Komatsu GD535-5 Motor Grader Shop Manual KEBM665002

$40.00

- Type Of Manual: Shop Manual

- Manual ID: KEBM665002

- Format: PDF

- Size: 96.8MB

- Number of Pages: 1550

Category: Komatsu Shop Manual PDF

-

Model List:

- GD535-5 Motor Grader

- 1. Notice of revision

- 2. Index and foreword

- 2.1. Index and foreword

- 2.1.1. Table of contents

- 2.1.2. Acronyms

- 2.1.3. Foreword and general information

- 3. Specification

- 3.1. Specification

- 3.1.1. Contents

- 3.1.2. Acronyms

- 3.1.3. Specifications

- 4. Structure and function

- 4.1. Structure and function

- 4.1.1. Contents

- 4.1.2. Acronyms

- 4.1.3. Engine and cooling system

- 4.1.4. Power train system

- 4.1.5. Steering system

- 4.1.6. Brake system

- 4.1.7. Undercarriage and frame

- 4.1.8. Hydraulic system

- 4.1.9. Work equipment system

- 4.1.10. Cab and its attachments

- 4.1.11. Electrical system

- 5. Standard value table

- 5.1. Standard value table

- 5.1.1. Contents

- 5.1.2. Acronyms

- 5.1.3. Standard value table

- 6. Testing and adjusting

- 6.1. Testing and adjusting

- 6.1.1. Contents

- 6.1.2. Acronyms

- 6.1.3. Tools for testing, adjusting, and troubleshooting

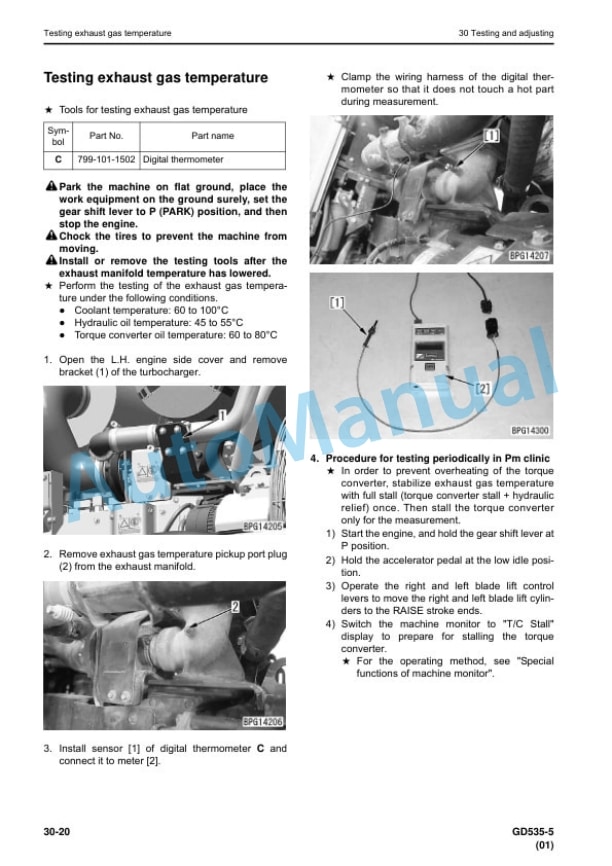

- 6.1.4. Engine and cooling system

- 6.1.5. Power train

- 6.1.6. Steering system

- 6.1.7. Brake system

- 6.1.8. Hydraulic system

- 6.1.9. Work equipment

- 6.1.10. Electrical system

- 6.1.11. Pm Clinic

- 7. Troubleshooting

- 7.1. Troubleshooting

- 7.1.1. Contents

- 7.1.2. Acronyms

- 7.1.3. Information related to troubleshooting

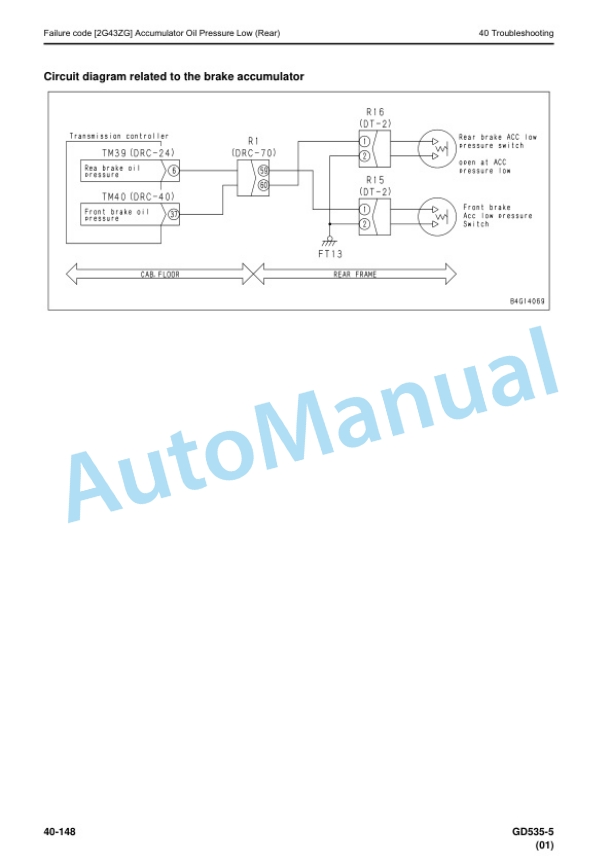

- 7.1.4. Troubleshooting by failure code (display of code)

- 7.1.5. Troubleshooting of electrical system (Emode)

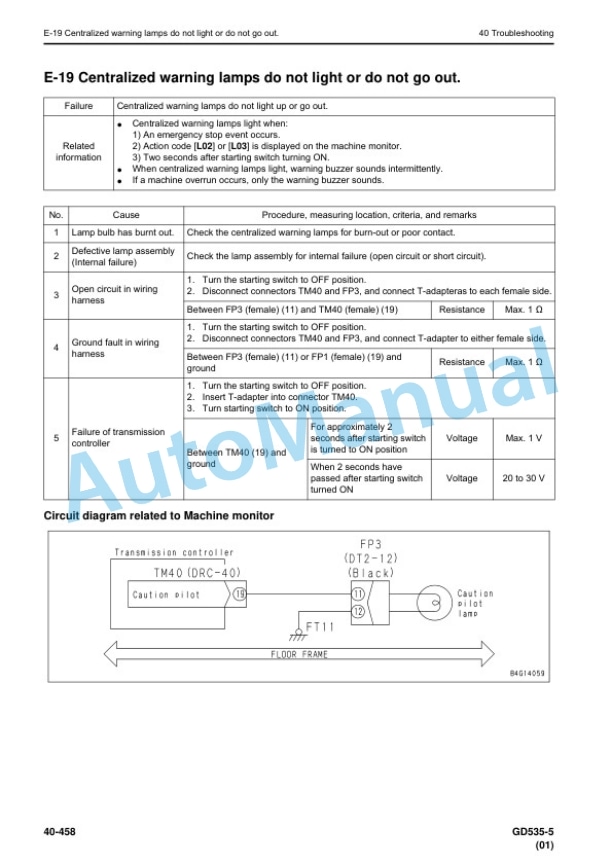

- 7.1.6. Troubleshooting of hydraulic and mechanical system (Hmode)

- 7.1.7. Troubleshooting of engine (Smode)

- 8. Disassembly and assembly

- 8.1. Contents

- 8.2. Acronyms

- 8.3. Related information on disassembly and assembly

- 8.3.1. How to read this manual

- 8.3.2. Coating materials list

- 8.3.3. Special tool list

- 8.3.4. Sketches of special tools

- 8.4. Engine and cooling system

- 8.4.1. Removal and installation of supply pump assembly

- 8.4.2. Removal and installation of injector assembly

- 8.4.3. Removal and installation of cylinder head assembly

- 8.4.4. Removal and installation of air conditioner compressor belt

- 8.4.5. Removal and installation of alternator belt

- 8.4.6. Removal and installation of engine front oil seal

- 8.4.7. Removal and installation of engine rear oil seal

- 8.4.8. Removal and installation of cooling fan pump assembly

- 8.4.9. Removal and installation of cooling fan and fan motor assembly

- 8.4.10. Removal and installation of radiator assembly

- 8.4.11. Removal and installation of aftercooler assembly

- 8.4.12. Removal and installation of power train oil cooler assembly

- 8.4.13. Removal and installation of fuel tank assembly

- 8.4.14. Removal and installation of engine hood assembly

- 8.4.15. Removal and installation of air conditioner compressor assembly

- 8.5. Power train

- 8.5.1. Removal and installation of engine, transmission, and torque converter assembly

- 8.5.2. Disconnection and connection of engine, transmission, and torque converter assembly

- 8.5.3. Disassembly and assembly of torque converter assembly

- 8.5.4. Disassembly and assembly of transmission assembly

- 8.5.5. Removal and installation of tandem drive and final drive assembly

- 8.5.6. Disassembly and assembly of tandem drive assembly

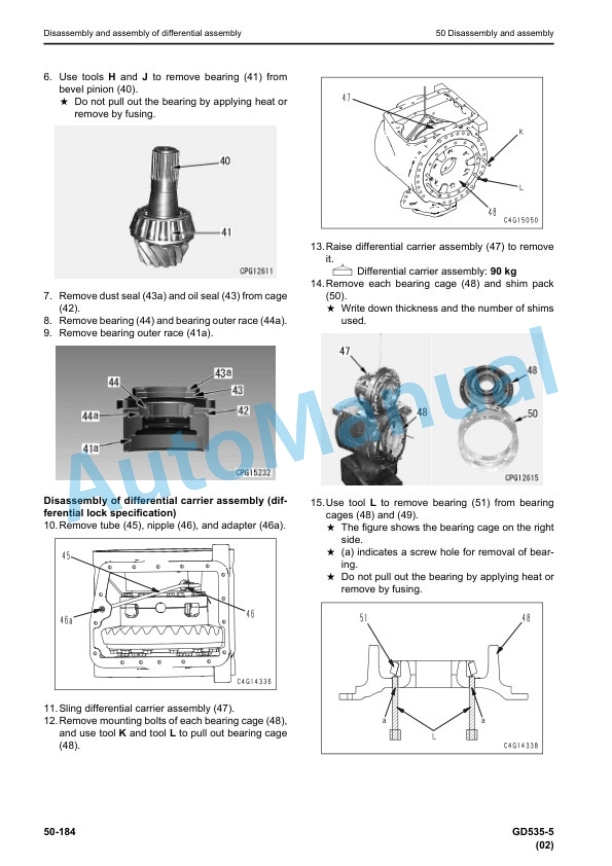

- 8.5.7. Disassembly and assembly of differential assembly

- 8.5.8. Disassembly and assembly of final drive assembly

- 8.6. Steering system

- 8.6.1. Removal and installation of Orbitrol valve assembly

- 8.7. Brake system

- 8.7.1. Disassembly and assembly of wheel brake assembly

- 8.8. Undercarriage and frame

- 8.8.1. Removal and installation of center hinge pin

- 8.9. Hydraulic system

- 8.9.1. Removal and installation of hydraulic tank, battery, and frame assembly

- 8.9.2. Removal and installation of hydraulic tank assembly

- 8.9.3. Removal and installation of control valve assembly

- 8.9.4. Disassembly and assembly of hydraulic cylinder assembly

- 8.10. Work equipment

- 8.10.1. Removal and installation of blade assembly

- 8.10.2. Removal and installation of circle drawbar assembly

- 8.10.3. Removal and installation of circle rotation gear assembly

- 8.10.4. Disassembly and assembly of circle rotation gear assembly

- 8.11. Cab and its attachments

- 8.11.1. Removal and installation of operators cab assembly

- 8.11.2. Removal and installation of operator cab glass (adhered glass)

- 8.11.3. Removal and installation of floor frame assembly

- 8.11.4. Removal and installation of operators cab and floor frame assembly

- 8.11.5. Removal and installation of air conditioner unit assembly

- 8.11.6. Removal and installation operators seat

- 8.11.7. Removal and installation seat belt

- 8.12. Electrical system

- 8.12.1. Removal and installation of engine controller assembly

- 8.12.2. Removal and installation of machine monitor assembly

- 8.12.3. Removal and installation of transmission controller assembly

- 8.12.4. Removal and installation of rearview camera

- 8.12.5. Removal and installation of KOMTRAX terminal assembly

- 8.13. Disassembly and assembly

- 9. Maintenance standard

- 9.1. Maintenance standard

- 9.1.1. Contents

- 9.1.2. Acronyms

- 9.1.3. Engine and cooling system

- 9.1.4. Power train system

- 9.1.5. Steering system

- 9.1.6. Brake system

- 9.1.7. Undercarriage and frame

- 9.1.8. Hydraulic system

- 9.1.9. Work equipment

- 10. Appendix

- 10.1. Appendix

- 10.1.1. Contents

- 10.1.2. Acronyms

- 10.1.3. Air conditioner system

- 10.1.4. Component parts of air conditioner system

- 10.1.5. Testing air leakage (duct)

- 10.1.6. Check temperature control function

- 10.1.7. Testing fresh/recirc air changeover

- 10.1.8. Test evaporator temperature sensor

- 10.1.9. Test relays

- 10.1.10. Check blower AMP

- 10.1.11. Connection of service tool

- 11. Diagrams and drawings

- 11.1. Contents

- 11.2. Acronyms

- 11.3. Hydraulic diagrams and drawings

- 11.3.1. Symbols used in hydraulic circuit diagrams

- 11.4. Hydraulic circuit diagram

- 11.4.1. Hydraulic circuit diagram (1/2)

- 11.4.2. Hydraulic circuit diagram (2/2)

- 11.5. Power train hydraulic circuit diagram

- 11.5.1. Power train hydraulic circuit diagram

- 11.6. Electrical diagrams and drawings

- 11.6.1. Symbols used in electric circuit diagrams

- 11.6.2. Chassis electric circuit diagram

- 11.6.3. Floor electric circuit diagram

- 11.7. Chassis electric circuit diagram

- 11.7.1. Chassis electric circuit diagram (1/5)

- 11.7.2. Chassis electric circuit diagram (2/5)

- 11.7.3. Chassis electric circuit diagram (3/5)

- 11.7.4. Chassis electric circuit diagram (4/5)

- 11.7.5. Chassis electric circuit diagram (5/5)

- 11.7.6. Floor electric circuit diagram (1/7)

- 11.7.7. Floor electric circuit diagram (2/7)

- 11.7.8. Floor electric circuit diagram (3/7)

- 11.7.9. Floor electric circuit diagram (4/7)

- 11.7.10. Floor electric circuit diagram (5/7)

- 11.7.11. Floor electric circuit diagram (6/7)

- 11.7.12. Floor electric circuit diagram (7/7)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00