Komatsu P100-3, P100L-3, P120-3, P150HD-3, P150NHD-3 Shop Manual SEBM02020309

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM02020309

- Format: PDF

- Size: 67.7MB

- Number of Pages: 629

Category: Komatsu Shop Manual PDF

-

Model List:

- P100-3

- P100L-3

- P120-3

- P150HD-3

- P150NHD-3

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL VIEW

- 3.2. GENERAL ASSEMBLY DRAWING

- 3.3. SPECIFICATIONS

- 3.4. ENGINE ASSEMBLY DRAWING

- 3.5. LIST OF WEIGHT

- 3.6. LIST OF LUBRICANT AND WATER

- 4. ENGINE

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. ENGINE MOUNT

- 4.1.3. RADIATOR

- 4.1.4. FUEL TANK AND PIPING

- 4.1.5. ENGINE CONTROL

- 4.1.6. AUTODECELERATION SYSTEM (IF EQUIPPED)

- 4.2. TESTING AND ADJUSTING

- 4.2.1. TESTING AND ADJUSTING DATA

- 4.2.2. TESTING AND ADJUSTING TOOL LIST

- 4.2.3. TESTING AND ADJUSTING DECELERATOR SPEED

- 4.2.4. ADJUSTING VALVE CLEARANCE

- 4.2.5. MEASURING COMPRESSION PRESSURE

- 4.2.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 4.2.7. TESTING AND ADJUSTING FAN BELT TENSION

- 4.2.8. MEASURING BLOWBY PRESSURE

- 4.2.9. MEASURING EXHAUST GAS COLOR

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. FUEL INJECTION PUMP

- 4.3.1.1. DISMOUNTING

- 4.3.1.2. MOUNTING

- 4.3.2. ENGINE OIL COOLER

- 4.3.3. HYDRAULIC OIL COOLER

- 4.3.3.1. DISMOUNTING

- 4.3.3.2. MOUNTING

- 4.3.4. RADIATOR, HYDRAULIC OIL COOLER

- 4.3.5. DECELERATION CYLINDER

- 4.3.5.1. DISMOUNTING

- 4.3.5.2. MOUNTING

- 5. POWER TRAIN

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. POWER TRAIN

- 5.1.1.1. OUTLINE

- 5.1.1.2. POWER TRAIN HYDRAULIC PIPING

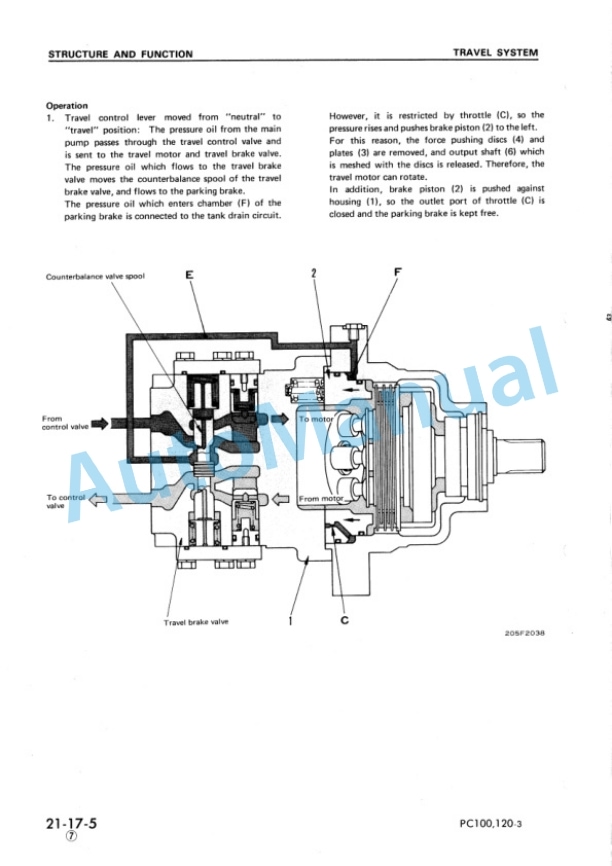

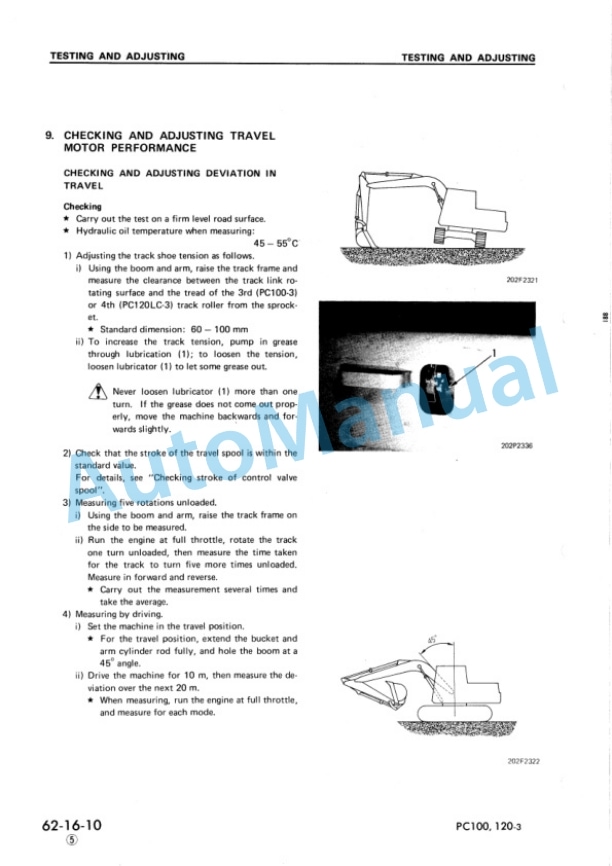

- 5.1.2. TRAVEL SYSTEM

- 5.1.2.1. OUTLINE

- 5.1.2.2. TRAVEL CONTROL (WRIST CONTROL TYPE)

- 5.1.2.3. TRAVEL CONTROL (LONG LEVER CONTROL TYPE)

- 5.1.2.4. CENTER SWIVEL JOINT

- 5.1.2.5. TRAVEL MOTOR

- 5.1.3. SWING SYSTEM

- 5.1.3.1. OUTLINE

- 5.1.3.2. SWING MOTOR AND BRAKE VALVE

- 5.1.3.3. SWING CIRCLE

- 5.1.3.4. SWING MACHINERY

- 5.2. DISASSEMBLY AND ASSEMBLY

- 5.2.1. CENTER SWIVEL JOINT

- 5.2.1.1. DISASSEMBLY (PC100,120)

- 5.2.1.2. ASSEMBLY (PC100,120)

- 5.2.1.3. DISASSEMBLY (PC100L)

- 5.2.1.4. ASSEMBLY (PC100L)

- 5.2.2. SWING MACHINERY

- 5.3. MAINTENANCE STANDARD

- 5.3.1. SWING MACHINERY

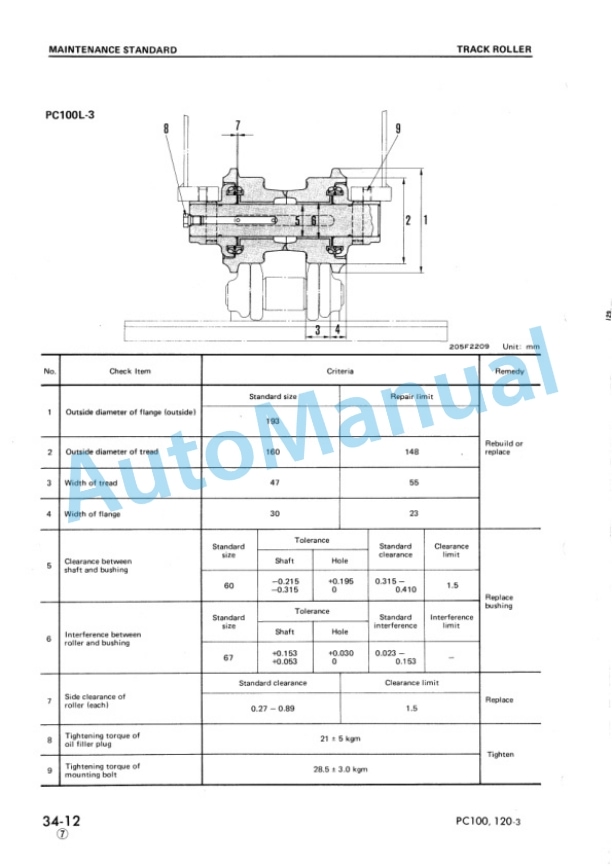

- 6. UNDERCARRIAGE

- 6.1. STRUCTURE AND FUNCTION

- 6.2. DISASSEMBLY AND ASSEMBLY

- 6.2.1. IDLER, RECOIL SPRING

- 6.3. MAINTENANCE STANDARD

- 7. HYDRAULIC SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. OUTLINE

- 7.1.1.1. WORK EQUIPMENT PIPING

- 7.1.1.2. HYDRAULIC CIRCUIT DIAGRAM (WRIST CONTROL TYPE)

- 7.1.1.3. SCHEMATIC OF HYDRAULIC SYSTEM (WRIST CONTROL TYPE)

- 7.1.1.4. HYDRAULIC CIRCUIT DIAGRAM (WRIST CONTROL TYPE)

- 7.1.1.5. SCHEMATIC OF HYDRAULIC SYSTEM (WRIST CONTROL TYPE)

- 7.1.1.6. HYDRAULIC CIRCUIT DIAGRAM (WRIST CONTROL TYPE)

- 7.1.1.7. SCHEMATIC OF HYDRAULIC SYSTEM (LONG LEVER CONTROL TYPE)

- 7.1.1.8. HYDRAULIC CIRCUIT DIAGRAM (LONG LEVER CONTROL TYPE)

- 7.1.1.9. SCHEMATIC OF HYDRAULIC SYSTEM (LONG LEVER CONTROL TYPE)

- 7.1.1.10. HYDRAULIC CIRCUIT DIAGRAM (LONG LEVER CONTROL TYPE)

- 7.1.1.11. SCHEMATIC OF HYDRAULIC SYSTEM

- 7.1.1.12. HYDRAULIC CIRCUIT DIAGRAM

- 7.1.2. HYDRAULIC TANK (WITH FUEL TANK)

- 7.1.3. HYDRAULIC PUMP

- 7.1.3.1. MAIN PUMP (HPV 055055)

- 7.1.3.2. SERVO VALVE , TVC VALVE, CO VALVE AND NC VALVE

- 7.1.4. OLSS SYSTEM (OPEN CENTER LOAD SENSING SYSTEM)

- 7.1.4.1. OUTLINE

- 7.1.4.2. BASIC CIRCUIT OF OLSS

- 7.1.4.3. SCHEMATIC OF OLSS

- 7.1.4.4. FUNCTION OF OLSS

- 7.1.5. CONTROL VALVE

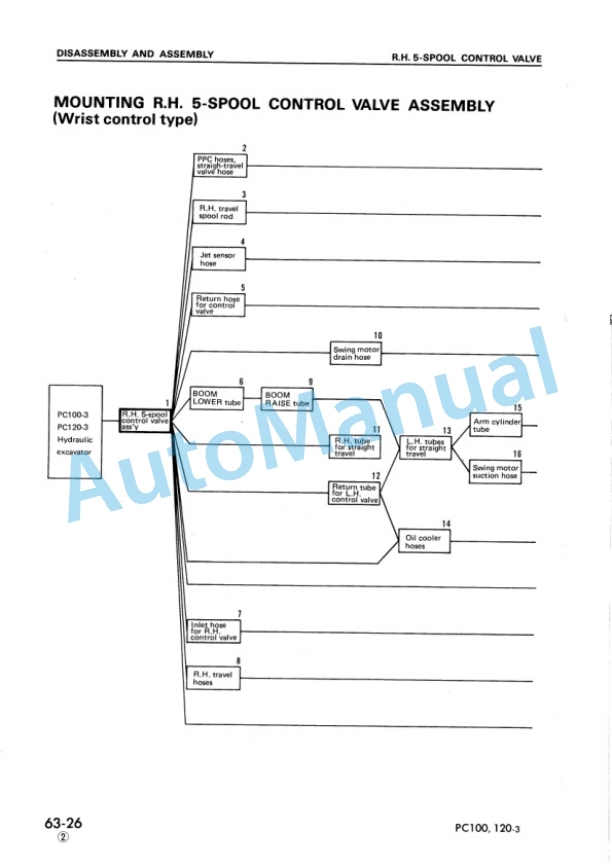

- 7.1.5.1. SPOOL CONTROL VALVE (WRIST CONTROL TYPE)

- 7.1.5.2. SPOOL CONTROL VALVE (WRIST CONTROL TYPE)

- 7.1.5.3. SPOOL CONTROL VALVE (LONG LEVER CONTROL TYPE)

- 7.1.5.4. SPOOL CONTROL VALVE (LONG LEVER CONTROL TYPE)

- 7.1.5.5. RELIEF VALVE

- 7.1.5.6. SAFETYSUCTION VALVE

- 7.1.5.7. SAFETY VALVE

- 7.1.5.8. SUCTION VALVE

- 7.1.6. HYDRAULIC CYLINDER

- 7.1.6.1. BOOM CYLINDER

- 7.1.6.2. ARM CYLINDER

- 7.1.6.3. BUCKET CYLINDER

- 7.1.6.4. CUSHION CYLINDER (ARM CYLINDER HEAD,BOTTOM SIDE)

- 7.1.7. WORK EQUIPMENT HYDRAULIC CONTROL (WRIST CONTROL TYPE)

- 7.1.7.1. OUTLINE

- 7.1.7.2. BOOM CONTROL

- 7.1.7.3. ARM CONTROL

- 7.1.7.4. BUCKET CONTROL

- 7.1.7.5. PPC VALVE (PROPORTIONAL PRESSURE CONTROL VALVE)

- 7.1.7.6. SHUTTLE VALVE

- 7.1.7.7. ACCUMULATOR

- 7.1.8. WORK EQUIPMENT HYDRAULIC CONTROL (LONG LEVER CONTROL TYPE)

- 7.1.8.1. OUTLINE

- 7.1.8.2. BOOM CONTROL

- 7.1.8.3. ARM CONTROL

- 7.1.8.4. BUCKET CONTROL

- 7.2. TESTING AND ADJUSTING

- 7.2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 7.2.2. TROUBLESHOOTING TOOLS

- 7.2.3. TESTING AND ADJUSTING

- 7.2.4. TROUBLESHOOTING

- 7.2.4.1. ELECTRICAL CIRCUIT

- 7.2.4.2. CONNECTION TABLE FOR CONNECTOR PINS

- 7.2.4.3. TROUBLESHOOTING PROCEDURE

- 7.2.4.4. CHECKS BEFORE TROUBLESHOOTING

- 7.2.4.5. JUDGEMENT TABLE

- 7.2.4.6. TROUBLESHOOTING CHART

- 7.2.4.7. FAILURE MODE AND COMPONENTS

- 7.3. DISASSEMBLY AND ASSEMBLY

- 7.3.1. MAIN PUMP INPUT SHAFT OIL SEAL

- 7.3.2. SPOOL CONTROL VALVE

- 7.3.2.1. DISMOUNTING

- 7.3.2.2. MOUNTING

- 7.3.3. SPOOL CONTROL VALVE

- 7.3.4. BUCKET CYLINDER

- 7.3.4.1. DISMOUNTING

- 7.3.4.2. MOUNTING

- 7.3.5. HYDRAULIC CYLINDER

- 7.3.5.1. DISASSEMBLY

- 7.3.5.2. ASSEMBLY

- 7.3.6. PISTON RING AND WEAR RING OF HYDRAULIC CYLINDER

- 7.4. MAINTENANCE STANDARD

- 7.4.1. CHARGING PUMP (BAR20)

- 7.4.2. SPOOL CONTROL VALVE

- 7.4.3. SPOOL CONTROL VALVE

- 7.4.4. SPOOL CONTROL VALVE (OPTION)

- 7.4.5. SPOOL CONTROL VALVE (OPTION)

- 7.4.6. HYDRAULIC CYLINDER

- 8. WORK EQUIPMENT

- 8.1. DISASSEMBLY AND ASSEMBLY

- 8.1.1. WORK EQUIPMENT (PC100,1203)

- 8.2. MAINTENANCE STANDARD

- 8.2.1. WORK EQUIPMENT

- 9. ELECTRICAL SYSTEM

- 9.1. STRUCTURE AND FUNCTION

- 9.1.1. ELECTRICAL SYSTEM

- 9.1.2. ELECTRICAL WIRING

- 9.1.3. ELECTRICAL CIRCUIT DIAGRAM

- 9.1.4. ELECTRIC VEHICLE MONITOR SYSTEM (EVMS)

- 9.2. TESTING AND ADJUSTING

- 9.2.1. ELECTRICAL CIRCUIT DIAGRAM

- 9.2.2. PRECAUTION WHEN TROUBLESHOOTING

- 9.2.3. TROUBLESHOOTING CHART

- 9.2.3.1. PC1003 SERIAL NO.1800121844,PC100L3 SERIAL NO.1200112324,PC1203 SERIAL NO.1800123282

- 9.2.3.2. PC1003 SERIAL NO. 21845 AND UP,PC100L3 SERIAL NO. 12325 AND UP,PC1203 SERIAL NO. 23283 AND UP

- 10. OTHERS

- 10.1. STRUCTURE AND FUNCTION

- 10.1.1. HEATER

Rate this product

You may also like