Komatsu GD305A-3 Motor Grader Shop Manual SEBM018000

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM018000

- Format: PDF

- Size: 23.4MB

- Number of Pages: 417

Category: Komatsu Shop Manual PDF

-

Model List:

- GD305A-3 Motor Grader

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DIMENSION DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. FUEL,COOLANT AND LUBRICANTS

- 4. STRUCTURE AND FUNCTION

- 4.1. ACCELERATOR CONTROL LINKAGE

- 4.2. ACCELERATOR PEDAL

- 4.3. POWER TRAIN DIAGRAM

- 4.4. TRANSMISSION HYDRAULIC PIPING DRAWING

- 4.5. TRANSMISSION CONTROL

- 4.6. TRANSMISSION

- 4.7. TRANSMISSION CONTROL VALVE

- 4.8. FINAL DRIVE

- 4.9. TANDEM DRIVE

- 4.10. STEERING HYDRAULIC PIPING DRAWING

- 4.11. FLOW PRIORITY VALVE

- 4.12. STEERING VALVE(ORBIR ROLL TYPE)

- 4.13. FRONT AXLE

- 4.14. BRAKE HYDRAULIC PIPING DRAWING

- 4.15. WHEEL BRAKE

- 4.16. BRAKE VALVE

- 4.17. UNLOAD RELIEF VALVE

- 4.18. BRAKE OIL PRESSURE BOOSTER

- 4.19. ACCUMULATOR

- 4.20. PARKING BRAKE CONTROL

- 4.21. PARING BRAKE

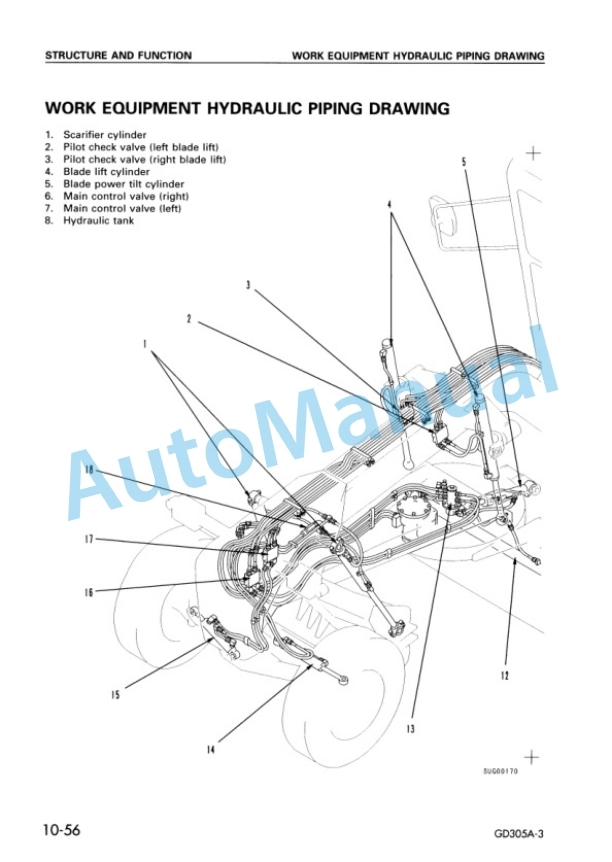

- 4.22. WORK EQUIPMENT HYDRAULIC PIPING DRAWING

- 4.23. MAIN CONTROL VALVE

- 4.24. CLSS

- 4.25. PILOT CHECK VALVE

- 4.26. SLOW RETURN VALVE

- 4.27. CIRCLE ROTATION MOTOR

- 4.28. CIRCLE,DRAWBAR

- 4.29. BLADE

- 4.30. CIRCLE ROTATION GEAR

- 4.31. SCARIFIER

- 4.32. MAIN FRAME

- 4.33. AIR CONDITIONER

- 4.34. ELECTRIC WIRING DIAGRAM

- 4.35. ENGINE START,STOP DEVICE

- 4.36. AUTOMATIC SHIFT CONTROL SYSTEM

- 4.37. SPEED LIMIT SOLENOID CONTROL

- 4.38. MONITOR

- 4.39. SENSORS

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 5.3. TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING

- 5.4. ADJUSTING VALUE CLEARANCE

- 5.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.6. MEASURING EXHAUST COLOR

- 5.7. MEASURING COMPRESSION PRESSURE

- 5.8. MEASURING BLOWBY PRESSURE

- 5.9. MEASURING EXHAUST GAS TEMPERATURE

- 5.10. MEASURING ENGINE OIL PRESSURE

- 5.11. ADJUSTING ENGINE STOP SOLENOID

- 5.12. MEASURING ENGINE SPEED

- 5.13. MEASURING CLUTCH OIL PRESURE CIRCUIT

- 5.14. ADJUSTING ACCELERATOR LINKAGE

- 5.15. ADJUSTING SPEED LIMIT CONTROL

- 5.16. TESTING WHEEL BRAKE

- 5.17. ADJUSTING WHEEL BRAKE

- 5.18. BLEEDING AIR FROM BRAKE PIPING

- 5.19. TESTING AND ADJUSTING PARING BRAKE

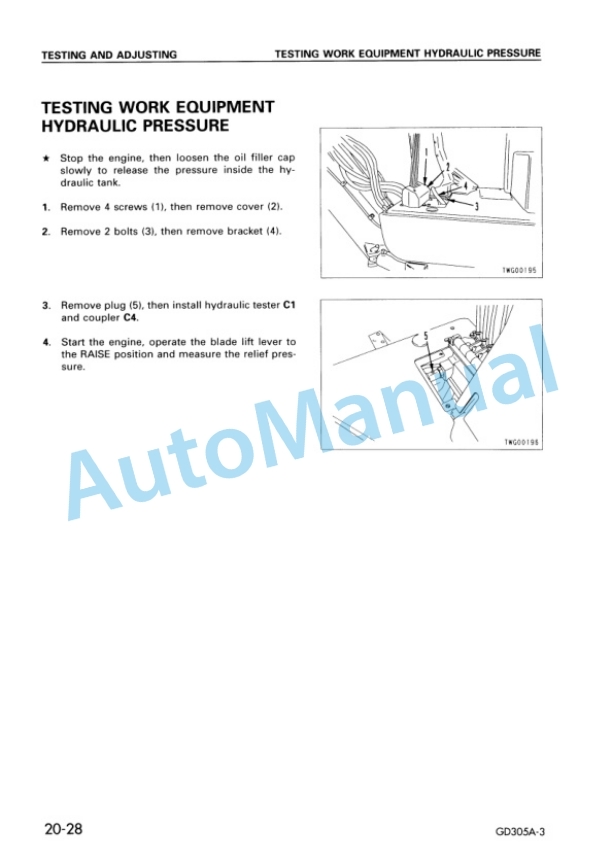

- 5.20. TESTING WORK EQUIPMENT HYDRAULIC PRESSURE

- 5.21. ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE

- 5.22. MEASURING INTERNAL LEAKAGE OF CYLINDER

- 5.23. PRIMING OIL

- 5.24. TESTING CIRCLE GUIDE CLEARANCE

- 5.25. ADJUSTING CLEARANCE OF CIRCLE GUIDE

- 5.26. ADJUSTING MOUNTING POSITION OF IDLE SWITCH

- 5.27. TROUBLESHOOTING

- 5.27.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.27.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.27.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.27.4. CHECKS BEFORE TROUBLESHOOTING

- 5.27.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.27.6. CONNECTOR PIN ARRANGEMENT DIAGRAM

- 5.27.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.27.8. TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)

- 5.27.9. TROUBLESHOOTING OF ENGINE(S MODE)

- 5.27.10. TROUBLESHOOTING OF TRANSMISSION CONTROL SYSTEM (A MODE)

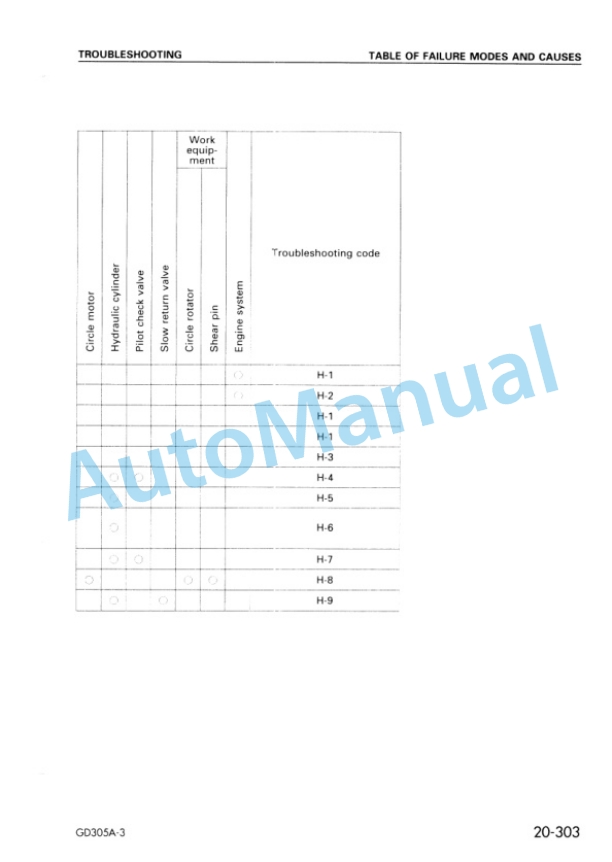

- 5.27.11. TROUBLESHOOTING OF WORK EQUIPMENT HYDRAULIC SYSTEM (H MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. STARTING MOTOR

- 6.4.1. REMOVAL AND INSTALLATION

- 6.5. ALTERNATOR

- 6.5.1. REMOVAL AND INSTALLATION

- 6.6. ENGINE OIL COOLER CORE

- 6.6.1. REMOVAL AND INSTALLATION

- 6.7. FUEL INJECTION PUMP

- 6.7.1. REMOVAL

- 6.7.2. INSTALLATION

- 6.8. WATER PUMP

- 6.8.1. REMOVAL AND INSTALLATION

- 6.9. TURBOCHARGER

- 6.9.1. REMOVAL AND INSTALLATION

- 6.10. NOZZLE HOLDER

- 6.10.1. REMOVAL

- 6.10.2. INSTALLATION

- 6.11. THERMOSTAT

- 6.11.1. REMOVAL AND INSTALLATION

- 6.12. CYLINDER HEAD

- 6.12.1. REMOVAL

- 6.12.2. INSTALLATION

- 6.13. RADIATOR

- 6.13.1. REMOVAL AND INSTALLATION

- 6.14. FUEL TANK

- 6.14.1. REMOVAL AND INSTALLATION

- 6.15. ENGINE

- 6.15.1. REMOVAL

- 6.15.2. INSTALLATION

- 6.16. TRANSMISSION

- 6.16.1. REMOVAL AND INSTALLATION

- 6.17. DRIVE CHAIN

- 6.17.1. REMOVAL

- 6.17.2. INSTALLATION

- 6.18. TANDEM AND FINAL DRIVE

- 6.18.1. REMOVAL

- 6.18.2. INSTALLATION

- 6.18.3. DISASSEMBLY

- 6.18.4. ASSEMBLY

- 6.19. FINAL DRIVE SIDE CASE

- 6.19.1. DISASSEMBLY

- 6.19.2. ASSEMBLY

- 6.20. FINAL DRIVE PINION

- 6.20.1. DISASSEMBLY

- 6.20.2. ASSEMBLY

- 6.21. FRONT WHEEL

- 6.21.1. REMOVAL AND INSTALLATION

- 6.22. REAR WHEEL

- 6.22.1. REMOVAL AND INSTALLATION

- 6.23. FRONT AXLE

- 6.23.1. REMOVAL AND INSTALLATION

- 6.23.2. DISASSEMBLY

- 6.23.3. ASSEMBLY

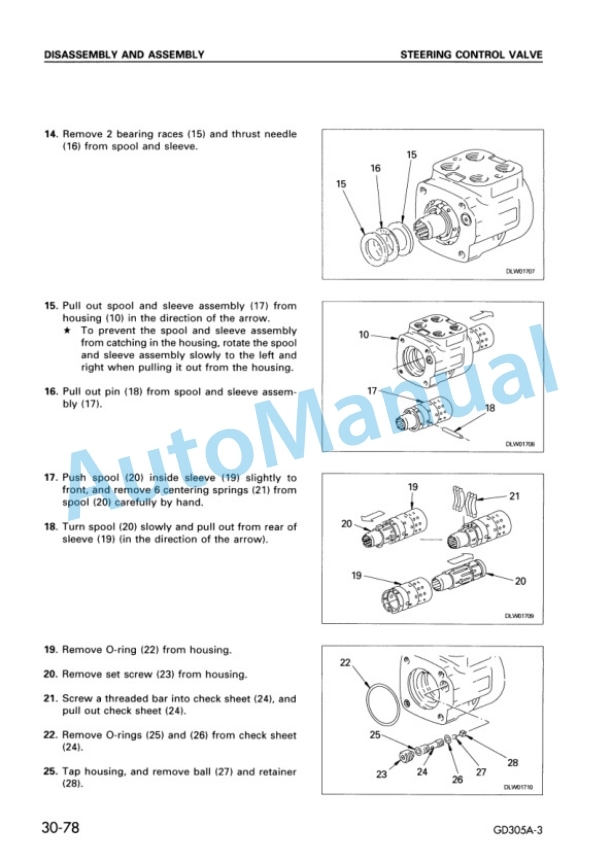

- 6.24. STEERING CONTROL VALVE

- 6.24.1. DISASSEMBLY

- 6.24.2. ASSEMBLY

- 6.25. WHEEL BRAKE

- 6.25.1. REMOVAL AND INSTALLATION

- 6.26. CIRCLE ROTATION MOTOR

- 6.26.1. DISASSEMBLY

- 6.26.2. ASSEMBLY

- 6.27. CIRCLE ROTATION AND HYDRAULIC MOTOR

- 6.27.1. REMOVAL

- 6.27.2. INSTALLATION

- 6.28. CIRCLE ROTATION GEAR

- 6.28.1. REMOVAL AND INSTALLATION

- 6.29. ENGINE HOOD

- 6.29.1. REMOVAL AND INSTALLATION

- 6.29.2. ADJUSTMENT

- 6.30. FRONT WEIGHT

- 6.30.1. REMOVAL AND INSTALLATION

- 6.31. REAR WEIGHT

- 6.31.1. REMOVAL AND INSTALLATION

- 6.32.1. REMOVAL

- 6.32.2. INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. TRANSMISSION

- 7.2. TRANSMISSION CONTROL VALVE

- 7.3. BRAKE OIL PRESSURE BOOSTER

- 7.4. PARKING BRAKE

- 7.5. HYDRAULIC PUMP

- 7.6. MAIN CONTROL VALVE

- 7.7. HYDRAULIC CYLINDER

- 7.8. CIRCLE,DRAWBAR

- 7.9. BLADE

- 7.10. CIRCLE ROTATION GEAR

- 7.11. SCARIFIER

- 8. OTHERS

- 8.1. TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM

- 8.2. HYDRAULIC CIRCUIT DIAGRAM

- 8.3. ELECTRICAL CIRCUIT DIAGRAM (1/2)

- 8.4. ELECTRICAL CIRCUIT DIAGRAM (2/2)

Rate this product

You may also like