Komatsu GD530A-2EY, GD650A-2EY, GD670A-2EY, AW-2EY Motor Grader Operation and Maintenance Manual CEAM003900

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM003900

- Format: PDF

- Size: 5.9MB

- Number of Pages: 277

-

Model List:

- GD530A-2EY Motor Grader

- GD650A-2EY Motor Grader

- GD670A-2EY Motor Grader

- AW-2EY Motor Grader

- 1. MAIN MENU

- 2. COVER

- 3. INTRODUCTION

- 3.1. GENERAL

- 3.2. PIN LOCATIONS

- 3.3. SERIAL NUMBERS (S/N)

- 3.3.1. ENGINE S/N

- 3.3.2. TRANSMISSION S/N

- 3.3.3. CAB S/N

- 3.4. MACHINE SHIPPING

- 3.4.1. LONGDISTANCE SHIPPING

- 3.5. LIFTING THE MACHINE FOR TRANSPORT

- 3.6. MOVING A DISABLED MACHINE

- 3.6.1. METHODS OF TOWING

- 3.7. MACHINE STORAGE

- 3.7.1. PREPARING FOR STORAGE

- 3.7.2. SERVICING MACHINE DURING STORAGE

- 3.7.3. PREPARING FOR OPERATION

- 3.8. ROLLOVER PROTECTIVE STRUCTURE (ROPS)

- 3.9. TABLE OF CONTENTS

- 4. SAFETY

- 4.1. GENERAL PRECAUTIONS

- 4.2. SOUND AND VIBRATION

- 4.2.1. SOUND LEVLE FOR ENCLOSED CAB

- 4.2.2. VIBRATION LEVEL

- 4.3. OPERATIONAL SAFETY

- 4.3.1. GENERAL

- 4.3.2. BEFORE STARTING THE OPERATION

- 4.3.3. AFTER STARTING THE ENGINE

- 4.3.4. DURING OPERATION

- 4.3.5. PARKING

- 5. OPERATION

- 5.1. UNIVERAL SYMBOLS

- 5.2. PREPARATION FOR USE

- 5.3. OPERATIONAL CONTROLS AND INSTRUMENTATION

- 5.3.1. OPERATORS CAB AND CONTROLS

- 5.3.2. STEERING WHEEL AND SPINNER KNOB

- 5.3.3. CONTROL VALVE LEVERS

- 5.3.4. FOOT CONTROLS

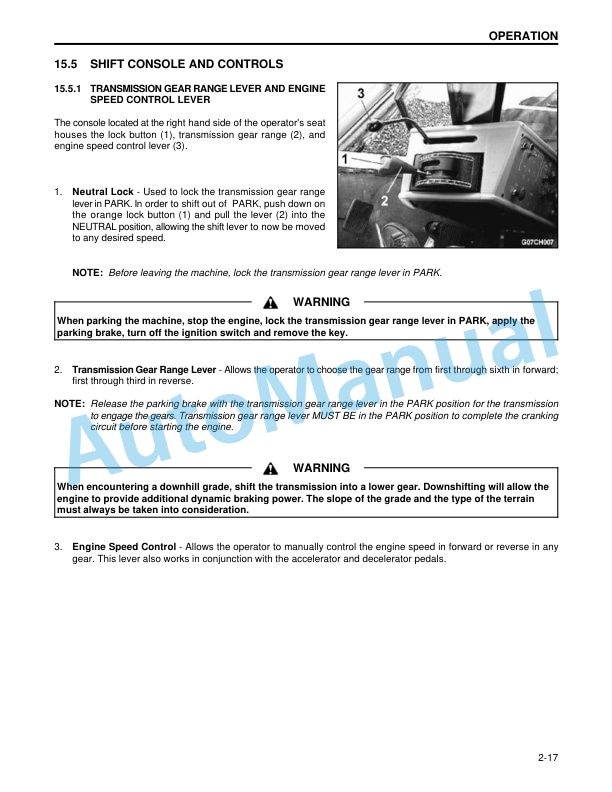

- 5.3.5. SHIFT CONSOLE AND CONTROLS

- 5.3.6. STEERING CONSOLE CONTROLS AND GAUGES

- 5.3.7. SPEEDOMETER AND WARNING LIGHT PANEL

- 5.3.8. OPERATORS SEAT

- 5.3.9. SUN SHADE

- 5.3.10. DOME LIGHTS AND FANS

- 5.3.11. MISCELLANEOUS GAUGES AND VALVES

- 5.3.12. ACCESS COVERS, HOOD SIDES

- 5.3.13. INTERACTING CONTROLS

- 5.4. PRECAUTIONS

- 5.4.1. PUSH STARTING

- 5.4.2. TOWING

- 5.4.3. ENTERING OR LEAVING THE CAB

- 5.4.4. MOUNTED EQUIPMENT OPERATION

- 5.4.5. BEFORE STARTING THE ENGINE

- 5.5. PREPARATION FOR ROADING OR JOB SITE OPERATION

- 5.5.1. ROADING CONFIGURATION

- 5.5.2. JOB SITE CONFIGURATION

- 5.5.3. ENGINE STARTING

- 5.5.4. PUTTING THE GRADER INTO OPERATION

- 5.6. EMERGENCY STOPPING

- 5.6.1. PRIMARY AND SECONDARY/EMERGENCY STOPPING SYSTEM

- 5.7. PARKING THE GRADER

- 5.7.1. ENGINE SHUTDOWN

- 5.8. TROUBLESHOOTING GUIDE

- 5.9. OPERATION UNDER UNUSUAL CONDITIONS

- 5.9.1. OPERATION IN EXTREME COLD

- 5.9.2. OPERATION IN EXTREME HEAT

- 5.9.3. OPERATION IN DUSTY OR SANDY AREAS

- 5.9.4. OPERATION IN RAINY OR HUMID CONDITIONS

- 5.9.5. OPERATION IN SALT WATER AREAS

- 5.9.6. OPERATION AT HIGH ALTITUDES

- 5.10. APPLICATION

- 5.10.1. LEANING WHEELS

- 5.10.2. ARTICULATION

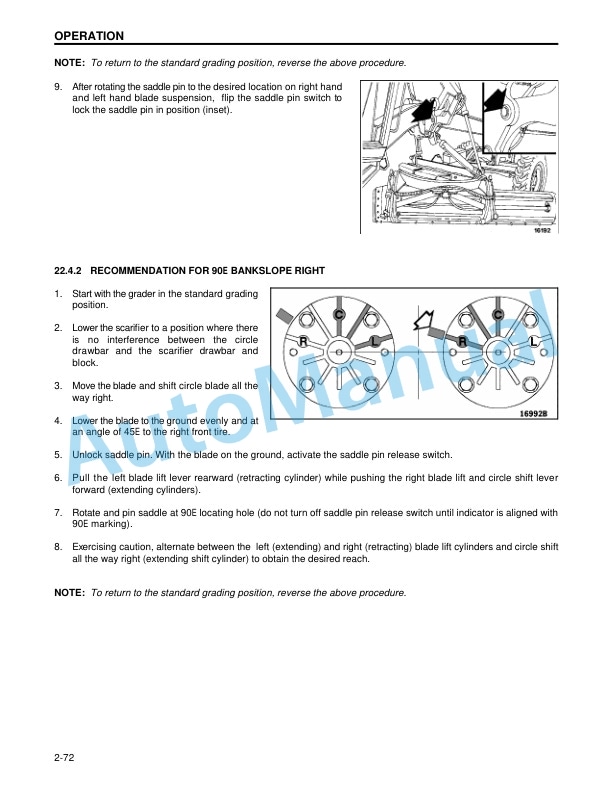

- 5.10.3. BANKS SLOPE OVERVIEW

- 5.10.4. SADDLE PIN INDICATORS

- 5.10.5. CIRCLE DRIVE

- 5.10.6. DITCHING

- 5.10.7. BANK SLOPING

- 5.10.8. CUTTING THE FLAT BOTTOM DITCH

- 5.10.9. SNOW REMOVAL

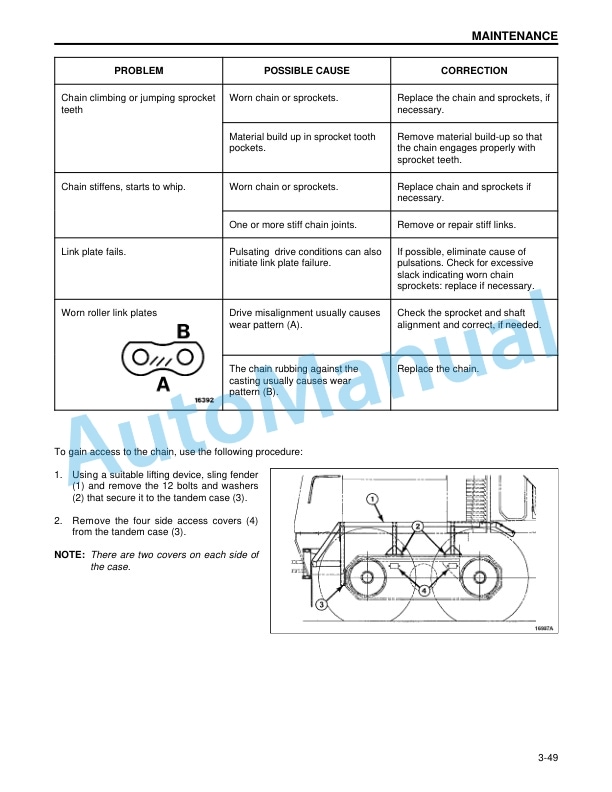

- 6. MAINTENANCE

- 6.1. MAINTENANCE

- 6.1.1. PRECAUTIONS

- 6.1.2. CARE OF HYDRAULIC SYSTEM

- 6.1.3. LUBRICATION INSTRUCTION

- 6.1.4. PERIODIC LUBRICATION

- 6.2. SERVICE PROCEDURE

- 6.2.1. EACH SHIFT/10 HOUR SERVICE

- 6.2.2. HOUR SERVICE

- 6.2.3. WEEKLY/50 HOUR SERVICE

- 6.2.4. HOUR SERVICE

- 6.2.5. MONTHLY/250 HOUR SERVICE

- 6.2.6. MONTHS/250 HOUR SERVICE

- 6.2.7. MONTHS/500 HOURS SERVICE

- 6.2.8. MONTHS/1,000 HOUR SERVICE

- 6.2.9. YEARLY/2,000 HOUR SERVICE

- 6.2.10. BIENNIAL/2,000 HOUR SERVICE

- 6.2.11. NOT SPECIFIED/AS REQUIRED SERVICE

- 6.3. OIL CHANGE RECOMMENDATIONS

- 6.4. OIL, FLUIDS AND GREASE

- 6.4.1. ENGINE OIL

- 6.4.2. GEAR LUBRICANT

- 6.4.3. HYDRAULIC TRANSMISSION FLUID

- 6.4.4. EXTREME PRESSURE GREASE

- 6.4.5. AUTOMATIC TRANSMISSION FLUID

- 6.5. WEAR LIMITS

- 6.6. FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 6.6.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 6.6.2. ENGINE OIL SPECIFICATIONS

- 6.6.3. TRANSMISSION, TORQUE CONVETER AND OIL COOLER, TANDEM DRIVE CASE, FRONT WHEEL DRIVE GEAR CASE, IF EQUIPPED AND HYDRAULIC

- 6.6.4. REAR DRIVE AXLE AND CIRCLE DRIVE BRAKE HOUSING OIL SPECIFICATIONS

- 6.6.5. DIESEL FUEL SPECIFICATIONS

- 6.6.6. COOLANT SPECIFICATIONS

- 6.6.7. CIRCLE DRIVE GEAR CASE OIL SPECIFICATIONS

- 6.7. VENTING AND PRIMING ENGINE

- 6.8. ENGINE CRANKCASE VENTILATION

- 6.8.1. KOMATSU S6D102E1 AND S6D114E1 DIESEL ENGINES

- 6.9. ELECTRICAL SYSTEM

- 6.9.1. BATTERIES

- 6.9.2. BATTERY CHARGING

- 6.10. SPEEDOMETER CALIBRATION

- 6.11. TIRES

- 6.11.1. DIRECTION OF TIRE TREADS

- 6.11.2. RIM CENTERING

- 6.11.3. TIRE INFLATION

- 6.11.4. TIRE MATCHING

- 6.11.5. TIRE SIZES

- 6.12. TURBOCHARGER

- 6.12.1. PRECAUTIONS

- 6.12.2. PRIMING

- 7. SPECIFICATIONS

- 7.1. GENERAL DESCRIPTION

- 7.1.1. BLADE SUSPENSION IDENTIFICATION

- 7.2. GENERAL SPECIFICATIONS

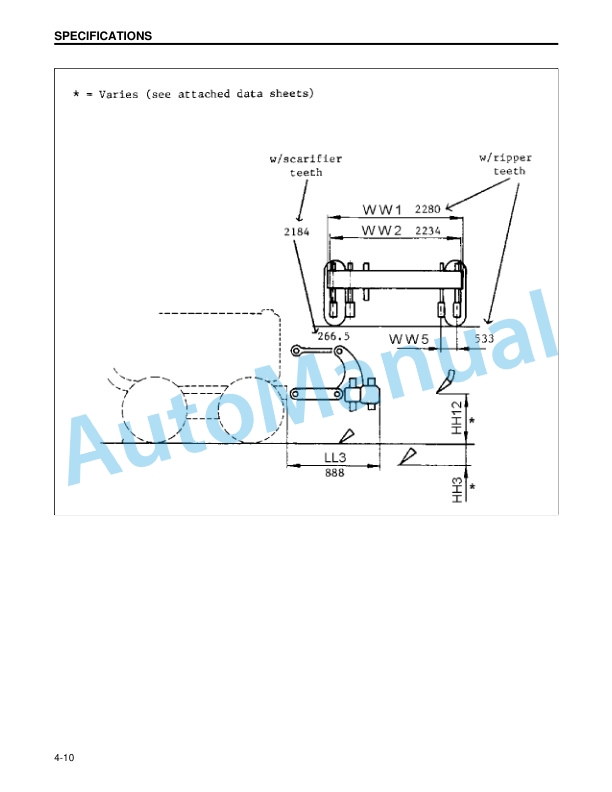

- 7.2.1. OVERALL DIMENSIONS

- 7.2.2. APPENDIX A

- 7.3. TORQUE VALUES FOR STANDARD ENGLISH FASTENERS

- 7.3.1. BOLT IDENTIFICATION CHART

- 7.3.2. TYPE 1, 5 AND 8 NONPHOSPHATE COATED HARDWARE

- 7.3.3. TYPE 8 PHOSPATE COATED HARDWARE

- 7.4. TORQUE VALUES FOR STANDARD METRIC FASTENERS

- 7.5. TORQUE VALUES FOR HOSE CLAMPS

- 7.6. TORQUE VALUES FOR SPLIT FLANGE CONNECTIONS

- 7.7. TORQUE VALUES FOR HYDRAULIC TUBES AND FITTINGS

- 7.8. SPECIFIC BOLT TORQUES

- 7.8.1. RIM TO WHEEL NUTS

- 7.8.2. RIM TO WHEEL NUTS (REAR)

- 7.8.3. FRONT AXLE TO FRAME PIVOT PIN CAPS

- 7.8.4. PLANETARY CARRIER

- 7.8.5. TIE ROD

- 7.8.6. STEERING CYLINDERS

- 7.8.7. STEERING YOKE TO AXLE

- 7.8.8. LEANING WHEEL CYLINDER TIE BAR

- 7.8.9. DRAWBAR TO FRAME

- 7.8.10. CIRCLE SHOE BOLTS (FOUR SHOE CIRCLE)

- 7.8.11. UPPER SLIDE RAIL WEAR PAD BOLTS

- 7.8.12. BLADE SHIFT CYLINDER

- 7.8.13. LIFT CYLINDER TO YOKE

- 7.8.14. YOKE TO SUSPENSION ARM

- 7.8.15. LOCK PIN CYLINDER

- 7.8.16. SUSPENSION ARM TO FRAME

- 7.8.17. SUSPENSION ARM TO LINK

- 7.8.18. BLADE PIVOT LOCK NUT

- 7.8.19. BLADE PITCH PIVOT SLOT

- 7.8.20. ARTICULATION CYLINDERS

- 7.8.21. ARTICULATION JOINT

- 7.8.22. CAB MOUNTS

- 7.8.23. REAR AXLE TO FRAME

- 7.8.24. BEARING HOUSING TO TANDEM CASE

- 7.8.25. TANDEM CASE TO AXLE

- 7.8.26. DRIVE SHAFT

- 7.8.27. PARKING BRAKE DISC TO FINAL DRIVE INPUT YOKE

- 7.8.28. PARKING BRAKE CALIPER (MICO) TO MOUNTING BRACKET

- 7.8.29. REAR TRANSMISSION SUPPORT

- 7.8.30. FRONT ENGINE SUPPORT

- 7.8.31. ALTERNATOR PULLEY NUT

- 7.9. DECALS

- 7.9.1. DECAL LOCATION

- 7.9.2. DECAL PART NUMBERS

- 7.9.3. INDIVIDUAL DECALS

- 8. OPTIONS, ATTACHMENTS

- 8.1. HEATING AND AIR CONDITIONING

- 8.1.1. HEATER/AIR CONDITIONING CONTROLS

- 8.1.2. AIR PRESSURIZATION RECICULATION VENTS

- 8.2. ALL WHEEL DRIVE

- 8.2.1. USE OF ALL WHEEL DRIVE

- 8.2.2. AWD CONTROLS AND INDICATOR LIGHTS

- 8.2.3. OPERATIONAL CHECKS

- 8.3. BATTERY CHARGING RECEPTICLE

- 8.4. COLDWEATHER STARTING AID

- 8.4.1. ETHER STARTING

- 8.4.2. ENGINE BLOCK HEATER

- 8.5. FIRE EXTINGUISHER

- 8.6. HYDRAULIC ACCUMULATOR (DRAWBAR AND CIRCLE OPTION)

- 8.7. HYDRAULIC LOCK/UNLOCK DIFFERENTIAL

- 8.8. FRONT BLADE ATTACHMENT

- 8.8.1. OPERATION

- 8.8.2. FRONT BLADE CONTROLS

- 8.8.3. INSTALLATION AND STORAGE OF THE SHEATH

- 8.8.4. FRONT BLADE REMOVAL AND INSTALLATION

- 8.9. FRONTMOUNTED SCARIFIER

- 8.9.1. FRONTMOUNTED SCARFIER SETUP

- 8.9.2. SCARFIER TOOTH REPLACEMENT

- 8.9.3. FRONTMOUNTED SCARFIER REMOVAL AND INSTALLATION

- 8.9.4. SCARFIER CONTROLS

- 8.10. MASTER SWITCH

- 8.11. REARMOUNTED RIPPER

- 8.11.1. REARMOUNTED RIPPER SETUP

- 8.11.2. RIPPER CONTROLS

- 8.11.3. RIPPER TOOTH REPLACEMENT

- 8.11.4. REARMOUNTED RIPPER HITCH PIN

- 8.11.5. REARMOUNTED RIPPER LOCK BAR

- 8.11.6. REARMOUNTED RIPPER REMOVAL AND INSTALLATION

- 8.12. SPARE TIRE

- 8.12.1. OPERATION AND SET UP

- 8.13. WHEEL CHOCKS

- 8.14. WORK LIGHT SOCKET

- 8.15. ELECTRIC FLOAT

- 8.15.1. FLOAT SWITCH

- 8.15.2. AUXILIARY FLOAT SWITCH

- 8.16. AM/FM/WB STEREO RADIO

- 8.16.1. CONTROLS

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738