Komatsu GD825A-2 Motor Grader Shop Manual SEBM002309

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM002309

- Format: PDF

- Size: 46.3MB

- Number of Pages: 954

Category: Komatsu Shop Manual PDF

-

Model List:

- GD825A-2 Motor Grader

- 1. COVER

- 2. CONTENTS

- 3. Notice of revision

- 4. FORWORD

- 4.1. Safety notice

- 4.2. How to read the shop manual

- 4.3. Explanation of terms for maintenance standard

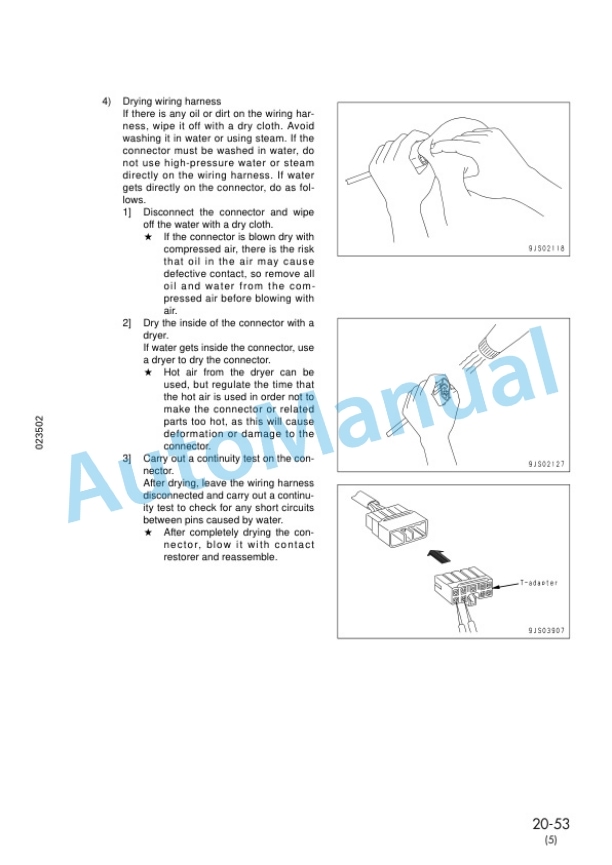

- 4.4. Handling of electric equipment and hydraulic component

- 4.5. Handling of connectors newly used for engines

- 4.6. How to read electric wire code

- 4.7. Precautions when carrying out operation

- 4.8. Method of disassembling and connecting pushpull type coupler

- 4.9. Standard tightening torque table

- 4.10. Conversion table

- 5. GENERAL

- 5.1. Specification dimension drawings

- 5.2. Specifications

- 5.3. Weight table

- 5.4. Fuel, coolant and lubricants

- 6. STRUCTURE AND FUNCTION

- 6.1. General

- 6.2. Power train diagram

- 6.3. Joint

- 6.4. HYDROSHIFT transmission and transfer piping

- 6.5. Hydraulic circuit for power train

- 6.6. Hydraulic circuit diagram for power train

- 6.7. PTO (Power Take Off)

- 6.8. HYDROSHIFT transmission and transfer

- 6.9. Transmission control valve

- 6.10. Transmission control

- 6.11. Inching control

- 6.12. Drive shaft

- 6.13. Final drive, differential lock and unlock piping

- 6.14. Final drive

- 6.15. Tandem drive

- 6.16. Steering piping

- 6.17. Steering circuit system

- 6.18. Steering circuit diagram

- 6.19. Steering valve

- 6.20. Double relief valve

- 6.21. Check valve

- 6.22. Emergency steering system

- 6.23. Front axle

- 6.24. Wheel

- 6.25. Disc brake

- 6.26. Parking brake

- 6.27. Brake air piping

- 6.28. Brake air circuit system

- 6.29. Brake air circuit diagram

- 6.30. Air drier

- 6.31. Air governor

- 6.32. Air tank

- 6.33. Safety valve

- 6.34. Automatic drain valve

- 6.35. Check valve

- 6.36. Brake valve

- 6.37. Parking brake system

- 6.38. Parking brake solenoid valve

- 6.39. Exhaust valve

- 6.40. Spring cylinder

- 6.41. Hydraulic control piping

- 6.42. Hydraulic circuit system

- 6.43. Hydraulic circuit diagram

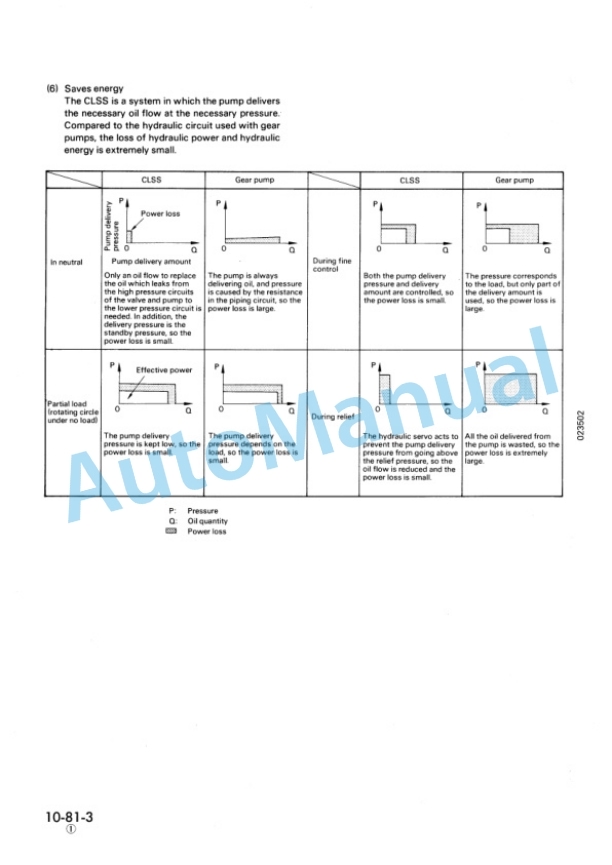

- 6.44. Closed center load sensing system (CLSS)

- 6.45. Hydraulic pump

- 6.46. Priority flow divider valve

- 6.47. Surge pressure absorbing valve

- 6.48. Hydraulic control valve

- 6.49. Pressure compensating mechanism of hydraulic control valve

- 6.50. Blade lift speed adjustment mechanism

- 6.51. Pilot check valve

- 6.52. Pilot check valve (with safety valve)

- 6.53. Circle rotation motor

- 6.54. Blade accumulator system

- 6.55. Blade float system

- 6.56. Drawbar and lifter

- 6.57. Blade

- 6.58. Lifter bracket control piping

- 6.59. Circle rotation gear

- 6.60. Rear mount ripper

- 6.61. Hydraulic control linkage

- 6.62. Main Frame

- 6.63. Air conditioner

- 6.64. Electrical wiring diagram

- 6.65. Monitor panel, cluster gauge and pilot lamp

- 6.66. Electrical circuit diagram

- 6.67. Electrical vehicle monitoring system (EVMS)

- 6.68. Transmission control system

- 6.69. Sensors

- 6.70. Engine starting circuit

- 6.71. Engine stopping circuit

- 7. TESTING AND ADJUSTING

- 7.1. Standard value table for engine

- 7.2. Standard value table for chassis

- 7.3. Tool list for testing and adjusting

- 7.4. Testing and adjusting valve clearance

- 7.5. Measuring compression pressure

- 7.6. Testing and adjusting fuel injection timing

- 7.7. Measuring blowby pressure

- 7.8. Measuring engine oil pressure

- 7.9. Measuring exhaust gas color

- 7.10. Measuring exhaust gas temperature

- 7.11. Measuring intake air pressure (boost pressure)

- 7.12. Testing and adjusting belt tension

- 7.13. Procedure for adjusting the engine stop motor cable

- 7.14. Adjusting accelerator control

- 7.15. Inching pedal travel and operating force

- 7.16. HYDROSHIFT transmission

- 7.17. Checking differential locking device oil pressure

- 7.18. Steering system

- 7.19. Checking tire runout

- 7.20. Checking air pressure of tire

- 7.21. Checking toein

- 7.22. Installation of articulate center pins

- 7.23. Checking wear of brake disc

- 7.24. Checking parking brake

- 7.25. Checking work equipment control lever travel and operating force

- 7.26. Checking hydraulic oil temperature

- 7.27. Checking work equipment hydraulic pressure

- 7.28. Adjusting work equipment hydraulic pressure

- 7.29. Measuring hydraulic drift

- 7.30. Charging blade accumulator with gas

- 7.31. Adjusting blade lift speed

- 7.32. Bleeding air from hydraulic pump

- 7.33. Adjusting slip load of circle rotation clutch

- 7.34. Adjusting speedometer module of machine monitor

- 7.35. TROUBLESHOOTING

- 7.35.1. Points to remember when troubleshooting

- 7.35.2. Sequence of events in troubleshooting

- 7.35.3. Handling of electric equipment and hydraulic component

- 7.35.4. Checks before troubleshooting

- 7.35.5. Electrical circuit system diagram

- 7.35.6. Connector types and mounting locations

- 7.35.7. Electrical wiring diagram

- 7.35.8. Connection table for connector pin numbers

- 7.35.9. Tbranch box and Tbranch adapter table

- 7.35.10. Method of using troubleshooting charts

- 7.35.11. Details of troubleshooting and troubleshooting procedure

- 7.35.12. TROUBLESHOOTING OF ENGINE (S MODE)

- 7.35.13. TROUBLESHOOTING CHART FOR ELECTRONIC VEHICLE MONITORING SYSTEM (M MODE)

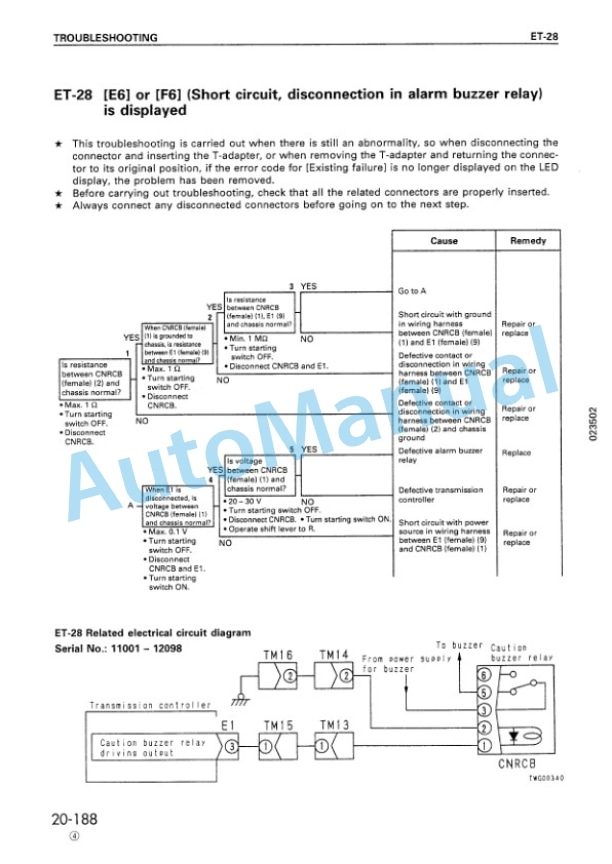

- 7.35.14. TROUBLESHOOTING CHART FOR ELECTRONIC (ENGINE, PARKING BRAKE, TRANSMISSION CONTROL) (E MODE)

- 7.35.15. TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM (ET MODE)

- 7.35.16. TROUBLESHOOTING CHART FOR HYDRAULIC SYSTEM (H MODE)

- 8. DISASSEMBLY AND ASSEMBLY

- 8.1. HOW TO READ THIS MANUAL

- 8.2. COATING MATERIAL LIST

- 8.3. SPECIAL TOOL LIST

- 8.4. STARTING MOTOR

- 8.4.1. Removal and Installation

- 8.5. ALTERNATOR

- 8.5.1. Removal and Installation

- 8.6. NOZZLE HOLDER

- 8.6.1. Removal and Installation

- 8.7. FUEL INJECTION PUMP

- 8.7.1. Removal and Installation

- 8.8. WATER PUMP

- 8.8.1. Removal and Installation

- 8.9. ENGINE OIL COOLER CORE

- 8.9.1. Removal and Installation

- 8.10. TURBOCHARGER

- 8.10.1. Removal and Installation

- 8.11. AIR COMPRESSOR

- 8.11.1. Removal and Installation

- 8.12. CYLINDER HEAD

- 8.12.1. Removal

- 8.12.2. Installation

- 8.13. ENGINE (INCL. TRANSMISSION)

- 8.14. TRANSMISSION CONTROL VALVE

- 8.14.1. Disassembly

- 8.14.2. Assembly

- 8.15. HYDROSHIFT TRANSMISSION PUMP

- 8.15.1. Removal and Installation

- 8.16. TANDEM AND FINAL DRIVE

- 8.16.1. Removal and Installation

- 8.17. HYDRAULIC TANK

- 8.17.1. Removal and Installation

- 8.18. HYDRAULIC CONTROL VALVE

- 8.18.1. Removal

- 8.18.2. Installation

- 8.19. MAIN CONTROL VALVE

- 8.19.1. Disassembly

- 8.19.2. Assembly

- 8.20. CIRCLE ROTATION MOTOR

- 8.20.1. Disassembly

- 8.20.2. Assembly

- 8.21. DRAWBAR SHIFT CYLINDER, BLADE LIFT CYLINDER, LIFTER GUIDE

- 8.21.1. Removal

- 8.21.2. Installation

- 8.22. ARTICULATE CYLINDER

- 8.22.1. Removal and Installation

- 8.23. REAR MOUNT RIPPER CYLINDER

- 8.23.1. Removal and Installation

- 8.24. HYDRAULIC CYLINDER

- 8.24.1. Serial No. 11001 12502

- 8.24.2. Serial No. 12503 and up

- 8.25. CIRCLE ROTATION GEAR AND HYDRAULIC OIL MOTOR

- 8.25.1. Removal and installation

- 8.26. CIRCLE AND DRAWBAR

- 8.26.1. Removal and Installation

- 8.26.2. Disassembly

- 8.26.3. Assembly

- 8.27. REAR MOUNT RIPPER

- 8.27.1. Removal

- 8.27.2. Installation

- 8.28. METHOD FOR LIFTING UP ROPS CAB

- 8.29. INSTALLATION OF ROPS

- 8.30. ROPS cab

- 8.30.1. Removal

- 8.30.2. Installation

- 8.31. DISCONNECTION AND CONNECTION OF ARTICULATE SECTION

- 8.31.1. Serial No. 11001 12502

- 8.31.2. Serial No. 12503 and up

- 9. MAINTENANCE STANDARD

- 9.1. HYDROSHIFT transmission and transfer

- 9.2. Transmission pump

- 9.3. Transmission control valve

- 9.4. Transmission solenoid valve

- 9.5. Final drive

- 9.6. Differential lockup pump

- 9.7. Tandem drive

- 9.8. Front axle

- 9.9. Steering cylinder

- 9.10. Disc brake

- 9.11. Parking brake

- 9.12. Spring cylinder

- 9.13. Hydraulic control valve

- 9.14. Hydraulic cylinder

- 9.15. Hydraulic pump

- 9.16. Drawbar and lifter

- 9.17. Blade

- 9.18. Circle rotation gear

- 9.19. Ripper

- 9.20. Frame

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00