Komatsu D85ESS-2A Crawler Dozer Shop Manual SEBM002904

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM002904

- Format: PDF

- Size: 52.9MB

- Number of Pages: 906

Category: Komatsu Shop Manual PDF

-

Model List:

- D85ESS-2A Crawler Dozer

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE AND FUNCTION

- 4.1. RADIATOR, OIL COOLER

- 4.2. ENGINE CONTROL

- 4.3. POWER TRAIN SYSTEM

- 4.4. POWER TRAIN SKELETON

- 4.5. POWER TRAIN UNIT

- 4.6. POWER TRAIN HYDRAULIC PIPING DIAGRAM

- 4.7. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 4.8. POWER TRAIN HYDRAULIC SYSTEM DIAGRAM

- 4.9. DAMPER, UNIVERSAL JOINT

- 4.10. TORQUE CONVERTER AND PTO

- 4.11. TRANSMISSION CONTROL

- 4.12. TRANSMISSION

- 4.13. TRANSMISSION CONTROL VALVE

- 4.14. MAIN RELIEF VALVE

- 4.15. LUBRICATION RELIEF VALVE

- 4.16. STEERING, BRAKE CONTROL

- 4.17. BEVEL GEAR SHAFT, STEERING CLUTCH, STEERING BRAKE

- 4.18. STEERING CONTROL VALVE

- 4.19. STEERING BRAKE VALVE

- 4.20. REDUCING VALVE

- 4.21. SCAVENGING PUMP STRAINER

- 4.22. POWER TRAIN OIL STRAINER

- 4.23. POWER TRAIN OIL FILTER

- 4.24. WORK EQUIPMENT HYDRAULIC PIPING DIAGRAM

- 4.25. PPC CONTROL PIPING DIAGRAM

- 4.26. WORK EQUIPMENT CONTROL

- 4.27. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 4.28. WORK EQUIPMENT HYDRAULIC SYSTEM DIAGRAM

- 4.29. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 4.30. WORK EQUIPMENT HYDRAULIC SYSTEM DIAGRAM

- 4.31. HYDRAULIC TANK AND FILTER

- 4.32. PPC VALVE

- 4.33. PPC CHARGE VAVLE

- 4.34. PPC LOCK VAVLE

- 4.35. MAIN CONTROL VALVE

- 4.36. OPERATION OF MAIN CONTROL VALVE

- 4.37. OPERATION OF WORK EQUIPMENT CONTROL CIRCUIT

- 4.38. SUCTION VAVLE

- 4.39. PISTON VALVE

- 4.40. WORK EQUIPMENT

- 4.41. ELECTRICAL CIRCUIT DIAGRAM

- 4.42. ENGINE CONTROL

- 4.43. MACHINE MONITOR SYSTEM (GAUGE TYPE PANEL)

- 4.44. MACHINE MONITOR SYSTEM (MONITOR TYPE PANEL)

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM

- 5.4. TOOL LIST FOR TESTING AND ADJUSTING

- 5.5. ADJUSTING VALVE CLEARANCE

- 5.6. MEASURING COMPRESSION PRESSURE

- 5.7. MEASURING BLOWBY

- 5.8. ADJUSTING FUEL INJECTION TIMING

- 5.9. MEASURING EXHAUST COLOR

- 5.10. MEASURING BOOST PRESSURE

- 5.11. MEASURING EXHAUST TEMPERATURE

- 5.12. MEASURING ENGINE OIL PRESSURE

- 5.13. MEASURING ENGINE SPEED

- 5.14. TESTING FAN BELT TENSION

- 5.15. MEASURING SPEED AT TORQUE CONVERTER STALL

- 5.16. ADJUSTING FUEL CONTROL LINKAGE

- 5.17. ADJUSTING STEERING AND DIRECTIONAL LEVER, GEAR SHIFT LEVER, PARKING BRAKE LEVER LINKAGE

- 5.18. ADJUSTING BRAKE PEDAL LINKAGE

- 5.19. ADJUSTING WORK EQUIPMENT CONTROL LINKAGE

- 5.20. ADJUSTING STRAIGHT TILTDOZER

- 5.21. ADJUSTING PPC VAVLE

- 5.22. MEASURING POWER TRAIN OIL PRESSURE

- 5.23. TESTING AND ADJUSTING WORK EQUIPNENT HYDRAULIC PRESSURE

- 5.24. TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE

- 5.25. MEASURING OUTPUT PRESSURE OF PPC VAVLE

- 5.26. MEASURING LEAKAGE INSIDE CYLINDER

- 5.27. BLEEDING AIR FROM HYDRAULIC CYLINDER

- 5.28. RELEASING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT

- 5.29. PROCEDURE FOR SIMPLE TEST OF STEERING BRAKE PERFORMANCE

- 5.30. PROCEDURE FOR TESTING SENSORS

- 5.31. TESTING AND ADJUSTING OF VIBRATION STOPPER,OPEN OPEN/CLOSE LOCK OF OPERATORS CAB DOOR

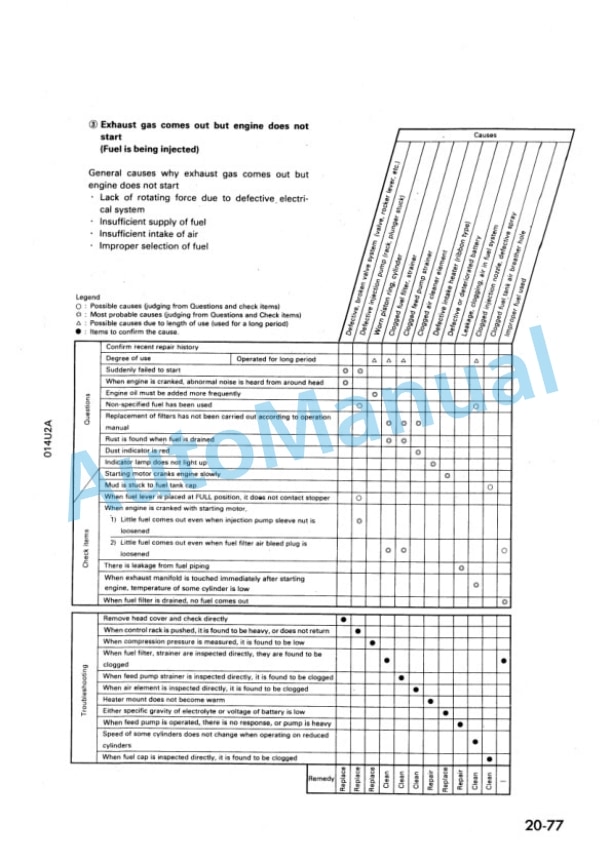

- 5.32. TROUBLESHOOTING

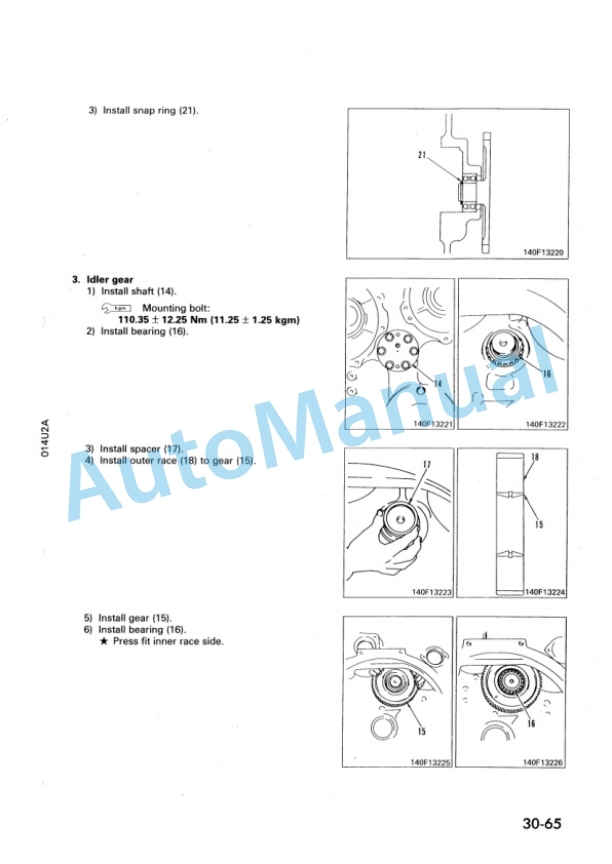

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SPECIAL TOOL SKETCH

- 6.5. ENGINE OIL COOLER CORE

- 6.6. FUEL INJECTION PUMP

- 6.7. ENGINE FRONT SEAL

- 6.8. ENGINE REAR SEAL

- 6.9. AIR COMPRESSOR

- 6.10. HYDRAULIC COOLER

- 6.11. ENGINE (CAB SPECIFICATION)

- 6.12. ENGINE (CANOPY SPECIFICATION)

- 6.13. DAMPER

- 6.14. POWER TRAIN UNIT

- 6.15. TORQUE CONVERTER

- 6.17. TORQFLOW TRANSMISSION

- 6.18. STEERING CASE

- 6.19. TORQUE CONVERTER VALVE

- 6.20. TRANSMISSION CONTROL VALVE

- 6.21. STEERING CONTROL VALVE

- 6.22. REDUCING VALVE

- 6.23. SCAVENGING PUMP

- 6.24. POWER TARIN PUMP

- 6.25. EQUALIZER BAR SIDE BUSHING

- 6.26. SEGMENT TEETH

- 6.27. WORK EQUIPMENT PUMP

- 6.28. PPC PUMP

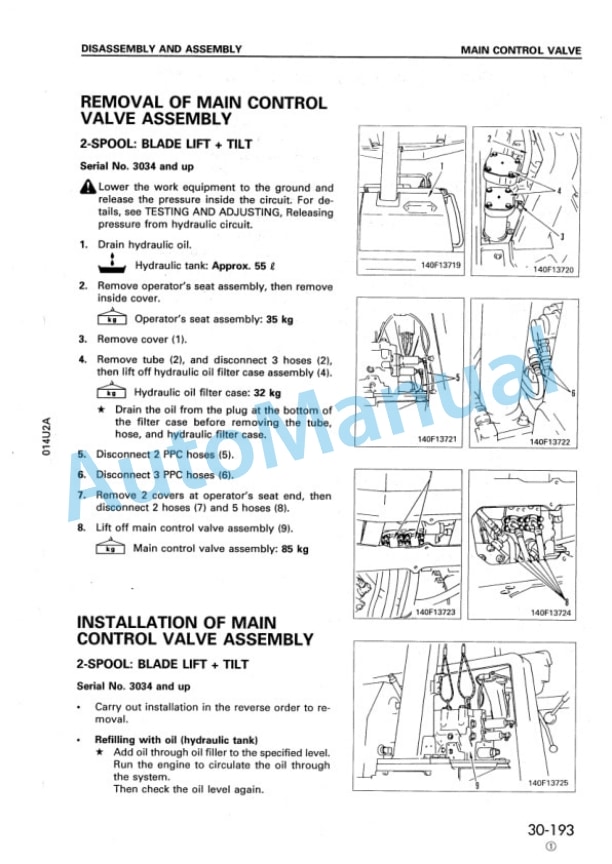

- 6.29. MAIN CONTROL VALVE

- 6.30. MAIN CONTROL VALVE

- 6.31. RIPPER VALVE

- 6.32. MAIN RELIEF VALVE

- 6.33. PPC CHARGE RELIEF VALVE

- 6.34. SUCTION VALVE

- 6.35. BLADE LIFT CYLINDER (ANGLEDOZER)

- 6.36. BLADE LIFT CYLINDER (STRAIGHT TILT DOZER)

- 6.37. BLADE TILT CYLINDER

- 6.38. HYDRAULIC CYLINDER

- 6.39. BLADE (ANGLEDOZER)

- 6.40. BLADE (STRAIGHT TILT DOZER)

- 6.41. DASHBOARD (GAUGE TYPE PANEL)

- 6.42. DASHBOARD (MONITOR TYPE PANEL)

- 6.43. PANEL (GAUGE TYPE PANEL)

- 6.44. PANEL (MONITOR TYPE PANEL)

- 6.45. FLOOR FRAME (CANOY SPECIFICATION)

- 6.46. FLOOR FRAME (CAB SPECIFICATION)

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT

- 7.2. POWER TRAIN UNIT MOUNT

- 7.3. DAMPER, UNIVERSAL JOINT

- 7.4. TORQUE CONVERTER, PTO

- 7.5. TRANSMISSION

- 7.6. TRANSMISSION CONTROL VALVE

- 7.7. MAIN RELIEF VALVE

- 7.8. BEVEL GEAR SHAFT, STEERING CLUTCH, STEERING BRAKE

- 7.9. STEERING CONTROL VALVE

- 7.10. STEERING BRAKE VALVE

- 7.11. POWER TRAIN, LUBRICATION PUMP

- 7.12. PPC PUMP

- 7.13. PPC VALVE

- 7.14. PPC CHARGE VALVE

- 7.15. FINAL DRIVE

- 7.16. HULL FRAME

- 7.17. TRACK FRAME, RECOIL SPRING

- 7.18. MAIN CONTROL VALVE

- 7.19. WORK EQUIPMENT CYLINDER

- 7.20. WORK EQUIPMENT

- 7.21. CUTTING EDGE, END BIT

- 7.22. RIPPER

- 8. OTHERS

- 8.1. GENERAL

- 8.2. STRUCTURE AND FUNCTION

- 8.3. TESTING AND ADJUSTING

- 8.4. DISASSEMBLY AND ASSEMBLY

- 8.5. MAINTENANCE STANDARD

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00