Komatsu D85A-21 Bull Dozer Shop Manual SEBM015C2104

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM015C2104

- Format: PDF

- Size: 18.8MB

- Number of Pages: 392

Category: Komatsu Shop Manual PDF

-

Model List:

- D85A-21 Bull Dozer

- 1. COVER

- 2. CONTENTS

- 3. ENGINE

- 3.1. TESTING AND ADJUSTING

- 3.1.1. TABLE OF JUDGEMENT STANDARD VALUE

- 3.1.2. TESTING AND ADJUSTING TOOL LIST

- 3.1.3. ADJUSTING VALVE CLEARANCE

- 3.1.4. MEASURING COMPRESSION PRESSURE

- 3.1.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.1.6. BLEEDING AIR FROM FUEL SYSTEM

- 3.2. DISASSEMBLY AND ASSEMBLY

- 3.2.1. FUEL INJECTION PUMP

- 3.2.1.1. REMOVAL

- 3.2.1.2. INSTALLATION

- 3.2.2. ENGINE OIL COOLER

- 3.2.2.1. REMOVAL

- 3.2.2.2. INSTALLATION

- 3.3. STRUCTURE AND FUNCTION

- 3.3.1. GENERAL

- 3.3.2. POWER TRAIN HYDRAULIC SYSTEM

- 3.3.3. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 3.3.4. TORQUE CONVERTER

- 3.3.5. TORQFLOW TRANSMISSION

- 3.3.6. TRANSMISSION CONTROL

- 3.3.7. TRANSMISSION HYDRAULIC PIPING

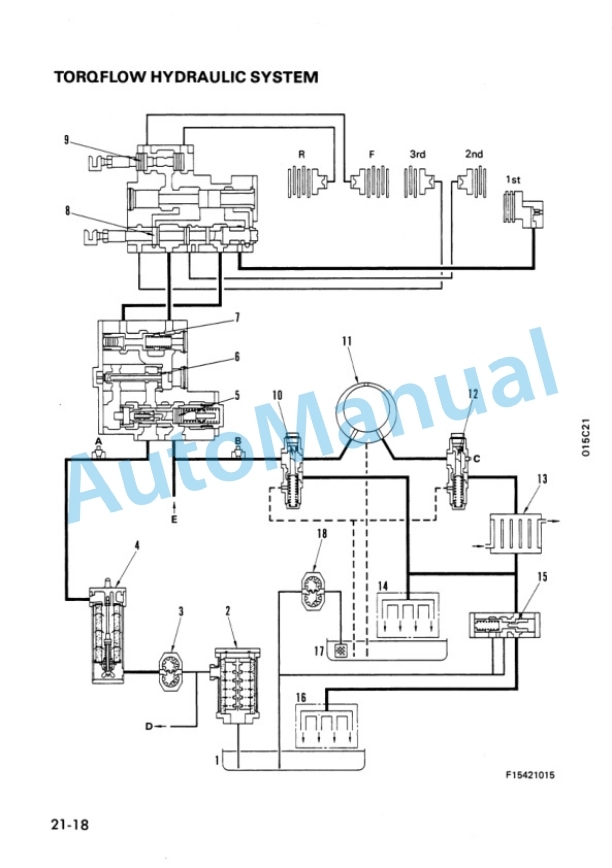

- 3.3.8. TORQFLOW HYDRAULIC SYSTEM

- 3.3.9. TORQFLOW HYDRAULIC CIRCUIT DIAGRAM

- 3.3.10. TRANSMISSION CONTROL VALVE

- 3.3.11. TRANSMISSION LUBRICATION VALVE

- 3.3.12. TRANSMISSION PUMP

- 3.3.13. TRANSMISSION AND STEERING OIL STRAINER

- 3.3.14. TRANSMISSION AND STEERING OIL FILTER

- 3.3.15. BEVEL GEAR SHAFT AND STEERING CLUTCH

- 3.3.16. STEERING CONTROL

- 3.3.17. STEERING HYDRAULIC PIPING

- 3.3.18. STEERING AND BRAKE HYDRAULIC SYSTEM

- 3.3.19. STEERING AND BRAKE HYDRAULIC CIRCUIT DIAGRAM

- 3.3.20. STEERING PUMP

- 3.3.21. STEERING MAIN RELIEF VALVE

- 3.3.22. STEERING AND BRAKE CONTROL VALVE

- 3.3.23. STEERING BRAKE

- 3.3.24. FINAL DRIVE

- 3.4. TESTING AND ADJUSTING

- 3.4.1. STANDARDS FOR TESTING AND ADJUSTING

- 3.4.2. TESTING AND ADJUSTING TOOL LIST

- 3.4.3. MEASURING TORQUE CONVERTER STALL SPEED

- 3.4.4. MEASURING OIL PRESSURE

- 3.4.5. ADJUSTING FUEL CONTROL LINKAGE

- 3.4.6. ADJUSTING GEAR SHIFT LEVER

- 3.4.7. ADJUSTING STEERING CLUTCH LINKAGE

- 3.4.8. ADJUSTING TRAVEL OF BRAKE PEDAL

- 3.4.9. ADJUSTING BRAKE PEDAL LINKAGE

- 3.4.10. TROUBLESHOOTING

- 3.4.11. PREPARATION FOR TROUBLESHOOTING

- 3.4.12. METHOD OF READING TROUBLESHOOTING TABLE

- 3.4.13. PREVENTING RECURRENCE OF THE SAME TROUBLE

- 3.4.14. TROUBLESHOOTING

- 3.4.14.1. TORQUE CONVERTER TEMPERATURE TOO HIGH

- 3.4.14.2. MACHINE DOES NOT MOVE

- 3.4.14.3. MACHINE LACKS POWER OR SPEED

- 3.4.14.4. MACHINE MOVES WHEN ENGINE IS STARTED

- 3.4.14.5. EXCESSIVE TIME LAG WHEN STARTING MACHINE OR SHIFTING GEAR

- 3.4.14.6. EXCESSIVE SHOCK WHEN STARTING MACHINE OR SHIFTING GEAR

- 3.4.14.7. MACHINE TRAVELS IN ONE DIRECTION ONLY (FORWARD OR REVERSE)

- 3.4.14.8. STEERING CLUTCH DOES NOT DISENGAGE

- 3.4.14.9. STEERING CLUTCH SLIPS

- 3.4.14.10. STEERING BRAKE DOES NOT WORK

- 3.5. DISASSEMBLY AND ASSEMBLY

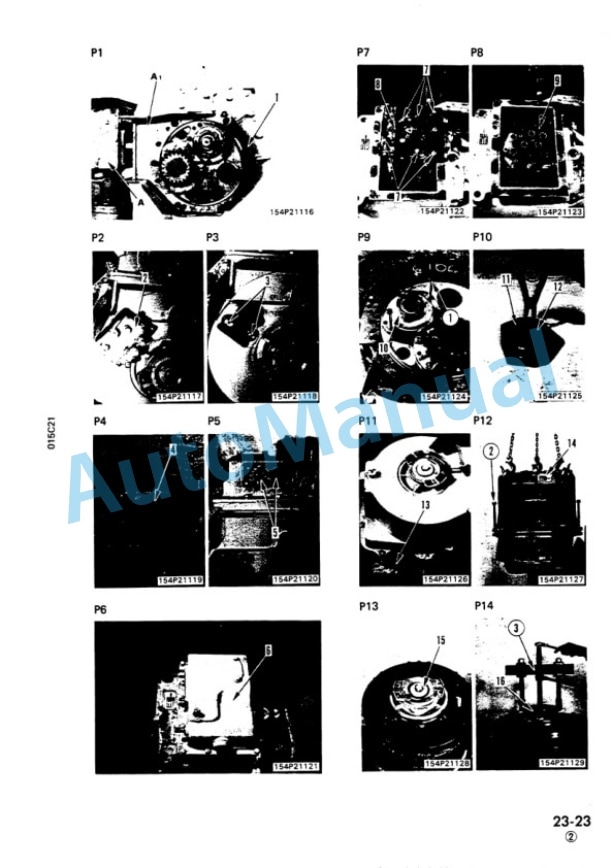

- 3.5.1. TORQUE CONVERTER

- 3.5.1.1. REMOVAL

- 3.5.1.2. INSTALLATION

- 3.5.1.3. DISASSEMBLY

- 3.5.1.4. ASSEMBLY

- 3.5.2. TORQUE CONVERTER RELIEF VALVE

- 3.5.2.1. REMOVAL

- 3.5.2.2. INSTALLATION

- 3.5.2.3. DISASSEMBLY

- 3.5.2.4. ASSEMBLY

- 3.5.3. TORQUE CONVERTER REGULATOR VALVE

- 3.5.3.1. REMOVAL

- 3.5.3.2. INSTALLATION

- 3.5.3.3. DISASSEMBLY

- 3.5.3.4. ASSEMBLY

- 3.5.4. TRANSMISSION CONTROL VALVE

- 3.5.4.1. REMOVAL

- 3.5.4.2. INSTALLATION

- 3.5.4.3. DISASSEMBLY

- 3.5.4.4. ASSEMBLY

- 3.5.5. TRANSMISSION LUBRICATION VALVE

- 3.5.5.1. REMOVAL

- 3.5.5.2. INSTALLATION

- 3.5.5.3. DISASSEMBLY

- 3.5.5.4. ASSEMBLY

- 3.5.6. BEVEL GEAR AND SHAFT

- 3.5.6.1. REMOVAL

- 3.5.6.2. INSTALLATION

- 3.5.7. STEERING CLUTCH

- 3.5.8. STEERING RELIEF VALVE

- 3.5.8.1. REMOVAL

- 3.5.8.2. INSTALLATION

- 3.5.8.3. DISASSEMBLY

- 3.5.8.4. ASSEMBLY

- 3.5.9. STEERING BRAKE VALVE

- 3.5.9.1. REMOVAL

- 3.5.9.2. INSTALLATION

- 3.5.9.3. DISASSEMBLY

- 3.5.9.4. ASSEMBLY

- 3.5.10. TRANSMISSION PUMP

- 3.6. MAINTENANCE STANDARD

- 3.6.1. TORQUE CONVERTER

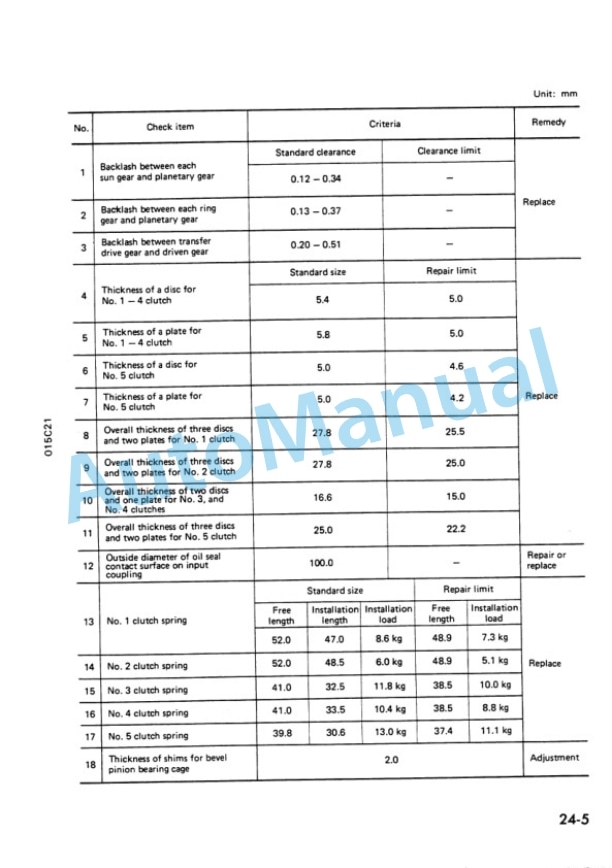

- 3.6.2. TORQFLOW TRANSMISSION

- 3.6.3. TRANSMISSION CONTROL VALVE

- 3.6.4. TRANSMISSION LUBRICATION VALVE

- 3.6.5. TRANSMISSION PUMP

- 3.6.6. BEVEL GEAR SHAFT

- 3.6.7. STEERING CLUTCH

- 3.6.8. STEERING PUMP

- 3.6.9. STEERING MAIN RELIEF VALVE

- 3.6.10. STEERING AND BRAKE CONTROL VALVE

- 3.6.11. STEERING BRAKE

- 3.6.12. FINAL DRIVE

- 4. UNDERCARRIAGE

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. TRACK

- 4.1.2. TRACK GROUP

- 4.1.3. IDLER

- 4.1.4. IDLER CUSHION

- 4.1.5. TRACK ROLLER AND CARRIER ROLLER

- 4.1.6. SUSPENSION

- 4.2. DISASSEMBLY AND ASSEMBLY

- 4.3. MAINTENANCE STANDARD

- 5. HYDRAULIC SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. HYDRAULIC PIPING

- 5.1.2. HYDRAULIC CONTROL

- 5.1.3. HYDRAULIC SYSTEM

- 5.1.4. HYDRAULIC CIRCUIT DIAGRAM

- 5.1.5. HYDRAULIC TANK

- 5.1.6. HYDRAULIC PUMP

- 5.1.7. HYDRAULIC CONTROL VALVE

- 5.1.8. HYDRAULIC LEVER OPERATION

- 5.1.9. HYDRAULIC CYLINDER

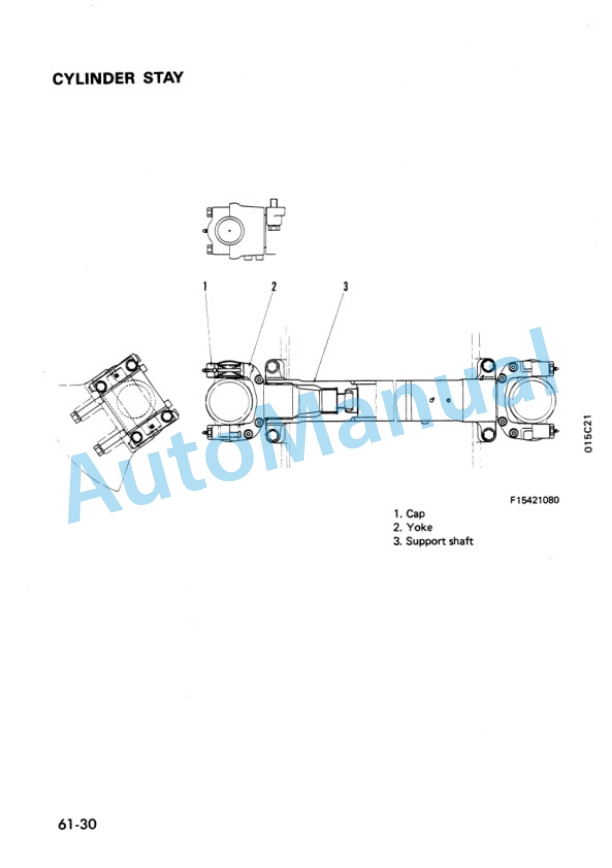

- 5.1.10. CYLINDER STAY

- 5.2. TESTING AND ADJUSTING

- 5.2.1. STANDARDS FOR TESTING AND ADJUSTING

- 5.2.2. TESTING AND ADJUSTING TOOL LIST

- 5.2.3. MEASURING OIL PRESSURE

- 5.2.4. ADJUSTING BLADE CONTROL LINKAGE

- 5.2.5. ADJUSTING RIPPER CONTROL LINKAGE

- 5.2.6. TROUBLESHOOTING

- 5.2.6.1. DIAGNOSTIC TABLES

- 5.2.6.1.1. BLADE LIFT LACKS POWER AND SPEED

- 5.2.6.1.2. BLADE DOES NOT LIFT

- 5.2.6.1.3. THE FRONT OF MACHINE CANNOT BE RAISED OFF GROUND BY THE BLADE

- 5.2.6.1.4. HYDRAULIC DRIFT OF LIFT CYLINDER IS LARGE

- 5.2.6.1.5. BLADE MOVES UNSTEADILY WHEN LEVELING THE GROUND (CONTROL LEVER IN HOLD)

- 5.2.6.1.6. BLADE LOWERS UNDER THE FOLLOWING CONDITIONS

- 5.2.6.1.7. TRAVEL OF THE PISTON RODS IN THE RIGHT AND LEFT LIFT CYLINDERS IS DIFFERENT (APPLICABLE TO STRAIGHTTILT DOZER ONLY)

- 5.2.6.1.8. BLADE TILTING FORCE IS LACK, BLADE TILTING SPEED IS SLOW, THE MACHINE CANNOT BE RAISED OFF GROUND BY BLADE TILTING FORCE

- 5.2.6.1.9. TILT CYLINDER DOES NOT MOVE OFF (TILTING IS IMPOSSIBLE)

- 5.2.6.1.10. HYDRAULIC DRIFT OF TILT CYLINDER IS LARGE

- 5.2.6.1.11. OPERATION FORCE IS HEAVY

- 5.2.6.1.12. HYDRAULIC DRIFT OF RIPPER CYLINDER IS LARGE

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. HYDRAULIC PUMP

- 5.3.1.1. REMOVAL

- 5.3.1.2. INSTALLATION

- 5.3.2. BLADE CONTROL VALVE

- 5.3.2.1. REMOVAL

- 5.3.2.2. INSTALLATION

- 5.3.2.3. DISASSEMBLY

- 5.3.2.4. ASSEMBLY

- 5.3.3. RIPPER CONTROL VALVE

- 5.3.3.1. REMOVAL

- 5.3.3.2. INSTALLATION

- 5.3.3.3. DISASSEMBLY

- 5.3.3.4. ASSEMBLY

- 5.3.4. BLADE LIFT CYLINDER

- 5.3.4.1. REMOVAL

- 5.3.4.2. INSTALLATION

- 5.3.5. BLADE TILT CYLINDER

- 5.3.5.1. REMOVAL

- 5.3.5.2. INSTALLATION

- 5.3.6. RIPPER CYLINDER

- 5.3.6.1. REMOVAL

- 5.3.6.2. INSTALLATION

- 5.3.7. HYDRAULIC CYLINDER

- 5.3.7.1. DISASSEMBLY

- 5.3.7.2. ASSEMBLY

- 5.3.8. BLADE RELIEF VALVE

- 5.3.8.1. REMOVAL

- 5.3.8.2. INSTALLATION

- 5.3.9. RIPPER RELIEF VALVE

- 5.3.9.1. REMOVAL

- 5.3.9.2. INSTALLATION

- 5.4. MAINTENANCE STANDARD

- 5.4.1. HYDRAULIC CONTROL VALVE

- 5.4.2. HYDRAULIC CYLINDER

- 5.4.3. CYLINDER STAY

- 5.4.4. HYDRAULIC PUMP

- 6. WORK EQUIPMENT

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. ANGLEDOZER

- 6.1.2. STRAIGHT TILTDOZER

- 6.1.3. FIXED MULTISHANK RIPPER

- 6.2. DISASSEMBLY AND ASSEMBLY

- 6.3. MAINTENANCE STANDARD

- 6.3.1. ANGLEDOZER

- 6.3.2. STRAIGHT TILTDOZER

- 6.3.3. CUTTING EDGE, END FIT

- 6.3.4. FIXED MULTISHANK RIPPER

- 7. ELECTRIC SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. WIRING DIAGRAM

- 8. OTHERS

- 8.1. DISASSEMBLY AND ASSEMBLY

- 8.1.1. FLOOR FRAME

- 8.1.1.1. REMOVAL

- 8.1.1.2. INSTALLATION

Rate this product

You may also like