Komatsu MWL22-1A Forklift Truck Service Manual

$30.00

- Type Of Manual: Service Manual

- Format: PDF

- Size: 2.5MB

- Number of Pages: 243

Category: Komatsu Service Manual PDF

-

Model List:

- MWL22-1A Forklift Truck

- 1. BXINTRO

- 1.1. Introduction, Service Manual

- 1.2. Contents, Section M

- 1.2.1. Machine Information

- 1.3. General Product Information

- 1.3.1. Presentation of the MWL221A.

- 1.3.1.1. Intended Application of the Trucks

- 1.3.1.2. Forbidden Application of the Trucks

- 1.3.1.3. Truck Data

- 1.3.1.4. MWL221A Dimensions

- 1.3.1.5. Data Plate

- 1.3.2. Main Components

- 1.4. Inch (SAE) and Metric Fasteners

- 1.4.1. Introduction

- 1.4.2. Nomenclature, Threads

- 1.4.3. Strength Identification

- 1.4.4. Conversion of Metric and English Units

- 2. BXBATT

- 2.1. Swing Out Battery Pack

- 2.1.1. Charger Diagram

- 2.1.2. Battery Cable routing diagram

- 2.1.3. Troubleshooting

- 2.1.4. Electrical testing

- 2.2. GNB Battery Pack

- 2.2.1. General Information

- 2.2.2. Troubleshooting

- 2.2.2.1. Troubleshooting Symptom

- 2.3. Battery Controller / Hourmeter Lift Interrupt

- 2.3.1. General Information

- 2.3.2. Electrical

- 2.3.2.1. Voltage

- 2.3.3. Battery Controller (BC)

- 2.3.3.1. General Information

- 2.3.3.2. Reset

- 2.3.3.3. Key Switch

- 2.3.3.4. Hourmeter

- 2.3.4. Troubleshooting

- 2.3.4.1. Battery Discharge Indicator (BDI)

- 2.3.4.2. Hourmeter

- 2.4. Battery Discharge Indicator / Hourmeter

- 2.4.1. General Information

- 2.4.2. Electrical

- 2.4.2.1. Voltage

- 2.4.3. Battery Discharge Indicator (BDI)

- 2.4.3.1. General Information

- 2.4.3.2. Key Switch

- 2.4.3.3. Hourmeter

- 2.4.4. Troubleshooting

- 2.4.4.1. Battery Discharge Indicator (BDI)

- 2.4.4.2. Hourmeter

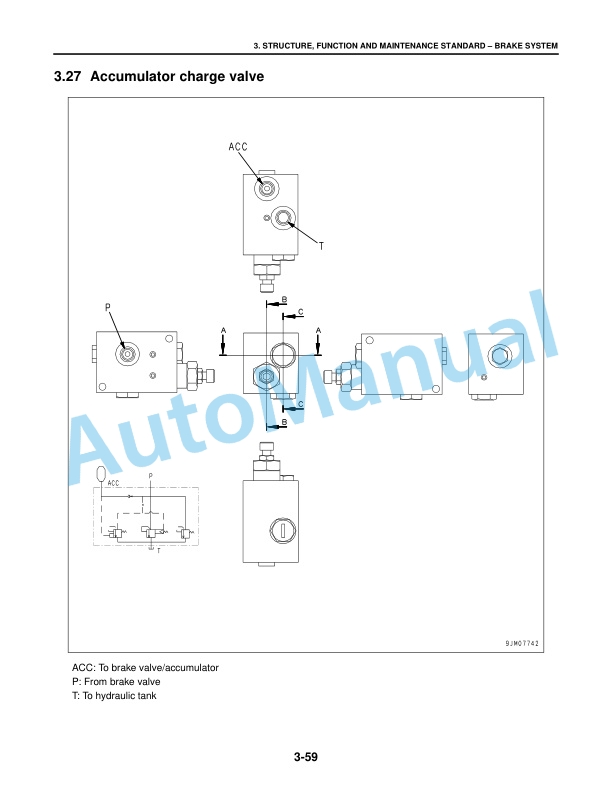

- 3. BXBRAKE

- 3.1. Parking Brake System

- 3.1.1. Brake Theory of Operation

- 3.1.2. Brake Adjustment

- 3.1.3. Brake Shoe Removal / Installation

- 3.2. Drive Wheel

- 3.2.1. Removal

- 3.2.2. Installation

- 3.3. Load Wheels

- 3.3.1. Removal/Installation

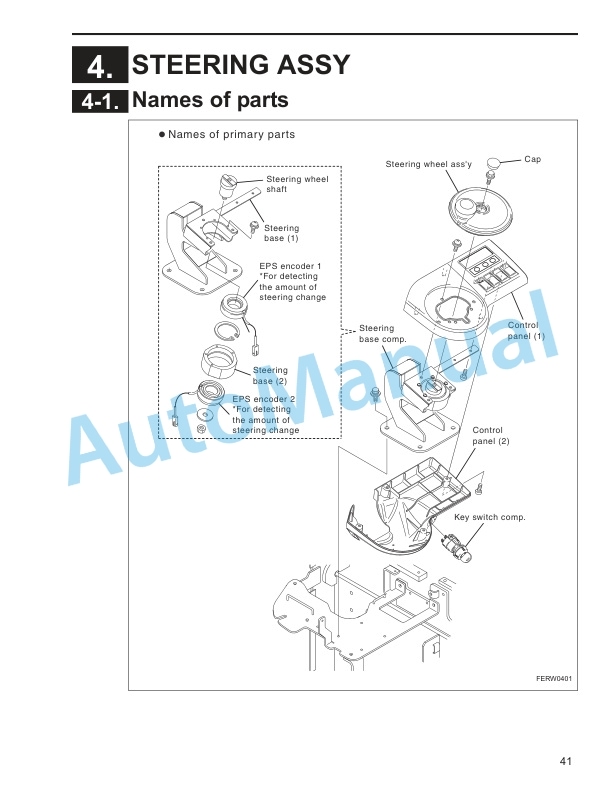

- 3.4. Steering

- 3.4.1. Control Handle Head

- 3.4.1.1. Removal

- 3.4.1.2. Installation

- 3.5. Steering Handle Head

- 3.5.1. Control Handle Head

- 3.5.1.1. Removal

- 3.5.1.2. Installation

- 3.5.2. Direction Control Switches

- 3.5.3. Horn, Raise, and Lower Switches

- 3.5.4. Potentiometer

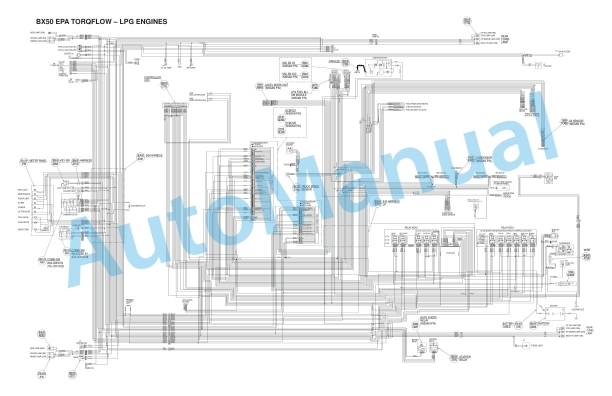

- 4. BXELEC

- 4.1. MWL221A 12 Volt Electrical System

- 4.1.1. Electrical Panel Components

- 4.1.1.1. Electrical Schematic

- 4.1.1.2. Electrical Schematic Symbols

- 4.2. MWL221A 12 Volt Transistor Controller

- 4.2.1. Maintenance

- 4.2.1.1. Safety

- 4.2.1.2. Cleaning

- 4.2.1.3. Troubleshooting

- 4.2.2. Basics Of Circuit Operation

- 4.2.2.1. Battery connected and emergency disconnect switch in the RUN position.

- 4.2.2.2. Key switch turned ON

- 4.2.2.3. Control handle pulled down brakes released and brake interlock switch closed.

- 4.2.2.4. Reverse travel (fork direction) switch is closed.

- 4.2.2.5. Forward travel (control handle direction) switch is closed.

- 4.2.2.6. Curtis PMC controller power circuits.

- 4.2.2.7. Accelerator Potentiometer Circuits

- 4.2.2.8. Emergency Reverser Switch

- 4.2.2.9. Lift Pallet Forks

- 4.2.2.10. Lower Pallet Forks

- 4.2.2.11. Controller Adjustments

- 4.3. MWL221A 12 Volt Transistor Controller Troubleshooting

- 4.3.1. Troubleshooting Chart Index

- 4.3.2. Troubleshooting Charts

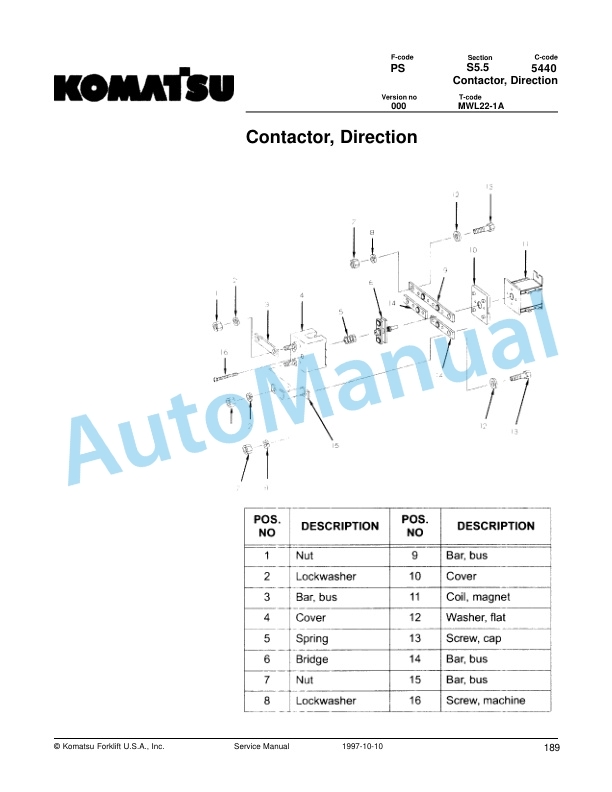

- 4.4. Contactor, Direction

- 4.4.1. Maintenance

- 4.4.1.1. Removal/Replacement of Contact Tips

- 4.5. MWL221A 24 Volt Electrical System

- 4.5.1. Electrical Panel Components

- 4.5.2. List of Symbols

- 4.5.2.1. Circuit Diagram 1(3)

- 4.5.2.2. Circuit Diagram 2(3)

- 4.5.2.3. Circuit Diagram 3(3)

- 4.5.3. Description of Function

- 4.5.3.1. General Information

- 4.5.3.2. References Information

- 4.5.3.3. Key Switch S17 in the ON Position

- 4.5.3.4. The Operating Arm in Drive Position, S10, Brake Switch Closed

- 4.5.3.5. Driving, Fork Direction

- 4.5.3.6. Driving, Steer Wheel Direction

- 4.5.3.7. Reversing/Motor Brake Fork Direction to Steer Wheel Direction

- 4.5.3.8. Reversing/Motor Brake Steer Wheel Direction to Fork Direction

- 4.5.3.9. Reverser switch

- 4.5.3.10. Lifting the Forks

- 4.5.3.11. Lowering the Forks

- 4.5.3.12. Horn

- 4.5.3.13. Lift lnterrupt

- 4.6. MWL221A 24 Volt, Transistor Controller

- 4.6.1. Maintenance

- 4.6.1.1. Safety

- 4.6.1.2. Cleaning

- 4.6.1.3. Diagnostics and Troubleshooting

- 4.6.2. Basics Of Circuit Operation

- 4.6.2.1. Control Feature

- 4.6.3. Motor Circuit

- 4.6.4. Control Circuit

- 4.6.5. Diagnostics and Troubleshooting

- 4.6.5.1. Programmer Diagnostics

- 4.6.5.2. Troubleshooting Chart

- 4.6.5.3. Technical Specification

- 4.6.5.4. Troubleshooting Chart Using the Handset

- 4.7. MWL221A 24 Volt, Transistor Controller Troubleshooting

- 4.7.1. Troubleshooting Chart Index

- 4.7.2. Troubleshooting Charts

- 4.8. Handset Operation

- 4.8.1. Operating Modes

- 4.8.2. Revert to Previous Settings

- 4.8.3. Handset Self Test

- 5. BXHYDRA

- 5.1. Pump Motor

- 5.1.1. Component Repair

- 5.1.1.1. Motor Disassembly

- 5.1.2. Inspection and Troubleshooting

- 5.1.2.1. Drive End Head

- 5.1.2.2. Commutator End Head

- 5.1.2.3. Bearings

- 5.1.2.4. Brush and Commutator

- 5.1.2.5. Armature

- 5.1.2.6. Frame and Field Assembly

- 5.1.2.7. Assembly

- 5.1.3. Changing Brushes

- 5.2. Hydraulic System

- 5.2.1. Hydraulic Schematic

- 5.2.2. General Information

- 5.2.3. Description

- 5.2.3.1. Lift

- 5.2.3.2. Lower

- 5.2.3.3. Relief Pressure

- 5.2.4. Maintenance

- 5.2.5. Adjustments

- 5.2.6. Lift Limit Switch

- 5.2.7. Troubleshooting

- 5.3. Lift Pump Assembly

- 5.3.0.1. Solenoid Operated Valve

- 5.4. Lift Cylinder

- 5.4.1. Cylinder Repair

- 5.5. Technical Service Data

- 5.6. Ordering Spare Parts

- 5.7. Contents, Section P

- 5.7.1. Planned Maintenance

- 5.8. Introduction, Maintenance

- 5.8.1. Safe Jacking Procedure

- 5.9. Service Schedule

- 5.9.1. Planned Maintenance Schedule

- 5.9.2. Planned Maintenance Procedures

- 5.9.2.1. Services to be Performed Daily

- 5.9.2.2. Services to be Performed Monthly

- 5.9.2.3. Services to be Performed Annually

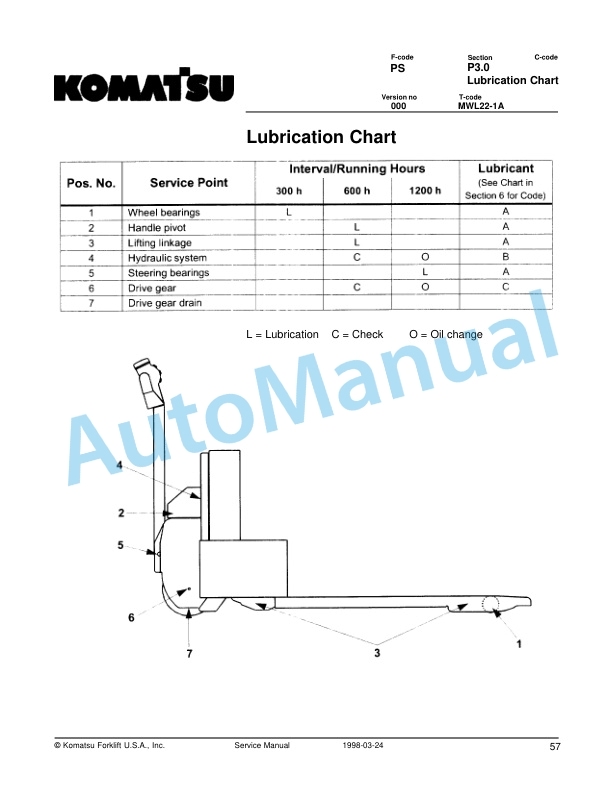

- 5.10. Lubrication Chart

- 5.11. Oil and Grease Specifications

- 5.11.1. Approved Oils and Grease

- 6. BXMOTOR

- 6.1. Drive Motor Mounting Points

- 6.1.1. Drive Motor Brush

- 6.1.1.1. Removal and Installation

- 6.1.2. Drive Motor Assembly

- 6.1.2.1. Remove

- 6.1.2.2. Installation

- 6.2. Drive Motor

- 6.2.1. General Information

- 6.2.2. Operating Conditions

- 6.2.3. Troubleshooting

- 6.3. Volt Drive Motor

- 6.3.1. Component Repair

- 6.3.1.1. Disassembly

- 6.3.2. Inspection and Troubleshooting

- 6.3.2.1. Drive End Head

- 6.3.2.2. Commutator End Head

- 6.3.2.3. Bearings

- 6.3.2.4. Brush and Commutator

- 6.3.2.5. Armature

- 6.3.2.6. Frame and Field Assembly

- 6.3.2.7. Assembly

- 6.3.3. Changing Brushes

- 6.4. Volt Drive Motor

- 6.4.1. Component Repair

- 6.4.1.1. Disassembly

- 6.4.2. Inspection and Troubleshooting

- 6.4.2.1. Drive End Head

- 6.4.2.2. Commutator End Head

- 6.4.2.3. Bearings

- 6.4.2.4. Brush and Commutator

- 6.4.2.5. Armature

- 6.4.2.6. Frame and Field Assembly

- 6.4.2.7. Assembly

- 6.4.3. Changing Brushes

- 6.5. Transmission

- 6.5.1. System Description

- 6.5.2. Troubleshooting

- 6.5.3. Axle Seal Removal and Installation

- 6.5.3.1. Removal

- 6.5.3.2. Installation

- 6.5.4. Transmission Removal/Installation

- 6.5.4.1. Removal

- 6.5.4.2. Installation

- 6.5.5. Transmission Assembly

- 6.5.5.1. Disassembly

- 6.5.5.2. Assembly

- 7. BXSAFETY

- 7.1. Standard Codes

- 7.2. Warning Symbols

- 7.2.1. Warning Levels

- 7.3. Prohibitory Symbols

- 7.3.1. Ordinance Symbols

- 8. BXSERV

- 8.1. Contents, Section S

- 8.1.1. Service Instructions

- 8.1.2. Carrier Frame Bushings

- 8.2. Chassis

- 8.2.1. General Information

Rate this product

You may also like

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu FR15K-3, FR18K-3, FR23K-3 Electric AC-Powered Stand-Up Rider Service Manual SM151

$30.00

Komatsu Service Manual PDF

Komatsu ASX Stand-up Counterbalanced Electric Forklift Truck Service Manual SM401

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00