Komatsu GD500R-1 Motor Grader Shop Manual GD500R.1-BE1

$40.00

- Type Of Manual: Shop Manual

- Manual ID: GD500R.1-BE1

- Format: PDF

- Size: 18.0MB

- Number of Pages: 266

Category: Komatsu Shop Manual PDF

-

Model List:

- GD500R-1 Motor Grader

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL

- 3.1.1. GENERAL LOCATIONS

- 3.1.2. SPECIFICATIONS

- 3.1.3. ENGINE PERFORMANCE CURVE

- 3.1.4. WEIGHT TABLE

- 3.1.5. POWER TRANSMITTING SYSTEM

- 4. POWER TRAIN

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. STRUCTURE AND FUNCTION

- 4.2. TESTING AND ADJUSTING

- 4.2.1. TESTING AND ADJUSTING

- 4.2.1.1. ADJUSTING CLUTCH

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. DISASSEMBLY AND ASSEMBLY

- 4.3.1.1. DISMOUNTING POWER TRAIN

- 4.3.1.2. MOUNTING POWER TRAIN

- 4.3.1.3. DISMOUNTING ENGINE

- 4.3.1.4. MOUNTING ENGINE

- 4.3.1.5. DISASSEMBLY OF CLUTCH

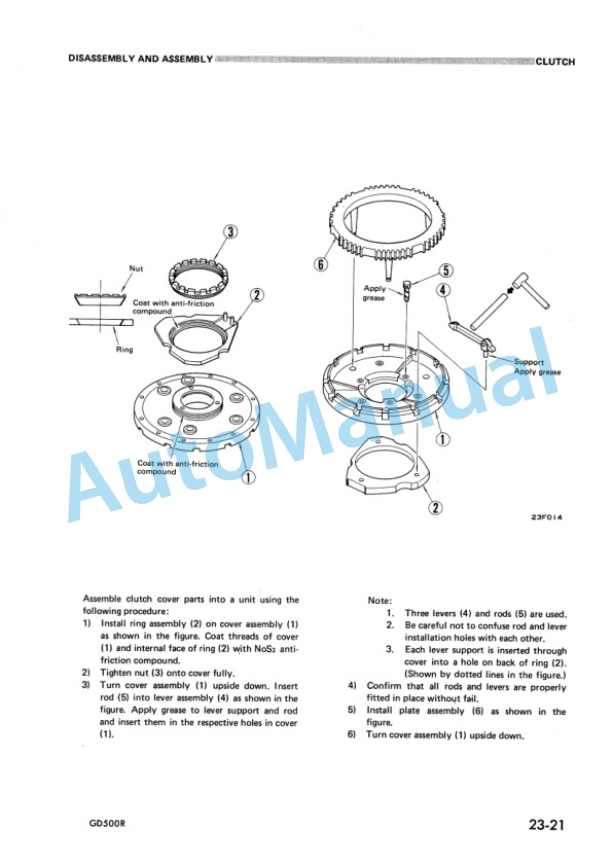

- 4.3.1.6. ASSEMBLY OF CLUTCH

- 4.3.1.7. DISASSEMBLY OF CLUTCH BOOSTER

- 4.3.1.8. ASSEMBLY OF CLUTCH BOOSTER

- 4.3.1.9. DISASSEMBLY OF CLUTCH BOOSTER ASSEMBLY

- 4.3.1.10. ASSEMBLY OF CLUTCH BOOSTER ASSEMBLY

- 4.3.1.11. DISMOUNTING TRANSMISSION

- 4.3.1.12. MOUNTING TRANSMISSION

- 4.3.1.13. DISASSEMBLY OF TRANSMISSION

- 4.3.1.14. ASSEMBLY OF TRANSMISSION

- 4.3.1.15. DISASSEMBLY OF REAR AXLE

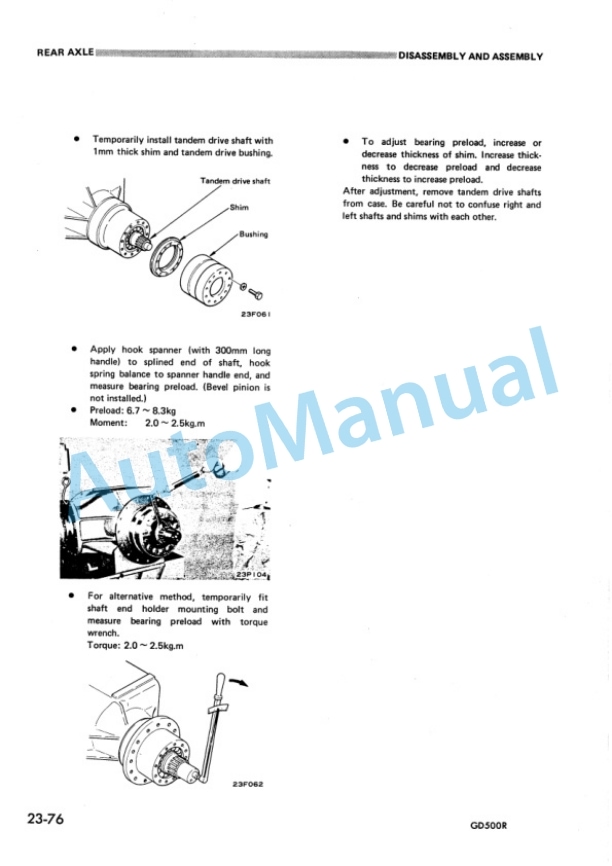

- 4.3.1.16. ASSEMBLY OF REAR AXLE

- 4.3.1.17. DISMOUNTING TANDEM DRIVE

- 4.3.1.18. MOUNTING TANDEM DRIVE

- 4.3.1.19. DISASSEMBLY OF TANDEM DRIVE

- 4.3.1.20. ASSEMBLY OF TANDEM DRIVE

- 4.4. MAINTENANCE STANDARD

- 4.4.1. MAINTENANCE STANDARD

- 4.4.1.1. CLUTCH

- 4.4.1.2. CLUTCH BOOSTER

- 4.4.1.3. TRANSMISSION

- 4.4.1.4. TANDEM DRIVE

- 5. STEERING SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. STRUCTURE AND FUNCTION

- 5.1.1.1. STEERING SYSTEM

- 5.1.1.2. STEERING BOOSTER

- 5.1.1.3. FUNCTION OF STEERING BOOSTER

- 5.2. TESTING AND ADJUSTING

- 5.2.1. TESTING AND ADJUSTING

- 5.2.1.1. CHECKING AND ADJUSTING FRONT WHEEL BEARING PLAY

- 5.2.1.2. CHECK THE RETIGHTENING OF WHEEL HUB NUTS

- 5.2.1.3. CHECKING AND ADJUSTING FOOT BRAKE

- 5.2.1.4. CHECKING AND ADJUSTING PARKING BRAKE

- 5.2.1.5. CHECKING AND ADJUSTING TOEIN

- 5.2.1.6. CHECKING TIEROD FOR WEAR OR LOOSENING

- 5.2.1.7. CHECKING AND ADJUSTING PLAY OF STEERING WHEEL

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. DISASSEMBLY AND ASSEMBLY

- 5.3.1.1. DISMOUNTING FRONT AXLE

- 5.3.1.2. MOUNTING FRONT AXLE

- 5.3.1.3. DISASSEMBLY OF FRONT AXLE

- 5.3.1.4. ASSEMBLY OF FRONT AXLE

- 5.3.1.5. DISMOUNTING WHEEL

- 5.3.1.6. MOUNTING WHEEL

- 5.3.1.7. DISASSEMBLY OF WHEEL

- 5.3.1.8. ASSEMBLY OF WHEEL

- 5.3.1.9. DISMOUNTING WHEEL BRAKE

- 5.3.1.10. MOUNTING WHEEL BRAKE

- 5.3.1.11. DISASSEMBLY OF WHEEL BRAKE

- 5.3.1.12. ASSEMBLY OF WHEEL BRAKE

- 5.3.1.13. DISASSEMBLY AND ASSEMBLY OF MASTER CYLINDER

- 5.3.1.14. DISMOUNTING AND MOUNTING STEERING GEAR

- 5.3.1.15. DISASSEMBLY OF STEERING GEAR

- 5.3.1.16. ASSEMBLY OF STEERING GEAR

- 5.3.1.17. DISMOUNTING STEERING BOOSTER

- 5.3.1.18. MOUNTING STEERING BOOSTER

- 5.3.1.19. DISASSEMBLY OF STEERING BOOSTER

- 5.3.1.20. ASSEMBLY OF STEERING BOOSTER

- 5.4. MAINTENANCE STANDARD

- 5.4.1. MAINTENANCE STANDARD

- 5.4.1.1. STEERING HANDLE

- 5.4.1.2. FRONT AXLE

- 5.4.1.3. TIE ROD

- 5.4.1.4. PARKING BRAKE

- 5.4.1.5. SERVICE BRAKE

- 6. HYDRAULIC SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. STRUCTURE AND FUNCTION

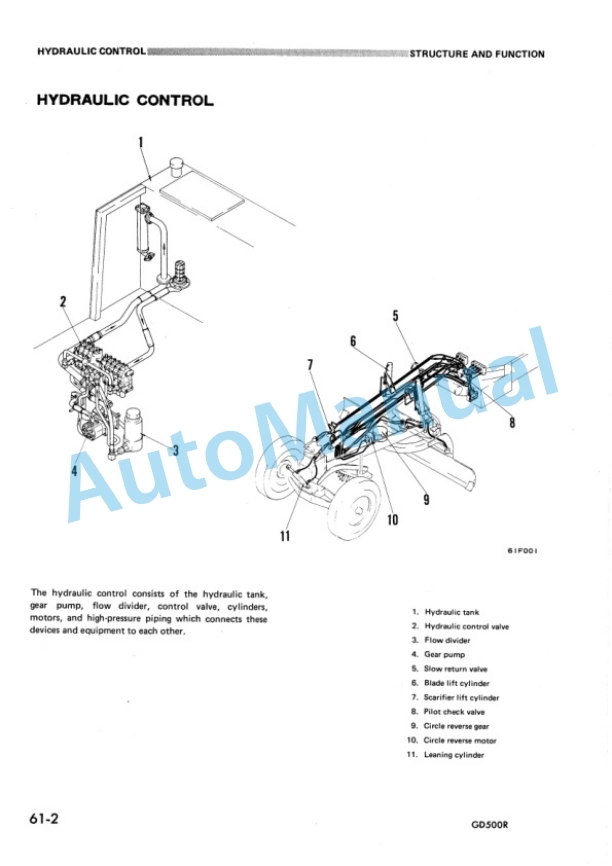

- 6.1.1.1. HYDRAULIC CONTROL

- 6.1.1.2. PIPING DIAGRAM

- 6.1.1.3. HYDRAULIC CONTROL VALVE

- 6.1.1.4. RELIEF VALVE OPERATION

- 6.1.1.5. CONTROL VALVE OPERATION

- 6.1.1.6. HYDRAULIC CYLINDER

- 6.1.1.7. FLOW DIVIDER

- 6.1.1.8. PILOT CHECK VALVE

- 6.1.1.9. SLOW RETURN VALVE

- 6.1.1.10. HYDRAULIC PUMP

- 6.1.1.11. HYDRAULIC MOTOR

- 6.2. TESTING AND ADJUSTING

- 6.2.1. TESTING AND ADJUSTING

- 6.2.1.1. GENERAL

- 6.2.1.2. OIL PRESSURE TEST GUIDE

- 6.3. MAINTENANCE STANDARD

- 6.3.1. MAINTENANCE STANDARD

- 6.3.1.1. HYDRAULIC CONTROL VALVE

- 6.3.1.2. HYDRAULIC CYLINDER

- 7. WORK EQUIPMENT

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. STRUCTURE AND FUNCTION

- 7.1.1.1. BLADE

- 7.1.1.2. WORK EQUIPMENT CONTROL LEVEL

- 7.1.1.3. CIRCLE REVERSE GEAR

- 7.1.1.4. SCARIFIER(OPTION)

- 7.2. TESTING AND ADJUSTING

- 7.2.1. TESTING AND ADJUSTING

- 7.2.1.1. CHECKING AND ADJUSTING BALL JOINT CLEARANCE

- 7.2.1.2. ADJUSTING BLADE CUTTING ANGLE

- 7.2.1.3. CHECKING AND ADJUSTING CIRCLE GUIDE BLOCK CLEARANCE

- 7.2.1.4. CHECKING DRAWBAR FRONT BALL JOINT FOR LOOSENING

- 7.2.1.5. ADJUSTING SCARIFIER CUTTING ANGLE AND DEPTH

- 7.3. DISASSEMBLY AND ASSEMBLY

- 7.3.1. DISASSEMBLY AND ASSEMBLY

- 7.3.1.1. DISMOUNTING BLADE CIRCLE REVERSE GEAR

- 7.3.1.2. MOUNTING BLADE CIRCLE REVERSE GEAR

- 7.3.1.3. DISASSEMBLY OF BLADE CIRCLE REVERSE GEAR

- 7.3.1.4. ASSEMBLY OF BLADE CIRCLE REVERSE GEAR

- 7.4. MAINTENANCE STANDARD

- 7.4.1. MAINTENANCE STANDARD

- 7.4.1.1. CIRCLE REVERSE GEAR

- 7.4.1.2. BLADE LIFTER BRACKET

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00