Komatsu HM400-3R Articulated Dump Truck Operation and Maintenance Manual PEN00635-15

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: PEN00635-15

- Format: PDF

- Size: 25.4MB

- Number of Pages: 421

-

Model List:

- HM400-3R Articulated Dump Truck

- 1. COVER

- 2. FOREWORD

- 2.1. BEFORE READING THIS MANUAL

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. USE OF MACHINE

- 2.3.2. DIRECTIONS OF MACHINE

- 2.3.3. VISIBILITY FROM OPERATORS SEAT

- 2.3.4. PROXIMITY VISIBILITY

- 2.3.5. m CIRCUMFERENCE VISIBILITY

- 2.4. PRODUCT INFORMATION

- 2.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 2.4.2. ENGINE NUMBER PLATE

- 2.4.3. SERVICE METER LOCATION

- 2.4.4. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 2.5. CONTENTS

- 3. SAFETY

- 3.1. SAFETY

- 3.2. SAFETY LABELS

- 3.2.1. LOCATION OF SAFETY LABELS

- 3.2.2. SAFETY LABELS

- 3.3. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 3.3.1. PRECAUTIONS BEFORE STARTING OPERATION

- 3.3.2. PREPARATIONS FOR SAFE OPERATION

- 3.3.3. FIRE PREVENTION

- 3.3.4. PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

- 3.3.5. DO NOT GET CAUGHT IN WORK EQUIPMENT

- 3.3.6. PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES

- 3.3.7. UNAUTHORIZED MODIFICATION

- 3.3.8. PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

- 3.3.9. PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING

- 3.4. PRECAUTIONS FOR OPERATION

- 3.4.1. PRECAUTIONS FOR JOBSITE

- 3.4.2. STARTING ENGINE

- 3.4.3. OPERATION

- 3.4.4. TRANSPORTATION

- 3.4.5. TOWING

- 3.5. PRECAUTIONS FOR MAINTENANCE

- 3.5.1. PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE

- 3.5.2. PRECAUTIONS FOR INSPECTION AND MAINTENANCE

- 3.5.3. TIRES

- 4. OPERATION

- 4.1. GENERAL VIEW

- 4.1.1. GENERAL VIEW OF MACHINE

- 4.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

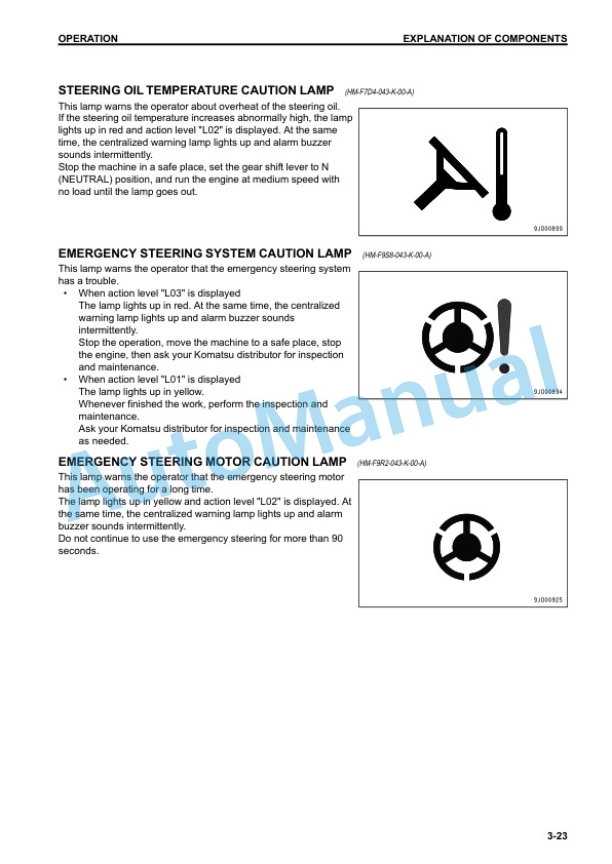

- 4.2. EXPLANATION OF COMPONENTS

- 4.2.1. MACHINE MONITOR

- 4.2.2. SWITCHES

- 4.2.3. CONTROL LEVERS AND PEDALS

- 4.2.4. CIGARETTE LIGHTER

- 4.2.5. EMERGENCY ESCAPE HAMMER

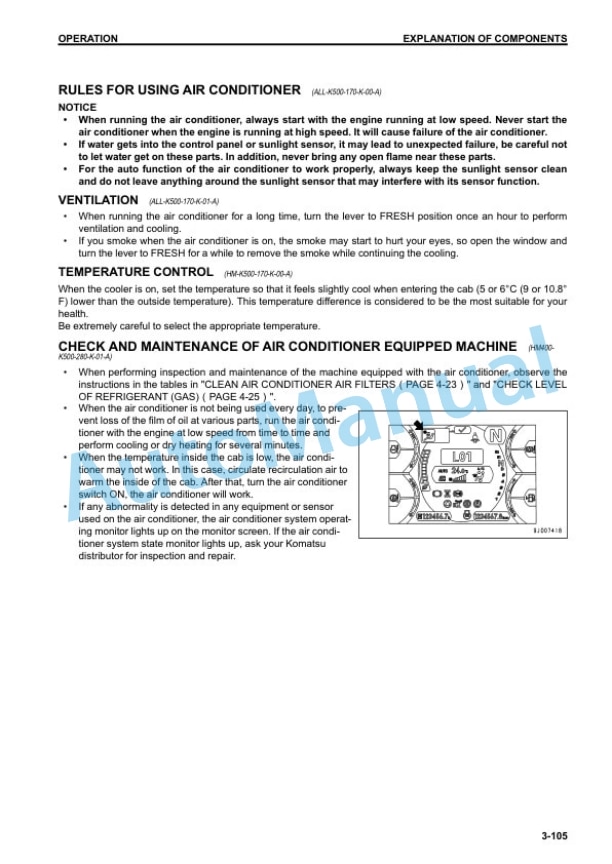

- 4.2.6. HANDLING AIR CONDITIONER

- 4.2.7. HANDLING RADIO

- 4.2.8. AUXILIARY ELECTRIC POWER

- 4.2.9. FUSE

- 4.2.10. OPEN AND CLOSE CAB DOOR

- 4.2.11. STORAGE FOR TOOLS

- 4.2.12. STORAGE FOR FIRE EXTINGUISHER

- 4.2.13. BATTERY DISCONNECT SWITCH

- 4.2.14. CIRCUIT BREAKER

- 4.2.15. DUST INDICATOR

- 4.2.16. ARTICULATION LOCK

- 4.2.17. BODY PIVOT PINS

- 4.2.18. HANDLING MACHINES EQUIPPED WITH KOMTRAX

- 4.3. MACHINE OPERATIONS AND CONTROLS

- 4.3.1. CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE

- 4.3.2. STARTING ENGINE

- 4.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 4.3.4. STOPPING ENGINE

- 4.3.5. CHECKS AFTER STOPPING ENGINE

- 4.3.6. MACHINE OPERATION

- 4.3.7. SHIFTING GEARS

- 4.3.8. TRAVELING DOWNHILL

- 4.3.9. STEERING MACHINE

- 4.3.10. OPERATE WITH INTERAXLE DIFFERENTIAL LOCK

- 4.3.11. HANDLING AUTOMATIC RETARDER, ACCELERATOR CONTROL (ARAC)

- 4.3.12. HANDLING KOMATSU TRACTION CONTROL SYSTEM (KTCS)

- 4.3.13. LOADING WORK

- 4.3.14. DUMPING

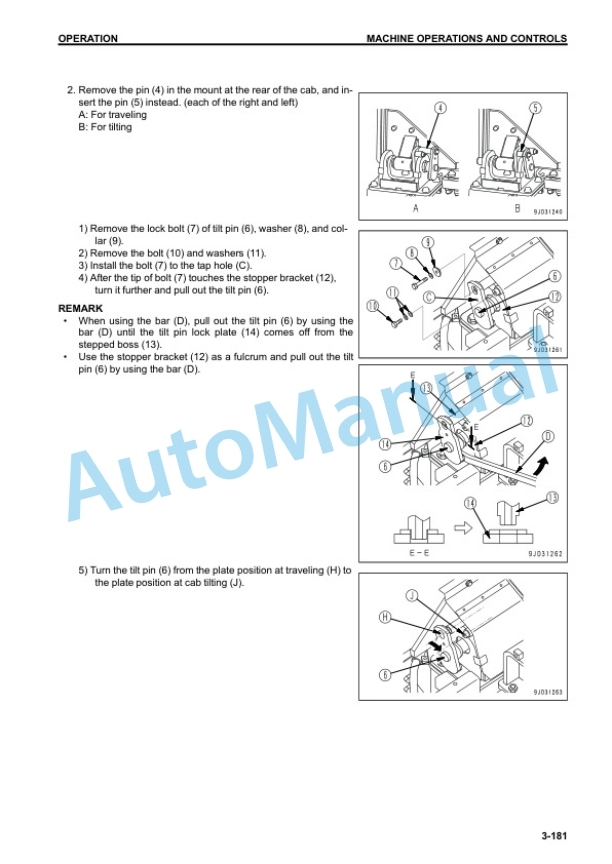

- 4.3.15. CAB TILT OPERATION

- 4.3.16. OPERATION

- 4.3.17. PARKING MACHINE

- 4.3.18. AFTER DAILY WORK COMPLETION

- 4.3.19. LOCKING

- 4.3.20. HANDLING TIRES

- 4.4. DETERMINE AND MAINTAIN TRAVEL ROAD

- 4.4.1. DETERMINE TRAVEL ROAD

- 4.4.2. MAINTAIN TRAVEL ROAD

- 4.5. TRANSPORTATION

- 4.5.1. TRANSPORTATION

- 4.5.2. SECURING MACHINE

- 4.5.3. LIFTING MACHINE

- 4.6. COLD WEATHER OPERATION

- 4.6.1. COLD WEATHER OPERATION INFORMATION

- 4.6.2. AFTER DAILY WORK COMPLETION

- 4.7. LONGTERM STORAGE

- 4.7.1. BEFORE STORAGE

- 4.8. TROUBLES AND ACTIONS

- 4.8.1. RUNNING OUT OF FUEL

- 4.8.2. IF TRANSMISSION HAS TROUBLE

- 4.8.3. LOWERING DUMP BODY IN EMERGENCY

- 4.8.4. TOWING MACHINE

- 4.8.5. DISCHARGED BATTERY

- 4.8.6. OTHER TROUBLE

- 5. MAINTENANCE

- 5.1. RULES FOR MAINTENANCE

- 5.1.1. SERVICE METER READING

- 5.1.2. KOMATSU GENUINE REPLACEMENT PARTS

- 5.1.3. KOMATSU GENUINE LUBRICANTS

- 5.1.4. ALWAYS USE CLEAN WASHER FLUID

- 5.1.5. FRESH AND CLEAN LUBRICANTS

- 5.1.6. CHECK DRAINED OIL AND USED FILTER

- 5.1.7. CAUTION FOR REFILLING OIL OR FUEL

- 5.1.8. WELDING INSTRUCTIONS

- 5.1.9. DO NOT DROP THINGS INSIDE MACHINE

- 5.1.10. DUSTY JOBSITES

- 5.1.11. AVOID MIXING OIL

- 5.1.12. LOCKING INSPECTION COVERS

- 5.1.13. BLEED AIR FROM HYDRAULIC CIRCUIT

- 5.1.14. PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES

- 5.1.15. CHECKS AFTER INSPECTION AND MAINTENANCE

- 5.1.16. FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE

- 5.2. OUTLINE OF MAINTENANCE

- 5.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 5.2.2. HANDLING ELECTRICAL COMPONENTS

- 5.3. STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS

- 5.3.1. TIGHTENING TORQUE LIST

- 5.4. MAINTENANCE SCHEDULE

- 5.4.1. MAINTENANCE SCHEDULE TABLE

- 5.4.2. MAINTENANCE INTERVAL WHEN DIESEL FUEL MIXED WITH BIOFUEL IS USED

- 5.5. MAINTENANCE PROCEDURE

- 5.5.1. INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

- 5.5.2. WHEN REQUIRED

- 5.5.3. CHECKS BEFORE STARTING

- 5.5.4. EVERY 50 HOURS MAINTENANCE

- 5.5.5. EVERY 250 HOURS MAINTENANCE

- 5.5.6. EVERY 500 HOURS MAINTENANCE

- 5.5.7. EVERY 1000 HOURS MAINTENANCE

- 5.5.8. EVERY 2000 HOURS MAINTENANCE

- 5.5.9. EVERY 4000 HOURS MAINTENANCE

- 5.5.10. EVERY 6000 HOURS MAINTENANCE

- 5.5.11. EVERY 8000 HOURS MAINTENANCE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 7. ATTACHMENTS AND OPTIONS

- 7.1. CAB POWER TILT

- 7.2. HANDLING PAYLOAD METER

- 7.2.1. OUTLINE OF SYSTEM

- 7.2.2. DISPLAY DURING NORMAL OPERATION

- 7.2.3. EXTERNAL DISPLAY LAMP

- 7.2.4. DETAILS OF DATA STORED IN MEMORY OF PAYLOAD METER

- 7.2.5. PROCEDURE WHEN DOWNLOADING

- 7.2.6. DISPLAY TOTAL PAYLOAD / NUMBER OF CYCLES

- 7.2.7. DISPLAY LOAD AND FUEL EFFICIENCY RECORD

- 7.2.8. SETTING MACHINE ID AND OPEN ID

- 7.2.9. PERFORMING CALIBRATION

- 7.2.10. PAYLOAD OF CYCLE DATA

- 7.2.11. SERVICE FUNCTION

- 7.2.12. THE OTHER INFORMATION

- 7.3. HANDLING CENTRALIZED BREATHERS

- 7.3.1. EVERY 250 HOURS MAINTENANCE

- 7.3.2. CLEAN BREATHER

- 7.3.3. EVERY 2000 HOURS MAINTENANCE

- 7.3.4. REPLACE BREATHER ELEMENT IN HYDRAULIC TANK

- 7.3.5. EVERY 4000 HOURS MAINTENANCE

- 7.3.6. REPLACE AIR CLEANER ELEMENT

- 7.3.7. CONSUMABLE PARTS LIST

- 7.4. HANDLING FUEL QUICK CHARGE SYSTEM

- 7.4.1. PROCEDURE FOR REFUELING

- 7.4.2. CHECK AND MAINTENANCE

- 7.5. ROLLOVER AVOIDANCE SYSTEM

- 7.5.1. OPERATION IF TROUBLES ON SYSTEM OCCUR

- 8. REPLACEMENT PARTS

- 8.1. SAFETY CRITICAL PARTS

- 8.1.1. SAFETY CRITICAL PARTS LIST

- 8.2. CONSUMABLE PARTS

- 8.2.1. CONSUMABLE PARTS LIST

- 8.3. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 8.3.1. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 8.3.2. RECOMMENDED BRANDS AND QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 9. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E