Komatsu MWL22-2A Forklift Truck Service Manual

$30.00

- Type Of Manual: Service Manual

- Format: PDF

- Size: 3.1MB

- Number of Pages: 250

Category: Komatsu Service Manual PDF

-

Model List:

- MWL22-2A Forklift Truck

- 1. BYINTRO

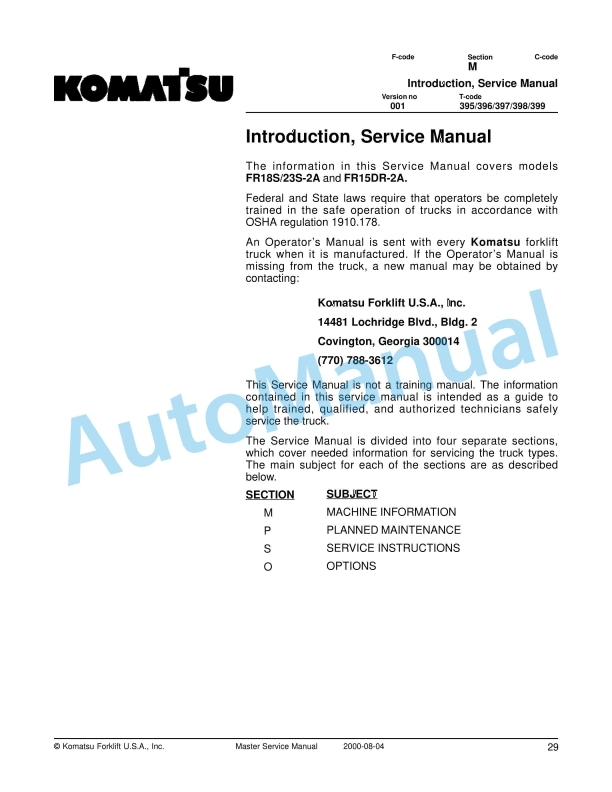

- 1.1. Introduction, Service Manual

- 1.2. Contents, Section M

- 1.2.1. Machine Information

- 1.3. General Product Information

- 1.3.1. Truck Presentation.

- 1.3.1.1. Truck Side Views

- 1.3.1.2. Intended Truck Application

- 1.3.1.3. Prohibited Truck Application

- 1.3.1.4. Truck Data

- 1.3.1.5. Truck Dimensions

- 1.3.1.6. Data Plate

- 1.3.2. Main Components

- 1.4. Inch and Metric (SAE) Fasteners

- 1.4.1. Introduction

- 1.4.2. Nomenclature, Threads

- 1.4.3. Strength Identification

- 1.4.4. Conversion of English and Metric Units

- 2. BYBRAKE

- 2.1. Parking Brake System

- 2.1.1. Brake Theory of Operation

- 2.1.2. Brake Adjustment

- 2.1.3. Brake Shoe Removal / Installation

- 2.2. Drive Wheel

- 2.2.1. Removal

- 2.2.2. Installation

- 2.2.3. Tire Pressing Procedure

- 2.3. Support/Swivel Wheel (Optional)

- 2.3.1. Maintenance and Adjustments

- 2.3.1.1. Caster Adjustment

- 2.3.2. Troubleshooting

- 2.3.2.1. Stabilizing Caster

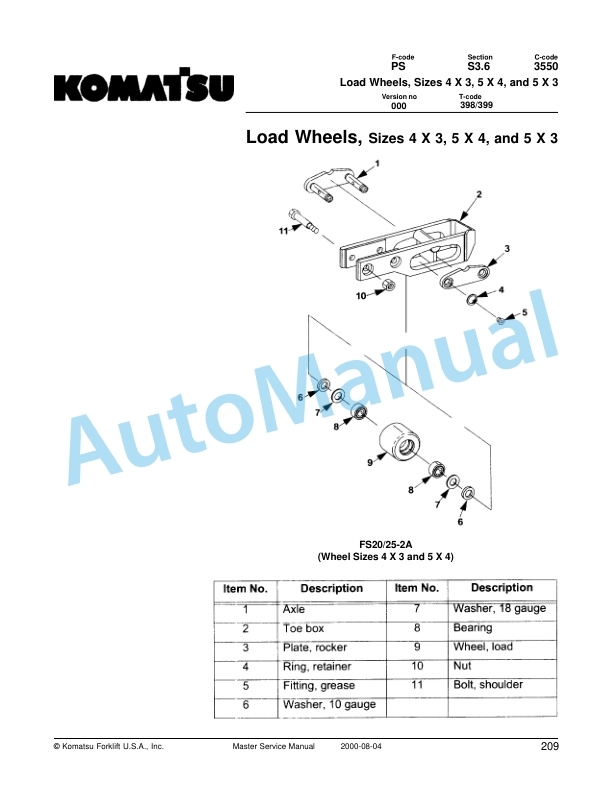

- 2.4. Fork Wheels

- 2.4.1. Removal/Installation

- 2.5. Steering

- 2.5.1. Control Handle Head

- 2.5.1.1. Removal

- 2.5.1.2. Installation

- 2.5.2. Driver Protection (Reverser) Assembly Replacement

- 2.5.3. Direction Control Switches

- 2.5.3.1. Removal

- 2.5.3.2. Installation

- 2.5.4. Raise, Lower, and Horn Switches

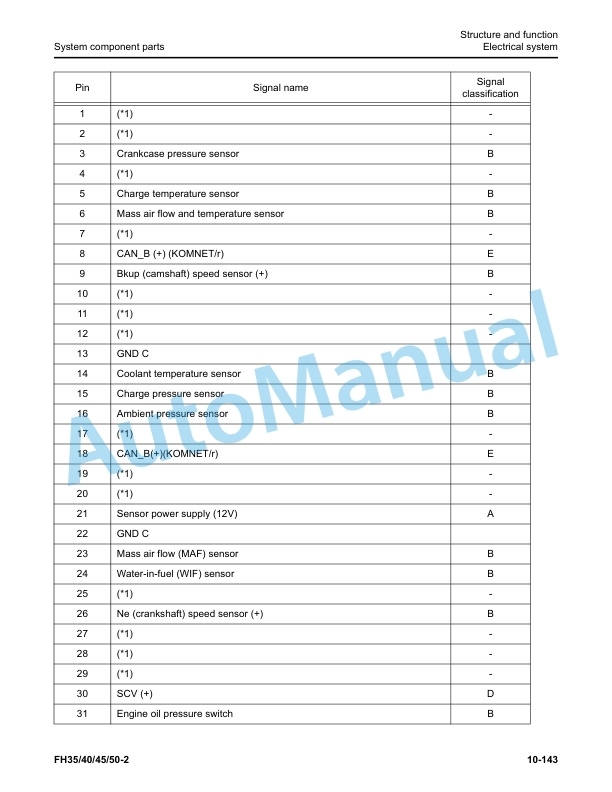

- 2.6. Electrical Functions

- 2.6.1. General

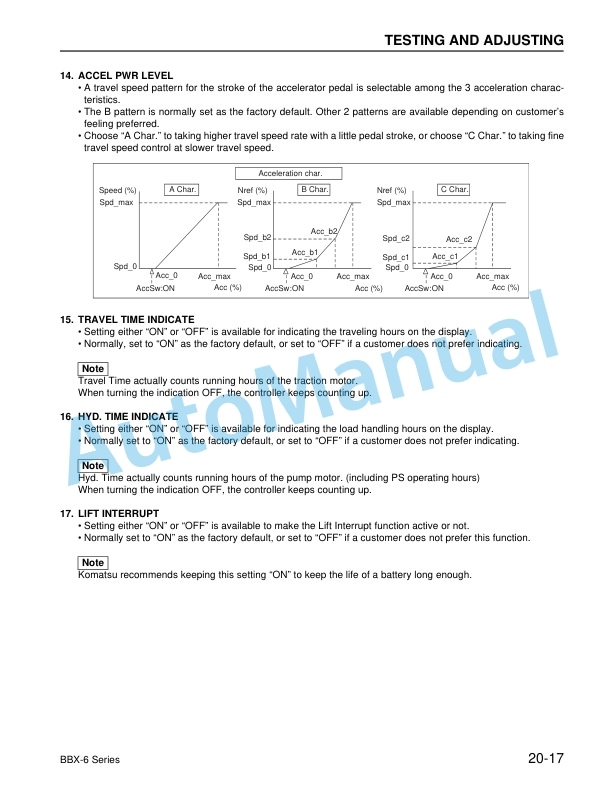

- 2.6.1.1. Adjustable Settings

- 2.6.1.2. References

- 2.6.1.3. Key Switch S17 in the ON Position

- 2.6.1.4. Operating Arm in Drive Position, S10, Brake Switch Closed

- 2.6.1.5. Travel Request, Fork First

- 2.6.1.6. Travel Request, Forks Trailing

- 2.6.1.7. Reversing/Motor Brake Forks First Direction to Forks Trailing Direction

- 2.6.1.8. Reversing/Motor Brake Forks Trailing Direction to Forks First Direction

- 2.6.1.9. Reverser switch

- 2.6.1.10. Lifting Forks

- 2.6.1.11. Lowering Forks

- 2.6.1.12. Horn

- 2.6.1.13. Lift Interrupt

- 2.7. Electrical Panel Components

- 2.8. Electrical Symbols

- 2.9. Electrical Schematics

- 2.10. Battery

- 2.10.1. Removal

- 2.10.2. Installation

- 2.10.3. Battery Maintenance

- 2.10.3.1. Battery Inspection and Care

- 2.10.3.2. Battery Exterior Cleaning

- 2.10.3.3. Charging

- 2.10.4. Storage

- 2.10.5. Battery History Record

- 2.11. Swing Out Battery Pack

- 2.11.1. Battery Cable Routing Diagram

- 2.11.2. Charger Diagram

- 2.11.3. Troubleshooting

- 2.11.3.1. Electrical Testing

- 2.12. Battery Connector

- 2.12.1. Location

- 2.12.2. Inspection

- 2.12.3. Installation

- 2.13. Battery Controller/Hourmeter/ Lift Interrupt (Optional)

- 2.13.1. General Information

- 2.13.2. Electrical

- 2.13.2.1. Voltage

- 2.13.3. Battery Controller (BC)

- 2.13.3.1. General Information

- 2.13.3.2. Reset

- 2.13.3.3. Key Switch

- 2.13.3.4. Hourmeter

- 2.13.4. Troubleshooting

- 2.13.4.1. Battery Discharge Indicator (BDI)

- 2.13.4.2. Hourmeter

- 2.14. Battery Discharge Indicator/ Hourmeter

- 2.14.1. General Information

- 2.14.2. Electrical

- 2.14.2.1. Voltage

- 2.14.3. Battery Discharge Indicator (BDI)

- 2.14.3.1. General Information

- 2.14.3.2. Key Switch

- 2.14.3.3. Hourmeter

- 2.14.4. Troubleshooting

- 2.14.4.1. Battery Discharge Indicator (BDI)

- 2.14.4.2. Hourmeter

- 2.15. Start/Stop Switches

- 2.15.1. General

- 2.15.1.1. Test/Inspection

- 2.15.2. Master Control On/Off Switch (S21)

- 2.15.2.1. Inspection

- 2.15.2.2. Removal

- 2.15.2.3. Installation

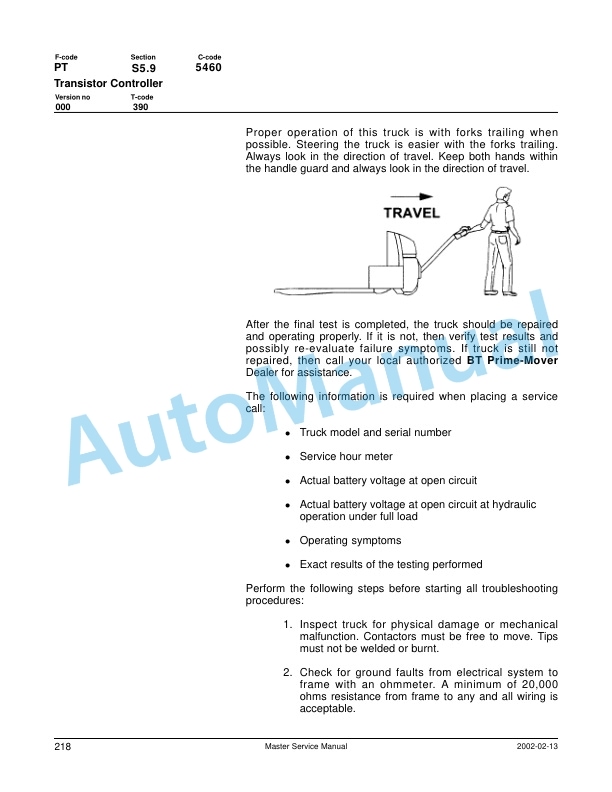

- 2.16. Transistor Controller

- 2.16.1. Basics Of Circuit Operation

- 2.16.1.1. Control Features

- 2.16.2. Maintenance

- 2.16.2.1. Safety

- 2.16.2.2. Cleaning

- 2.16.3. Motor Circuit

- 2.16.4. Control Circuit

- 2.16.5. Troubleshooting Guidelines

- 2.16.5.1. General

- 2.16.6. Shorts to Frame Test

- 2.16.7. Definitions

- 2.16.8. Diagnostics and Troubleshooting

- 2.16.8.1. Handset Diagnostics

- 2.16.8.2. Troubleshooting

- 2.16.8.3. Troubleshooting Chart

- 2.16.8.4. Technical Specification

- 2.16.8.5. Troubleshooting Chart Using Handset

- 2.17. Transistor Controller Troubleshooting

- 2.17.1. Troubleshooting Chart Index

- 2.17.2. Troubleshooting Charts

- 3. BYHYDRA

- 3.1. Hydraulic System

- 3.1.1. General

- 3.1.2. Troubleshooting

- 3.1.3. Schematic

- 3.1.4. Description

- 3.1.4.1. Lift

- 3.1.4.2. Lower

- 3.1.4.3. Relief Pressure

- 3.1.5. Maintenance

- 3.1.6. Lift Limit Switch

- 3.1.6.1. Solenoid Operated Valve

- 3.2. Lift Cylinder

- 3.2.1. Cylinder Repair

- 3.3. Battery Charger, Optima Pack

- 3.4. Handset Operation

- 3.4.1. Operating Modes

- 3.4.2. Revert to Previous Settings

- 3.4.3. Handset Self Test

- 4. BYMAINT

- 4.1. Technical Service Data

- 4.2. Ordering Spare Parts

- 4.3. Contents, Section P

- 4.3.1. Planned Maintenance

- 4.4. Introduction, Maintenance

- 4.4.1. Jacking Truck Off The Floor

- 4.4.1.1. Elevate Rear of Truck

- 4.4.1.2. Elevate Either Side of Truck

- 4.4.2. Lubricants

- 4.4.2.1. Standard

- 4.4.2.2. Corrosion

- 4.4.3. Cold Storage

- 4.5. Service Schedule

- 4.5.1. Planned Maintenance Schedule

- 4.5.2. Planned Maintenance Procedures

- 4.5.2.1. Services Performed Daily or Every 8 Operating Hours

- 4.5.2.2. Services Performed Monthly or Every 120 Operating Hours

- 4.5.2.3. Services Performed Every 480 or 960 Operating Hours

- 4.5.2.4. Services Performed Annually or Every 1440 Operating Hours

- 4.6. Lubrication Chart

- 4.7. Oil and Grease Specifications

- 4.7.1. Approved Oils and Grease

- 4.7.2. Grease Location Points

- 5. BYMOTOR

- 5.1. Pump Motor

- 5.1.1. Mounting Points

- 5.1.1.1. Removal

- 5.1.1.2. Installation

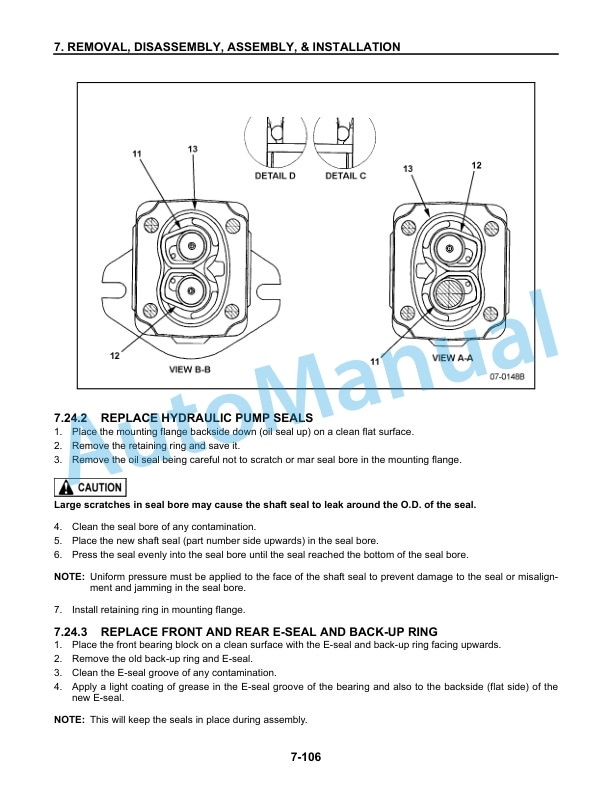

- 5.1.2. Pump Repair

- 5.1.2.1. Disassembly

- 5.1.3. Inspection and Troubleshooting

- 5.1.3.1. Drive End Head

- 5.1.3.2. Commutator End Head

- 5.1.3.3. Bearings

- 5.1.4. Brush Inspection

- 5.1.4.1. Brush Replacement Determination

- 5.1.4.2. Replacement Procedures

- 5.2. Drive Motor

- 5.2.1. Mounting Points

- 5.2.1.1. Drive Motor Brush

- 5.2.1.2. Drive Motor Removal

- 5.2.1.3. Drive Motor Installation

- 5.2.2. Component Repair

- 5.2.2.1. Motor Disassembly

- 5.2.3. Motor Inspection

- 5.2.3.1. External Motor

- 5.2.3.2. Brush and Commutator

- 5.2.3.3. Bearings

- 5.2.3.4. Armature Electrical Check

- 5.2.3.5. Frame and Field Service Recommendation

- 5.2.3.6. Assembly/Testing

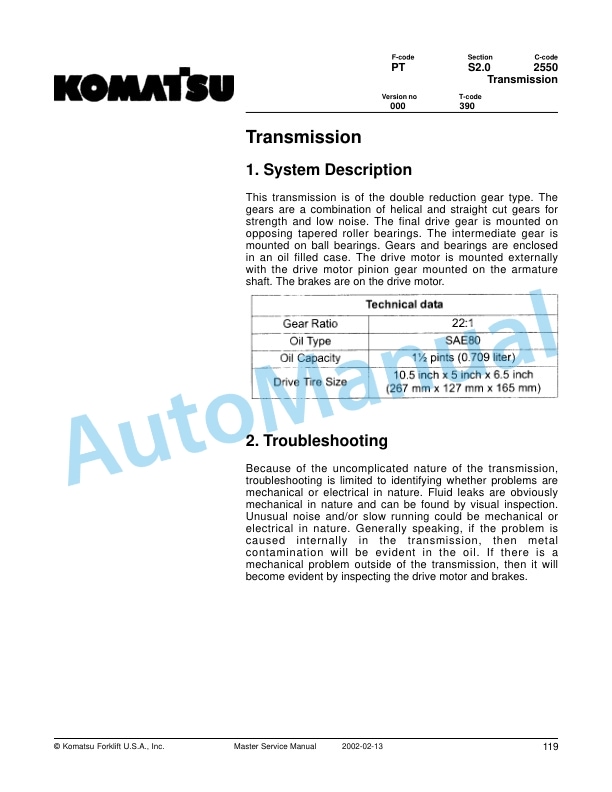

- 5.3. Transmission

- 5.3.1. System Description

- 5.3.2. Troubleshooting

- 5.3.3. Transmission Mounting

- 5.3.3.1. Wrap Around Bumper

- 5.3.3.2. Guards

- 5.3.3.3. Removal

- 5.3.3.4. Installation

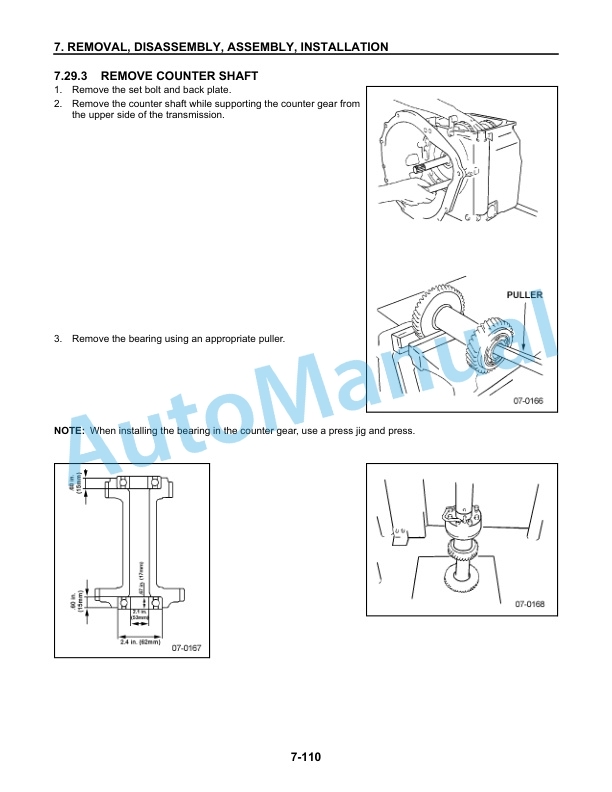

- 5.3.4. Transmission Repair

- 5.4. Warning Symbols

- 5.4.1. Warning Levels

- 5.5. Prohibitory Symbols

- 5.5.1. Ordinance Symbols

- 5.6. Contents, Section S

- 5.6.1. Service Instructions

- 5.7. Chassis/Lift Frame

- 5.7.1. Pull rod

- 5.7.1.1. Removal

- 5.7.1.2. Inspection

- 5.7.1.3. Installation

- 5.7.2. Carrier Frame Bushings

- 5.8. Inspection Covers

- 5.8.1. General Information

- 5.9. Driver Controls

- 5.10. Decals

- 5.10.1. Decal with Protective Sheet

- 5.10.2. Decal without Protective Sheet

- 5.11. Motor Maintenance Schedule/ Troubleshooting

- 5.11.1. General Information

- 5.11.2. Operating Conditions

- 5.11.3. Troubleshooting

Rate this product

You may also like

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu FR18S-2A, FR23S-2A, FR15DR-2A Forklift Truck Service Manual

$30.00

Komatsu Service Manual PDF

Komatsu CX50 Forklift Truck EPA Tier 2 Compliant Service Manual SM206

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

Komatsu 4D94E, 4D94L, 4D98E Diesel Engine Forklift Truck Service Manual 4D94E-BE4

$30.00

Komatsu Service Manual PDF

$30.00

Komatsu Service Manual PDF

$30.00