Komatsu HD465-7R, HD605-7R Dump Truck Field Assembly Instruction GEN00071-04

$20.00

- Type Of Manual: Field Assembly Instruction

- Manual ID: GEN00071-04

- Format: PDF

- Size: 5.0MB

- Number of Pages: 111

-

Model List:

- HD465-7R Dump Truck

- HD605-7R Dump Truck

- 1. CONTENTS

- 2. MAJOR POINTS CHANGED FROM MODEL 7

- 3. OUTLINE OF DIVISION

- 4. DIMENSIONS OF MAIN COMPONENTS

- 5. ROUGH SCHEDULE OF ASSEMBLY AND WELDING

- 6. LIST OF EQUIPMENTS, TOOLS, AND CONSUMABLES

- 7. ASSEMBLY PROCESS NO.

- 7.1. LIST OF JIGS, TOOLS, AND CONSUMABLES

- 7.2. OIL, GREASE, AND COOLANT

- 7.3. LEVELS OF OIL, GREASE, AND COOLANT

- 7.4. POSITIONING REAR AXLE ASSEMBLY

- 7.5. INSTALLING REAR SUSPENSION

- 7.6. INSTALLING OF AXLE ROD (UPPER)

- 7.7. SLINGING BARE MACHINE

- 7.8. INSTALLING REAR AXLE ASSEMBLY (CONNECTING AXLE RODS)

- 7.9. CONNECTING REAR SUSPENSION

- 7.10. POSITIONING BARE MACHINE

- 7.11. INSTALLING RIGHT FRONT AXLE (CONNECTING AARM)

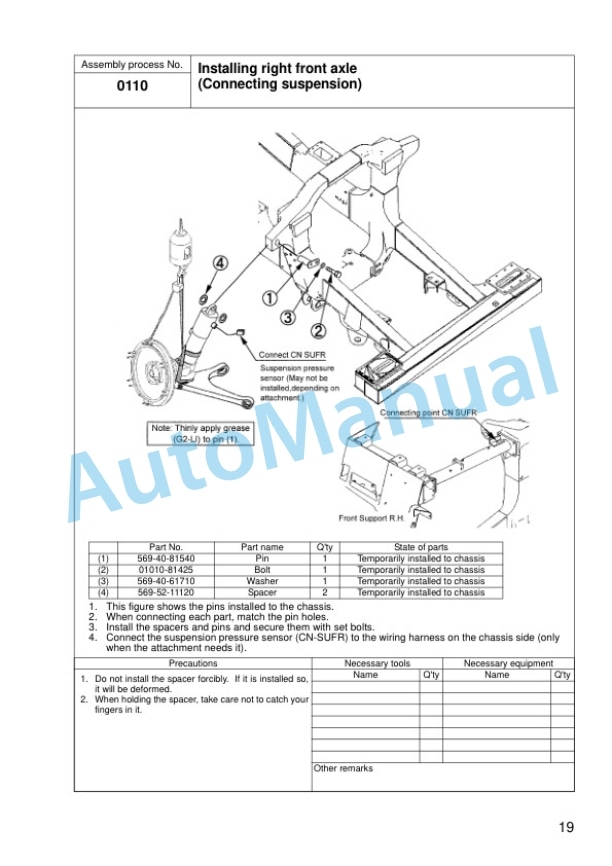

- 7.12. INSTALLING RIGHT FRONT AXLE (CONNECTING SUSPENSION)

- 7.13. INSTALLING RIGHT FRONT AXLE (CONNECTING STEERING CYLINDER AND TIE ROD)

- 7.14. INSTALLING RIGHT FRONT AXLE (CONNECTING BRAKE HOSE)

- 7.15. INSTALLING RIGHT FRONT AXLE (CONNECTING PIPING FOR AUTOMATIC SUSPENSION)

- 7.16. CONNECTION AND FIXING OF RIGHT FRONT AXLE WIRING HARNESS (ABS SPECIFICATION)

- 7.17. CONNECTION AND FIXING OF RIGHT FRONT CENTRALIZED LUBRICATION HOSES 4POINT GREASING SPECIFICATION

- 7.18. INSTALLING TIRE AND WHEEL ASSEMBLY

- 7.19. INSTALLING BODY HINGE GREASE TUBE

- 7.20. INSTALLATION OF REAR MONITOR

- 7.21. INSTALLING DRIVE SHAFT

- 7.22. CONNECTING COOLING HOSE

- 7.23. CONNECTING BRAKE ACTUATING HOSE

- 7.24. CONNECTION AND FIXING OF REAR CENTRALIZED LUBRICATION HOSES 4POINT GREASING SPECIFICATION

- 7.25. INSTALLING RIGHT FRONT SUPPORT

- 7.26. INSTALLING R.H PLATFORM ASSEMBLY

- 7.27. FIXING OF ORBCOMM ANTENNA CABLE

- 7.28. INSTALLATION OF ORBCOMM ANTENNAL POLE

- 7.29. INSTALLING OF FIRE PREVENTION COVER

- 7.30. INSTALLATION OF FIRE PREVENTION COVER (SAND TERRAIN SPECIFICATION)

- 7.31. INSTALLING RIGHT FENDER

- 7.32. INSTALLATION OF RIGHT FENDER (SIDE LAMP SPECIFICATION)

- 7.33. INSTALLING L.H CATWALK ASSEMBLY

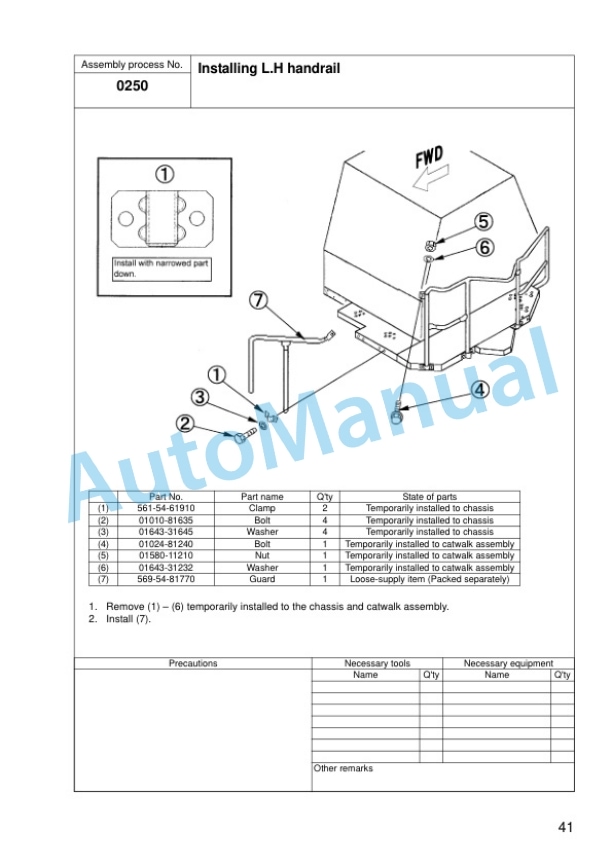

- 7.34. INSTALLING L.H HANDRAIL

- 7.35. INSTALLING RADIO ANTENNA AND FIXING ITS CABLE

- 7.36. INSTALLING L.H FENDER

- 7.37. INSTALLATION OF LEFT FENDER (SIDE LAMP SPECIFICATION)

- 7.38. INSTALLING LEFT SIDE MUDGUARD

- 7.39. INSTALLING RIGHT SIDE MUDGUARD

- 7.40. INSTALLATION OF R.H EXHAUST PIPE COVER (MUFFLER SPECIFICATION)

- 7.41. INSTALLATION OF R.H EXHAUST PIPE COVER (EXHAUST SELECTOR BOX SPECIFICATION)

- 7.42. INSTALLING TRANSMISSION UNDERGUARD

- 7.43. INSTALLATION OF RADIATOR CURTAIN (RADIATOR CURTAIN SPECIFICATION AND SAND TERRAIN SPECIFICATION)

- 7.44. REMOVING HOIST CYLINDER BRACKET

- 7.45. REMOVING HOIST PIPING BLIND PLATE

- 7.46. WELDING BODY

- 7.47. SLINGING BODY

- 7.48. INSTALLING HINGE PIN

- 7.49. CONNECTING HOIST CYLINDER

- 7.50. WELDING PROTECTIVE COVER BY ACTUALLY POSITIONING IT ON MACHINE

- 7.51. INSTALLING BODY MOUNT

- 7.52. PROCEDURE FOR ADJUSTING BODY MOUNT SHIM

- 7.53. WELDING FRONT BODY MOUNT BRACKET

- 7.54. WELDING EXHAUST TUBE BY ACTUALLY POSITIONING IT ON MACHINE

- 7.55. INSTALLATION OF GREASE JUNCTION TUBE 4POINT GREASING SPECIFICATION

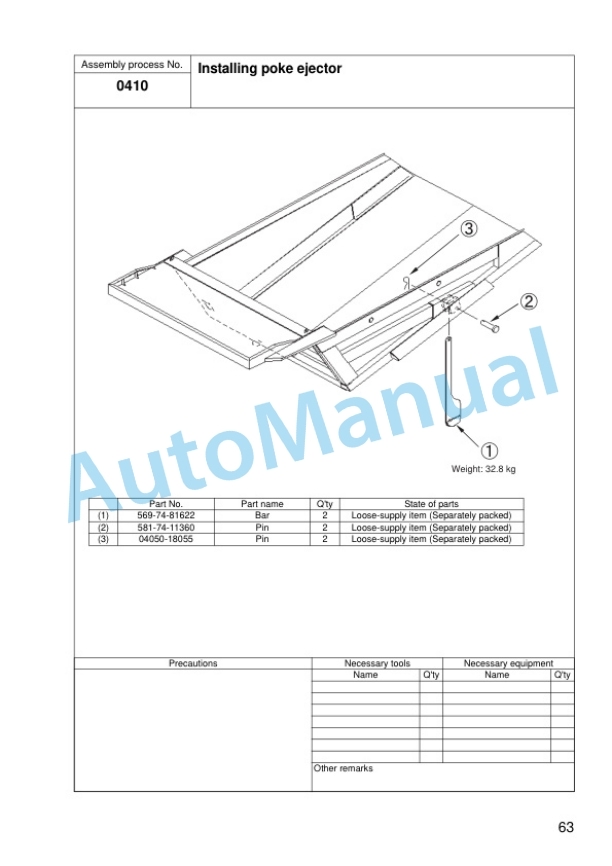

- 7.56. INSTALLING POKE EJECTOR

- 7.57. INSTALLING BODY LOCK PIN

- 7.58. INSTALLING BODY MUDGUARD

- 7.59. CONNECTING DUMP SENSOR

- 7.60. PROCEDURE FOR ADJUSTING DUMP SENSOR

- 7.61. CALIBRATING DUMP CONTROL

- 7.62. BLEEDING AIR FROM BRAKE SYSTEM (PREPARATION)

- 7.63. BLEEDING AIR FROM BRAKE SYSTEM (FRONT)

- 7.64. BLEEDING AIR FROM BRAKE SYSTEM (REAR)

- 7.65. ADJUSTING SUSPENSION

- 7.66. GREASING (RIGHT FRONT AXLE)

- 7.67. GREASING (HOIST CYLINDER)

- 7.68. GREASING (REAR SUSPENSION AND AXLE ROD)

- 7.69. PAINTING

- 7.70. STICKING BODY DECAL

- 7.71. Sticking body decal (2/2)

- 7.72. REMOVING JIG

- 7.73. ADJUSTING ANGLES OF MIRRORS

- 7.74. CHECKING/ADDING LUBRICANTS

- 7.75. G350 Installation of cab

- 7.76. G420 Connection of steering column

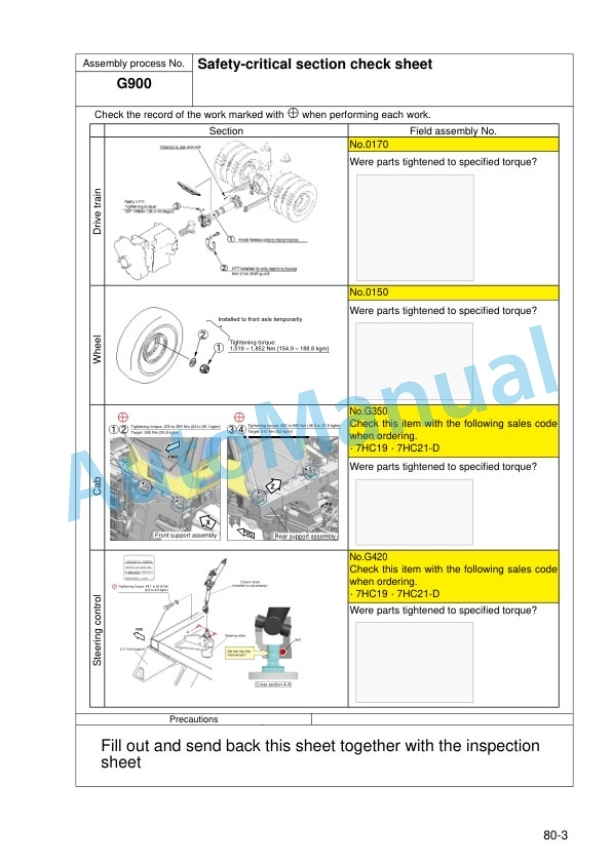

- 7.77. G900 Safetycritical section check sheet

- 7.78. G910 Check of inflation pressure of tires and inflation of them

- 7.79. C0010 PREPARATION OF WELDING BODY

- 7.80. C0020 ASSEMBLY OF SPLIT BODY

- 7.81. C0030 TACK WELDING BODY

- 7.82. C0040 WELDING BODY

- 7.83. C0050 WELDING BODY INSTRUCTION (1/2)

- 7.84. C0060 WELDING BODY INSTRUCTION (2/2)

- 7.85. C0070 TURN OVER THE BODY

- 7.86. C0080 WELDING BODY PROTECTOR (1/2)

- 7.87. C0090 WELDING BODY PROTECTOR (2/2)

- 7.88. C0100 FINISHING AND PAINTING WELDED PARTS OF BODY

- 7.89. C0110 REWORKING ON BODY (EXHAUST SELECTOR BOX SPECIFICATION)

- 7.90. C0120 WELDING OF BODY EXHAUST PIPE (EXHAUST SELECTOR BOX SPECIFICATION)

- 8. FIELD ASSEMBLY INSPECTION REPORT

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700