Komatsu D75S-5 Shop Manual SEBM01450503

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM01450503

- Format: PDF

- Size: 63.4MB

- Number of Pages: 477

Category: Komatsu Shop Manual PDF

-

Model List:

- D75S-5

- 1. MAIN MENU

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 4. ENGINE

- 4.1. ENGINE TESTING AND ADJUSTING

- 4.1.1. STANDARDS FOR TESTING AND ADJUSTING

- 4.1.2. TOOLS FOR TESTING AND ADJUSTING

- 4.1.3. CHECKING AND ADJUSTING FUEL INJECTION TIMING

- 4.1.4. MEASURING BLOWBY

- 4.1.5. MEASURING AIR SUPPLY PRESSURE

- 4.1.6. MEASURING EXHAUST COLOR

- 4.1.7. MEASURING EXHAUST TEMPERATURE

- 4.1.8. MEASURING ENGINE OIL PRESSURE

- 4.1.9. MEASURING ENGINE SPEED

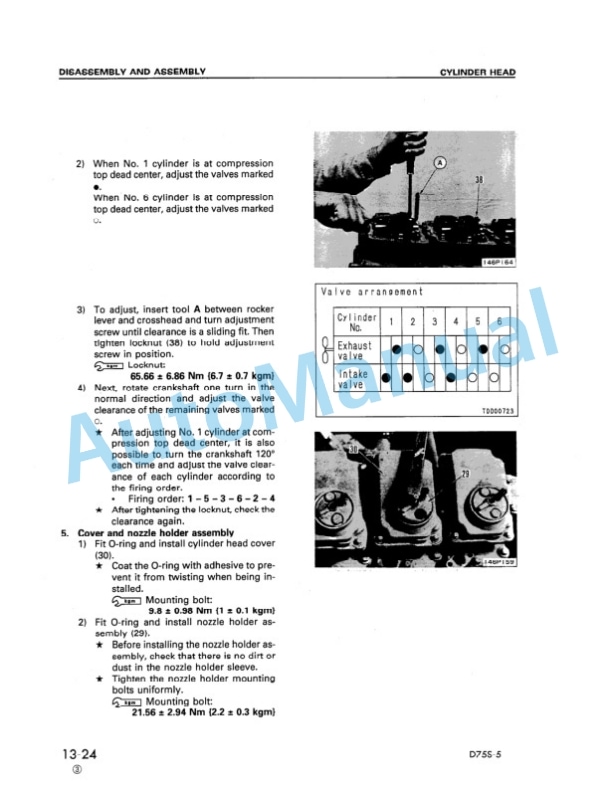

- 4.1.10. ADJUSTING VALVE CLEARANCE

- 4.1.11. MEASURING COMPRESSION PRESSURE

- 4.1.12. CHECKING AND ADJUSTING FAN BELT TENSION

- 4.1.13. MEASURING TORQUE CONVERTER STALL SPEED

- 4.1.14. BLEEDING AIR FROM FUEL FILTER

- 4.1.15. BLEEDING AIR FROM HYDRAULIC CYLINDER

- 4.1.16. TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)

- 4.1.16.1. METHOD OF USING TROUBLESHOOTING CHARTS

- 4.1.16.2. S1 Starting performance is poor (starting always takes time)

- 4.1.16.3. S2 Engine does not start

- 4.1.16.4. S3 Engine does not pick up smoothly (followup is poor)

- 4.1.16.5. S4 Engine stops during operations

- 4.1.16.6. S5 Engine does not rotate smoothly (hunting)

- 4.1.16.7. S6 Engine lacks output (no power)

- 4.1.16.8. S7 Exhaust smoke is black (incomplete combustion)

- 4.1.16.9. S8 Oil consumption is excessive (or exhaust smoke is blue)

- 4.1.16.10. S9 Oil becomes contaminated quickly

- 4.1.16.11. S10 Fuel consumption is excessive

- 4.1.16.12. S11 Oil is in cooling water, or water spurts back, or water level goes down

- 4.1.16.13. S12 Oil pressure caution lamp lights up (drop in oil pressure)

- 4.1.16.14. S13 Oil level rises (water, fuel in oil)

- 4.1.16.15. S14 Water temperature becomes too high (overheating)

- 4.1.16.16. S15 Abnormal noise is made

- 4.1.16.17. S16 Vibration is excessive

- 4.2. DISASSEMBLY AND ASSEMBLY

- 4.2.1. TORQUE CONVERTER COOLER

- 4.2.1.1. DISMOUNTING

- 4.2.1.2. MOUNTING

- 4.2.2. FUEL INJECTION PUMP

- 4.2.2.1. DISMOUNTING

- 4.2.2.2. MOUNTING

- 4.2.3. ENGINE OIL COOLER

- 4.2.4. ENGINE FRONT SEAL

- 4.2.4.1. REMOVAL

- 4.2.4.2. INSTALLATION

- 4.2.5. ENGINE REAR SEAL

- 4.3. STRUCTURE AND FUNCTION

- 4.3.1. GENERAL

- 4.3.2. TORQUE CONVERTER

- 4.3.3. PTO (POWER TAKEOFF)

- 4.3.4. TORQFLOW TRANSMISSION

- 4.3.5. TORQFLOW TRANSMISSION CONTROL

- 4.3.6. STEERING AND TORQFLOW HYDRAULIC SYSTEM (PIPING)

- 4.3.7. SCHEMATIC OF TORQFLOW HYDRAULIC SYSTEM

- 4.3.8. TORQFLOW HYDRAULIC CIRCUIT DIAGRAM

- 4.3.9. SCHEMATIC OF TORQFLOW HYDRAULIC SYSTEM

- 4.3.10. TORQFLOW HYDRAULIC CIRCUIT DIAGRAM

- 4.3.11. TRANSMISSION CONTROL VALVE

- 4.3.12. TRANSMISSION LUBRICATING SYSTEM

- 4.3.13. TRANSMISSION LUBRICATING RELIEF VALVE

- 4.3.14. TORQFLOW AND STEERING PUMP

- 4.3.15. TORQFLOW AND STEERING OIL FILTER

- 4.3.16. SCHEMATIC OF STEERING HYDRAULIC SYSTEM

- 4.3.17. STEERING HYDRAULIC CIRCUIT DIAGRAM

- 4.3.18. BEVEL GEAR AND STEERING CLUTCH

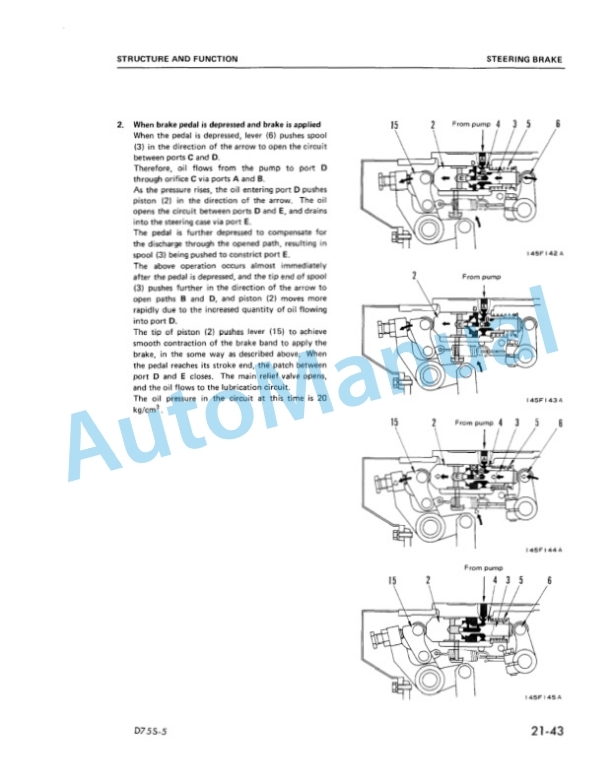

- 4.3.19. STEERING BRAKE

- 4.3.20. STEERING CONTROL VALVE

- 4.3.21. STEERING MAIN RELIEF VALVE

- 4.3.22. STEERING CONTROL

- 4.3.23. FINAL DRIVE

- 4.4. TESTING AND ADJUSTING

- 4.4.1. STANDARDS FOR TESTING AND ADJUSTING

- 4.4.2. TESTING AND ADJUSTING TOOL LIST

- 4.4.3. TROUBLESHOOTING

- 4.4.3.1. PREPARATION FOR TROUBLESHOOTING

- 4.4.3.2. HOW TO USE DIAGNOSTIC TABLES

- 4.4.3.3. PREVENTING RECURRENCE OF THE SAME TROUBLE

- 4.4.3.4. TROUBLESHOOTING

- 4.5. DISASSEMBLY AND ASSEMBLY

- 4.5.1. TORQUE CONVERTER RELIEF VALVE

- 4.5.1.1. DISMOUNTING

- 4.5.1.2. MOUNTING

- 4.5.2. TORQUE CONVERTER

- 4.5.2.1. DISMOUNTING

- 4.5.2.2. MOUNTING

- 4.5.3. TORQUE CONVERTER AND PTO

- 4.5.3.1. DISASSEMBLY

- 4.5.3.2. ASSEMBLY

- 4.5.4. TORQFLOW TRANSMISSION

- 4.5.4.1. DISMOUNTING

- 4.5.4.2. MOUNTING

- 4.5.4.3. DISASSEMBLY (1/2)

- 4.5.4.4. DISASSEMBLY (2/2)

- 4.5.4.5. ASSEMBLY (1/2)

- 4.5.4.6. ASSEMBLY (2/2)

- 4.5.5. TRANSMISSION CONTROL VALVE

- 4.5.5.1. DISMOUNTING

- 4.5.5.2. MOUNTING

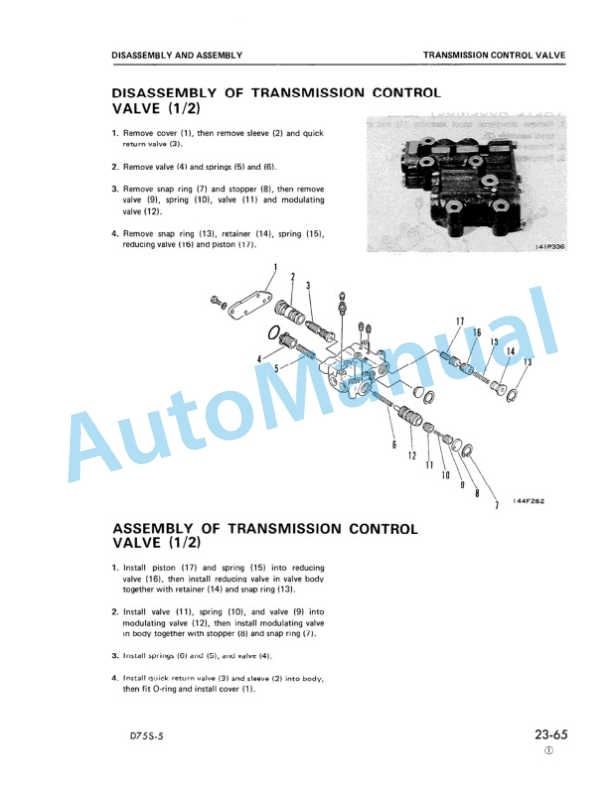

- 4.5.5.3. DISASSEMBLY (1/2)

- 4.5.5.4. ASSEMBLY (1/2)

- 4.5.5.5. DISASSEMBLY (2/2)

- 4.5.6. STEERING CLUTCH

- 4.5.7. STEERING CONTROL VALVE

- 4.5.7.1. DISMOUNTING

- 4.5.7.2. MOUNTING

- 4.5.7.3. DISASSEMBLY

- 4.5.7.4. ASSEMBLY

- 4.5.8. STEERING MAIN RELIEF VALVE

- 4.5.8.1. DISASSEMBLY

- 4.5.8.2. ASSEMBLY

- 4.5.9. FINAL DRIVE 1ST PINION

- 4.6. MAINTENANCE STANDARD

- 4.6.1. TORQUE CONVERTER

- 4.6.2. TORQFLOW TRANSMISSION

- 4.6.3. TRANSMISSION CONTROL VALVE

- 4.6.4. TRANSMISSION LUBRICATION VALVE

- 4.6.5. TRANSMISSION, STEERING PUMP

- 4.6.6. BEVEL GEAR AND STEERING CLUTCH

- 4.6.7. STEERING MAIN RELIEF VALVE

- 4.6.8. STEERING CONTROL VALVE

- 4.6.9. STEERING BRAKE

- 4.6.10. FINAL DRIVE

- 5. UNDERCARRIAGE

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. TRACK GROUP

- 5.1.2. RECOIL SPRING

- 5.1.3. IDLER

- 5.1.4. TRACK ROLLER AND CARRIER ROLLER

- 5.1.5. TRACK SHOE

- 5.1.6. SUSPENSION

- 5.2. DISASSEMBLY AND ASSEMBLY

- 5.2.0.1. CHECKING BEFORE REMOVAL

- 5.2.0.2. REMOVAL (NORMAL)

- 5.2.0.3. REMOVAL (WHEN THERE IS ABNORMALITY INSIDE TRACK FRAME)

- 5.3. MAINTENANCE STANDARD

- 5.3.1. TRACK GROUP

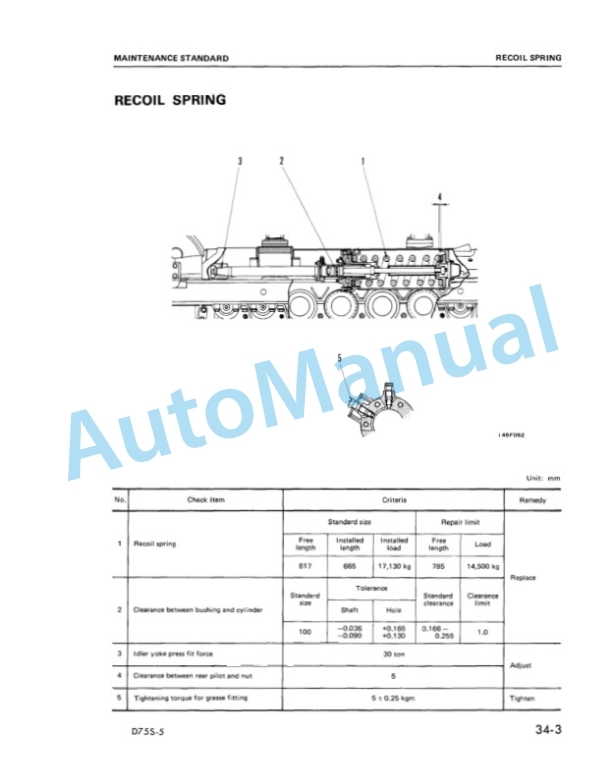

- 5.3.2. RECOIL SPRING

- 5.3.3. IDLER

- 5.3.4. TRACK ROLLER

- 5.3.5. CARRIER ROLLER

- 5.3.6. TRACK

- 5.3.7. SUSPENSION

- 6. HYDRAULIC SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. HYDRAULIC SYSTEM (PIPING)

- 6.1.2. SCHEMATIC OF HYDRAULIC SYSTEM

- 6.1.3. HYDRAULIC CIRCUIT DIAGRAM

- 6.1.4. HYDRAULIC TANK

- 6.1.5. HYDRAULIC FILTER

- 6.1.6. HYDRAULIC PUMP

- 6.1.7. HYDRAULIC CONTROL VALVE

- 6.1.8. MAIN RELIEF VALVE

- 6.1.9. SUCTION VALVE

- 6.1.10. SAFETY VALVE

- 6.1.11. HYDRAULIC CYLINDER

- 6.2. TESTING AND ADJUSTING

- 6.2.1. STANDARDS FOR TESTING AND ADJUSTING

- 6.2.2. TESTING AND ADJUSTING TOOL LIST

- 6.2.3. POINTS FOR MEASURING HYDRAULIC PRESSURE

- 6.2.4. ADJUSTING HYDRAULIC PRESSURE OF RELIEF VALVE

- 6.2.5. PERFORMANCE OF HYDRAULIC PUMP

- 6.2.6. TROUBLESHOOTING

- 6.2.6.1. LIFT ARM LACKS LIFTING POWER OR SPEED

- 6.2.6.2. LIFT ARM DOES NOT MOVE

- 6.2.6.3. HYDRAULIC DRIFT OF LIFT ARM IS EXCESSIVE

- 6.2.6.4. LACK OF TILTBACK POWER OR SPEED (DUMP AND TILT BACK)

- 6.2.6.5. DUMP CYLINDER DOES NOT MOVE

- 6.2.6.6. HYDRAULIC DRIFT OF BUCKET (DUMP) IS EXCESSIVE

- 6.2.6.7. CONTROL LEVER IS HEAVY

- 6.2.6.8. DURING LEVELING OPERATIONS (CONTROL LEVER AT HOLD), BUCKET FOLLOWS LEVEL OF GROUND AND LIFT ARM WAVERS

- 6.2.6.9. LIFT ARM DROPS

- 6.2.6.10. BUCKET WAVERS WHEN TRAVELING IN REVERSE DURING LEVELING OPERATIONS (CONTROL LEVER AT HOLD)

- 6.2.6.11. BUCKET TIPS FORWARD

- 6.2.6.12. LIFT ARM DOES NOT MOVE UP WHEN BUCKET IS AT MAXIMUM DUMP

- 6.3. DISASSEMBLY AND ASSEMBLY

- 6.3.1. HYDRAULIC PUMP

- 6.3.1.1. DISMOUNTING

- 6.3.1.2. MOUNTING

- 6.3.2. MAIN CONTROL VALVE

- 6.3.2.1. DISMOUNTING

- 6.3.2.2. MOUNTING

- 6.3.3. HYDRAULIC CONTROL VALVE

- 6.3.3.1. DISASSEMBLY (1/2)

- 6.3.3.2. ASSEMBLY (1/2)

- 6.3.3.3. DISASSEMBLY (2/2)

- 6.3.4. HYDRAULIC CYLINDER

- 6.3.4.1. DISASSEMBLY

- 6.3.4.2. ASSEMBLY

- 6.4. MAINTENANCE STANDARD

- 6.4.1. HYDRAULIC FILTER

- 6.4.2. HYDRAULIC PUMP

- 6.4.3. HYDRAULIC CONTROL VALVE

- 6.4.4. MAIN RELIEF VALVE

- 6.4.5. SUCTION VALVE

- 6.4.6. SAFETY VALVE

- 6.4.7. HYDRAULIC CYLINDER

- 7. WORK EQUIPMENT

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. POSITIONER CONTROL

- 7.1.2. KICK OUT CONTROL

- 7.1.3. LIFT ARM AND SIDE FRAME

- 7.1.4. BUCKET

- 7.2. DISASSEMBLY AND ASSEMBLY

- 7.2.1. WORK EQUIPMENT

- 7.2.2. OPERATORS COMPARTMENT FRAME AND COVER ASSEMBLY

- 7.2.2.1. DISMOUNTING

- 7.2.2.2. MOUNTING

- 7.3. MAINTENANCE STANDARD

- 7.3.1. LIFT ARM AND SIDE FRAME

- 7.3.2. BUCKET

- 8. ELECTRICAL SYSTEM

- 8.1. STRUCTURE AND FUNCTION

- 8.1.1. ELECTRICAL WIRING

- 8.1.2. ELECTRICAL CIRCUIT DIAGRAM

- 8.2. TESTING AND ADJUSTING

- 8.2.1. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 8.2.1.1. E1 Engine does not start

- 8.2.1.2. E2 Preheating does not work

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00