Komatsu D65EX-15, D65PX-15, D65WX-15 Bull Dozer Shop Manual SEBM029508

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM029508

- Format: PDF

- Size: 74.9MB

- Number of Pages: 922

Category: Komatsu Shop Manual PDF

-

Model List:

- D65EX-15 Bull Dozer

- D65PX-15 Bull Dozer

- D65WX-15 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DIMENSIONS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL, COOLANT AND LUBRICANT

- 4. STRUCTURE,FUNCTION AND MAINTENANCE STANDARD

- 4.1. COOLING SYSTEM

- 4.2. ENGINE MOUNT

- 4.3. POWER TRAIN

- 4.4. OVERALL DRAWING OF POWER TRAIN UNIT

- 4.5. HYDRAULIC PIPING OF POWER TRAIN

- 4.6. DAMPER,UNIVERSAL JOINT

- 4.7. TRANSMISSION,STEERING,BRAKE CONTROL

- 4.8. TORQUE CONVERTER,PTO

- 4.9. TRANSMISSION

- 4.10. TRANSMISSION ECMV

- 4.11. MAIN RELIEF VALVE

- 4.12. LUBRICATION RELIEF VALVE

- 4.13. SCAVENGING PUMP

- 4.14. POWER TRAIN PUMP,LUBRICATION PUMP

- 4.15. HSS SYSTEM

- 4.16. HYDRAULIC,HSS PUMP

- 4.17. HSS MOTOR

- 4.18. BEVEL GEAR SHAFT,HSS,BRAKE

- 4.19. BRAKE VALVE

- 4.20. FINAL DRIVE

- 4.21. FRAME ASSEMBLY

- 4.22. SUSPENSION

- 4.23. TRACK FRAME, RECOIL SPRING

- 4.24. WORK EQUIPMENT HYDRAULIC PIPING DIAGRAM

- 4.25. WORK EQUIPMENT CONTROL

- 4.26. HYDRAULIC TANK

- 4.27. ACCUMULATOR

- 4.28. PPC LOCK VALVE

- 4.29. HYDRAULIC CYLINDER

- 4.30. PISTON VALVE

- 4.31. QUICK DROP VALVE

- 4.32. COOLING FAN PUMP

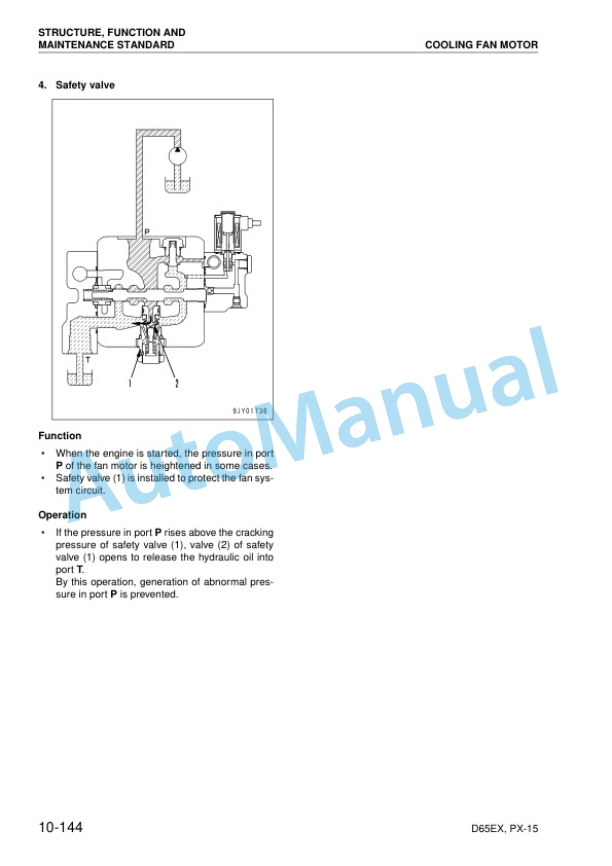

- 4.33. COOLING FAN MOTOR

- 4.34. PPC VALVE

- 4.35. PCCS LEVER

- 4.36. CONTROL VALVE

- 4.37. SELF PRESSURE REDUCING VALVE

- 4.38. WORK EQUIPMENT

- 4.39. CUTTING EDGE,END BIT

- 4.40. RIPPER

- 4.41. CAB MOUNT

- 4.43. AIR CONDITIONER PIPING

- 4.44. ENGINE CONTROL

- 4.45. ENGINE CONTROL SYSTEM

- 4.46. CRI ENGINE CONTROL SYSTEM

- 4.47. COOLING SYSTEM CONTROL SYSTEM

- 4.48. PALM COMMAND CONTROL SYSTEM

- 4.49. SYSTEM COMPONENTS

- 4.50. ENGINE CONTROLLER

- 4.51. TRANSMISSION AND STEERING CONTROLLER

- 4.52. MONITOR SYSTEM

- 4.53. MONITOR PANEL

- 4.54. SENSORS

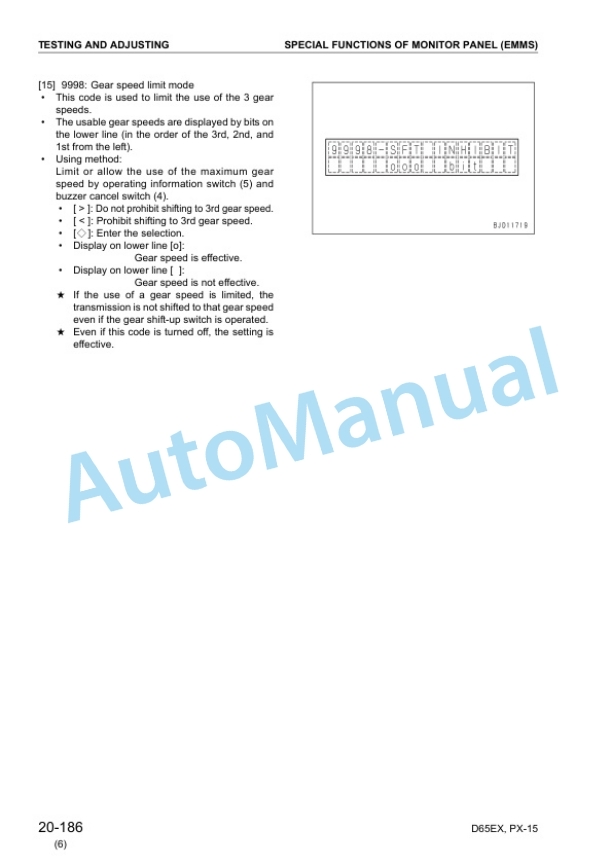

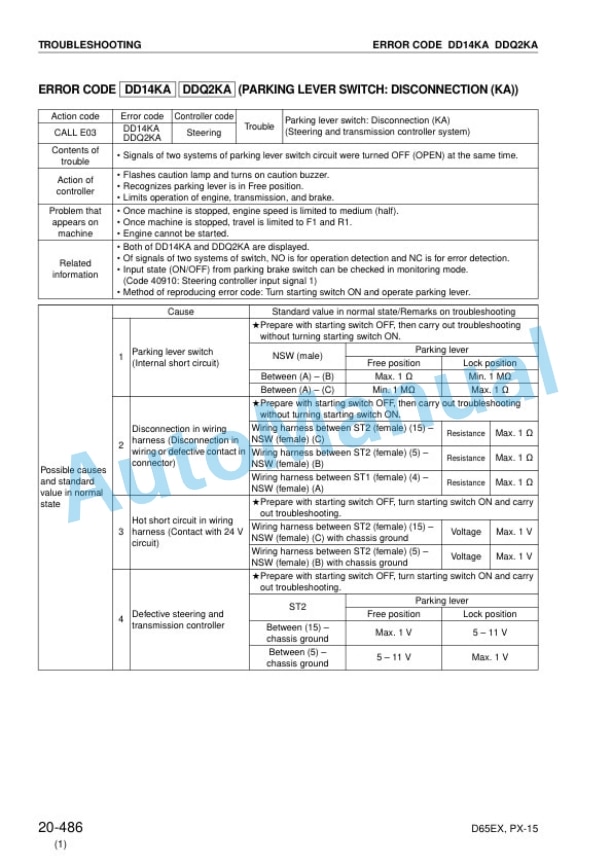

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. TESTING AND ADJUSTING

- 5.4. TROUBLESHOOTING

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. HOW TO READ THIS MANUAL

- 6.2. COATING MATERIALS LIST

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCHES OF SPECIAL TOOLS

- 6.5. REMOVAL AND INSTALLATION OF FUEL SUPPLY PUMP ASSEMBLY

- 6.6. REMOVAL AND INSTALLATION OF ENGINE HOOD ASSEMBLY

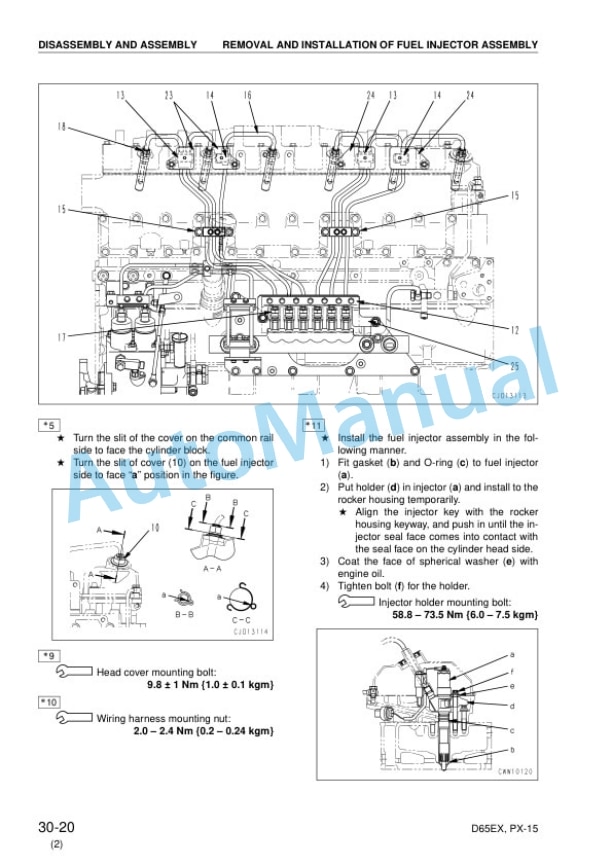

- 6.7. REMOVAL AND INSTALLATION OF FUEL INJECTOR ASSEMBLY

- 6.8. REMOVAL AND INSTALLATION OF NOZZLE TIP

- 6.9. REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL

- 6.10. REMOVAL AND INSTALLATION OF DAMPER ASSEMBLY

- 6.11. REMOVAL AND INSTALLATION OF ENGINE REAR SEAL

- 6.12. REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 6.13. REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY

- 6.14. REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY

- 6.15. REMOVAL AND INSTALLATION OF ENGINE ASSEMBLY

- 6.16. REMOVAL AND INSTALLATION OF POWER TRAIN UNIT ASSEMBLY

- 6.17. DISCONNECTION AND CONNECTION OF POWER TRAIN UNIT ASSEMBLY

- 6.18. DISASSEMBLY AND ASSEMBLY OF TORQFLOW TRANSMISSION ASSEMBLY

- 6.19. DISASSEMBLY AND ASSEMBLY OF HSS ASSEMBLY

- 6.20. DISASSEMBLY AND ASSEMBLY OF PTO ASSEMBLY

- 6.21. DISASSEMBLY AND ASSEMBLY OF TORQUE CONVERTER ASSEMBLY

- 6.22. REMOVAL AND INSTALLATION OF SCAVENGING PUMP ASSEMBLY

- 6.23. REMOVAL AND INSTALLATION OF HSS PUMP ASSEMBLY

- 6.24. REMOVAL AND INSTALLATION OF COOLING FAN PUMP ASSEMBLY

- 6.25. REMOVAL AND INSTALLATION OF POWER TRAIN AND LUBRICATING OIL PUMP ASSEMBLY

- 6.26. REMOVAL AND INSTALLATION OF MOTOR ASSEMBLY

- 6.27. REMOVAL AND INSTALLATION OF FINAL DRIVE ASSEMBLY

- 6.28. DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY

- 6.29. REMOVAL AND INSTALLATION OF TRACK FRAME ASSEMBLY

- 6.30. REMOVAL AND INSTALLATION OF IDLER ASSEMBLY

- 6.31. DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY

- 6.32. REMOVAL AND INSTALLATION OF RECOIL SPRING ASSEMBLY

- 6.33. DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY

- 6.34. REMOVAL AND INSTALLATION OF TRACK ROLLER ASSEMBLY

- 6.35. DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 6.36. REMOVAL AND INSTALLATION OF CARRIER ROLLER ASSEMBLY

- 6.37. DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY

- 6.38. EXPANSION AND INSTALLATION OF TRACK SHOE ASSEMBLY

- 6.39. WHOLE DISASSEMBLY AND WHOLE ASSEMBLY OF TRACK SHOE ASSEMBLY

- 6.40. FIELD DISASSEMBLY AND ASSEMBLY OF ONE LINK

- 6.41. REMOVAL AND INSTALLATION OF PIVOT SHAFT ASSEMBLY

- 6.42. REMOVAL AND INSTALLATION OF EQUALIZER BAR ASSEMBLY

- 6.43. DISASSEMBLY AND ASSEMBLY OF EQUALIZER BAR SIDE BUSHING

- 6.44. REMOVAL AND INSTALLATION OF CONTROL VALVE ASSEMBLY

- 6.45. DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY

- 6.46. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 6.47. REMOVAL AND INSTALLATION OF BLADE ASSEMBLY

- 6.48. REMOVAL AND INSTALLATION OF ROPS GUARD

- 6.49. REMOVAL AND INSTALLATION OF OPERATORS CAB ASSEMBLY

- 6.50. REMOVAL AND INSTALLATION OF OPERATORS CAB GLASS (STUCK GLASS)

- 6.51. REMOVAL AND INSTALLATION OF FLOOR FRAME ASSEMBLY

- 6.52. REMOVAL AND INSTALLATION OF STEERING AND TRANSMISSION CONTROLLER ASSEMBLY

- 6.53. REMOVAL AND INSTALLATION OF ENGINE CONTROLLER ASSEMBLY

- 6.54. REMOVAL AND INSTALLATION OF FAN DRIVE ASSEMBLY

- 6.55. REMOVAL AND INSTALLATION OF FAN MOTOR ASSEMBLY

- 7. OTHERS

- 7.1. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 7.2. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 7.3. ELECTRICAL CIRCUIT DIAGRAM (1/6)

- 7.4. ELECTRICAL CIRCUIT DIAGRAM (2/6)

- 7.5. ELECTRICAL CIRCUIT DIAGRAM (3/6)

- 7.6. ELECTRICAL CIRCUIT DIAGRAM (4/6)

- 7.7. ELECTRICAL CIRCUIT DIAGRAM (5/6)

- 7.8. ELECTRICAL CIRCUIT DIAGRAM (6/6)

- 7.9. CAB ELECTRICAL CIRCUIT DIAGRAM

Rate this product

You may also like