. Engine control system

- 6.13.2. Cooling system control system

- 6.13.3. Palm command control system

- 6.13.4. PPC lock system

- 6.13.5. Component parts of system

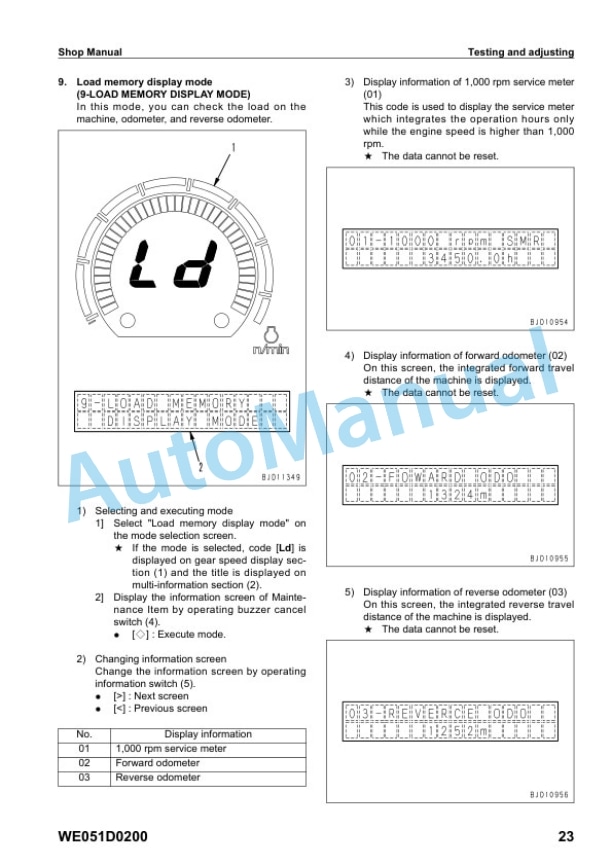

- 6.13.6. Monitor system

- 6.13.7. Monitor panel

- 6.13.8. Sensor

- 7. TESTING, ADJUSTING TROUBLESHOOTING

- 7.1. Standard value table

- 7.1.1. Standard value table for engine

- 7.1.2. Standard value table for chassis

- 7.2. Testing and adjusting

- 7.2.1. Testing and adjusting (1/2)

- 7.2.2. Testing and adjusting (2/2)

- 7.3. Troubleshooting

- 7.3.1. Preface

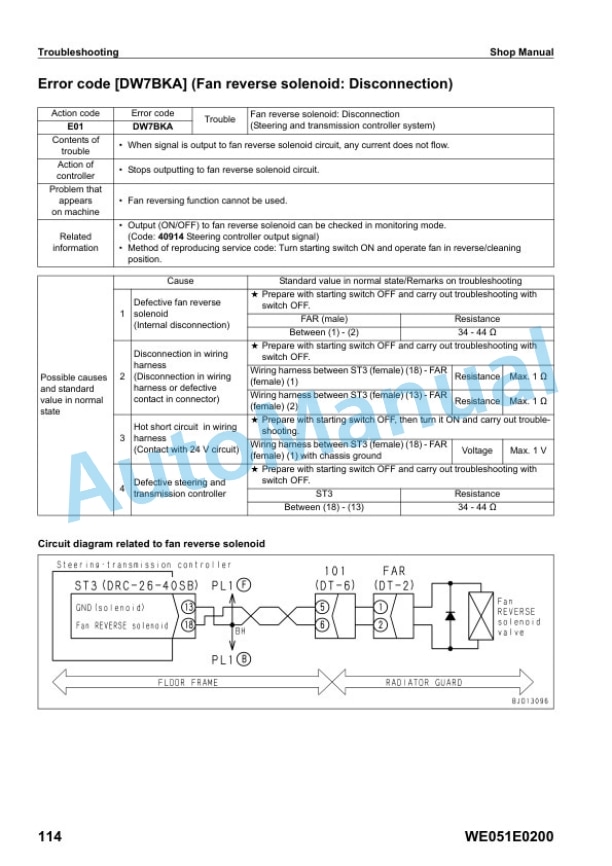

- 7.3.2. Troubleshooting when error code is displayed (Error code) CONTENTS

- 7.3.3. Troubleshooting of electrical system (Emode) CONTENTS

- 7.3.4. Troubleshooting of hydraulic and mechanical system (Hmode) CONTENTS

- 7.3.5. Troubleshooting of engine system (Smode) CONTENTS

- 8. DISASSEMBLY AND ASSEMBLY

- 8.1. Preface

- 8.1.1. How to read this manual

- 8.1.2. Standard tightening torque table

- 8.1.3. Precautions when performing operation

- 8.1.4. List of coatings

- 8.1.5. Special tool list

- 8.1.6. Sketches of special tools

- 8.2. Engine related procedures

- 8.2.1. Removal and installation of fuel injection pump assembly

- 8.2.2. Removal and installation of cylinder head assembly

- 8.2.3. Removal and installation of engine front seal

- 8.2.4. Removal and installation of engine rear seal

- 8.2.5. Removal and installation of engine assembly

- 8.2.6. Removal and installation of damper assembly

- 8.2.7. Removal and installation of radiator guard assembly

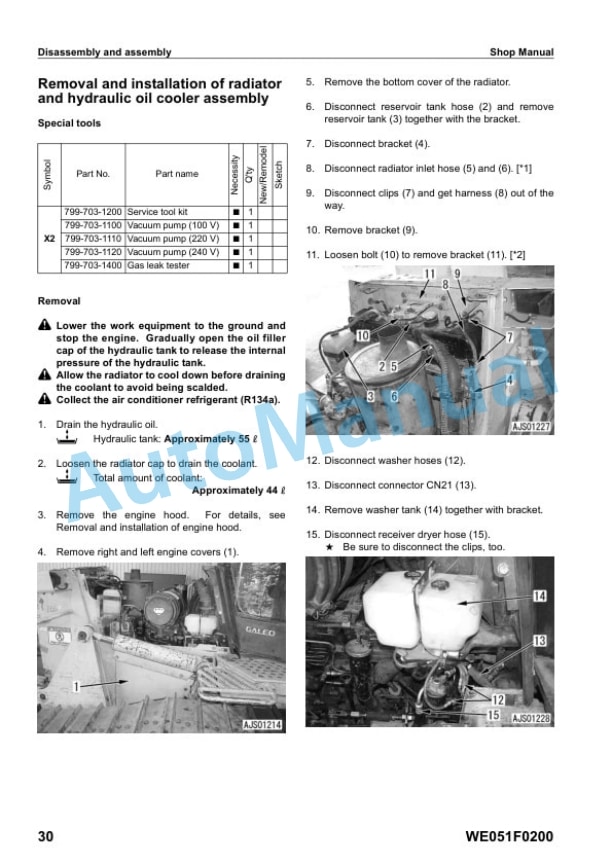

- 8.2.8. Removal and installation of radiator and hydraulic oil cooler assembly

- 8.2.9. Removal and installation of fan drive assembly

- 8.2.10. Removal and installation of fan motor assembly

- 8.2.11. Removal and installation of engine hood assembly

- 8.2.12. Removal and installation of fuel tank assembly

- 8.3. Power train

- 8.3.1. Removal and installation of PTO, torque converter and transmission assembly

- 8.3.2. Disconnection and connection of PTO, torque converter and transmission assembly

- 8.3.3. Disassembly and assembly of PTO assembly

- 8.3.4. Disassembly and assembly of torque converter assembly

- 8.3.5. Disassembly and assembly of TORQFLOW transmission assembly

- 8.3.6. Removal and installation of torque converter main relief valve assembly

- 8.3.7. Disassembly and assembly of torque converter main relief valve assembly

- 8.4. Power train

- 8.4.1. Removal and installation of power train and lubricating oil pump assembly

- 8.4.2. Removal and installation of HSS and work equipment pump assembly

- 8.4.3. Removal and installation of scavenging pump assembly

- 8.4.4. Removal and installation of HSS motor assembly

- 8.4.5. Disassembly and assembly of HSS assembly

- 8.4.6. Removal and installation of final drive assembly

- 8.4.7. Disassembly and assembly of final drive assembly

- 8.5. Undercarriage

- 8.5.1. Removal and installation of track frame assembly

- 8.5.2. Removal and installation of idler assembly

- 8.5.3. Disassembly and assembly of idler assembly

- 8.5.4. Removal and installation of recoil spring assembly

- 8.5.5. Disassembly and assembly of recoil spring assembly

- 8.5.6. Removal and installation of track roller assembly

- 8.5.7. Disassembly and assembly of track roller assembly

- 8.5.8. Removal and installation of carrier roller assembly

- 8.5.9. Disassembly and assembly of carrier roller assembly

- 8.6. Undercarriage

- 8.6.1. Check before expanding track shoe assembly

- 8.6.2. Expansion (normal), expansion (internal abnormality) and installation of track shoe assembly

- 8.6.3. Overall disassembly and overall assembly of track shoe assembly

- 8.6.4. Link pressfitting jig dimensions table

- 8.6.5. Field disassembly and assembly of one link

- 8.6.6. Removal and installation of pivot shaft assembly

- 8.6.7. Removal and installation of equalizer bar assembly

- 8.6.8. Removal and installation of equalizer bar side bushing

- 8.6.9. Removal and installation of segment teeth

- 8.7. Hydraulic system

- 8.7.1. Removal and installation of main control valve assembly

- 8.7.2. Assembly of main control valve assembly

- 8.7.3. Removal and installation of cooling fan pump assembly

- 8.7.4. Removal and installation of work equipment assembly

- 8.7.5. Disassembly and assembly of work equipment assembly

- 8.7.6. Disassembly and assembly of hydraulic cylinder assembly

- 8.8. Others

- 8.8.1. Removal and installation of operators cab assembly

- 8.8.2. Removal and installation of operators cab glass (stuck glass)

- 8.8.3. Removal and installation of ROPS canopy

- 8.8.4. Removal and installation of dashboard assembly

- 8.8.5. Removal and installation of floor frame assembly

- 8.8.6. Removal and installation of steering and transmission controller assembly

- 9. OTHERS

- 9.1. Hydraulic circuit diagram

- 9.1.1. Power train hydraulic circuit diagram

- 9.1.2. Work equipment hydraulic circuit diagram Power angle power tilt dozer (PAT)

- 9.1.3. Work equipment hydraulic circuit diagram Power tilt dozer (PT)

- 9.2. Electrical circuit diagram

- 9.2.1. Electrical circuit diagram (1/6)

- 9.2.2. Electrical circuit diagram (2/6)

- 9.2.3. Electrical circuit diagram (3/6)

- 9.2.4. Electrical circuit diagram (4/6)

- 9.2.5. Electrical circuit diagram (5/6)

- 9.2.6. Electrical circuit diagram (6/6)

- 9.2.7. Cab electrical circuit diagram

Rate this product

You may also like