Komatsu HD465-7E0, HD605-7E0 Dump Truck Operation and Maintenance Manual TEN00332-00

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: TEN00332-00

- Format: PDF

- Size: 9.1MB

- Number of Pages: 401

-

Model List:

- HD465-7E0 Dump Truck

- HD605-7E0 Dump Truck

- 1. COVER

- 2. FOREWORD

- 2.1. BEFORE READING THIS MANUAL

- 2.2. SAFETY INFORMATION

- 2.3. INTENDED USE

- 2.3.1. USE OF MACHINE

- 2.3.2. GENERAL VIEW AND DIRECTIONS OF MACHINE

- 2.3.3. VISIBILITY FROM OPERATORS SEAT

- 2.4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 2.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 2.4.2. EPA REGULATIONS, ENGINE NUMBER PLATE

- 2.4.3. SERVICE METER POSITION

- 2.4.4. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 2.5. CONTENTS

- 3. SAFETY

- 3.1. IMPORTANT SAFETY INFORMATION

- 3.2. SAFETY LABELS

- 3.2.1. POSITION FOR ATTACHING SAFETY LABELS

- 3.2.2. SAFETY LABELS

- 3.3. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 3.3.1. PRECAUTIONS BEFORE STARTING OPERATION

- 3.3.2. PREPARATIONS FOR SAFE OPERATION

- 3.3.3. FIRE PREVENTION

- 3.3.4. PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

- 3.3.5. DO NOT GET CAUGHT IN DUMP BODY

- 3.3.6. PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES

- 3.3.7. UNAUTHORIZED MODIFICATION

- 3.3.8. PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

- 3.3.9. PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING

- 3.4. PRECAUTIONS FOR OPERATION

- 3.4.1. PRECAUTIONS FOR JOBSITE

- 3.4.2. STARTING ENGINE

- 3.4.3. OPERATION

- 3.4.4. TRANSPORTATION

- 3.4.5. TOWING

- 3.5. PRECAUTIONS FOR MAINTENANCE

- 3.5.1. PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE

- 3.5.2. PRECAUTIONS FOR INSPECTION AND MAINTENANCE

- 3.5.3. TIRES

- 4. OPERATION

- 4.1. GENERAL VIEW

- 4.1.1. GENERAL VIEW OF MACHINE

- 4.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 4.1.3. DASHBOARD

- 4.2. EXPLANATION OF COMPONENTS

- 4.2.1. GENERAL VIEW OF MACHINE

- 4.2.2. OPERATORS CAB

- 4.2.3. CONTROL LEVERS AND PEDALS

- 4.2.4. MACHINE MONITOR

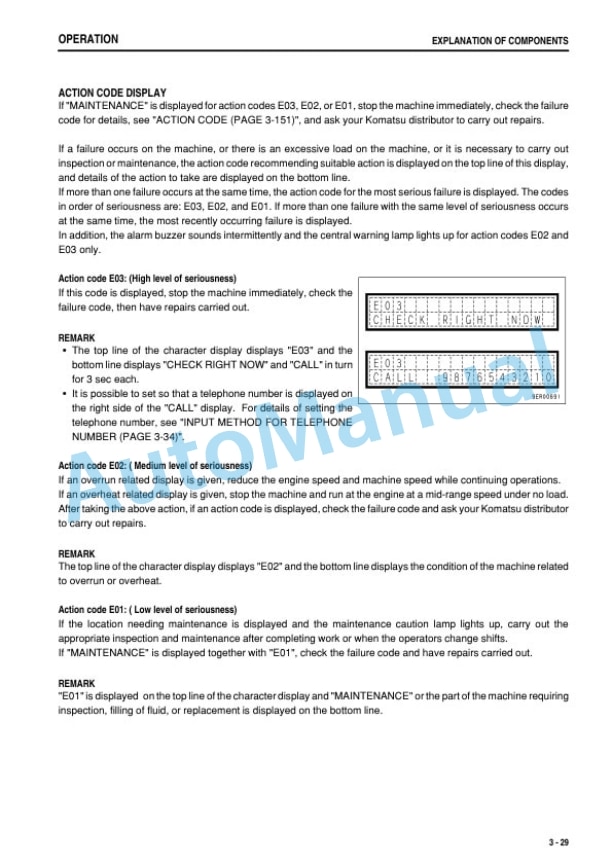

- 4.2.5. DISPLAY OF CHARACTER DISPLAY

- 4.2.6. OTHER FUNCTIONS OF CHARACTER DISPLAY

- 4.2.7. SWITCHES

- 4.2.8. BODY PIVOT PIN

- 4.2.9. LOCATION OF FIRE EXTINGUISHER

- 4.2.10. DUST INDICATOR

- 4.2.11. FUSES

- 4.2.12. CAR RADIO

- 4.2.13. CAR STEREO

- 4.2.14. AIR CONDITIONER

- 4.3. OPERATION

- 4.3.1. CHECK BEFORE STARTING ENGINE

- 4.3.2. STARTING ENGINE

- 4.3.3. OPERATIONS, CHECKS AFTER STARTING ENGINE

- 4.3.4. STOPPING ENGINE

- 4.3.5. MOVING MACHINE OFF (FORWARD, REVERSE), STOPPING

- 4.3.6. SHIFTING GEAR

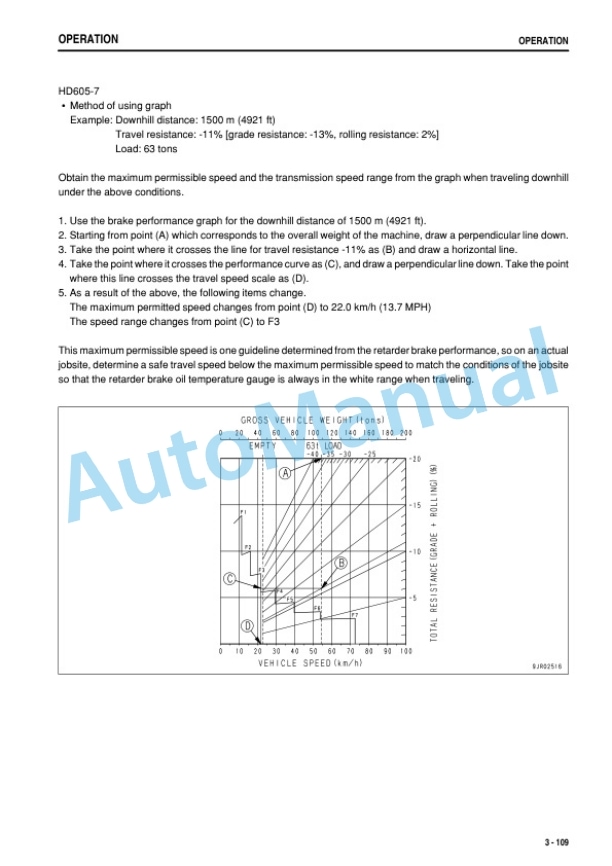

- 4.3.7. TRAVELING DOWNHILL

- 4.3.8. STEERING THE MACHINE

- 4.3.9. LOADING OPERATIONS

- 4.3.10. DUMP OPERATIONS

- 4.3.11. PRECAUTIONS FOR OPERATION

- 4.3.12. PARKING MACHINE

- 4.3.13. CHECKS AFTER COMPLETION OF WORK

- 4.3.14. CHECKS AFTER STOPPING ENGINE

- 4.3.15. LOCKING

- 4.3.16. HANDLING TIRES

- 4.4. DETERMINING AND MAINTAINING TRAVEL ROAD

- 4.4.1. DETERMINING TRAVEL ROAD

- 4.4.2. MAINTAINING TRAVEL ROAD

- 4.5. WORKSITE

- 4.5.1. EXAMINATION AN CONFIRMATION OF WORKSITE

- 4.5.2. WORKING ON LOOSE GROUND

- 4.5.3. DO NOT GO CLOSE TO HIGHVOLTAGE CABLE

- 4.5.4. ENSURE GOOD VISIBILITY

- 4.5.5. CONFIRMATION OF MARK

- 4.6. TRANSPORTATION

- 4.6.1. PRECAUTIONS WHEN TRANSPORTING

- 4.6.2. STEPS FOR TRANSPORTATION

- 4.6.3. METHOD OF SECURING MACHINE

- 4.6.4. METHOD OF LIFTING MACHINE

- 4.7. COLD WEATHER OPERATION

- 4.7.1. PRECAUTIONS FOR LOW TEMPERATURE

- 4.7.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 4.7.3. AFTER COLD WEATHER

- 4.8. LONGTERM STORAGE

- 4.8.1. BEFORE STORAGE

- 4.8.2. DURING STORAGE

- 4.8.3. AFTER STORAGE

- 4.8.4. PRECAUTIONS BEFORE TRAVELING AFTER LONGTERM STORAGE

- 4.9. TROUBLESHOOTING

- 4.9.1. AFTER RUNNING OUT OF FUEL

- 4.9.2. IF TRANSMISSION HAS TROUBLE

- 4.9.3. METHOD OF LOWERING DUMP BODY IN EMERGENCY

- 4.9.4. METHOD OF TOWING MACHINE

- 4.9.5. IF BATTERY IS DISCHARGED

- 4.9.6. ACTION IF FIRE OCCURS

- 4.9.7. OTHER TROUBLE

- 5. MAINTENANCE

- 5.1. GUIDES TO MAINTENANCE

- 5.2. SECONDARY MATERIALS FOR OPERATION

- 5.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 5.3. OUTLINE OF ELECTRIC SYSTEM

- 5.4. WEAR PARTS

- 5.4.1. WEAR PARTS LIST

- 5.5. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 5.5.1. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 5.5.2. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 5.6. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 5.6.1. TORQUE LIST

- 5.7. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5.7.1. SAFETY CRITICAL PARTS

- 5.8. MAINTENANCE SCHEDULE CHART

- 5.8.1. MAINTENANCE SCHEDULE CHART

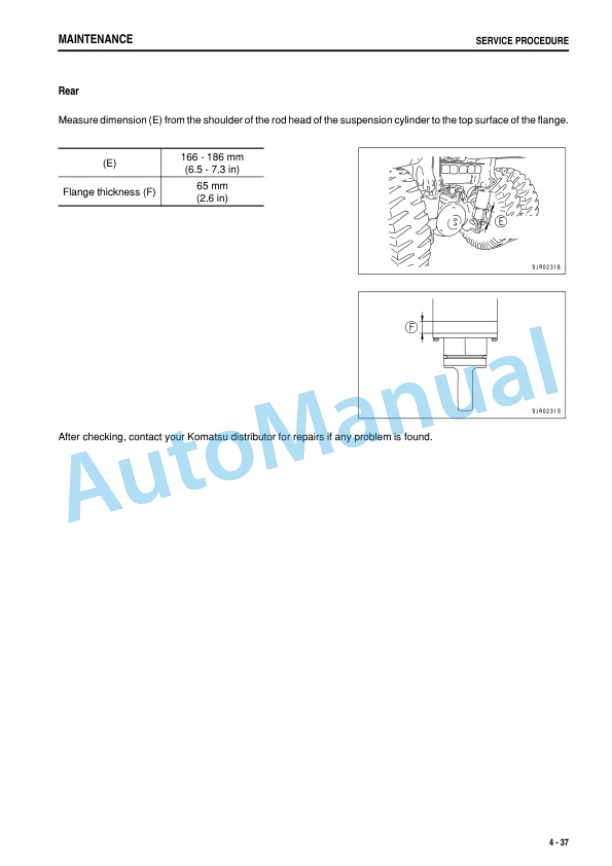

- 5.9. SERVICE PROCEDURE

- 5.9.1. INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)

- 5.9.2. WHEN REQUIRED

- 5.9.3. CHECK BEFORE STARTING

- 5.9.4. EVERY 250 HOURS SERVICE

- 5.9.5. EVERY 500 HOURS SERVICE

- 5.9.6. EVERY 1000 HOURS SERVICE

- 5.9.7. EVERY 2000 HOURS SERVICE

- 5.9.8. EVERY 4000 HOURS SERVICE

- 5.9.9. EVERY 8000 HOURS SERVICE

- 5.9.10. EVERY 15000 HOURS SERVICE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 7. ATTACHMENTS, OPTIONS

- 7.1. SELECTING DUMP BODY

- 7.2. HANDLING TACHOGRAPH (TCO2090W)

- 7.2.1. EXPLANATION OF COMPONENTS

- 7.2.2. METHOD OF USE

- 7.3. HANDLING AIR SUSPENSION SEAT

- 7.3.1. OPERATORS SEAT ADJUSTMENT

- 7.3.2. REMOVAL AND INSTALLATION OF HEADREST

- 7.4. HANDLING AUTOMATIC SPIN REGULATOR (ASR)

- 7.4.1. EXPLANATION OF COMPONENTS

- 7.4.2. ACTUATION OF ASR SYSTEM

- 7.4.3. PRECAUTION WHEN USING ASR SYSTEM

- 7.4.4. TROUBLESHOOTING

- 7.4.5. BLEEDING AIR FROM ASR CIRCUIT

- 7.5. HANDLING ANTI SKID BRAKE SYSTEM (ABS)

- 7.5.1. EXPLANATION OF COMPONENTS

- 7.5.2. ABS SYSTEM CHECK AFTER STARTING ENGINE

- 7.5.3. OPERATION OF ABS

- 7.5.4. PRECAUTION WHEN USING ABS SYSTEM

- 7.5.5. TROUBLESHOOTING

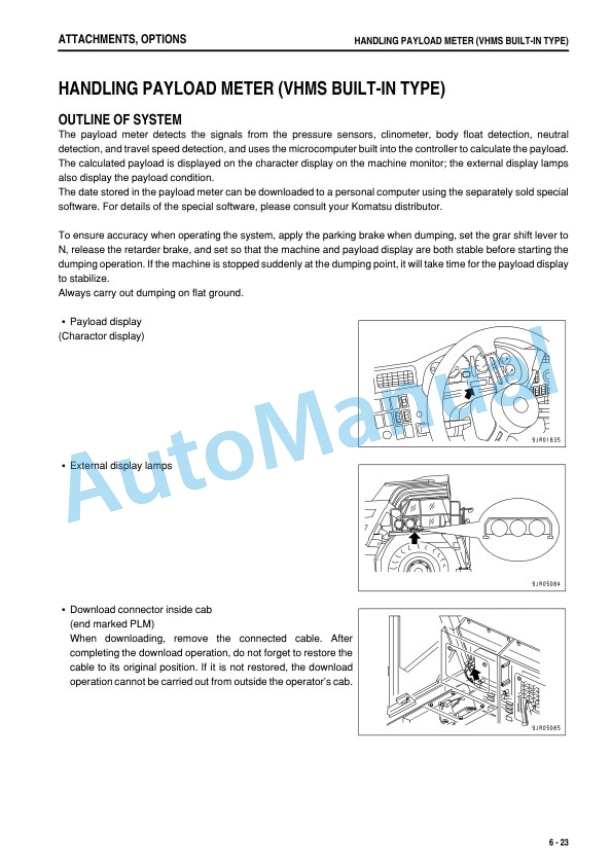

- 7.6. HANDLING PAYLOAD METER (VHMS BUILTIN TYPE)

- 7.6.1. OUTLINE OF SYSTEM

- 7.6.2. NORMAL OPERATION DISPLAY

- 7.6.3. EXTERNAL DISPLAY LAMPS

- 7.6.4. PERFORMING CALIBRATION

- 7.6.5. DATA STORED IN PAYLOAD METER

- 7.6.6. PROCEDURE WHEN DOWNLOADING

- 7.6.7. MACHINE ID, OPEN ID

- 7.6.8. PAYLOAD (CYCLE DATA ITEM)

- 7.6.9. SERVICE FUNCTIONS

- 7.6.10. OTHERS

- 7.7. HANDLING PAYLOAD METER II (CARD TYPE)

- 7.7.1. METHOD OF USING ACCURATELY

- 7.7.2. GENERAL LOCATIONS

- 7.7.3. CONTENT OF DISPLAY (CONTROLLER, EXTERNAL DISPLAY LAMPS)

- 7.7.4. EXTERNAL DISPLAY LAMPS

- 7.7.5. DETAILS OF DATA STORED IN MEMORY OF PAYLOAD METER

- 7.7.6. OPERATION OF SWITCHES

- 7.7.7. PROBLEM AND WARNING DISPLAY (ERROR CODE)

- 7.7.8. WHEN ERROR CODE F09 IS DISPLAYED (PROCEDURE FOR REPLACING BATTERY)

- 7.7.9. OPERATION WHEN ERROR CODE F.CAL IS DISPLAYED OR CONTROLLER HAS BEEN REPLACED

- 7.8. USE OF REAR VIEW MONITOR

- 7.8.1. NAME AND FUNCTON OF EACH PART OF REAR VIEW MONITOR

- 7.8.2. SETTING OF REAR VIEW MONITOR

- 7.8.3. CAUTIONS WHEN USING REAR VIEW MONITOR

- 7.9. HANDLING DUMPING COUNTER

- 7.10. HANDLING BATTERY ISOLATOR

- 7.11. HANDLING MACHINES EQUIPPED WITH VHMS

- 7.11.1. VHMS INSTALLED, COMMUNICATIONS TERMINAL NOT INSTALLED

- 7.11.2. VHMS AND COMMUNICATIONS TERMINAL INSTALLED

- 7.11.3. PROCEDURE WHEN DOWNLOADING

- 7.11.4. CHECK BEFORE STARTING

- 8. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714