Komatsu D61EX-24, D61EX-24E0, D61PX-24, D61PX-24E0 Bull Dozer Shop Manual SEN06855-00

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN06855-00

- Format: PDF

- Size: 13.2MB

- Number of Pages: 452

Category: Komatsu Shop Manual PDF

-

Model List:

- D61EX-24 Bull Dozer

- D61EX-24E0 Bull Dozer

- D61PX-24 Bull Dozer

- D61PX-24E0 Bull Dozer

- 1. COVER

- 2. INDEX AND FOREWORD

- 2.1. INDEX

- 2.2. FOREWORD, SAFETY, BASIC INFORMATION

- 2.2.1. HOW TO READ THE SHOP MANUAL

- 2.2.2. SAFETY NOTICE FOR OPERATION

- 2.2.3. PRECAUTIONS TO PREVENT FIRE

- 2.2.4. ACTIONS IF FIRE OCCURS

- 2.2.5. PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS

- 2.2.6. ACTIONS TAKEN TO MEET EXHAUST GAS REGULATIONS

- 2.2.7. PRECAUTIONS FOR DEF

- 2.2.8. STORE AdBlue/DEF

- 2.2.9. PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT

- 2.2.10. PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS

- 2.2.11. PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT

- 2.2.12. PRECAUTIONS FOR HANDLING FUEL SYSTEM EQUIPMENT

- 2.2.13. PRECAUTIONS FOR HANDLING INTAKE SYSTEM EQUIPMENT

- 2.2.14. PRACTICAL USE OF KOMTRAX

- 2.2.15. DISCONNECT AND CONNECT PUSHPULL TYPE COUPLER

- 2.2.16. PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF CONNECTORS

- 2.2.17. METHOD FOR DISCONNECTING AND CONNECTING DEUTSCH CONNECTOR

- 2.2.18. METHOD FOR DISCONNECTING AND CONNECTING SLIDE LOCK TYPE CONNECTOR

- 2.2.19. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PULL

- 2.2.20. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH LOCK TO PUSH

- 2.2.21. METHOD FOR DISCONNECTING AND CONNECTING CONNECTOR WITH HOUSING TO ROTATE

- 2.2.22. HOW TO READ ELECTRICAL WIRE CODE

- 2.2.23. EXPLANATION OF TERMS FOR MAINTENANCE STANDARD

- 2.2.24. STANDARD TIGHTENING TORQUE TABLE

- 2.2.25. CONVERSION TABLE

- 2.2.26. ABBREVIATION LIST

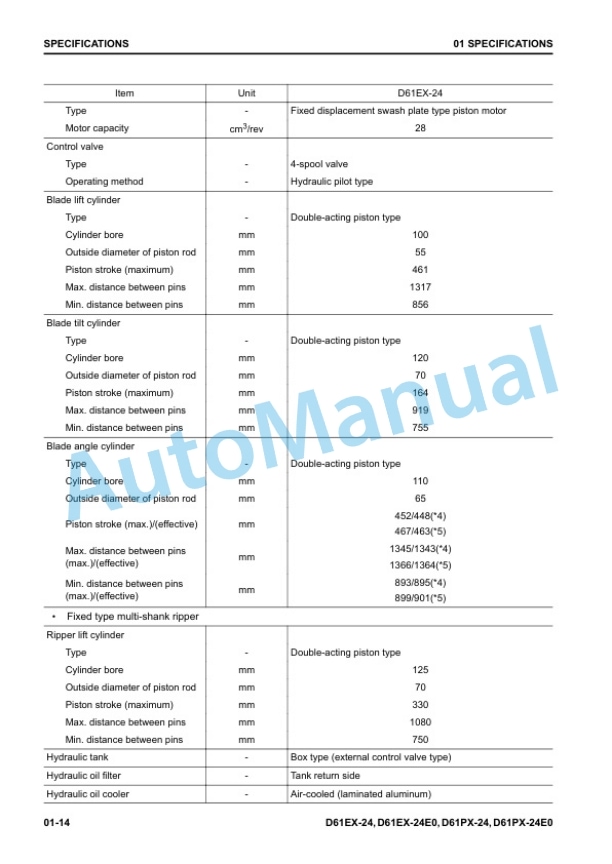

- 3. SPECIFICATIONS

- 3.1. CONTENTS

- 3.2. SPECIFICATIONS

- 3.2.1. SPECIFICATION DRAWING

- 3.2.2. SPECIFICATIONS

- 3.2.3. WEIGHT TABLE

- 3.2.4. FUEL, COOLANT, LUBRICANTS (FOR NORTH AMERICA)

- 3.2.5. FUEL, COOLANT, LUBRICANTS (FOR EUROPEAN UNION)

- 4. STRUCTURE AND FUNCTION

- 4.1. CONTENTS

- 4.2. UREA SCR SYSTEM

- 4.2.1. LAYOUT DRAWING OF UREA SCR SYSTEM

- 4.2.2. UREA SCR SYSTEM DIAGRAM

- 4.2.3. FUNCTION OF UREA SCR SYSTEM

- 4.2.4. COMPONENT PARTS OF UREA SCR SYSTEM

- 4.3. BOOTUP SYSTEM

- 4.3.1. LAYOUT DRAWING OF BOOTUP SYSTEM

- 4.3.2. SYSTEM OPERATING LAMP SYSTEM

- 4.3.3. BATTERY DISCONNECT SWITCH

- 4.4. ENGINE SYSTEM

- 4.4.1. LAYOUT DRAWING OF ENGINE SYSTEM

- 4.4.2. ENGINE CONTROL SYSTEM

- 4.4.3. AUTOMATIC IDLE STOP SYSTEM

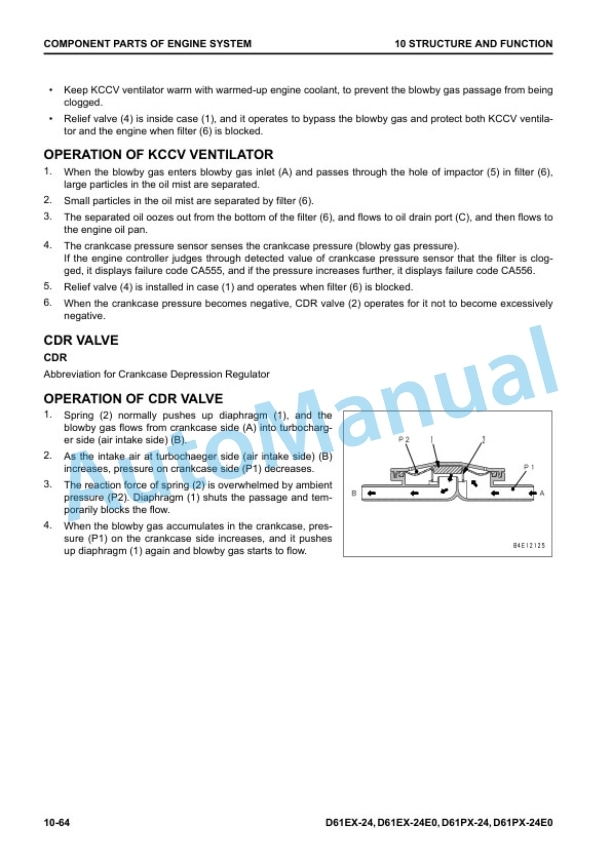

- 4.4.4. COMPONENT PARTS OF ENGINE SYSTEM

- 4.5. COOLING SYSTEM

- 4.5.1. LAYOUT DRAWING OF COOLING SYSTEM

- 4.5.2. COOLING FAN CONTROL SYSTEM

- 4.5.3. COMPONENT PARTS OF COOLING SYSTEM

- 4.6. CONTROL SYSTEM

- 4.6.1. LAYOUT DRAWING OF CONTROL SYSTEM

- 4.6.2. MACHINE MONITOR SYSTEM

- 4.6.3. KOMTRAX SYSTEM

- 4.6.4. COMPONENT PARTS OF CONTROL SYSTEM

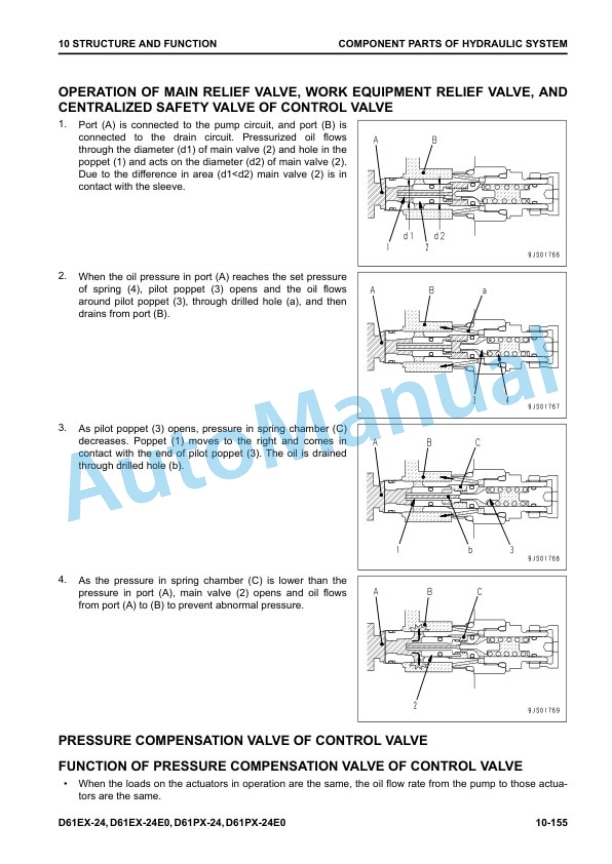

- 4.7. HYDRAULIC SYSTEM

- 4.7.1. LAYOUT DRAWING OF HYDRAULIC SYSTEM

- 4.7.2. CLSS

- 4.7.3. COMPONENT PARTS OF HYDRAULIC SYSTEM

- 4.8. POWER TRAIN SYSTEM

- 4.8.1. LAYOUT DRAWING OF HST SYSTEM

- 4.8.2. OPERATION OF HST SYSTEM

- 4.8.3. STEERING AND BRAKE CONTROL SYSTEM

- 4.8.4. HST CONTROL SYSTEM

- 4.8.5. PARKING BRAKE CONTROL SYSTEM

- 4.8.6. COMPONENT PARTS OF POWER TRAIN SYSTEM

- 4.9. WORK EQUIPMENT SYSTEM

- 4.9.1. WORK EQUIPMENT CONTROL

- 4.9.2. LAYOUT DRAWING OF FRONT WORK EQUIPMENT

- 4.9.3. LAYOUT OF FIXED MULTISHANK RIPPER

- 4.9.4. COMPONENT PARTS OF WORK EQUIPMENT SYSTEM

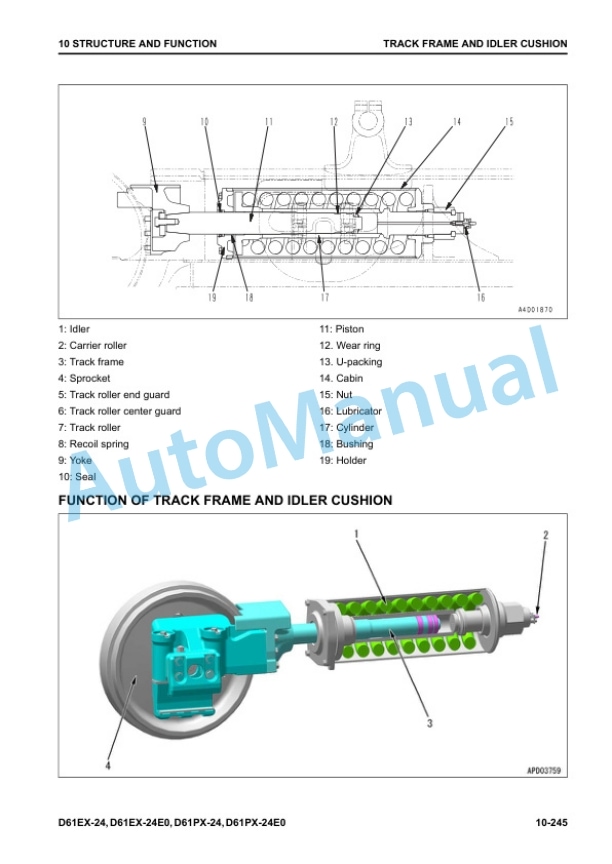

- 4.10. UNDERCARRIAGE AND FRAME

- 4.10.1. MAIN FRAME

- 4.10.2. SUSPENSION

- 4.10.3. TRACK FRAME AND IDLER CUSHION

- 4.11. WORK EQUIPMENT

- 4.11.1. STRUCTURE OF FRONT WORK EQUIPMENT

- 4.11.2. STRUCTURE OF FIXED MULTISHANK RIPPER

- 4.12. CAB AND ITS ATTACHMENTS

- 4.12.1. ROPS CAB

- 4.12.2. CAB MOUNT

- 5. MAINTENANCE STANDARD

- 5.1. CONTENTS

- 5.2. ABBREVIATION LIST

- 5.3. ENGINE AND COOLING SYSTEM

- 5.3.1. MAINTENANCE STANDARD OF ENGINE MOUNT

- 5.3.2. MAINTENANCE STANDARD OF DAMPER

- 5.3.3. MAINTENANCE STANDARD OF COOLING SYSTEM

- 5.3.4. MAINTENANCE STANDARD OF COOLING FAN MOTOR

- 5.3.5. MAINTENANCE STANDARD OF WORK EQUIPMENT AND COOLING FAN PUMP

- 5.4. POWER TRAIN

- 5.4.1. MAINTENANCE STANDARD OF HST PUMP

- 5.4.2. MAINTENANCE STANDARD OF HST CHARGE PUMP

- 5.4.3. MAINTENANCE STANDARD OF HST MOTOR

- 5.4.4. MAINTENANCE STANDARD OF FINAL DRIVE

- 5.4.5. MAINTENANCE STANDARD OF SPROCKET FOR CONVENTIONAL TYPE TRACK SHOE

- 5.4.6. MAINTENANCE STANDARD OF SPROCKET TOOTH PROFILE FULLSCALE DRAWING FOR CONVENTIONAL TYPE TRACK SHOE

- 5.4.7. MAINTENANCE STANDARD OF SPROCKET FOR PLUS TYPE TRACK SHOE

- 5.4.8. MAINTENANCE STANDARD OF SPROCKET TOOTH PROFILE FULLSCALE DRAWING FOR PLUS TYPE TRACK SHOE

- 5.5. UNDERCARRIAGE AND FRAME

- 5.5.1. MAINTENANCE STANDARD OF SUSPENSION

- 5.5.2. MAINTENANCE STANDARD OF TRACK FRAME AND IDLER CUSHION

- 5.5.3. MAINTENANCE STANDARD OF IDLER

- 5.5.4. MAINTENANCE STANDARD OF TRACK ROLLER FOR CONVENTIONAL TYPE TRACK SHOES (SINGLE FLANGE TYPE)

- 5.5.5. MAINTENANCE STANDARD OF TRACK ROLLER FOR CONVENTIONAL TYPE TRACK SHOES (DOUBLE FLANGE TYPE)

- 5.5.6. MAINTENANCE STANDARD OF TRACK ROLLER FOR PLUS TYPE TRACK SHOES (SINGLE FLANGE TYPE)

- 5.5.7. MAINTENANCE STANDARD OF TRACK ROLLER FOR PLUS TYPE TRACK SHOES (DOUBLE FLANGE TYPE)

- 5.5.8. MAINTENANCE STANDARD OF CARRIER ROLLER FOR CONVENTIONAL TYPE TRACK SHOE

- 5.5.9. MAINTENANCE STANDARD OF CARRIER ROLLER FOR PLUS TYPE TRACK SHOE

- 5.5.10. MAINTENANCE STANDARD OF CONVENTIONAL TYPE TRACK SHOE

- 5.5.11. MAINTENANCE STANDARD OF PLUS TYPE TRACK SHOE

- 5.5.12. MAINTENANCE STANDARD OF SINGLE SHOE

- 5.5.13. MAINTENANCE STANDARD OF SWAMP SHOE

- 5.6. HYDRAULIC SYSTEM

- 5.6.1. MAINTENANCE STANDARD OF HYDRAULIC TANK

- 5.6.2. MAINTENANCE STANDARD OF WORK EQUIPMENT AND COOLING FAN PUMP

- 5.6.3. MAINTENANCE STANDARD OF CONTROL VALVE

- 5.6.4. MAINTENANCE STANDARD OF RIPPER PPC VALVE

- 5.6.5. MAINTENANCE STANDARD OF 5PORT VALVE OF EPC AND SOLENOID

- 5.6.6. MAINTENANCE STANDARD OF ANGLE OPERATION EPC VALVE

- 5.6.7. MAINTENANCE STANDARD OF QUICK DROP VALVE

- 5.7. WORK EQUIPMENT

- 5.7.1. MAINTENANCE STANDARD OF FRONT WORK EQUIPMENT

- 5.7.2. MAINTENANCE STANDARD OF CUTTING EDGE AND END BIT

- 5.7.3. MAINTENANCE STANDARD OF BLADE LIFT CYLINDER

- 5.7.4. MAINTENANCE STANDARD OF BLADE TILT CYLINDER

- 5.7.5. MAINTENANCE STANDARD OF BLADE ANGLE CYLINDER

- 5.7.6. MAINTENANCE STANDARD OF FIXED MULTISHANK RIPPER

- 5.7.7. MAINTENANCE STANDARD OF RIPPER LIFT CYLINDER

- 5.8. CAB AND ITS ATTACHMENTS

- 5.8.1. MAINTENANCE STANDARD OF CAB MOUNT

- 5.9. ELECTRICAL SYSTEM

- 5.9.1. MAINTENANCE STANDARD OF ELECTRIC STEERING CONTROL LEVER

- 6. INDEX

Rate this product

You may also like