Komatsu D63E-1 Bull Dozer Shop Manual SEBMU1410102

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBMU1410102

- Format: PDF

- Size: 44.7MB

- Number of Pages: 404

Category: Komatsu Shop Manual PDF

-

Model List:

- D63E-1 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. ENGINE

- 3.1. STRUCTURE AND FUNCTION

- 3.1.1. RADIATOR AND OIL COOLER

- 3.1.2. ENGINE MOUNT

- 3.1.3. ENGINE CONTROL

- 3.1.4. FUEL TANK

- 3.2. TESTING AND ADJUSTING

- 3.2.1. STANDARD FOR TESTING AND ADJUSTING

- 3.2.2. TOOLS FOR TESTING AND ADJUSTMENT

- 3.2.3. ADJUSTMENT OF VALVE CLEARANCE

- 3.2.4. MEASURING OF COMPRESSION PRESSURE

- 3.2.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.2.6. TESTING AND ADJUSTING FAN BELT TENSION

- 3.3. DISASSEMBLY AND ASSEMBLY

- 3.3.1. ENGINE OIL COOLER

- 3.3.1.1. DISMOUNTING

- 3.3.1.2. MOUNTING

- 3.3.2. FULE INJECTION PUMP

- 3.4. STRUCTURE AND FUNCTION

- 3.4.1. GENERAL

- 3.4.2. POWER TRAIN HYDRAULIC SYSTEM

- 3.4.3. DAMPER AND UNIVERSAL JOINT

- 3.4.4. TORQUE CONVERTER

- 3.4.5. TORQUE CONVERTER RELIEF VALVE

- 3.4.6. TORQFLOW TRANSMISSION

- 3.4.7. TORQFLOW TRANSMISSION CONTROL LINKAGE

- 3.4.8. TORQFLOW HYDRAULIC SYSTEM

- 3.4.9. TORQFLOW HYDRAULIC CONTROL

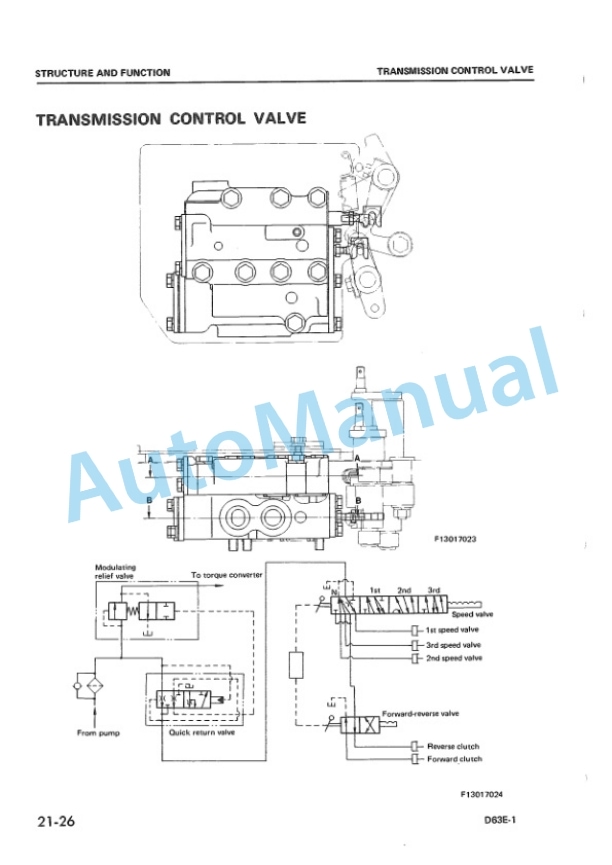

- 3.4.10. TRANSMISSION CONTROL VALVE

- 3.4.11. TRANSMISSION LUBRICATING SYSTEM

- 3.4.12. TRANSMISSION LUBRICATING VALVE

- 3.4.13. TRANSMISSION PUMP

- 3.4.14. TRANSMISSION OIL FILTER

- 3.4.15. STEERING CLUTCH AND BRAKE PIPING

- 3.4.16. STEERING CLUTCH AND BRAKE HYDRAULIC SYSTEM

- 3.4.17. STEERING CLUTCH AND BEVEL GEAR

- 3.4.18. STEERING CONTROL VALVE

- 3.4.19. STEERING BRAKE AND BOOSTER

- 3.4.20. STEERING RELIEF VALVE

- 3.4.21. STEERING PUMP

- 3.4.22. STEERING STRAINER

- 3.4.23. STEERING OIL FILTER

- 3.4.24. STEERING LEVERCONTROL LINKAGE

- 3.4.25. BRAKE PEDAL LINKAGE

- 3.4.26. FINAL DRIVE

- 3.5. TESTING AND ADJUSTING

- 3.5.1. STANDARDS FOR TESTING AND ADJUSTING

- 3.5.2. LIST OF TROUBLESHOOTING TOOLS

- 3.5.3. OIL PRESSURE MEASUREMENT LOCATIONS

- 3.5.4. OIL PRESSURE ADJUSTMENT LOCATIONS

- 3.5.5. ADJUSTING CLEARANCE BETWEEN BRAKE BAND AND DRUM

- 3.5.6. ADJUSTING STEERING LEVER TRAVEL

- 3.5.7. ADJUSTING BRAKE PEDAL TRAVEL

- 3.5.8. TROUBLESHOOTING

- 3.5.8.1. DIAGNOSTIC TABLES

- 3.5.8.1.1. HIGH OIL TEMPERATURE IN TORQUE CONVERTER

- 3.5.8.1.2. THE MACHINE WILL NOT START

- 3.5.8.1.3. WEAK TRACTION POWER OR SLOW MACHINE TRAVEL SPEED

- 3.5.8.1.4. THE MACHINE MOVES WHEN THE ENGINE IS STARTED

- 3.5.8.1.5. EXCESSIVE TIME LAG WHEN STARTING OFF OR CHANGING GEAR SPEEDS

- 3.5.8.1.6. THE MACHINE RECEIVES SEVERE SHOCKS WHEN STARTING OFF OR WHEN CHANGING GEAR SPEEDS

- 3.5.8.1.7. SHIFT LEVER SLIPS OUT

- 3.5.8.1.8. SHIFT LEVER IS HEAVY TO SHIFT

- 3.5.8.1.9. THE OIL LEVEL IN THE TRANSMISSION CASE AND STEERING CASE GOES UP OR GOES DOWN

- 3.5.8.1.10. STEERING CLUTCH FAILS TO DISENGAGE

- 3.5.8.1.11. STEERING CLUTCH SLIPS

- 3.5.8.1.12. STEERING BRAKE DOES NOT WORK

- 3.6. DISASSEMBLY AND ASSEMBLY

- 3.6.1. DAMPER

- 3.6.1.1. DISMOUNTING

- 3.6.1.2. MOUNTING

- 3.6.2. TORQFLOW TRANSMISSION AND TORQUE CONVERTER

- 3.6.2.1. DISMOUNTING

- 3.6.2.2. MOUNTING

- 3.6.2.3. DISJOINTING

- 3.6.2.4. JOINTING

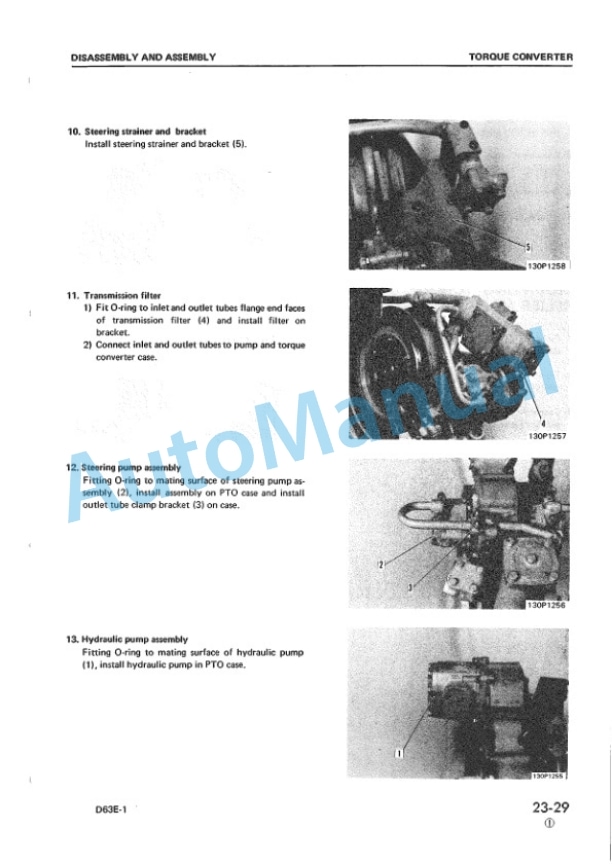

- 3.6.3. TORQUE CONVERTER

- 3.6.3.1. DISASSEMBLY

- 3.6.3.2. ASSEMBLY

- 3.6.4. TORQUE CONVERTER RELIEF VALVE

- 3.6.4.1. DISMOUNTING

- 3.6.4.2. MOUNTING

- 3.6.5. TORQFLOW TRANSMISSION

- 3.6.5.1. DISASSEMBLY

- 3.6.5.2. ASSEMBLY

- 3.6.6. TRANSMISSION CONTROL VALVE

- 3.6.7. BEVEL GEAR SHAFT AND STEERING CLUTCH

- 3.6.7.1. DISMOUNTING

- 3.6.7.2. MOUNTING

- 3.6.7.3. DISASSEMBLY

- 3.6.7.4. ASSEMBLY

- 3.6.8. STEERING BRAKE BOOSTER

- 3.6.8.1. DISMOUNTING

- 3.6.8.2. MOUNTING

- 3.6.9. STEERING CONTROL VALVE

- 3.6.10. STEERING MAIN RELIEF VALVE

- 3.6.10.1. DISASSEMBLY

- 3.6.10.2. ASSEMBLY

- 3.6.11. TRANSMISSION PUMP

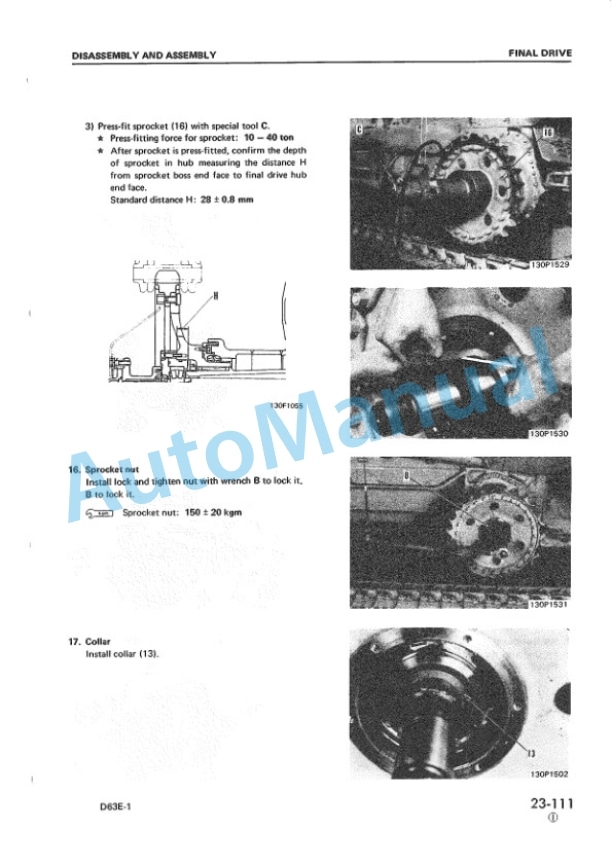

- 3.6.12. FINAL DRIVE FIRST PINION

- 3.7. MAINTENANCE STANDARD

- 3.7.1. DAMPER AND UNIVERSAL JOINT

- 3.7.2. TORQUE CONVERTER

- 3.7.3. TORQFLOW TRANSMISSION

- 3.7.4. TRANSMISSION CONTROL VALVE

- 3.7.5. TRANSMISSION LUBRICATING VALVE

- 3.7.6. TRANSMISSION PUMP

- 3.7.7. BEVEL GEAR SHAFT AND STEERING SYSTEM

- 3.7.8. STEERING CONTROL VALVE

- 3.7.9. RELIEF VALVE

- 3.7.10. STEERING PUMP

- 3.7.11. STEERING BRAKE

- 3.7.12. FINAL DRIVE

- 4. UNDERCARRIAGE

- 4.1. STRUCTURE AND FUNCTION

- 4.2. DISASSEMBLY AND ASSEMBLY

- 4.3. MAINTENANCE STANDARD

- 4.3.1. MEASURING PROCEDURE OF ROLLERS

- 4.3.2. TRACK

- 4.3.3. SUSPENSION

- 5. HYDRAULIC SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. HYDRAULIC OIL PIPING FOR BLADE LIFT

- 5.1.2. HYDRAULIC OIL PIPING FOR BLADE TILT

- 5.1.3. RIPPER PIPING AND CONTROL LINKAGE

- 5.1.4. HYDRAULIC PUMP

- 5.1.5. HYDRAULIC CONTROL SYSTEM

- 5.1.5.1. STRAIGHTTILTDOZER

- 5.1.5.2. STRAIGHTTILTDOZER WITH RIPPER

- 5.1.6. BLADE CONTROL

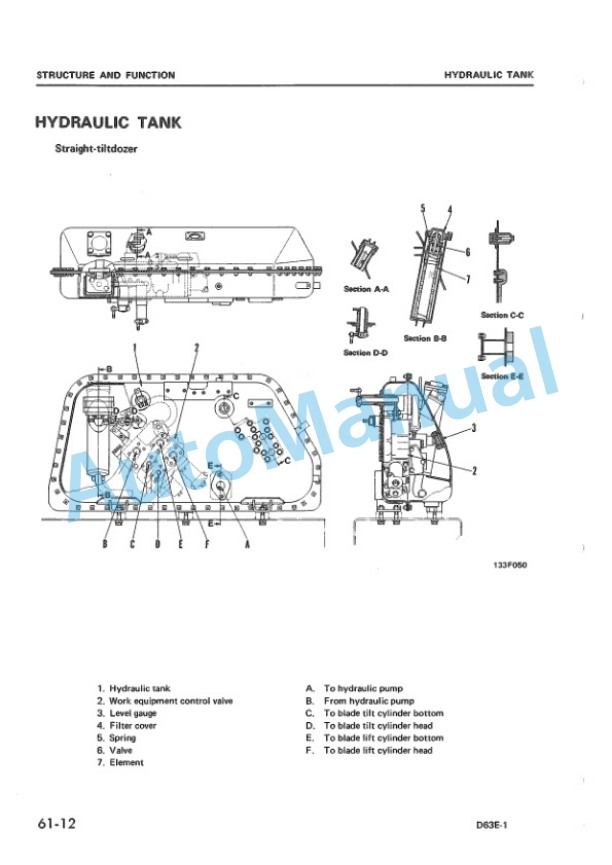

- 5.1.7. HYDRAULIC TANK

- 5.1.8. BLADE LIFT AND TILT CONTROL VALVE

- 5.1.9. MAIN RELIEF VALVE

- 5.1.10. SUCTION VALVE

- 5.1.11. RIPPER CONTROL VALVE

- 5.1.12. WORK EQUIPMENT CYLINDER

- 5.2. TESTING AND ADJUSTING

- 5.2.1. STANDARDS FOR TESTING AND ADJUSTING

- 5.2.2. TESTING AND ADJUSTING TOOL LIST

- 5.2.3. MEASUREMENT LOCATIONS FOR HYDRAULIC OIL PRESSURE

- 5.2.4. HYDRAULIC OIL PRESSURE ADJUSTMENT

- 5.2.5. TROUBLESHOOTING

- 5.2.5.1. PREPARATION FOR TROUBLESHOOTING

- 5.2.5.2. HOW TO USE DIAGNOSTIC TABLES

- 5.2.5.3. PREVENTING RECURRENCE OF THE SAME TROUBLE

- 5.2.5.4. DIAGNOSTIC TABLES

- 5.2.5.4.1. INSUFFICIENT RAISING POWER AND RAISING SPEED OF BLADE

- 5.2.5.4.2. BLADE FAILS TO BE RAISED

- 5.2.5.4.3. BLADE CANNOT LIFT THE MACHINE BODY

- 5.2.5.4.4. EXCESSIVE HYDRAULIC DRIFT OF BLADE

- 5.2.5.4.5. THE BLADE FLUCTUATES UP AND DOWN IN LEVELING WORK (WITH CONTROL LEVER IN HOLD POSITION)

- 5.2.5.4.6. THE BLADE LOWERS

- 5.2.5.4.7. THE BLADE IS RAISED UNEVENLY (APPLICABLE ONLY TO STRAIGHT DOZER)

- 5.2.5.4.8. INSUFFICIENT TILTING POWER AND TILTING SPEED, OR INABILITY TO RAISE THE MACHINE BODY WITH TILT DOZER

- 5.2.5.4.9. THE BLADE FAILS TO TILT

- 5.2.5.4.10. EXCESSIVE HYDRAULIC DRIFT OF TILTED BLADE

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. HYDRAULIC PUMP

- 5.3.1.1. DISMOUNTING

- 5.3.1.2. MOUNTING

- 5.3.2. WORK EQUIPMENT CONTROL VALVE

- 5.4. MAINTENANCE STANDARD

- 5.4.1. HYDRAULIC CONTROL VALVE

- 5.4.2. CYLINDER

- 5.4.3. HYDRAULIC PUMP

- 6. WORK EQUIPMENT

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. STRAIGHTTILTDOZER

- 6.1.2. RIPPER

- 6.2. DISASSEMBLY AND ASSEMBLY

- 6.2.1. WORK EQUIPMENT

- 6.2.1.1. DISMOUNTING

- 6.2.1.2. MOUNTING

- 6.2.2. STRAIGHTTILT DOZER

- 6.2.2.1. INSTALLATION AND ADJUSTING

- 6.2.3. DASHBOARD

- 6.2.3.1. DISMOUNTING

- 6.2.3.2. MOUNTING

- 6.2.4. OPERATORS SEAT AND FRAME

- 6.2.4.1. DISMOUNTING

- 6.2.4.2. MOUNTING

- 6.3. MAINTENANCE STANDARD

- 6.3.1. STRAIGHTTILTDOZER

- 6.3.2. RIPPER

- 7. ELECTRICAL SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. ELECTRICAL WIRING DIAGRAM

- 7.1.2. ELECTRICAL CIRCUIT DIAGRAM

Rate this product

You may also like