Komatsu GD610, GS620, GD660, GD670 Series Shop Manual SEBMG6150110

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBMG6150110

- Format: PDF

- Size: 45.5MB

- Number of Pages: 706

Category: Komatsu Shop Manual PDF

-

Model List:

- GD610 Series

- GS620 Series

- GD660 Series

- GD670 Series

- 1. COVER

- 2. CONTENTS

- 3. ENGINE

- 3.1. TESTING AND ADJUSTING

- 3.1.1. TABLE OF JUDGEMENT STANDARD VALUE

- 3.1.2. TESTING AND ADJUSTING TOOL LIST

- 3.1.3. ADJUSTING VALVE CLEARANCE

- 3.1.4. MEASURING COMPRESSION PRESSURE

- 3.1.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.1.6. BLEEDING AIR FROM FUEL SYSTEM

- 3.1.7. ENGINE SPEED CONTROL

- 3.1.8. MEASURING EXHAUST GAS COLOR

- 3.1.9. TESTING AND ADJUSTING FAN BELT TENSION

- 3.1.10. MEASURING ENGINE OIL PRESSURE AND TEMPERATURE

- 3.2. DISASSEMBLY AND ASSEMBLY

- 3.2.1. RADIATOR

- 3.2.2. FUEL TANK(Incl.HYDRAULIC TANK)ASSEMBLY

- 4. POWER TRAIN

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. GENERAL

- 4.1.2. POWER TRAIN

- 4.1.3. HYDROSHIFT TRANSMISSION PIPING

- 4.1.4. HYDROSHIFT TRANSMISSION CONTROL

- 4.1.5. POWER TRAIN HYDRAULIC CIRCUIT SCHEMATICS

- 4.1.6. POWER TRAIN HYDRAULIC CIRCUIT DIAGRAM

- 4.1.7. JOINT

- 4.1.8. PTO(POWER TAKE OFF)

- 4.1.9. HYDROSHIFT TRANSMISSION AND TRANSFER

- 4.1.10. HYDROSHIFT TRANSMISSION PUMP

- 4.1.11. TRANSMISSION CONTROL VALVE

- 4.1.12. FINAL DRIVE

- 4.1.13. DIFFERENTIAL LOCK PIPING

- 4.1.14. TANDEM DRIVE

- 4.2. TESTING AND ADJUSTING

- 4.2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 4.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 4.2.3. INCHING PEDAL TRAVEL AND OPERATING FORCE

- 4.2.4. CHECKING OIL PRESSURE

- 4.2.5. MACHINE TYPE AND INCHING PRESSURE

- 4.2.6. TRANSMISSION CONTROL LEVER TRAVEL AND OPERATING FORCE

- 4.2.7. CHECKING DIFFERENTIAL LOCKING DEVICE OIL PRESSURE

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. TRANSMISSION PUMP

- 4.3.2. ENGINE(Incl.TRANSMISSION)ASSEMBLY

- 4.3.4. HYDROSHIFT TRANSMISSION

- 4.3.5. TRANSFER ASSEMBLY

- 4.3.6. TANDEM AND FINAL DRIVE

- 4.3.7. TANDEM,FINAL DRIVE ASSEMBLY

- 4.3.8. FINAL DRIVE

- 4.3.9. TANDEM,FINAL DRIVE ASSEMBLY

- 4.3.10. SIDE CASE ASSEMBLY

- 4.3.11. BEVEL GEAR ASSEMBLY

- 4.3.12. PINION ASSEMBLY

- 4.4. MAINTENANCE STANDARD

- 4.4.1. PTO,HYDROSHIFT TRANSMISSION AND TRANSFER

- 4.4.2. HYDROSHIFT TRANSMISSION CONTROL VALVE

- 4.4.3. TRANSMISSION PUMP

- 4.4.4. FINAL DRIVE

- 4.4.5. TANDEM DRIVE

- 5. STEERING SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. STEERING PIPING

- 5.1.2. STEERING CIRCUIT DIAGRAM

- 5.1.3. STEERING CONTROL VALVE

- 5.1.4. FRONT AXLE

- 5.1.5. STEERING CYLINDER

- 5.1.6. WHEEL

- 5.2. TESTING AND ADJUSTING

- 5.2.1. TABLE OF JUDGEMENT STANDARD

- 5.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 5.2.3. CHECKING STEERING WHEEL

- 5.2.4. CHECKING TIRE RUNOUT

- 5.2.5. CHECKING TIRE INFLATION PRESSURE

- 5.2.6. CHECKING TOEIN

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. FRONT AXLE ASSEMBLY

- 5.3.2. FRONT AXLE ASSEMBLY

- 5.3.3. STEEREMBLY VALVE

- 5.3.4. DOUBLE RELIEF VALVE

- 5.4. MAINTENANCE STANDARD

- 5.4.1. FRONT AXLE

- 5.4.2. STEERING CYLINDER

- 6. BRAKE SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. BRAKE PIPING

- 6.1.2. BRAKE CIRCUIT DIAGRAM

- 6.1.3. BOOST MASTER

- 6.1.4. AIR BRAKE PIPING

- 6.1.5. AIR BRAKE CIRCUIT SCHEMATICS

- 6.1.6. AIR BRAKE CIRCUIT DIAGRAM

- 6.1.7. AUTOMATIC DRAIN VALVE(IF EQUIPPED)

- 6.1.8. AIR DRIER(IF EQUIPPED)

- 6.1.9. WHEEL BRAKE

- 6.1.10. PARKING BRAKE

- 6.2. TESTING AND ADJUSTING

- 6.2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 6.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 6.2.3. CHECKING BRAKE PEDAL

- 6.2.4. AIR BLEEDING FROM BRAKE CIRCUIT

- 6.2.5. CHECKING PARKING BRAKE LEVER

- 6.2.6. CHECKING WEAR OF BRAKE DISC

- 6.3. DISASSEMBLY AND ASSEMBLY

- 6.4. MAINTENANCE STANDARD

- 6.4.1. WHEEL BRAKE

- 6.4.2. PARKING BRAKE

- 6.4.3. BOOST MASTER

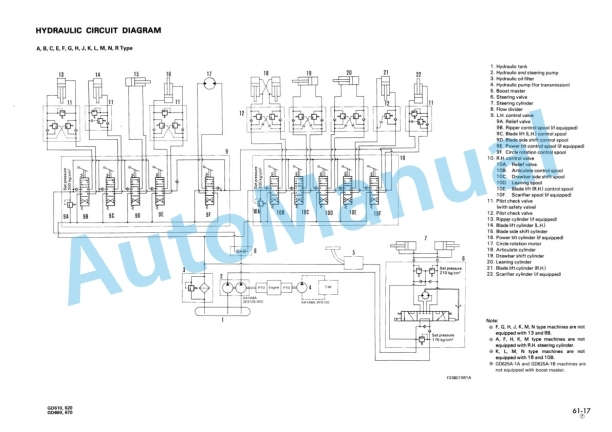

- 7. HYDRAULIC SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. HYDRAULIC PIPING

- 7.1.2. HYDUAULIC CONTROL

- 7.1.3. BLADE ACCUMULATOR SYSTEM(IF EQUIPPED)

- 7.1.4. HYDRAULIC CIRCUIT DIAGRAM

- 7.1.5. OIL COOLING FLOW

- 7.1.6. HYDRAULIC PUMP

- 7.1.7. CIRCLE ROTATION MOTOR

- 7.1.8. CONTROL VALVE

- 7.1.9. FLOW DIVIDER

- 7.1.10. PILOT CHECK VALVE

- 7.1.11. FLOW CONTROL VALVE

- 7.1.12. HYDRAULIC CYLINDER

- 7.2. TESTING AND ADJUSTING

- 7.2.1. TROUBLESHOOTING(CIRCLE ROTATION MOTOR)

- 7.3. DISASSEMBLY AND ASSEMBLY

- 7.3.1. HYDRAULIC PUMP(Incl.STEERING PUMP)

- 7.3.2. BLADE LIFT CYLINDER

- 7.3.3. DRAWBAR SHIFT CYLINDER

- 7.3.4. BLADE SIDE SHAFT CYLINDER

- 7.3.5. ARTICULATE CYLINDER

- 7.3.6. SCARIFIER CYLINDER

- 7.3.7. POWER TILT CYLINDER

- 7.3.8. REAR MOUNT RIPPER CYLINDER

- 7.3.9. HYDRAULIC CYLINDER

- 7.3.10. CIRCLE ROTATION MOTOR

- 7.4. MAINTENANCE STANDARD

- 7.4.1. HYDRAULIC PUMP

- 7.4.2. CONTROL VALVE

- 7.4.3. HYDRAULIC CYLINDER

- 8. WORK EQUIPMENT

- 8.1. STRUCTURE AND FUNCTION

- 8.1.1. DRAWBAR AND LIFTER

- 8.1.2. BLADE

- 8.1.3. CIRCLE ROTATION GEAR

- 8.1.4. FRAME

- 8.1.5. SCARIFIER(IF EQUIPPED)

- 8.1.6. REAR MOUNTING RIPPER(IF EQUIPPED)

- 8.2. TESTING AND ADJUSTING

- 8.2.1. TABLE OF JUDGEMENT STANDARD

- 8.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 8.2.3. CHECKING CONTROL LEVER

- 8.2.4. CHECKING HYDRAULIC OIL TEMPERATURE

- 8.2.5. CHECKING HYDRAULIC OIL PRESSURE

- 8.2.6. HYDRAULIC DRIFT

- 8.2.7. CHARGING BLADE ACCUMULATOR WITH GAS

- 8.2.8. ADJUSTMENT OF CIRCLE GUIDE

- 8.3. DISASSEMBLY AND ASSEMBLY

- 8.3.1. BLADE ASSEMBLY

- 8.3.2. CIRCLE ROTATION GEAR

- 8.3.3. REAR MOUNT RIPPER ASSEMBLY

- 8.3.4. CIRCLE ROTATION GEAR ASSEMBLY

- 8.4. MAINTENANCE STANDARD

- 8.4.1. DRAWBAR AND LIFTER

- 8.4.2. BLADE

- 8.4.3. CIRCLE ROTATION GEAR

- 8.4.4. SCARIFIER(IF EQUIPPED)

- 8.4.5. REAR MOUNT RIPPER(IF EQUIPPED)

- 9. ELECTRIC AND ELECTRONIC SYSTEM

- 9.1. STRUCTURE AND FUNCTION

- 9.1.1. ELECTRICAL CIRCUIT DIAGRAM

- 9.1.2. CIRCUIT DIAGRAM OF CAB

- 9.1.3. ELECTRONIC VEHICLE MONITORING SYSTEM(EVMS)

- 9.1.4. ADJUSTING SPEEDOMETER MODULE(IF EQUIPPED)

- 9.2. TESTING AND ADJUSTING

- 9.2.1. TABLE OF ELECTRICAL JUDGEMENT STANDARD VALUE

- 9.2.2. CIRCUIT DIAGRAM

- 9.2.3. CONNECTOR POSITION FOR TROUBLESHOOTING

- 9.2.4. POSITION OF CONNECTOR(D TYPE)

- 9.2.5. POSITION OF CONNECTOR(P,Q TYPE)

- 9.2.6. CONNECTOR TERMINAL NUMBERS

- 9.2.7. PROCEDURE FOR TROUBLESHOOTING

- 9.2.8. CHECKS BEFORE TROUBLESHOOTING

- 9.2.9. METHOD OF USING TROUBLESHOOTING CHART

- 9.2.10. TROUBLESHOOTING CHART FOR ELECTRONIC VEHICLE MONITORING SYSTEM(M1 TO M18)(D TYPE)

- 9.2.11. TROUBLESHOOTING CHART FOR ELECTRONIC VEHICLE MONITORING SYSTEM(M1 TO M22)(P,Q TYPE)

- 10. OTHERS

- 10.1. AIR CONDITIONER

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00