Komatsu GD705A-4 Motor Grader Shop Manual SEBM022104

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM022104

- Format: PDF

- Size: 21.1MB

- Number of Pages: 429

Category: Komatsu Shop Manual PDF

-

Model List:

- GD705A-4 Motor Grader

- 0.0.1. GENERAL PRECAUTIONS

- 0.0.2. PRECAUTIONS FOR WORK

- 0.0.3. PRECAUTIONS DURING WORK

- 1. FOREWARD

- 1.1. GENERAL

- 1.2. HOW TO READ THE SHOP MANUAL

- 1.2.1. VOLUMES

- 1.2.2. DISTRIBUTION AND UPDATING

- 1.2.3. FILING METHOD

- 1.2.4. REVISED EDITION MARK

- 1.2.5. REVISIONS

- 1.2.6. SYMBOLS

- 1.3. HOISTING INSTRUCTIONS

- 1.3.1. HOISTING

- 1.3.2. WIRE ROPES

- 1.4. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 1.5. COATING MATERIALS

- 1.6. STANDARD TIGHTENING TORQUE

- 1.6.1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS

- 1.6.2. TIGHTENING TORQUE OF HOSE NUTS

- 1.6.3. TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

- 1.6.4. TIGHTENING TORQUE FOR FLARED NUTS

- 1.6.5. TIGHTENING TORQUE FOR 102 ENGINE SERIES (BOLTS AND NUTS)

- 1.6.6. TIGHTENING TORQUE FOR 102 ENGINE SERIES (EYE JOINTS)

- 1.6.7. TIGHTENED TORQUE FOR 102 ENGINE SERIES (TAPERED SCREWS)

- 1.7. ELECTRIC WIRE CODE

- 1.7.1. CLASSIFICATION BY THICKNESS

- 1.7.2. CLASSIFICATION BY COLOR AND CODE

- 1.8. CONVERSION TABLES

- 1.8.1. METHOD OF USING THE CONVERSION TABLE

- 1.9. UNITS

- 2. GENERAL

- 2.1. GENERAL ASSEMBLY DRAWING

- 2.2. SPECIFICATIONS

- 2.3. WEIGHT TABLE

- 2.4. LIST OF LUBRICANT AND WATER

- 3. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 3.1. ENGINE MOUNTING

- 3.2. RADIATOR

- 3.3. FUEL TANK PIPING

- 3.4. ACCELERATOR CONTROL

- 3.5. POWER TRAIN

- 3.6. DAMPER

- 3.7. PTO (POWER TAKE OFF)

- 3.8. HYDROSHIFT TRANSMISSION

- 3.9. HYDROSHIFT TRANSMISSION CONTROL VALVE

- 3.10. HYDROSHIFT TRANSMISSION PIPING

- 3.11. LUBRICATION RELIEF VALVE

- 3.12. TRANSMISSION PUMP

- 3.13. TRANSMISSION CONTROL

- 3.14. DRIVE SHAFT

- 3.15. FINAL DRIVE

- 3.16. TANDEM DRIVE

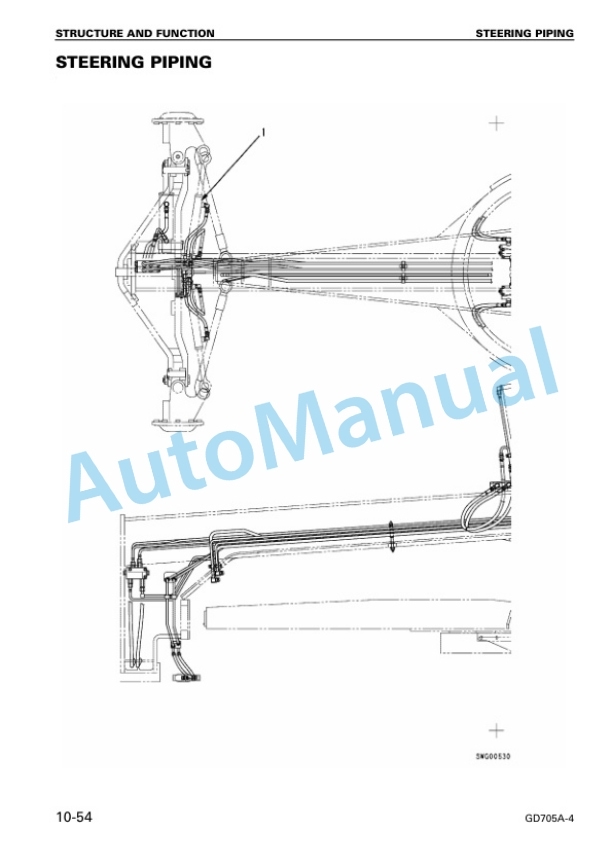

- 3.17. STEERING PIPING

- 3.18. STEERING WHEEL

- 3.19. STEERING VALVE (ORBIT ROLL TYPE)

- 3.20. STEERING SYSTEM

- 3.21. STEERING PUMP

- 3.22. STEERING CYLINDER

- 3.23. FRONT AXLE

- 3.24. WHEEL

- 3.25. BRAKE PIPING

- 3.26. DISC BRAKE SYSTEM

- 3.27. PRESSURE SWITCH

- 3.28. AUTOMATIC DRAIN VALVE

- 3.29. AIR DRIER

- 3.30. AIR COMPRESSOR

- 3.31. PARKING BRAKE

- 3.32. PARKING BRAKE CONTROL

- 3.33. HYDRAULIC PIPING

- 3.34. MAIN CONTROL VALVE

- 3.35. PILOT CHECK VALVE

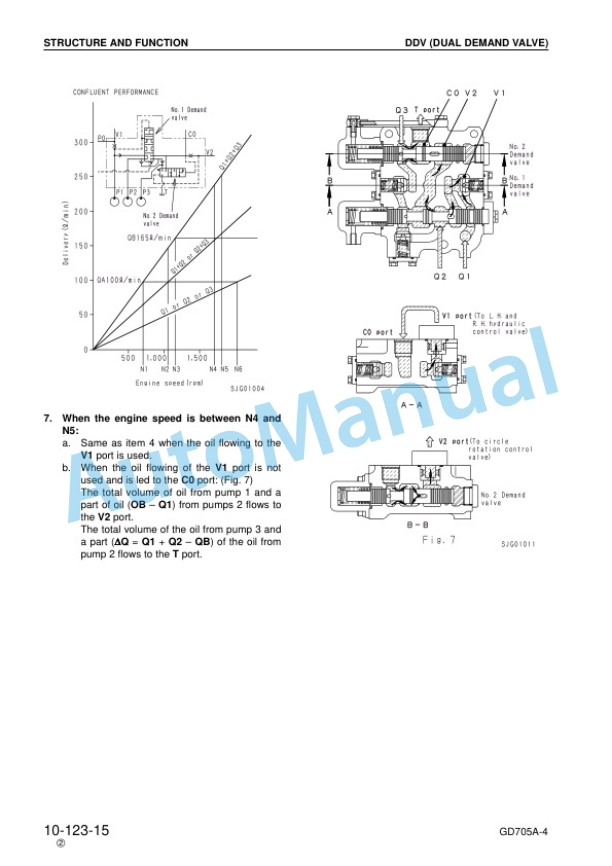

- 3.36. DDV (DUAL DEMAND VALVE)

- 3.37. FLOW DIVIDER VALVE

- 3.38. HYDRAULIC PUMP

- 3.39. CIRCLE ROTATION MOTOR

- 3.40. HYDRAULIC CYLINDER

- 3.41. WORK EQUIPMENT CONTROL

- 3.42. WORK EQUIPMENT

- 4. TESTING AND ADJUSTING

- 4.1. STANDARD VALUE TABLE FOR ENGINE

- 4.2. STANDARD VALUE TABLE FOR CHASSIS

- 4.3. TESTING AND ADJUSTING

- 4.3.1. TESTING AND ADJUSTING TOOL LIST (FOR ENGINE)

- 4.3.2. TESTING AND ADJUSTING VALVE CLEARANCE

- 4.3.3. MEASURING COMPRESSION PRESSURE

- 4.3.4. MEASURING BLOWBY

- 4.3.5. TESTING AND ADJUSTING FAN BELT TENSION

- 4.3.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 4.3.7. INCHING PEDAL STROKE AND OPERTING FORCE

- 4.3.8. HYDROSHIFT TRANSMISSION

- 4.3.9. TRANSMISSION CONTROL LEVER STROKE AND OPERATING FORCE

- 4.3.10. ADJUSTING F/R CONTROL CABLE

- 4.3.11. ADJUSTING TRANSMISSION CONTROL LINKAGE

- 4.3.12. STEERING WHEEL

- 4.3.13. CHECKING TIRE PLAY

- 4.3.14. CHECKING TIRE AIR PRESSURE

- 4.3.15. CHECKING TOEIN

- 4.3.16. CHECKING PARKING BRAKE LEVER STROKE AND OPERATING FORCE

- 4.3.17. CHECKING WEAR OF BRAKE DISC

- 4.3.18. CHECKING HYDRAULIC OIL PRESSURE

- 4.3.19. CHECKING HYDRAULIC OIL TEMPERATURE

- 4.3.20. WORK EQUIPMENT CONTROL LEVER STROKE AND OPERATING FORCE

- 4.3.21. HYDRAULIC DRIFT OF BLADE

- 4.3.22. MEASURING BLADE SINKING AMOUNT

- 4.4. TROUBLESHOOTING

- 4.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 4.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 4.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 4.4.4. CHECKS BEFORE TROUBLESHOOTING

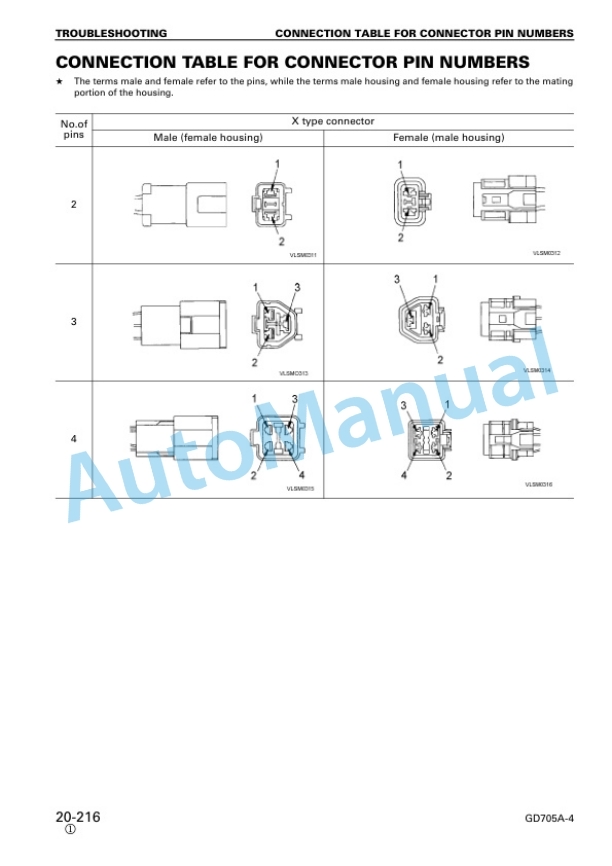

- 4.4.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 4.4.6. CONNECTOR TABLE FOR CONNECTOR PIN NUMBERS

- 4.4.7. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 4.4.7.1. E1 ENGINE DOES NOT START

- 4.4.7.2. E2 ELECTRIC SYSTEM DOES NOT WORK

- 4.4.7.3. E3 SERVICE METER DOES NOT WORK

- 4.4.7.4. E4 WATER TEMPERATURE GUAGE INDICATES ABNORMALLY HIGH TEMPERATURE

- 4.4.7.5. E5 WATER TEMPERATURE GUAGE DOES NOT WORK

- 4.4.7.6. E6 FUEL GUAGE ALWAYS INDICATES FULL

- 4.4.7.7. E7 FUEL GUAGE DOES NOT WORK

- 4.4.7.8. E8 ENGINE OIL PRESSURE GUAGE INDICATES ABNORMALLY HIGH PRESSURE

- 4.4.7.9. E9 ENGINE OIL PRESSURE GUAGE DOES NOT WORK

- 5. DISASSEMBLY AND ASSEMBLY

- 5.1. ALTERNATOR ASSEMBLY

- 5.1.1. REMOVAL AND INSTALLATION

- 5.2. STARTING MOTOR AND ASSEMBLY

- 5.2.1. REMOVAL AND INSTALLATION

- 5.3. OIL COOLER ASSMBLY

- 5.3.1. REMOVAL AND INSTALLATION

- 5.4. HYDROSHIFT TRANSMISSION OIL COOLER ASSEMBLY

- 5.4.1. REMOVAL AND INSTALLATION

- 5.5. WATER PUMP ASSEMBLY

- 5.5.1. REMOVAL AND INSTALLATION

- 5.6. FUEL INJECTION PUMP ASSEMBLY

- 5.6.1. REMOVAL AND INSTALLATION

- 5.7. AIR COMPRESSOR ASSEMBLY

- 5.7.1. REMOVAL AND INSTALLATION

- 5.8. TURBOCHARGER ASSEMBLY

- 5.8.1. REMOVAL AND INSTALLATION

- 5.9. NOZZLE HOLDER ASSEMBLY

- 5.9.1. REMOVAL AND INSTALLATION

- 5.10. CYLINDER HEAD ASSEMBLY

- 5.10.1. REMOVAL

- 5.10.2. INSTALLATION

- 5.11. RADIATOR ASSEMBLY

- 5.11.1. REMOVAL

- 5.11.2. INSTALLATION

- 5.12. FUEL TANK ASSEMBLY (INC. HYDRAULIC TANK)

- 5.12.1. REMOVAL

- 5.12.2. INSTALLATION

- 5.13. ENGINE ASSEMBLY (INC. TRANSMISSION)

- 5.13.1. REMOVAL

- 5.13.2. INSTALLATION

- 5.14. HYDROSHIFT TRANSMISSION ASSEMBLY

- 5.14.1. DISASSEMBLY

- 5.14.2. ASSEMBLY

- 5.15. CAGE AND REVERSE CARRIER ASSEMBLY

- 5.15.1. DISASSEMBLY AND ASSEMBLY

- 5.16. T SPEED AND 2ND SPEED CARRIER ASSEMBLY

- 5.16.1. DISASSEMBLY

- 5.16.2. ASSEMBLY

- 5.17. HIGH REVOLUTION CLUTCH ASSEMBLY

- 5.17.1. DISASSEMBLY

- 5.17.2. ASSEMBLY

- 5.18. PLANETARY GEAR

- 5.18.1. DISASSEMBLY AND ASSEMBLY

- 5.19. HYDROSHIFT TRANSMISSION PUMP ASSEMBLY

- 5.19.1. REMOVAL AND INSTALLATION

- 5.20. TANDEM AND FINAL DRIVE ASSEMBLY

- 5.20.1. REMOVAL

- 5.20.2. INSTALLATION

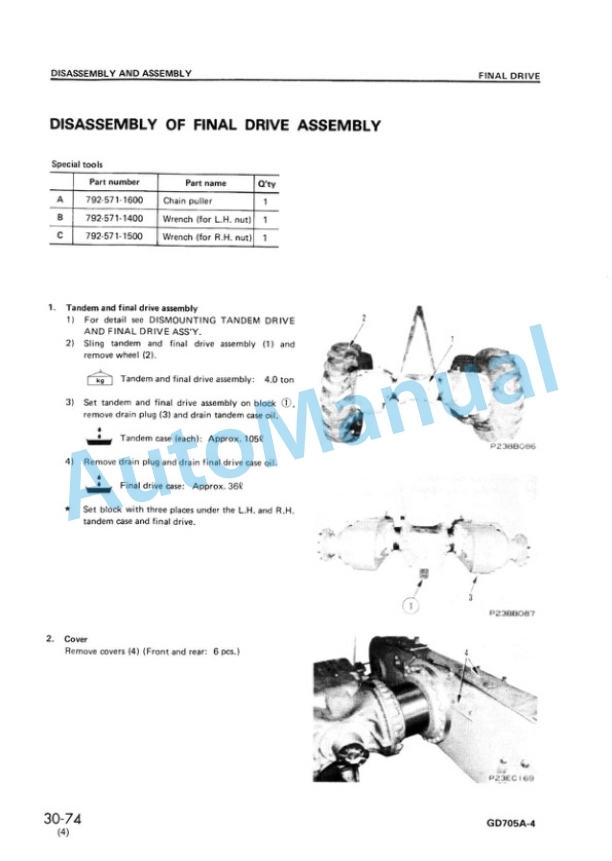

- 5.21. FINAL DRIVE ASSEMBLY

- 5.21.1. DISASSEMBLY

- 5.21.2. ASSEMBLY

- 5.22. BEVEL GEAR ASSEMBLY

- 5.22.1. DISASSEMBLY

- 5.22.2. ASSEMBLY

- 5.23. BEVEL PINION ASSEMBLY

- 5.23.1. REMOVAL

- 5.23.2. INSTALLATION

- 5.23.3. DISASSEMBLY

- 5.23.4. ASSEMBLY

- 5.24. SPROCKET ASSEMBLY

- 5.25. FRONT AXLE ASSEMBLY

- 5.25.1. REMOVAL

- 5.25.2. INSTALLATION

- 5.26. STEERING PUMP ASSEMBLY

- 5.26.1. REMOVAL AND INSTALLATION

- 5.27. STEERING CYLINDER ASSEMBLY

- 5.27.1. REMOVAL AND INSTALLATION

- 5.28. WHEEL BRAKE ASSEMBLY

- 5.28.1. DISASSEMBLY

- 5.28.2. ASSEMBLY

- 5.29. HYDRAULIC TANK

- 5.29.1. REMOVAL AND INSTALLATION

- 5.30. HYDRAULIC PUMP ASSEMBLY

- 5.30.1. REMOVAL AND INSTALLATION

- 5.31. HYDRAULIC CONTROL VALVE ASSEMBLY

- 5.31.1. REMOVAL

- 5.31.2. INSTALLATION

- 5.32. BLADE LIFT CYLINDER ASSEMBLY

- 5.32.1. REMOVAL AND INSTALLATION

- 5.33. DRAWBAR SHIFT CYLINDER ASSEMBLY

- 5.33.1. REMOVAL AND INSTALLATION

- 5.34. BLADE SIDE SHIFT CYLINDER ASSEMBLY

- 5.34.1. REMOVAL

- 5.34.2. INSTALLATION

- 5.35. LEANING CYLINDER ASSEMBLY

- 5.35.1. REMOVAL AND INSTALLATION

- 5.36. ARTICULATE CYLINDER ASSEMBLY

- 5.36.1. REMOVAL AND INSTALLATION

- 5.37. POWER TILT CYLINDER ASSEMBLY

- 5.37.1. REMOVAL AND INSTALLATION

- 5.38. HYDRAULIC CYLINDER ASSEMBLY

- 5.38.1. DISASSEMBLY

- 5.38.2. ASSEMBLY

- 5.39. BLADE ASSEMBLY

- 5.39.1. REMOVAL AND INSTALLATION

- 5.40. CIRCLE ROTATION GEAR AND HYDRAULIC MOTOR ASSEMBLY

- 5.40.1. REMOVAL AND INSTALLATION

- 5.40.2. DISASSEMBLY

- 5.40.3. ASSEMBLY

- 6. OTHERS

- 6.1. HYDRAULIC CIRCUIT DIAGRAM (STD SPEC.)

- 6.2. HYDRAULIC CIRCUIT DIAGRAM (DDV SPEC.)

- 6.3. HYDROSHIFT TRANSMISSION CONTROL CIRCUIT DIAGRAM

- 6.4. ELECTRICAL CIRCUIT DIAGRAM (1/2)

- 6.5. ELECTRICAL CIRCUIT DIAGRAM (2/2)

- 6.6. ELECTRICAL CIRCUIT DIAGRAM FOR AIR CONDITIONER

- 6.7. ELECTRICAL CIRCUIT DIAGRAM FOR CAB

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00