Komatsu GD655-7 Motor Grader Operation and Maintenance Manual TEN01038-03

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: TEN01038-03

- Format: PDF

- Size: 25.9MB

- Number of Pages: 577

-

Model List:

- GD655-7 Motor Grader

- 1. COVER

- 2. FOREWORD

- 2.1. CONTENTS

- 2.2. FOREWORD

- 2.3. SAFETY INFORMATION

- 2.4. INTRODUCTION

- 2.5. ENGINE TECHNOLOGY TO CONFORM EXHAUST GAS EMISSION

- 2.6. MACHINE INFORMATION

- 2.6.1. LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN) AND MACHINE SERIAL NO. PLATE

- 2.6.2. LOCATION OF ENGINE NUMBER PLATE

- 2.6.3. SERVICE METER LOCATION

- 2.6.4. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 2.7. ABBREVIATION LIST

- 3. SAFETY

- 3.1. SAFETY LABELS

- 3.2. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 3.2.1. PRECAUTIONS BEFORE STARTING OPERATION

- 3.2.2. PREPARATIONS FOR SAFE OPERATION

- 3.2.3. ACTIONS IF FIRE OCCURS

- 3.2.4. PRECAUTIONS TO PREVENT FIRE

- 3.2.5. PRECAUTIONS WHEN YOU GET ON OR OFF MACHINE

- 3.2.6. PRECAUTIONS FOR MACHINE AND JOBSITE

- 3.3. PRECAUTIONS FOR OPERATION

- 3.3.1. PRECAUTIONS FOR JOBSITE

- 3.3.2. START ENGINE

- 3.3.3. PRECAUTIONS FOR OPERATION

- 3.3.4. PRECAUTIONS FOR TRANSPORTATION

- 3.3.5. TOWING AND BEING TOWED

- 3.4. PRECAUTIONS FOR MAINTENANCE

- 3.4.1. PRECAUTIONS BEFORE YOU START INSPECTION AND MAINTENANCE

- 3.4.2. PRECAUTIONS FOR CHECK AND MAINTENANCE

- 3.5. PRECAUTIONS FOR TIRE

- 3.6. PRECAUTIONS FOR DEF

- 4. OPERATION

- 4.1. GENERAL VIEW

- 4.1.1. MACHINE EQUIPMENT NAME

- 4.1.2. CONTROLS AND GAUGES NAMES

- 4.1.3. NAMES OF OTHER EQUIPMENT

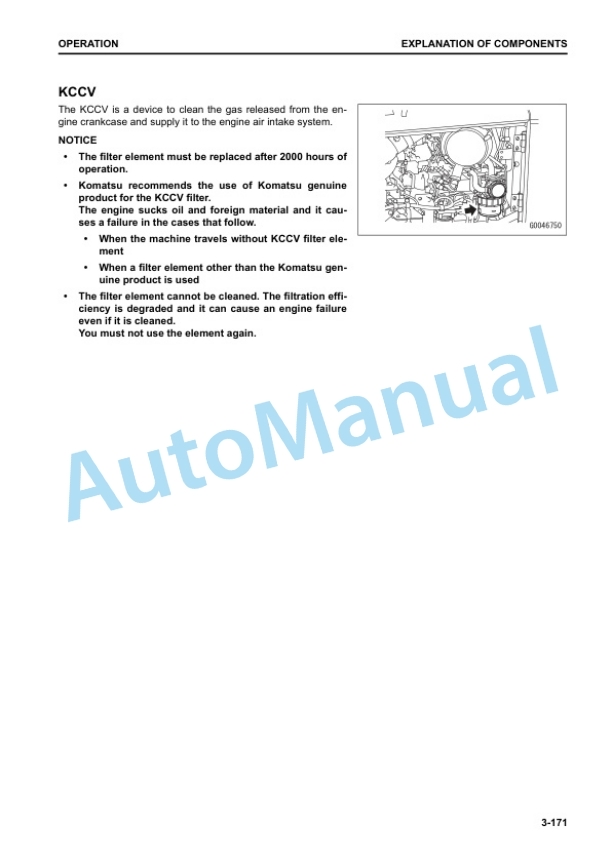

- 4.2. EXPLANATION OF COMPONENTS

- 4.2.1. MACHINE MONITOR EQUIPMENT

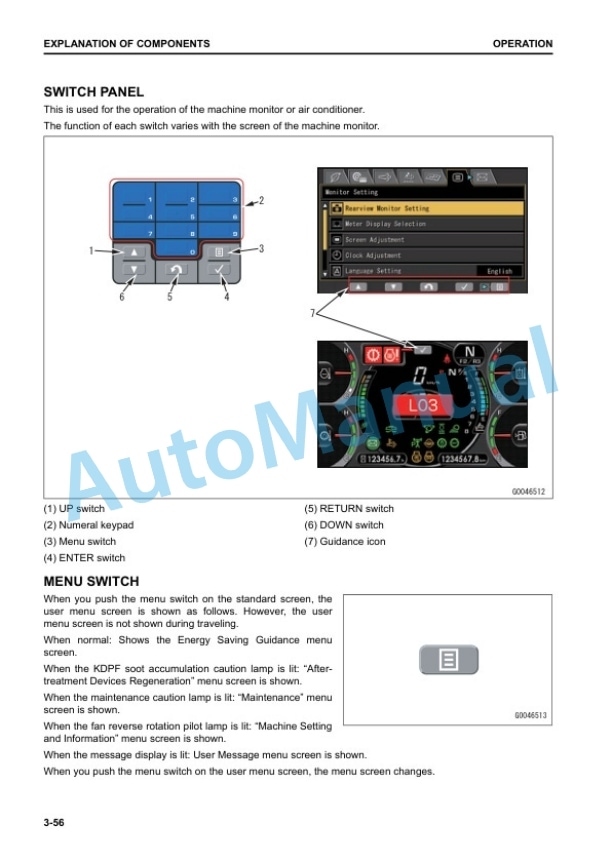

- 4.2.2. NAMES OF SWITCH PANEL EQUIPMENT

- 4.2.3. CONTROL LEVERS AND PEDALS

- 4.2.4. OTHER EQUIPMENT

- 4.3. MACHINE OPERATIONS AND CONTROLS

- 4.3.1. CHECKS AND ADJUSTMENT BEFORE YOU START ENGINE

- 4.3.2. START ENGINE

- 4.3.3. OPERATIONS AND CHECKS AFTER YOU START ENGINE

- 4.3.4. STOP ENGINE

- 4.3.5. CHECK AFTER YOU STOP ENGINE

- 4.3.6. START MACHINE (TRAVEL FORWARD AND REVERSE, GEAR SHIFT) AND STOP MACHINE

- 4.3.7. STEER MACHINE

- 4.3.8. OPERATE WORK EQUIPMENT

- 4.3.9. WORK PRECAUTIONS

- 4.3.10. ADJUST WORK EQUIPMENT POSTURE

- 4.3.11. BLADE ACCUMULATOR

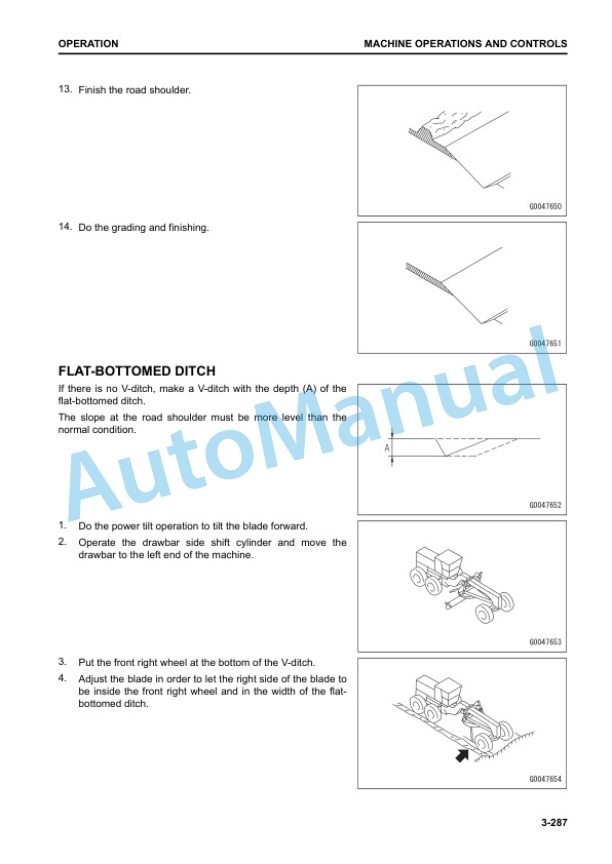

- 4.3.12. RECOMMENDED APPLICATIONS

- 4.3.13. PARK MACHINE

- 4.3.14. CHECK AFTER YOU FINISH WORK

- 4.3.15. LOCK

- 4.3.16. TIRES

- 4.4. AIR CONDITIONER

- 4.4.1. AIR CONDITIONER EQUIPMENT

- 4.4.2. OPERATE AIR CONDITIONER

- 4.5. RADIO

- 4.5.1. RADIO EQUIPMENT

- 4.5.2. OPERATE RADIO

- 4.5.3. RADIO SETTING

- 4.6. TRANSPORTATION

- 4.6.1. SELECT TRANSPORTATION METHOD

- 4.6.2. PRECAUTIONS WHEN YOU TRANSPORT MACHINE

- 4.6.3. LOAD AND UNLOAD A TRAILER

- 4.6.4. SECURE MACHINE

- 4.6.5. LIFT MACHINE

- 4.7. COLD WEATHER OPERATION

- 4.7.1. COLD WEATHER OPERATION INFORMATION

- 4.7.2. PRECAUTIONS AFTER DAILY WORK COMPLETION IN COLD WEATHER

- 4.7.3. IN COLD WEATHER

- 4.7.4. AFTER COLD WEATHER SEASON

- 4.8. LONGTERM STORAGE PRECAUTIONS

- 4.8.1. PREPARATION FOR LONGTERM STORAGE

- 4.8.2. MAINTENANCE DURING LONGTERM STORAGE

- 4.8.3. START MACHINE AFTER LONGTERM STORAGE

- 4.9. TROUBLES AND ACTIONS

- 4.9.1. ACTIONS WHEN YOU RUN OUT OF FUEL

- 4.9.2. IF LEANING PIPING IS BROKEN

- 4.9.3. USE LEANING STOPPER

- 4.9.4. PRECAUTIONS FOR TOWING MACHINE

- 4.9.5. PRECAUTIONS FOR DISCHARGED BATTERY

- 4.9.6. LOWER WORK EQUIPMENT (RELEASING WORK EQUIPMENT HYDRAULIC PRESSURE) WHILE ENGINE IS OFF

- 4.9.7. OTHER TROUBLE

- 5. MAINTENANCE

- 5.1. PRECAUTIONS FOR MAINTENANCE

- 5.2. MAINTENANCE INFORMATION

- 5.2.1. OIL, FUEL, AND COOLANT

- 5.2.2. BATTERY TERMINAL

- 5.2.3. ELECTRICAL COMPONENTS

- 5.3. STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS

- 5.4. MAINTENANCE SCHEDULE

- 5.4.1. MAINTENANCE INTERVAL TABLE

- 5.5. MAINTENANCE PROCEDURE

- 5.5.1. INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

- 5.5.2. INITIAL 1000 HOURS MAINTENANCE (ONLY AFTER THE FIRST 1000 HOURS)

- 5.5.3. WHEN REQUIRED

- 5.5.4. CHECK BEFORE YOU START OPERATION

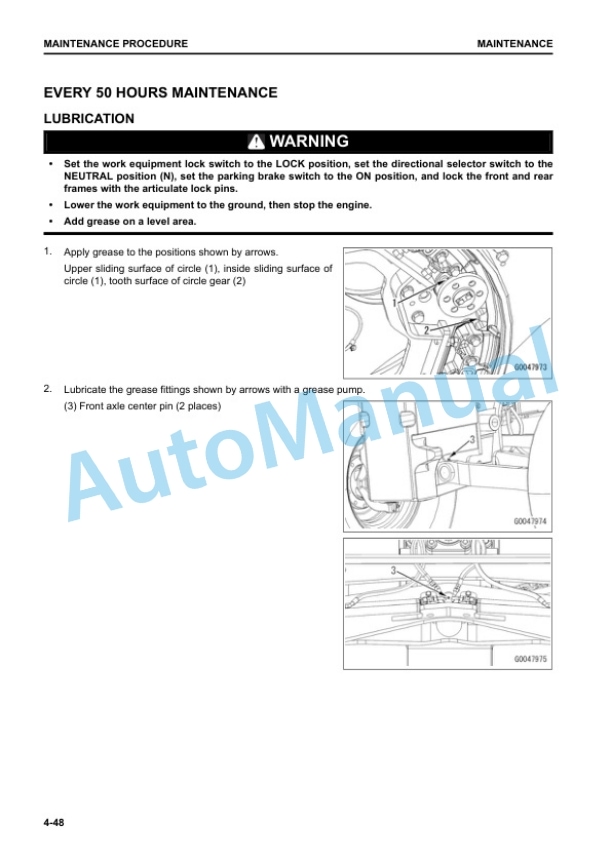

- 5.5.5. EVERY 50 HOURS MAINTENANCE

- 5.5.6. EVERY 250 HOURS MAINTENANCE

- 5.5.7. EVERY 500 HOURS MAINTENANCE

- 5.5.8. EVERY 1000 HOURS MAINTENANCE

- 5.5.9. EVERY 2000 HOURS MAINTENANCE

- 5.5.10. EVERY 4000 HOURS MAINTENANCE

- 5.5.11. EVERY 4500 HOURS MAINTENANCE

- 5.5.12. EVERY 8000 HOURS MAINTENANCE

- 5.5.13. EVERY 9000 HOURS MAINTENANCE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 7. ATTACHMENTS AND OPTIONS

- 7.1. MACHINES WITH ICT DEVICES

- 7.1.1. PRECAUTIONS FOR MACHINES WITH ICT DEVICES

- 7.2. MACHINE WITH CROSS SLOPE SYSTEM

- 7.2.1. OVERVIEW OF MACHINE WITH CROSS SLOPE SYSTEM

- 7.2.2. PRECAUTIONS FOR MACHINE WITH CROSS SLOPE SYSTEM

- 7.2.3. COMPONENTS ON MACHINES WITH CROSS SLOPE SYSTEM

- 7.2.4. USE CROSS SLOPE SYSTEM

- 8. REPLACEMENT PARTS

- 8.1. DEFINED LIFE PARTS

- 8.1.1. DEFINED LIFE PARTS LIST

- 8.2. CONSUMABLE PARTS

- 8.2.1. CONSUMABLE PARTS LIST

- 8.3. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 8.3.1. LUBRICATION CHART

- 8.3.2. USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 8.3.3. RECOMMENDED BRANDS AND QUALITIES OTHER THAN KOMATSU GENUINE OILS

- 9. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738