Komatsu HD465-8, HD605-8 Dump Truck Operation and Maintenance Manual EENAM03552

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: EENAM03552

- Format: PDF

- Size: 20.5MB

- Number of Pages: 426

-

Model List:

- HD465-8 Dump Truck

- HD605-8 Dump Truck

- 1. FOREWORD

- 1.1. READ THIS MANUAL

- 1.2. KOMATSU MACHINE OPERATOR PRIVACY POLICY

- 1.3. SAFETY INFORMATION

- 1.4. NOISE

- 1.5.1. VIBRATION OPERATING CONDITION

- 1.5.2. GUIDE TO REDUCE VIBRATION LEVELS ON MACHINE

- 1.6. VIBRATION LEVEL

- 1.7. INTRODUCTION

- 1.7.1. MAIN USE OF MACHINE

- 1.7.2. DIRECTIONS OF MACHINE

- 1.7.3. VISIBILITY FROM OPERATORS SEAT

- 1.8. PRODUCT INFORMATION

- 1.8.1. LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 1.8.2. LOCATION OF ENGINE NUMBER PLATE

- 1.8.3. FLUORINATED GREENHOUSE GASES

- 1.8.4. SERVICE METER LOCATION

- 1.8.5. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 1.9. SERIAL PLATE

- 1.10. DECLARATION OF CONFORMITY

- 1.11. TABLE OF CONTENTS

- 2. SAFETY

- 2.1. SAFETY LABELS

- 2.1.1. LOCATION OF SAFETY LABELS

- 2.1.2. CONTENTS OF SAFETY LABELS

- 2.2. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 2.2.1. PRECAUTIONS BEFORE STARTING OPERATION

- 2.2.2. PREPARATIONS FOR SAFE OPERATION

- 2.2.3. PRECAUTIONS TO PREVENT FIRE

- 2.2.4. PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

- 2.2.5. DO NOT GET CAUGHT IN WORK EQUIPMENT

- 2.2.6. PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES

- 2.2.7. UNAUTHORIZED MODIFICATION

- 2.2.8. PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

- 2.2.9. PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING

- 2.3. PRECAUTIONS FOR OPERATION

- 2.3.1. PRECAUTIONS FOR JOBSITE

- 2.3.2. START ENGINE

- 2.3.3. PRECAUTIONS FOR OPERATION

- 2.3.4. TRANSPORTATION

- 2.3.5. TOWING AND BEING TOWED

- 2.4. PRECAUTIONS FOR MAINTENANCE

- 2.4.1. PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE

- 2.4.2. PRECAUTIONS FOR CHECK AND MAINTENANCE

- 2.4.3. TIRES

- 3. OPERATION

- 3.1. GENERAL VIEW

- 3.1.1. MACHINE EQUIPMENT NAME

- 3.1.2. CONTROLS AND GAUGES NAMES

- 3.1.3. OTHER EQUIPMENT NAME

- 3.2. EXPLANATION OF COMPONENTS

- 3.2.1. EXPLANATION OF MACHINE MONITOR EQUIPMENT

- 3.2.2. SWITCHES

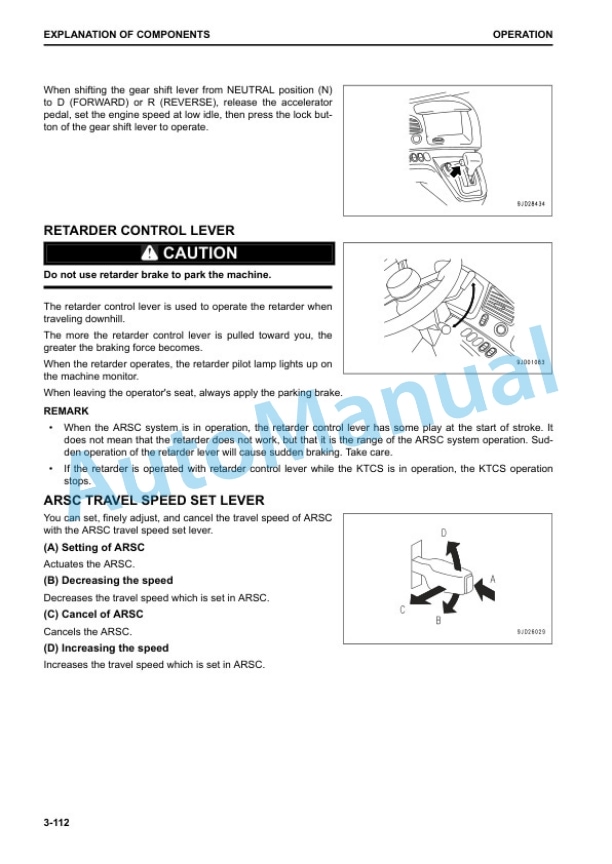

- 3.2.3. CONTROL LEVERS AND PEDALS

- 3.2.4. OTHER EQUIPMENT

- 3.3. MACHINE OPERATIONS AND CONTROLS

- 3.3.1. CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE

- 3.3.2. METHOD FOR STARTING ENGINE

- 3.3.3. METHOD FOR OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 3.3.4. METHOD FOR STOPPING ENGINE

- 3.3.5. METHOD FOR CHECKING AFTER STOPPING ENGINE

- 3.3.6. METHOD FOR STARTING MACHINE (TRAVEL FORWARD AND REVERSE) AND STOPPING MACHINE

- 3.3.7. METHOD FOR SHIFTING GEARS

- 3.3.8. METHOD FOR TRAVELING DOWNHILL

- 3.3.9. METHOD FOR TURNING MACHINE

- 3.3.10. HANDLE OVERLOAD SPEED LIMIT FUNCTION

- 3.3.11. METHOD FOR LOADING

- 3.3.12. HANDLING PAYLOAD METER

- 3.3.13. METHOD FOR DUMPING

- 3.3.14. PRECAUTIONS FOR OPERATION

- 3.3.15. METHOD FOR PARKING MACHINE

- 3.3.16. METHOD FOR CHECKING AFTER FINISHING WORK

- 3.3.17. LOCK

- 3.3.18. HANDLE TIRE

- 3.4. HANDLE AIR CONDITIONER

- 3.4.1. EXPLANATION OF AIR CONDITIONER EQUIPMENT

- 3.4.2. METHOD FOR OPERATING AIR CONDITIONER

- 3.5. HANDLE RADIO

- 3.5.1. EXPLANATION OF RADIO EQUIPMENT

- 3.5.2. METHOD FOR CONTROLLING RADIO

- 3.6. DUMP BODY HEATING SPECIFICATIONS

- 3.7. DETERMINE AND MAINTAIN TRAVEL ROAD

- 3.8. TRANSPORTATION

- 3.8.1. PRECAUTIONS FOR TRANSPORTATION

- 3.8.2. SELECT TRANSPORTATION METHOD

- 3.8.3. METHOD FOR SECURING MACHINE

- 3.8.4. PRECAUTIONS FOR LIFTING MACHINE

- 3.9. COLD WEATHER OPERATION

- 3.9.1. COLD WEATHER OPERATION INFORMATION

- 3.9.2. PRECAUTIONS AFTER DAILY WORK COMPLETION IN COLD WEATHER

- 3.9.3. AFTER COLD WEATHER SEASON

- 3.10. PRECAUTIONS FOR LONGTERM STORAGE

- 3.10.1. PREPARATION FOR LONGTERM STORAGE

- 3.10.2. MAINTENANCE DURING LONGTERM STORAGE

- 3.10.3. STARTING MACHINE AFTER LONGTERM STORAGE

- 3.10.4. PREPARATION BEFORE TRAVELING AFTER LONGTERM STORAGE

- 3.11. TROUBLES AND ACTIONS

- 3.11.1. ACTIONS WHEN RUNNING OUT OF FUEL

- 3.11.2. ACTIONS IF TRANSMISSION HAS TROUBLE

- 3.11.3. METHOD FOR LOWERING DUMP BODY IF TROUBLES OCCUR

- 3.11.4. PRECAUTIONS FOR TOWING MACHINE

- 3.11.5. PRECAUTIONS FOR DISCHARGED BATTERY

- 3.11.6. OTHER TROUBLE

- 4. MAINTENANCE

- 4.1. PRECAUTIONS FOR MAINTENANCE

- 4.1.1. CHECK SERVICE METER READING

- 4.1.2. KOMATSU GENUINE REPLACEMENT PARTS

- 4.1.3. KOMATSU GENUINE LUBRICANTS

- 4.1.4. ALWAYS USE CLEAN WASHER FLUID

- 4.1.5. FRESH AND CLEAN LUBRICANTS

- 4.1.6. CHECK DRAINED OIL AND USED FILTER

- 4.1.7. PRECAUTIONS FOR REFILLING OIL OR FUEL

- 4.1.8. PRECAUTIONS FOR WELDING

- 4.1.9. DO NOT DROP THINGS INSIDE MACHINE

- 4.1.10. PRECAUTIONS FOR KDPF

- 4.1.11. DUSTY JOBSITES

- 4.1.12. AVOID MIXING OIL

- 4.1.13. LOCK INSPECTION COVERS

- 4.1.14. BLEED AIR FROM HYDRAULIC CIRCUIT

- 4.1.15. PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES

- 4.1.16. CHECKS AFTER INSPECTION AND MAINTENANCE

- 4.1.17. FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE

- 4.1.18. CLOSE ENGINE SIDE COVER SECURELY

- 4.1.19. PRECAUTIONS FOR JACKUP

- 4.2. OUTLINE OF MAINTENANCE

- 4.2.1. HANDLE OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 4.2.2. HANDLE ELECTRICAL COMPONENTS

- 4.3. STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS

- 4.4. MAINTENANCE SCHEDULE

- 4.4.1. MAINTENANCE SCHEDULE TABLE

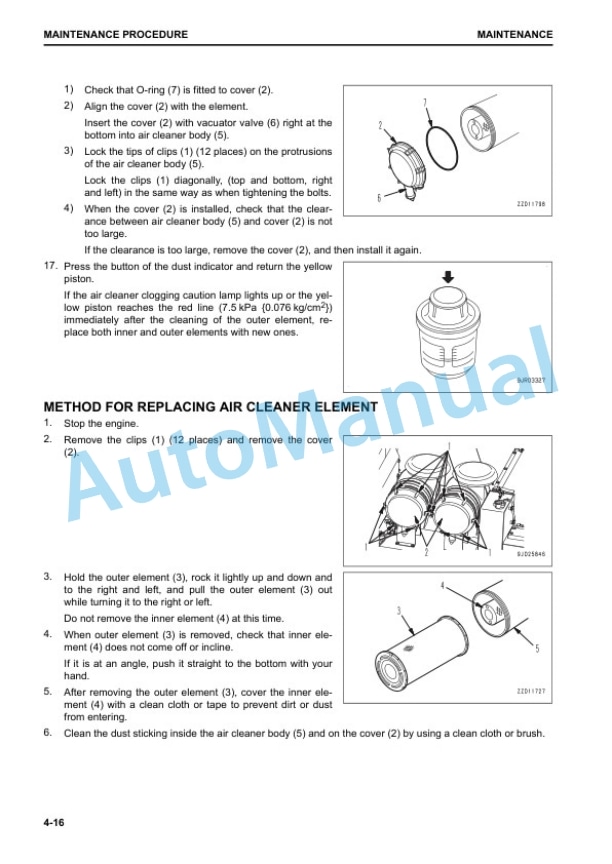

- 4.5. MAINTENANCE PROCEDURE

- 4.5.1. INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

- 4.5.2. WHEN REQUIRED

- 4.5.3. CHECKS BEFORE STARTING

- 4.5.4. EVERY 250 HOURS MAINTENANCE

- 4.5.5. EVERY 500 HOURS MAINTENANCE

- 4.5.6. EVERY 1000 HOURS MAINTENANCE

- 4.5.7. EVERY 2000 HOURS MAINTENANCE

- 4.5.8. EVERY 4000 HOURS MAINTENANCE

- 4.5.9. EVERY 4500 HOURS MAINTENANCE

- 4.5.10. EVERY 8000 HOURS MAINTENANCE

- 4.5.11. EVERY 9000 HOURS MAINTENANCE

- 4.5.12. EVERY 15000 HOURS MAINTENANCE

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS

- 5.1.1. SPECIFICATIONS HD4658

- 5.1.2. SPECIFICATIONS HD6058

- 6. ATTACHMENTS AND OPTIONS

- 6.1. BODY SELECTION

- 6.2. HANDLE ENGINE ROOM LAMP

- 6.2.1. METHOD FOR USING ENGINE ROOM LAMP

- 6.3. HANDLE KOMATSU TRACTION CONTROL SYSTEM (KTCS)

- 6.3.1. OPERATION OF KTCS

- 6.3.2. METHOD FOR OPERATING MACHINE WHEN TIRES ARE STUCK IN GROUND

- 6.4. HANDLE SPEED LIMIT FUNCTION

- 6.4.1. OPERATION OF SPEED LIMIT FUNCTION

- 6.4.2. OPERATION IF TROUBLES ON SYSTEM OCCUR

- 7. REPLACEMENT PARTS

- 7.1. PERIODIC REPLACEMENT OF DEFINED LIFE PARTS

- 7.1.1. DEFINED LIFE PARTS LIST

- 7.2. CONSUMABLE PARTS

- 7.2.1. CONSUMABLE PARTS LIST

- 7.3. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 7.3.1. LUBRICATION CHART

- 7.3.2. METHOD FOR USING FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 7.3.3. RECOMMENDED BRANDS AND QUALITIES OTHER THAN KOMATSU GENUINE OILS

- 8. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E