Komatsu H185S Hydraulic Shovel Shop Manual H185S06081SM

$40.00

- Type Of Manual: Shop Manual

- Manual ID: H185S06081SM

- Format: PDF

- Size: 28.1MB

- Number of Pages: 542

Category: Komatsu Shop Manual PDF

-

Model List:

- H185S Hydraulic Shovel

- 0.1. TECHNICAL SUMMARY

- 0.2. ASSEMBLING THE EXCAVATOR

- 0.2.0.1. FAN DRIVE AND COOLER ASSY

- 0.2.0.2. COUPLING

- 0.2.0.3. AIR FILTER

- 0.2.1. RPM ADJUSTMENTS (CUMMINS ENGINE KTA 38C)

- 0.2.2. ELECTRIC MOTOR

- 0.2.2.1. COUPLING

- 0.2.3. PUMP DISTRIBUTOR GEAR

- 0.2.3.1. LUBRICATION

- 0.2.4. LOCATION OF THE PUMPS AT THE DISTRIBUTOR GEAR

- 0.3. HYDRAULIC OIL TANK

- 0.3.1. HYDRAULIC OIL TANK

- 0.4. HYDRAULIC OIL COOLING

- 0.4.1. GENERAL

- 0.4.2. HYDRAULIC OIL COOLING CIRCUIT

- 0.4.3. FAN DRIVE

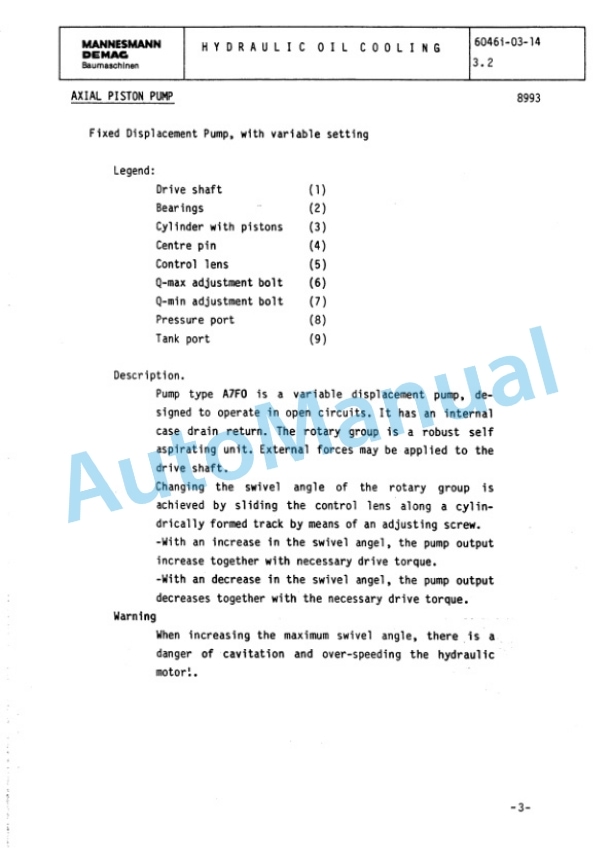

- 0.4.3.1. AXIAL PISTON PUMP

- 0.4.3.2. MEASURING AND SETTING OF THE FAN SPEED

- 0.4.3.3. FUNCTION CHECK FOR RPM CONTROL

- 0.5. CONTROL

- 0.5.1. PILOT PRESSURE SUPPLY

- 0.5.2. OVERVIEW FOR PILOT PRESSURE LINES

- 0.5.3. ELECTRO PROPORTIONAL CONTROL

- 0.5.3.1. GENERAL FUNCTION

- 0.5.3.2. DETAILED EXPLANATION

- 0.5.3.3. POTENTIOMETER CONTROL (LEVER)

- 0.5.4. ADJUSTMENTS

- 0.6. MAIN HYDRAULIC PUMPS AND PUMP REGULATION

- 0.6.1. HYDRAULIC PUMP A7V/HD D

- 0.6.1.1. DESCRIPTION OF THE SL BEARING

- 0.6.1.2. FUNCTION OF THE GOVERNOR

- 0.6.1.3. PUMP BEARING LUBRICATION

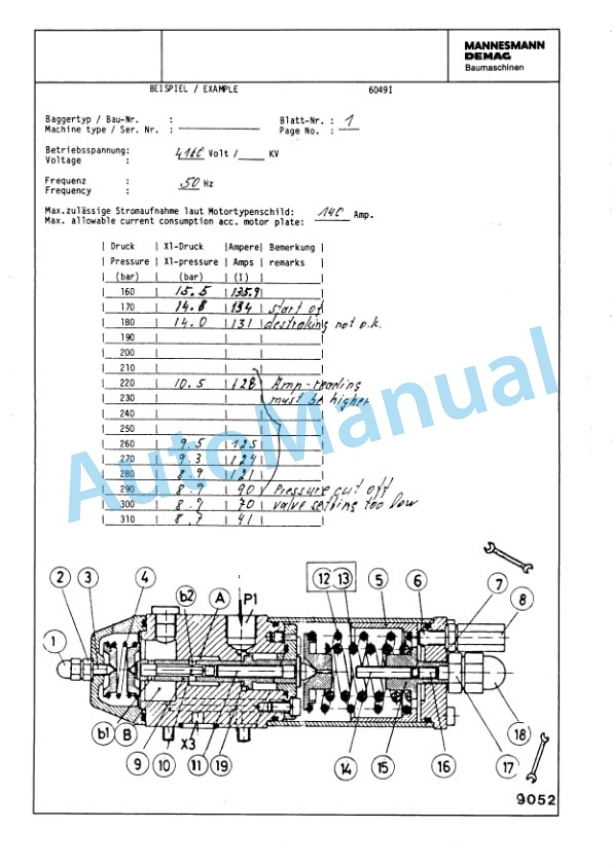

- 0.6.1.4. MEASURING AND SETTING OF THE PRESSURE CUTOFF VALVES

- 0.6.2. PUMP REGULATION SYSTEM

- 0.6.2.1. DIESEL ENGINE

- 0.6.2.1.1. DETAILED EXPLANATION FOR THE HYDRAULIC REGULATION

- 0.6.2.1.2. FUNCTION OF THE REGULATION CARTRIDGE

- 0.6.2.2. ELECTRIC MOTOR

- 0.6.2.2.1. DETAILED EXPLANATION FOR THE HYDRAULIC REGULATION

- 0.6.2.2.2. BASIC EXPLANATION OF THE POWER CONTROL VALVE

- 0.6.3. PUMP REGULATION SYSTEM

- 0.6.3.1. FOR MACHINES WITH A CUMMINS ENGINE ONLY)

- 0.6.3.2. FOR MACHINES WITH A CATERPILLAR ENGINE

- 0.6.3.3. FOR MACHINES WITH AN ELECTRIC MOTOR

- 0.6.4. DETAILED EXPLANATION FOR THE ELECTRONIC REGULATION FOR MACHINES WITH DIESEL ENGINE DRIVE

- 0.6.4.1. NORMAL ADJUSTMENTS/CHECKS FOR THE ELECTRONIC REGULATION

- 0.6.4.2. FIELD ADJUSTMENTS/CHECKS FOR THE ELECTRONIC REGULATION

- 0.6.5. DETAILED EXPLANATION FOR THE ELECTRONIC REGULATION FOR ELECTRIC MOTOR POWERED MACHINES

- 0.6.5.1. NORMAL ADJUSTMENTS/CHECKS FOR THE ELECTRONIC REGULATION

- 0.6.5.2. FIELD ADJUSTMENTS/CHECKS FOR THE ELECTRONIC REGULATION

- 0.7. OPERATING HYDRAULIC

- 0.7.1. REMOTE CONTROL, CONTROL BLOCKS AND DISTRIBUTOR MANIFOLD ARRANGEMENT

- 0.7.1.1. CONTROL BLOCKS

- 0.7.1.2. LOAD HOLDING VALVES

- 0.7.1.3. TRAVEL BRAKE VALVES

- 0.7.1.4. CONTROL BLOCK VALVES

- 0.7.1.5. PILOT OPERATED PRESSURE RELIEF VALVE

- 0.7.2. RESTRICTOR BLOCK

- 0.7.2.1. ANTI CAVITATION VALVE BLOCK

- 0.7.2.2. REMOTE CONTROL MANIFOLD

- 0.7.2.3. DIRECTIONAL SOLENOID VALVES

- 0.7.2.4. PROPORTIONAL SOLENOID VALVE

- 0.7.2.5. HIGH PRESSURE FILTER

- 0.7.2.6. HYDRAULIC CYLINDER

- 0.7.3. HYDRAULIC FOR ATTACHMENT CYLINDER

- 0.7.3.1. VALVES AND PRESSURE CHECK POINTS

- 0.7.3.2. EXEMPLARY EXPLANATION FOR ONE CIRCUIT

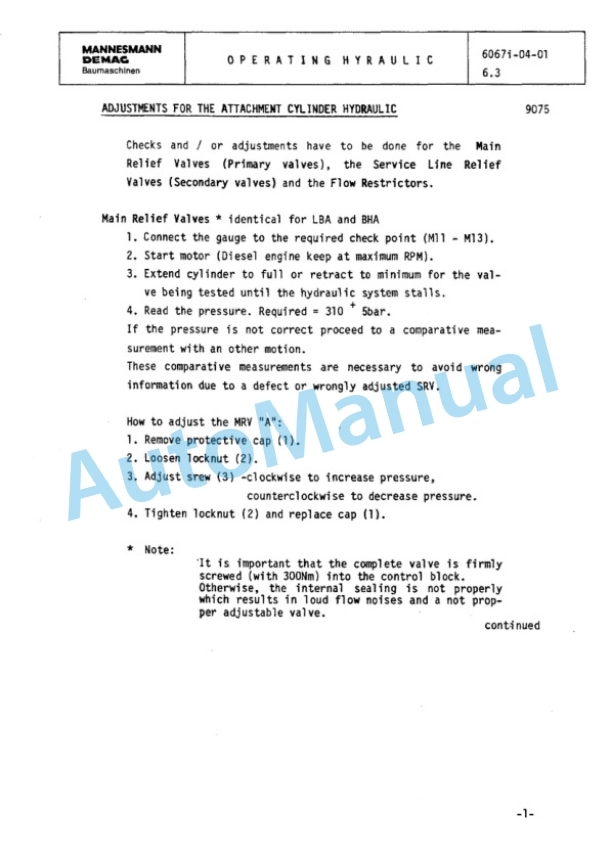

- 0.7.4. ADJUSTMENTS FOR THE ATTACHMENT CYLINDER HYDRAULIC

- 0.7.5. SLEW CIRCUIT

- 0.7.5.1. SLEW MOTOR (AXIAL PISTON MOTOR A2FM)

- 0.7.5.2. SLEW GEAR

- 0.7.5.3. SLEW GEAR HOUSE BRAKE

- 0.7.5.4. SLEW BRAKE VALVE

- 0.7.5.5. DETAILED EXPLANATION FOR RIGHT HAND SLEWING (EURO CONTROL)

- 0.7.5.6. DETAILED EXPLANATION FOR LEFT HAND SLEWING (EURO CONTROL)

- 0.7.5.7. SLEWING DOWN PATH

- 0.7.5.8. ANTICAVITATION CIRCUIT

- 0.7.5.9. ADJUSTMENTS FOR THE SLEW CIRCUIT

- 0.7.6. TRAVEL CIRCUIT

- 0.7.6.1. ROTARY DISTRIBUTOR

- 0.7.6.2. TRAVEL MOTOR (AXIAL PISTON MOTOR A2FM)

- 0.7.6.3. DRIVE ASSY

- 0.7.6.4. TRAVEL GEAR

- 0.7.6.5. TRAVEL GEAR HOUSE BRAKE

- 0.7.6.6. DETAILED EXPLANATION FOR TRAVELLING FORWARD

- 0.7.6.7. DETAILED EXPLANATION FOR TRAVELLING BACKWARD

- 0.7.6.8. ADJUSTMENTS FOR THE TRAVEL CIRCUIT

- 0.8. HYDRAULIC TRACK TENSION SYSTEM

- 0.8.1. LEGEND

- 0.8.1.1. GENERAL

- 0.8.2. LEGEND

- 0.8.2.1. FUNCTION

- 0.8.3. PRESSURE RELIEF VALVE, PILOT OPERATED TYPE DBD S

- 0.8.4. ADJUSTMENTS

- 0.9. HYDRAULIC DRIVE FOR AIR CONDITION COMPRESSOR

- 0.9.1. HYDRAULIC DRIVE FOR AIR CONDITION COMPRESSOR

- 0.9.2. ADJUSTMENTS FOR THE HYDRAULIC AIR CONDITION DRIVE

- 0.9.3. SOLENOID VALVE

- 0.9.4. PRESSURE RELIEF VALVE, PILOT OPERATED TYPE DBD S

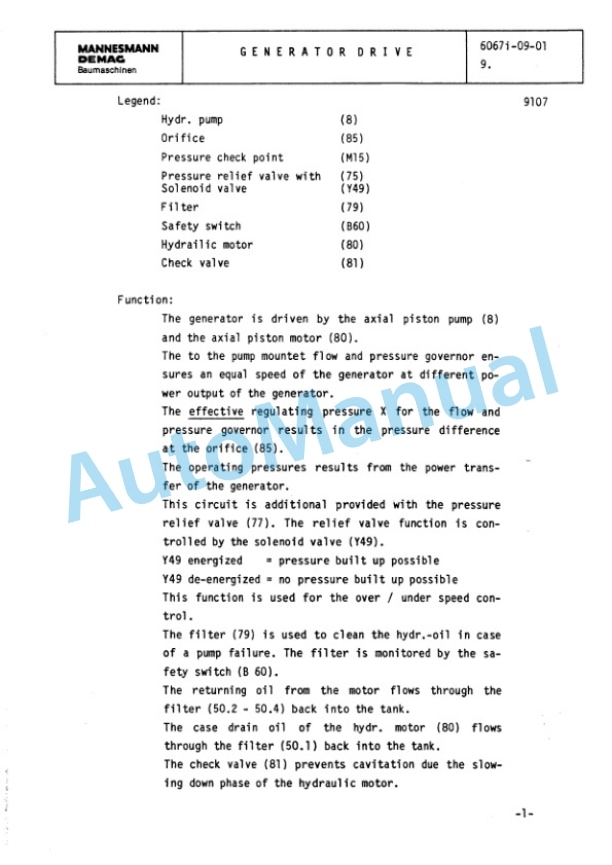

- 0.10. GENERATOR DRIVE

- 0.10.1. FUNCTION

- 0.10.2. ELECTRICAL FUNCTION

- 0.10.3. BASIC ADJUSTMENT

- 0.10.4. PRESSURE RELIEF VALVE WITH SOLENOID VALVE

- 0.10.5. AXIAL PISTON PUMP A10V 0

- 0.11. HINTS FOR THE HYDRAULIC CIRCUIT DIAGRAM

- 0.11.1. HINTS FOR READING THE CIRCUIT DIAGRAM

- 0.11.1.1. LEGEND TO THE HYDRAULIC CIRCUIT DIAGRAM H185 WITH DIESEL ENGINE

- 0.11.1.2. HOW TO READ THE CIRCUIT DIAGRAM

- 0.12. HINTS FOR THE ELECTRIC CIRCUIT DIAGRAM

- 0.12.1. MARKINGS OF ELECTRICAL COMPONENTS IN THE CIRCUIT DIAGRAMS

- 0.12.2. SYMBOLS

- 0.12.3. DEMAG CIRCUIT DIAGRAMS GENERAL INFORMATION

- 0.12.4. EXPLANATION OF THE DRAWING CONCEPT

- 0.12.5. LOCATION OF THE MAIN TERMINAL BOXES AND SOME IMPORTANT COMPONENTS

- 0.12.6. READING A CIRCUIT DIAGRAM

- 1. APPENDIX (PART 3)

- 1.1. CONTENTS

- 1.2. ELECTRICAL DIAGRAM

- 1.3. HYDRAULIC DIAGRAM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00