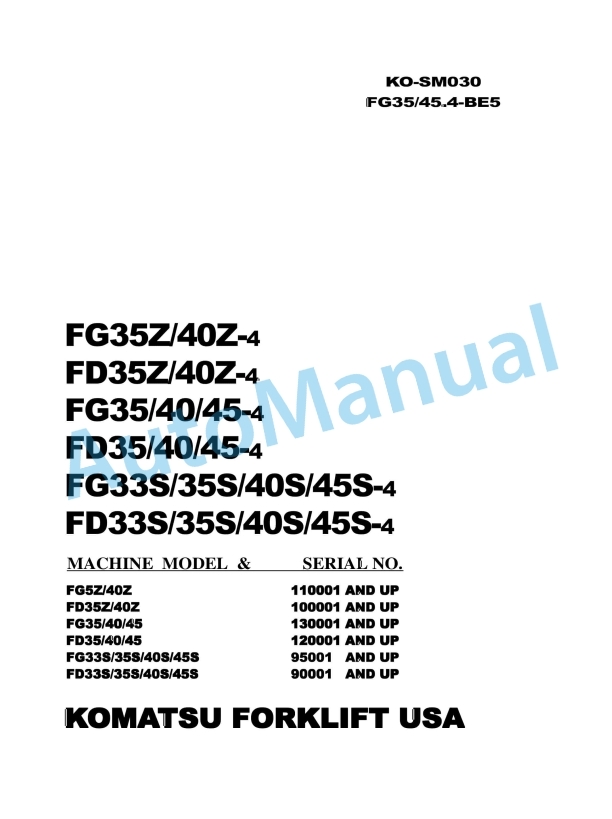

Komatsu FG35Z-4, FG40Z-4, FD35Z-4, FD40Z-4, FG35-4, FG40-4, FG45-4, FD35-4, FD40-4, FD45-4, FG33S-4, FG35S-4, FG40S Shop Manual KO-SM030

$40.00

- Type Of Manual: Shop Manual

- Manual ID: KO-SM030

- Format: PDF

- Size: 34.9MB

- Number of Pages: 770

Category: Komatsu Shop Manual PDF

-

Model List:

- FG35Z-4 Forklift Truck

- FG40Z-4 Forklift Truck

- FD35Z-4 Forklift Truck

- FD40Z-4 Forklift Truck

- FG35-4 Forklift Truck

- FG40-4 Forklift Truck

- FG45-4 Forklift Truck

- FD35-4 Forklift Truck

- FD40-4 Forklift Truck

- FD45-4 Forklift Truck

- FG33S-4 Forklift Truck

- FG35S-4 Forklift Truck

- FG40S-4 Forklift Truck

- FG45S-4 Forklift Truck

- FD33S-4 Forklift Truck

- FD35S-4 Forklift Truck

- FD40S-4 Forklift Truck

- FD45S-4 Forklift Truck

- 1. ATFORE

- 1.1. FOREWORD

- 1.2. GENERAL DISASSEMBLY AND ASSEMBLY

- 1.3. DESCRIPTION OF THE SYMBOLS

- 2. ATGEN

- 2.1. GENERAL AND SPECIFICATIONS

- 3. AADIS

- 3.1. DISASSEMBLY AND ASSEMBLY

- 4. AAGEN

- 4.1. GENERAL VIEW

- 4.2. SPECIFICATIONS

- 4.3. ENGINE PERFORMANCE CURVE

- 4.4. WEIGHT TABLE

- 5. AAINSPM

- 5.1. INSPECTION AND MAINTENANCE

- 6. AAINSPS

- 6.1. TURBOCHARGER (S6D95L)

- 6.2. CYLINDER HEAD

- 6.3. VALVE AND VALVE GUIDE

- 6.4. ROCKER ARM SHAFT, PUSH ROD AND TAPPET

- 6.5. CYLINDER BLOCK

- 6.6. CRANKSHAFT

- 6.7. PISTON, PISTON RING AND PISTON PIN

- 6.8. CONNECTING ROD

- 6.9. TIMING GEAR

- 6.10. CAMSHAFT

- 6.11. FLYWHEEL AND FLYWHEEL HOUSING

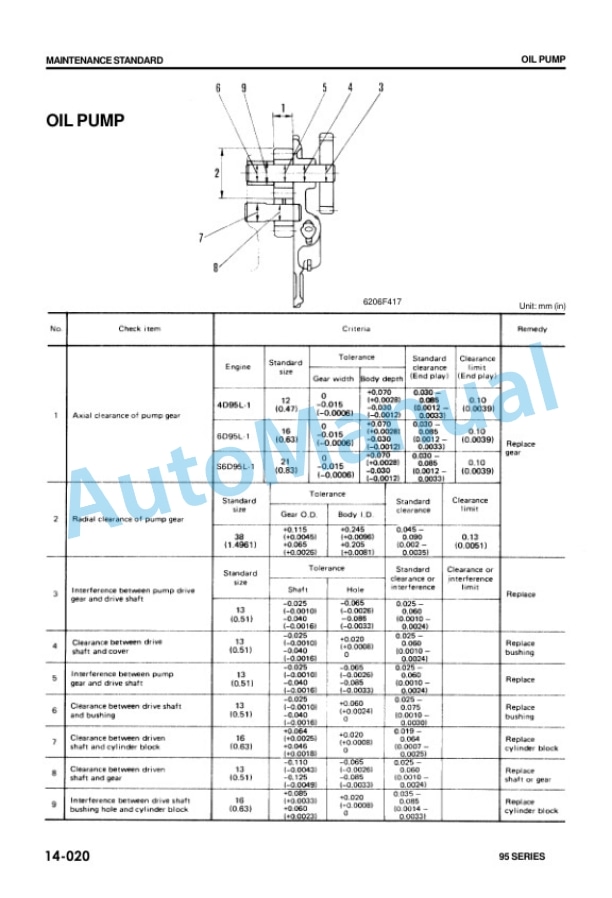

- 6.12. OIL PUMP

- 6.13. REGULATOR VALVE

- 6.14. WATER PUMP AND THERMOSTAT

- 7. AAREP

- 7.1. CYLINDER HEAD SECTION

- 7.2. CYLINDER BLOCK SECTION

- 8. AASTRUC

- 8.1. GENERAL STRUCTURE

- 8.2. INTAKE AND EXHAUST SYSTEM

- 8.3. ENGINE BODY

- 8.4. LUBRICATION SYSTEM

- 8.5. FUEL SYSTEM

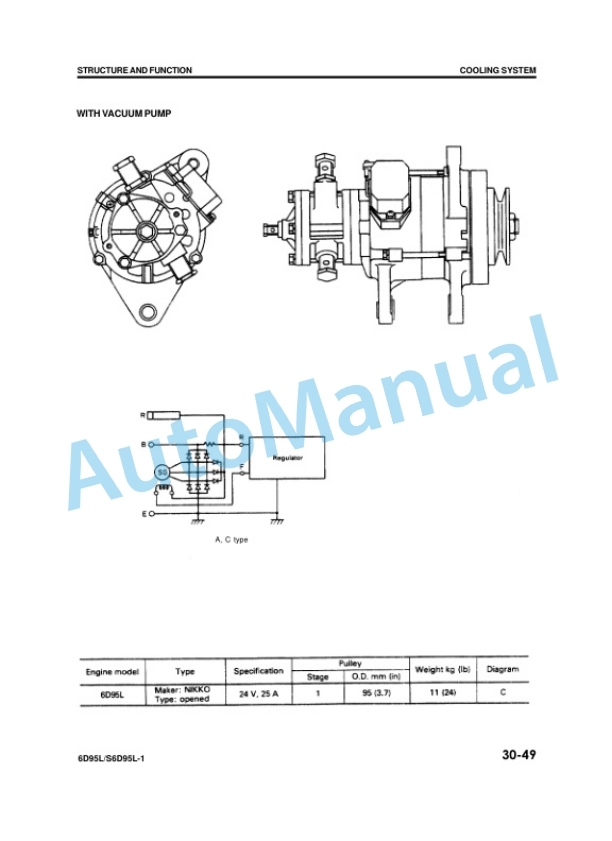

- 8.6. COOLING SYSTEM

- 8.7. ELECTRICAL SYSTEM

- 9. AATEST

- 9.1. TESTING AND ADJUSTING DATA

- 9.2. FUEL INJECTION PUMP CALIBRATION DATA

- 9.3. STANDARD VOLUME OF FUEL INJECTION

- 9.4. ADJUSTMENT OF GOVERNOR

- 9.5. PERFORMANCE TEST

- 10. AATROUB

- 10.1. METHOD OF USING TROUBLESHOOTING CHART

- 10.2. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 10.3. STARTING PERFORMANCE IS POOR

- 10.4. ENGINE DOES NOT START

- 10.5. ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOWUP IS POOR)

- 10.6. ENGINE STOPS DURING OPERATIONS

- 10.7. ENGINE DOES NOT ROTATE SMOOTHLY

- 10.8. ENGINE LACKS OUTPUT (NO POWER)

- 10.9. EXHAUST GAS IS BLACK (INCOMPLETE COMBUSTION)

- 10.10. OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)

- 10.11. OIL BECOMES CONTAMINATED QUICKLY

- 10.12. FUEL CONSUMPTION IS EXCESSIVE

- 10.13. OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN

- 10.14. OIL PRESSURE LAMP LIGHTS UP (DROP IN OIL PRESSURE)

- 10.15. OIL LEVEL RISES

- 10.16. WATER TEMPERATURE BECOMES TOO HIGHT (OVERHEATING)

- 10.17. ABNORMAL NOISE IS MADE

- 10.18. VIBRATION IS EXCESSIVE

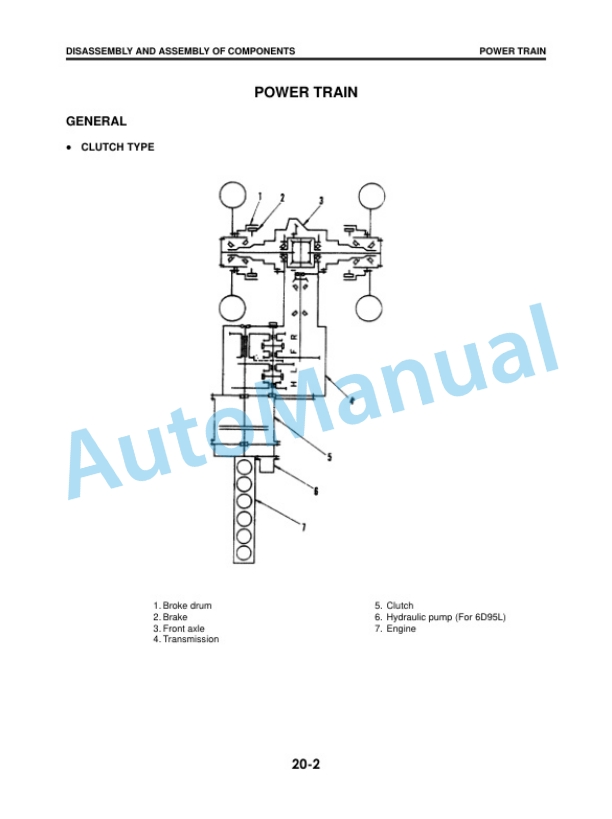

- 11. AGDIS

- 11.1. DISASSEMBLY AND ASSEMBLY

- 11.2. MAINTENANCE STANDARD

- 11.3. Turbocharger

- 11.4. Cylinder head

- 11.5. Valve and valve guide

- 11.6. Rocker arm shaft, push rod and tappet

- 11.7. Cylinder block

- 11.8. Crankshaft

- 11.9. Camshaft

- 11.10. Timing gear

- 11.11. Piston, piston ring and piston pin

- 11.12. Connecting rod

- 11.13. Flywheel and flywheel housing

- 11.14. Oil pump

- 11.15. Regulator valve

- 11.16. Water pump and thermostst

- 12. AGSERV

- 12.1. SERVICE INFORMATION

- 12.2. Procedure for selection and installation of pistons on 4D95S (L) and 6D95L engine

- 13. AGSTRUC

- 13.1. STRUCTURE AND FUNCTION

- 13.2. GENERAL STRUCTURE

- 13.3. INTAKE AND EXHAUST SYSTEM

- 13.4. ENGINE BODY

- 13.5. LUBRICATION SYSTEM

- 13.6. FUEL SYSTEM

- 13.7. COOLING SYSTEM

- 13.8. ELECTRICAL SYSTEM

- 14. AGTEST

- 14.1. TESTING AND ADJUSTING

- 14.2. INTAKE AND EXHAUST SYSTEM

- 14.3. ENGINE BODY

- 14.4. FUEL SYSTEM

- 14.5. LUBRICATION SYSTEM

- 14.6. COOLING SYSTEM

- 14.7. PERFORMANCE TEST

- 14.8. TROUBLESHOOTING

- 15. ATCONV

- 15.1. CONVERSION TABLE

- 15.2. STEERING SYSTEM

- 15.3. HYDRAULIC SYSTEM

- 15.4. MAST

- 15.5. ELECTRICAL

- 16. ATREMOV

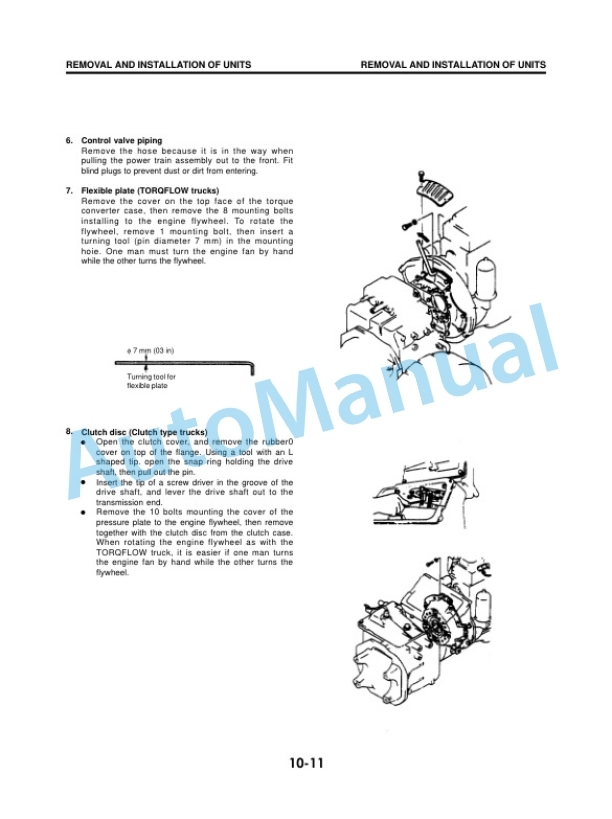

- 16.1. REMOVAL AND INSTALLATION OF UNITS

- 17. ATSERV

- 17.1. SERVICE INFORMATION

- 17.2. Change in engine mount bracket

- 17.3. Change in control valve for TORQFLOW transmission

- 17.4. Change in mast guide bar bushing

- 17.5. Change in lift cylinder rod and mast boom for FREE VIEW mast

- 18. ATTEST

- 18.1. TESTING AND ADJUSTING

- 19. ATTROUB

- 19.1. TROUBLESHOOTING

- 20. AXGEN

- 20.1. General view

- 20.2. Specifications

- 20.3. General assembly drawing

- 20.4. Engine performance curve

- 21. AXMAINT

- 21.1. MAINTENANCE STANDARD

- 21.2. Cylinder and cylinder head

- 21.3. Piston, Piston ring, piston pin and connecting rod

- 21.4. CRANKSHAFT

- 21.5. Camshaft, valve, tappet and timing

- 21.6. Manifold

- 21.7. Lubrication system

- 21.8. Cooling system

- 21.9. Fuel system

- 21.10. Ignition system

- 22. AXSERV

- 22.1. Idling check and adjustment

- 22.2. Clylinder head assembly

- 22.3. Manifold assembly

- 22.4. Carburetor assembly

- 22.5. Governor

- 22.6. Engine electricals

- 22.7. Radiator

- 22.8. Fan, fan pulley

- 22.9. Fuel system

- 23. AXSTRUC

- 23.1. STRUCTURE AND FUNCTION

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00