Komatsu GD750A-1 Motor Grader Operation and Maintenance Manual CEAM002402

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM002402

- Format: PDF

- Size: 6.2MB

- Number of Pages: 333

-

Model List:

- GD750A-1 Motor Grader

- 1. MAIN MENU

- 2. COVER PAGE

- 3. FORWARD

- 4. SAFETY INFORMATION

- 5. INTRODUCTION

- 5.1. INTENDED USE

- 5.2. FEATURES

- 5.3. BREAKING IN THE MACHINE

- 6. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 6.1. NUMBER LOCATIONS

- 6.2. ENGINE SERIAL NO. PLATE POSITION

- 6.3. TRANSMISSION SERIAL NO. PLATE POSITION

- 6.4. REAR AXLE SERIAL NO. PLATE POSITION

- 6.5. CAB ROPS/FOBS SERIAL NO. PLATE POSITION

- 6.6. GENERAL PART NO. PLATE

- 6.7. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 7. TABLE OF CONTENTS

- 8. SAFETY

- 8.1. GENERAL PRECAUTIONS

- 8.2. PRECAUTIONS DURING OPERATION

- 8.2.1. BEFORE STARTING ENGINE

- 8.2.2. OPERATING MACHINE

- 8.2.3. TRANSPORTATION

- 8.2.4. BATTERY

- 8.2.5. TOWING

- 8.2.6. TIRES

- 8.3. PRECAUTIONS FOR MAINTENANCE

- 8.3.1. BEFORE CARRYING OUT MAINTENANCE

- 8.3.2. DURING MAINTENANCE

- 8.4. POSITON FOR ATTACHING SAFETY LABELS

- 8.4.1. POSITION FOR ATTACHING SAFETY LABELS

- 9. OPERATION

- 9.1. GENERAL VIEW

- 9.1.1. GENERAL VIEW OF MACHINE

- 9.1.2. UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS

- 9.2. EXPLANATION OF COMPONENTS

- 9.2.1. STEERING CONSOLE CONTROLS AND GAUGES

- 9.2.2. RIGHT SIDE CONSOLE

- 9.2.3. MISCELLANEOUS CONTROLS

- 9.2.4. HEATER/AIR CONDITIONING CONTROLS

- 9.2.5. MISCELLANEOUS GAUGES AND VALVE

- 9.2.6. ACCESS COVERS, HOOD SIDES AND DOORS

- 9.2.7. CONTROL LEVERS AND PEDALS

- 9.2.8. CAP WITH LOCK

- 9.2.9. ARTICULATE LOCK PIN

- 9.2.10. PARKING BRAKE

- 9.2.11. BACKUP ALARM

- 9.2.12. CIRCUIT BREAKERS

- 9.3. MACHINE OPERATION

- 9.3.1. WALK AROUND CHECK

- 9.3.2. TOWING

- 9.3.3. CHECKS BEFORE STARTING

- 9.3.4. REMOVAL OF ARTICULATION PIN

- 9.3.5. ENTERING OPERATORS CAB

- 9.3.6. ADJUSTMENTS BEFORE OPERATION

- 9.3.7. OPERATIONS AND CHECKS BEFORE STARTING ENGINE

- 9.3.8. STARTING ENGINE

- 9.3.9. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 9.3.10. TRAVELING POSTURE FOR MACHINE

- 9.3.11. MOVING MACHINE

- 9.3.12. SHIFTING GEARS

- 9.3.13. SHIFTING BETWEEN FORWARD AND REVERSE

- 9.3.14. STOPPING MACHINE

- 9.3.15. TURNING MACHINE

- 9.3.16. OPERATING WORK EQUIPMENT

- 9.3.17. WORK APPLICATION

- 9.3.18. RIGHT DITCH FINISHING

- 9.3.19. LEFT DITCH FINISHING

- 9.3.20. FINISHING RIGHT ROAD SHOULDER

- 9.3.21. FINISHING LEFT ROAD SHOULDER

- 9.3.22. CONSTRUCTING ROAD METHOD OF MAKING VDITCH

- 9.3.23. FLATBOTTOM DITCH

- 9.3.24. CONSTRUCTING ROAD METHOD FOR MAKING FLAT BOTTOM DITCH

- 9.3.25. FINISHING WITH GRADER FOR DITCHES WHERE WET ROAD SHOULDER IS LOOSE

- 9.3.26. LEVELING 31 SLOPE FACE

- 9.3.27. BANK CUTTING METHOD RIGHT SIDE

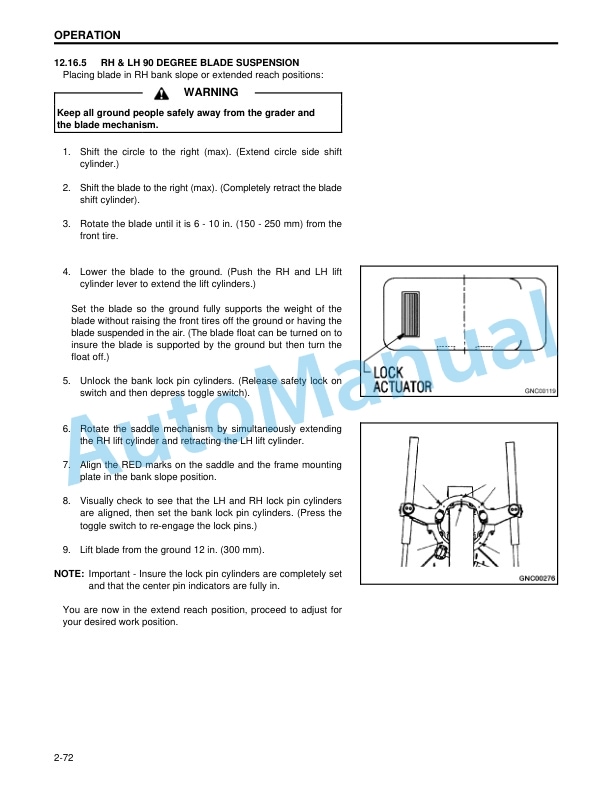

- 9.3.28. EXTREME SIDE REACH

- 9.3.29. RIPPER OPERATIONS WITH FRAME STRAIGHT

- 9.3.30. PRECAUTIONS FOR OPERATION

- 9.3.31. ADJUSTING WORK EQUIPMENT POSTURE

- 9.3.32. PARKING MACHINE

- 9.3.33. CHECK AFTER FINISHING WORK

- 9.3.34. STOPPING ENGINE

- 9.3.35. CHECK AFTER STOPPING ENGINE

- 9.3.36. LOCKING

- 9.3.37. TIRES

- 9.3.38. BLADE ACCUMULATOR

- 9.3.39. HANDLING BLADE FLOAT

- 9.4. TRANSPORTATION

- 9.4.1. GENERAL

- 9.4.2. MOVING A DISABLED MACHINE

- 9.4.3. METHODS OF TOWING

- 9.5. OPERATION UNDER UNUSUAL CONDITIONS

- 9.5.1. OPERATION IN EXTREME COLD

- 9.5.2. BATTERY

- 9.5.3. AFTER COLD WEATHER

- 9.5.4. OPERATION IN EXTREME HEAT

- 9.5.5. OPERATION IN DUSTY OR SANDY AREAS

- 9.5.6. OPERATION IN RAINY OR HUMID CONDITIONS

- 9.5.7. OPERATION IN SALT WATER AREAS

- 9.5.8. OPERATION AT HIGH ALTITUDES

- 9.6. MACHINE STORAGE

- 9.6.1. PREPARING FOR STORAGE

- 9.6.2. SERVICING MACHINE DURING STORAGE

- 9.6.3. PREPARING FOR OPERATION

- 9.6.4. ROLLOVER PROTECTIVE STRUCTURE

- 9.6.5. THEFT DETERRENT PRACTICES

- 9.7. TROUBLESHOOTING

- 9.7.1. ETHER STARTING

- 9.7.2. AFTER RUNNING OUT OF FUEL

- 9.7.3. WHEN LEANING PIPING IS DAMAGED

- 9.7.4. IF BATTERY IS DISCHARGED

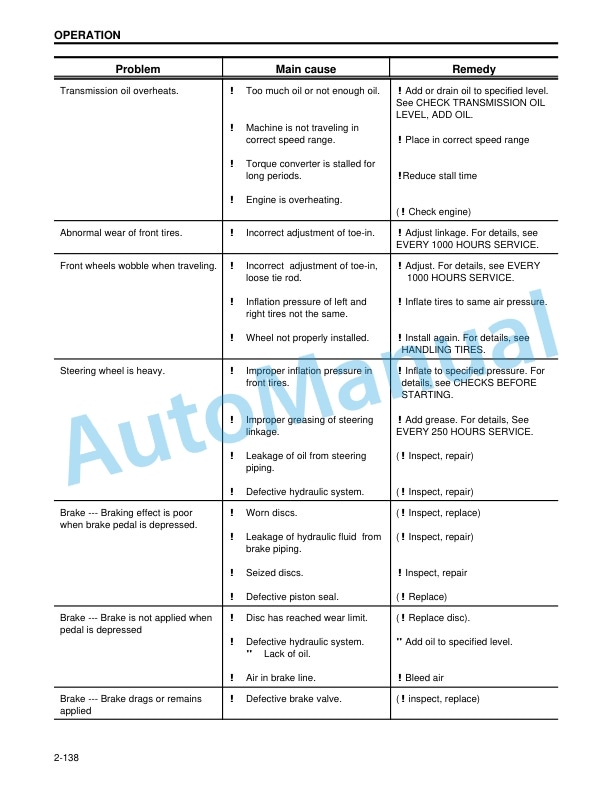

- 9.7.5. OTHER TROUBLE

- 10. MAINTENANCE

- 10.1. GUIDES TO MAINTENANCE

- 10.2. OUTLINES OF SERVICE

- 10.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 10.2.2. RELATING TO ELECTRIC SYSTEM

- 10.3. WEAR PARTS LIST

- 10.4. FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 10.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 10.4.2. ENGINE OIL SPECIFICATIONS

- 10.4.3. TRANSMISSION, TORQUE CONVERTER AND OIL COOLER, TANDEM DRIVE CASES

- 10.4.4. HYDRAULIC SYSTEM OIL SPECIFICATIONS

- 10.4.5. REAR DRIVE AXLE AND CIRCLE DRIVE BRAKE HOUSING OIL SPECIFICATIONS

- 10.4.6. DIESEL FUEL SPECIFICATIONS

- 10.4.7. COOLANT SPECIFICATIONS

- 10.4.8. CIRCLE DRIVE GEAR CASE OIL SPECIFICATIONS (HDTF)

- 10.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 10.5.1. INTRODUCTION OF NECESSARY TOOLS

- 10.5.2. TORQUE VALUES FOR STANDARD METRIC FASTENERS

- 10.5.3. TORQUE VALUES FOR STANDARD ENGLISH FASTENERS

- 10.6. PERIODIC REPLACEMENT OF CRITICAL PARTS

- 10.7. MAINTENANCE SCHEDULE CHART

- 10.7.1. MAINTENANCE SCHEDULE CHART

- 10.8. SERVICE PROCEDURES

- 10.8.1. PERIODIC SERVICE CHART

- 10.8.2. WHEN REQUIRED

- 10.8.3. CHECK BEFORE STARTING ENGINE

- 10.8.4. EVERY SHIFT/10 HOURS SERVICE

- 10.8.5. EVERY 50 MAN HOURS/WEEKLY SERVICE

- 10.8.6. HOURS INITIAL SERVICE

- 10.8.7. EVERY 250 HOURS/MONTHLY SERVICE

- 10.8.8. EVERY 500 HOUR/THREE MONTHS SERVICE

- 10.8.9. EVERY 1000 HOURS/SIX MONTHS SERVICE

- 10.8.10. EVERY 1500 HOURS SERVICE

- 10.8.11. EVERY 2000 HOUR/ONE YEAR SERVICE

- 10.8.12. EVERY 4000 HOURS/TWO YEAR SERVICE

- 10.8.13. EVERY 6000 HOURS/THREE YEAR SERVICE

- 11. SPECIFICATIONS

- 11.1. GD750A1

- 11.1.1. WEIGHT

- 11.1.2. TRANSMISSION AND TORQUE CONVERTER PERFORMANCE

- 11.1.3. LIQUID CAPACITIES

- 11.1.4. ENGINE

- 11.1.5. HYDRAULIC

- 11.1.6. CIRCLE

- 11.1.7. DRAWBAR

- 11.1.8. MOLDBOARD

- 11.1.9. BLADE RANGE

- 11.1.10. FRONT AXLE

- 11.1.11. AXLE REAR

- 11.1.12. STEERING

- 11.1.13. TANDEM DRIVE

- 11.1.14. WHEELS, FRONT AND REAR

- 11.1.15. BRAKES

- 11.1.16. OPERATORS COMPARTMENT

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF