Komatsu PC09-1 Hydraulic Excavator Operation and Maintenance Manual WEAM011800

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: WEAM011800

- Format: PDF

- Size: 7.9MB

- Number of Pages: 240

-

Model List:

- PC09-1 Hydraulic Excavator

- 1. FOREWORD

- 2. SAFETY INFORMATION

- 3. INTRODUCTION

- 3.1. IMPROPER OR UNAUTHORIZED USES

- 3.2. DIRECTIONS OF MACHINE

- 4. PRODUCT INFORMATION

- 4.1. MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN)

- 4.2. ENGINE SERIAL NUMBER PLATE AND ITS LOCATION

- 4.3. EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION

- 4.4. SERVICE METER LOCATION

- 4.5. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 4.6. DECLARATION OF CONFORMITY (for machines placed on the market as from 29 December 2009)

- 5. PAGE INTENTIONALLY LEFT BLANK

- 6. SAFETY, NOISE AND VIBRATION PLATES

- 6.1. POSITION OF THE SAFETY PLATES

- 6.2. WARNING LABELS AND PICTOGRAMS ACTUAL

- 6.3. PICTOGRAMS AND RELEVANT MEANINGS

- 6.4. POSITION OF THE NOISE PLATES

- 6.5. EXTERNAL NOISE

- 6.6. NOISE PERCEIVED BY THE OPERATOR

- 6.7. VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED

- 7. SAFETY INFORMATION

- 7.1. SAFETY RULES

- 7.2. IF ABNORMALITIES ARE FOUND

- 7.3. WORKING WEAR AND PERSONAL PROTECTIVE ITEMS

- 7.4. FIRE EXTINGUISHER AND FIRST AID KIT

- 7.5. SAFETY EQUIPMENT

- 7.6. KEEP MACHINE CLEAN

- 7.7. OPERATORS SEAT EQUIPMENT

- 7.8. LEAVING OPERATORS SEAT WITH LOCK

- 7.9. HANDRAILS AND STEPS

- 7.10. MOUNTING AND DISMOUNTING

- 7.11. NO PERSON ON ATTACHMENTS

- 7.12. LIFTING OF PERSONNEL PROHIBITED

- 7.13. BURNS PREVENTION

- 7.14. FIRE AND EXPLOSION PREVENTION

- 7.15. ACTION IF FIRE OCCURS

- 7.16. FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION

- 7.17. ATTACHMENTS INSTALLATION

- 7.18. ATTACHMENTS COMBINATIONS

- 7.19. UNAUTHORIZED MODIFICATIONS

- 7.20. SAFETY AT JOBSITE

- 7.21. WORKING ON LOOSE GROUND

- 7.22. DISTANCE TO HIGHVOLTAGE CABLES

- 7.23. ENSURE GOOD VISIBILITY

- 7.24. VENTILATION FOR ENCLOSED AREAS

- 7.25. ASBESTOS DUST HAZARD PREVENTION

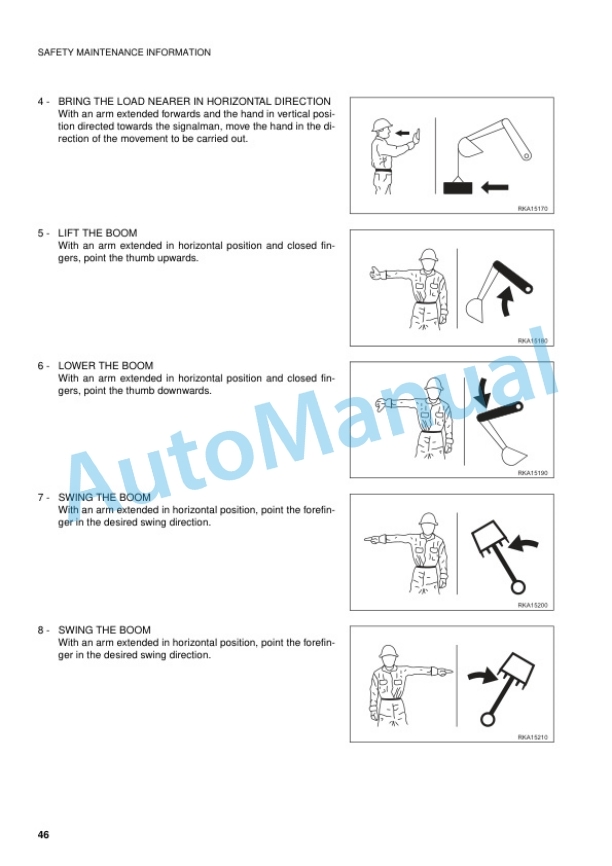

- 7.26. SIGNALMANS SIGNALS AND SIGNS

- 7.27. HAND SIGNALS

- 8. SAFETY MACHINE OPERATION

- 8.1. BEFORE STARTING ENGINE

- 8.2. PRECAUTIONS TO BE TAKEN WHEN WORKING

- 8.3. TRANSPORTATION

- 8.4. BATTERY

- 8.5. TOWING

- 8.6. LIFTING OBJECTS WITH BUCKET

- 9. SAFETY MAINTENANCE INFORMATION

- 9.1. WARNING TAG

- 9.2. STABILITY

- 9.3. KEEP WORK PLACE CLEAN AND TIDY

- 9.4. APPOINT LEADER WHEN WORKING WITH OTHERS

- 9.5. STOP ENGINE BEFORE CARRYING OUT MAINTENANCE

- 9.6. BATTERY MAIN SWITCH PRECAUTIONS (if installed)

- 9.7. TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING

- 9.8. PROPER TOOLS

- 9.9. PERSONNEL

- 9.10. ATTACHMENTS

- 9.11. WORK UNDER THE MACHINE

- 9.12. NOISE

- 9.13. WHEN USING HAMMER

- 9.14. WELDING WORKS

- 9.15. REMOVING BATTERY TERMINALS

- 9.16. SAFETY FIRST WHEN USING HIGH PRESSURE GREASE TO ADJUST TRACK TENSION

- 9.17. SAFETY RULES FOR HIGHPRESSURE OIL

- 9.18. SAFETY HANDLING HIGHPRESSURE HOSES

- 9.19. CHEMICAL HAZARD

- 9.20. WASTE MATERIALS

- 9.21. COMPRESSED AIR

- 9.22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 9.23. PRECAUTIONS TO BE TAKEN WHEN HANDLING TECHNOPOLYMERS AND ELASTOMERS

- 9.24. FINAL DISPOSAL OF THE MACHINE

- 10. PAGE INTENTIONALLY LEFT BLANK

- 11. MACHINE VIEW ILLUSTRATION

- 11.1. OVERALL MACHINE VIEW

- 11.2. CONTROLS AND GAUGES

- 12. DETAILED CONTROL AND GAUGES

- 12.1. METERS,LAMPS

- 12.2. SWITCHES

- 12.3. CONTROL LEVERS AND PEDALS

- 12.4. VARIABLE BLADE

- 12.5. ENGINE HOOD

- 12.6. FUSE

- 12.7. BLOCK FUSE

- 12.8. OPERATION MANUAL STORAGE

- 12.9. FIRE EXTINGUISHER

- 12.10. FIRST AID KIT

- 13. MACHINE OPERATIONS AND CONTROLS

- 13.1. BEFORE STARTING ENGINE

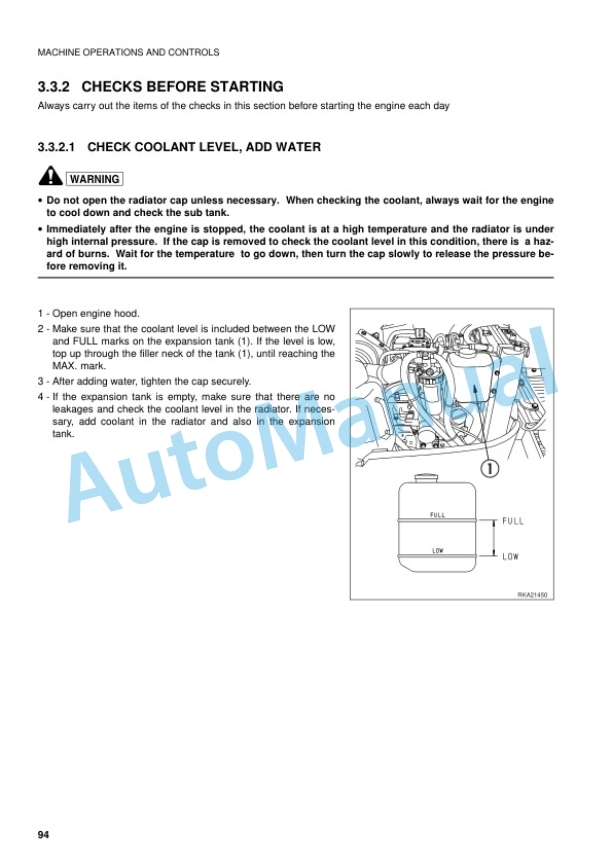

- 13.2. CHECKS BEFORE STARTING

- 13.3. ADJUSTMENT

- 13.4. SEAT BELT

- 13.5. OPERATIONS BEFORE STARTING ENGINE

- 13.6. STARTING ENGINE

- 13.7. AFTER STARTING ENGINE

- 13.8. STOPPING THE ENGINE

- 13.9. CHECK AFTER SHUT OFF ENGINE

- 13.10. MACHINE OPERATION

- 13.11. STEERING THE MACHINE

- 13.12. SWINGING

- 13.13. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 13.14. PROHIBITED OPERATIONS

- 13.15. GENERAL OPERATION INFORMATION

- 13.16. TRAVELING ON SLOPES

- 13.17. ESCAPE FROM MUD

- 13.18. WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR

- 13.19. BUCKET REPLACEMENT

- 13.20. PARKING MACHINE

- 13.21. MACHINE INSPECTION AFTER DAILY WORK

- 13.22. RUBBER SHOES (MACHINE WITH RUBBER SHOES ONLY)

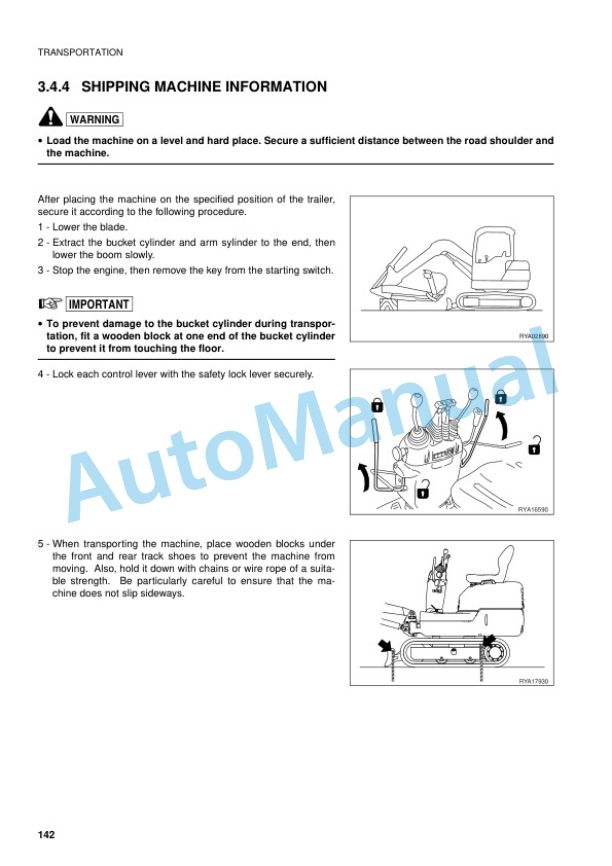

- 14. TRANSPORTATION

- 14.1. TRANSPORTATION PROCEDURE

- 14.2. LOADIND AND UNLOADING WITH TRAILER

- 14.3. LIFTING MACHINE

- 14.4. SHIPPING MACHINE INFORMATION

- 15. COLD WEATHER OPERATION

- 15.1. COLD WEATHER OPERATION INFORMATION

- 15.2. AFTER DAILY WORK COMPLETION

- 15.3. AFTER COLD WEATHER SEASON

- 16. LONGTERM STORAGE

- 16.1. BEFORE STORAGE

- 16.2. DURING STORAGE

- 16.3. AFTER STORAGE

- 16.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 16.5. AMBIENT TEMPERATURE RANGE FOR OPERATION AND LONG TERM STORAGE

- 17. TROUBLES AND ACTIONS

- 17.1. RUNNING OUT OF FUEL

- 17.2. PHENOMENA THAT ARE NOT FAILURES

- 17.3. TOWING THE MACHINE

- 17.4. SEVERE JOB CONDITION

- 17.5. DISCHARGED BATTERY

- 17.6. BATTERY REMOVAL AND INSTALLATION

- 17.7. BATTERY CHARGES

- 17.8. STARTING ENGINE WITH BOOSTER CABLES

- 17.9. OTHRE TROUBLE

- 18. MAINTENANCE INFORMATION

- 19. LUBRICANTS, COOLANT AND FILTERS

- 19.1. OIL, FUEL AND COOLANT

- 19.2. ELECTRIC SYSTEM MAINTENANCE

- 20. WEAR PARTS

- 20.1. WEAR PARTS LIST

- 21. LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS

- 21.1. COOLANT

- 22. TIGHTENING TORQUE SPECIFICATIONS

- 22.1. TIGHTENING TORQUE LIST

- 23. LUBRICATION

- 23.1. LUBRICATION DIAGRAM

- 24. SAFETY CRITICAL PARTS

- 24.1. SAFETY CRITICAL PARTS LIST

- 25. MAINTENANCE SCHEDULE

- 25.1. MAINTENANCE SCHEDULE CHART

- 25.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

- 26. MAINTENANCE PROCEDURE

- 26.1. INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

- 26.2. WHEN REQUIRED

- 26.3. CHECK BEFORE STARTING

- 26.4. EVERY 100 HOURS MAINTENANCE

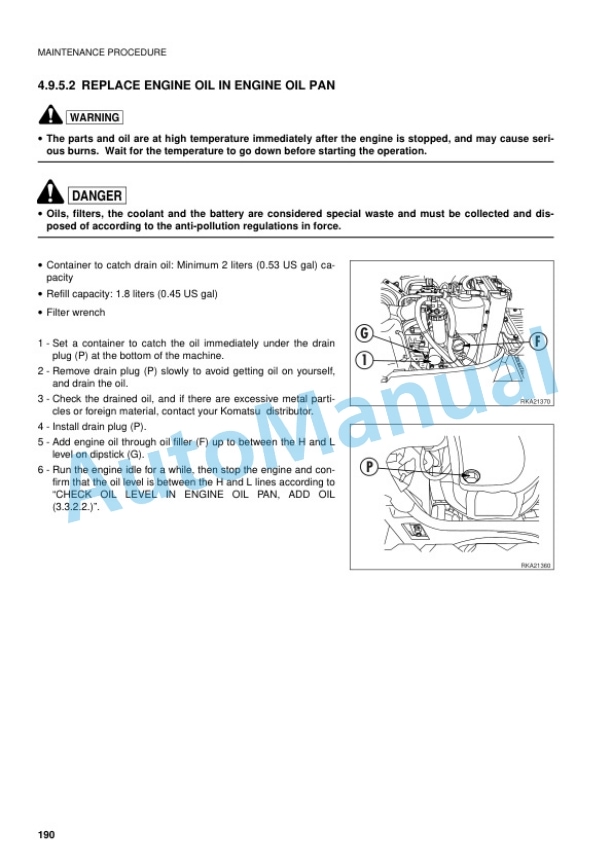

- 26.5. EVERY 250 HOURS MAINTENANCE

- 26.6. EVERY 500 HOURS MAINTENANCE

- 26.7. EVERY 1000 HOURS MAINTENANCE

- 26.8. EVERY 2000 HOURS MAINTENANCE

- 27. END OF SERVICE LIFE

- 28. SPECIFICATIONS

- 28.1. LIFTING CAPACITY

- 29. PAGE INTENTIONALLY LEFT BLANK

- 30. ATTACHMENTS AND OPTIONS GENERAL INFORMATION

- 30.1. SAFETY FIRST

- 30.2. ATTACHMENT INSTALLATION

- 31. BUCKET WITH HOOK

- 31.1. HOOK CONDITION

- 31.2. PROHIBITED OPERATIONS

- 32. ATTACHMENT GUIDE

- 32.1. ATTACHMENT COMBINATIONS

- 32.2. ATTACHMENT CONFIGURATION

- 32.3. SPECIFICATIONS

- 33. HANDLING ARM WITH BUILTIN BREAKER

- 33.1. BUCKET POSTURE

- 33.2. REMOVING AND INSTALLING CHISEL

- 33.3. PROCEDURE FOR BREAKER OPERATIONS

- 33.4. PRECAUTIONS WHEN CARRYING OUT BREAKER OPERATIONS

- 33.5. STOWING CHISEL, DUMMY CHISEL

- 33.6. PRECAUTIONS WHEN CARRYING OUT BUCKET OPERATIONS

- 33.7. HANDLING DUMMY LINK

- 33.8. CHECK BEFORE STARTING

- 34. HANDLING BUCKET COUPLER

- 34.1. PROCEDURE FOR REMOVING BUCKET

- 34.2. PROCEDURE FOR REMOVING BUCKET

- 35. RECOMMENDED ATTACHMENT OPERATIONS

- 35.1. HYDRAULIC BREAKER

- 36. PAGE INTENTIONALLY LEFT BLANK

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692