Komatsu PC09-1 Hydraulic Excavator Shop Manual SEBM026102

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM026102

- Format: PDF

- Size: 30.2MB

- Number of Pages: 199

Category: Komatsu Shop Manual PDF

-

Model List:

- PC09-1 Hydraulic Excavator

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. GENERAL

- 1.1. GENERAL ASSEMBLY DRAWING

- 1.2. SPECIFICATIONS

- 1.3. WEIGHT TABLE

- 1.4. LIST OF LUBRICANT AND WATER

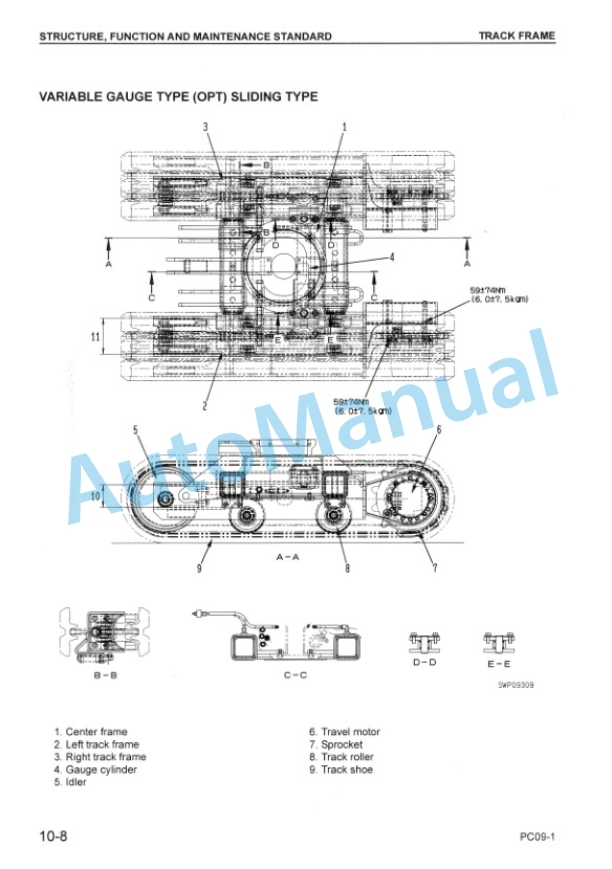

- 2. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 2.1. RADIATOR

- 2.2. ENGINE CONTROL

- 2.4. POWER TRAIN DIAGRAM

- 2.5. HYDRAULIC EQUIPMENT LAYOUT

- 2.6. VALVE CONTROL

- 2.7. HYDRAULIC TANK

- 2.8. HYDRAULIC PUMP

- 2.9. SPOOL CONTROL VALVE

- 2.10. CENTER SWIVEL JOINT

- 2.11. SWING MOTOR

- 2.12. TRAVEL MOTOR

- 2.13. HYDRAULIC CYLINDER

- 2.14. WORK EQUIPMENT

- 2.15. DIMENSION OF WORK EQUIPMENT

- 2.16. MACHINE MONITOR SYSTEM

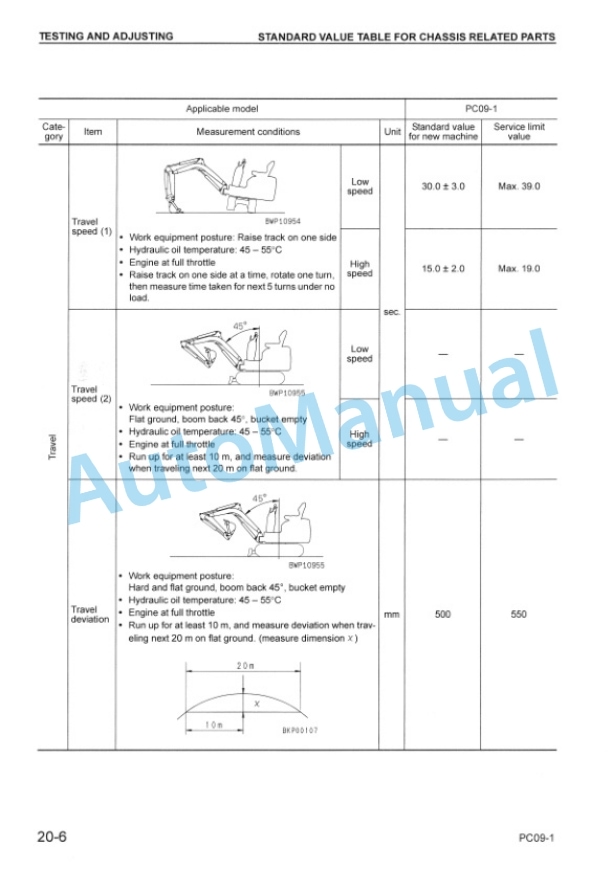

- 3. TESTING AND ADJUSTING

- 3.1. STANDARD VALUE TABLE

- 3.1.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 3.1.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 3.2. TESTING AND ADJUSTING

- 3.2.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 3.2.2. MEASUREMENT OF ENGINE ROTATION

- 3.2.3. MEASURING EXHAUST COLOR

- 3.2.4. ADJUSTMENT VALVE CLEARANCE

- 3.2.5. MEASURING COMPRESSION PRESSURE

- 3.2.6. MEASURING ENGINE OIL PRESSURE

- 3.2.7. INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

- 3.2.8. ADJUSTMENT OF FUEL CONTROL CABLE

- 3.2.9. BLEEDING AIR FROM FUEL CIRCUIT

- 3.2.10. TESTING AND ADJUSTING ALTERNATOR FAN BELT TENSION

- 3.2.11. TESTING AND ADJUSTING TRACK SHOE TENSION

- 3.2.12. INSPECTION AND ADJUSTMENT OF HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING AND TRAVEL CIRCUITS

- 3.2.13. IDENTIFICATION OF SPOT CAUSING WORK EQUIPMENT HYDRAULIC DRIFT

- 3.2.14. MEASUREMENT OF OIL LEAK AMOUNT INSIDE WORK EQUIPMENT CYLINDER

- 3.2.15. BLEEDING AIR FROM HYDRAULIC CIRCUITS

- 3.2.16. PRESSURIZING HYDRAULIC TANK

- 3.3. TROUBLESHOOTING

- 3.3.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 3.3.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 3.3.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 3.3.4. CHECKS BEFORE TROUBLESHOOTING

- 3.3.5. METHOD OF USING TROUBLESHOOTING

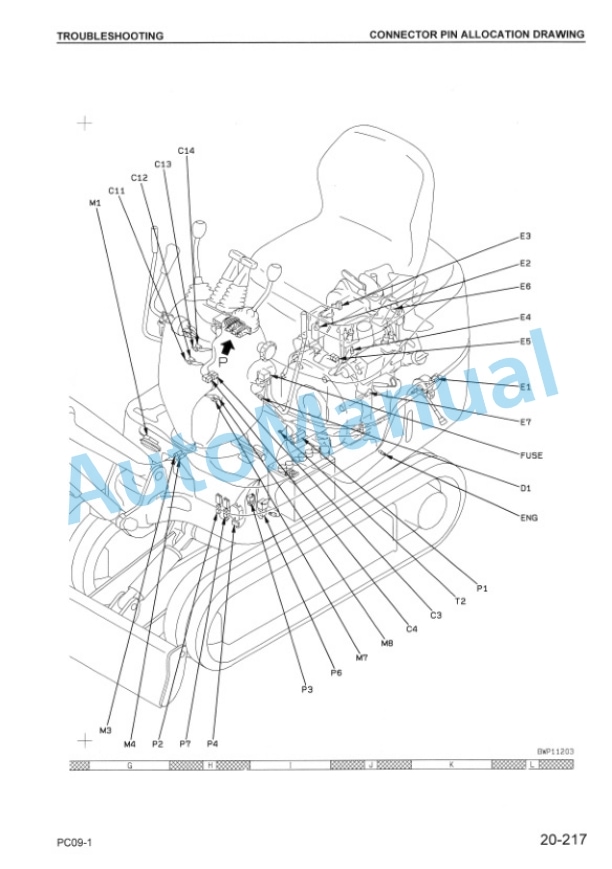

- 3.3.6. CONNECTOR MOUNTING LOCATIONS AND ELECTRICAL CIRCUITS

- 3.3.7. CONNECTOR PIN ALLOCATION DRAWING

- 3.3.8. ELECTRICAL CIRCUIT DIAGRAM FOR ENGINE START, STOP, PREHEATING AND CHARGING SYSTEMS (E CIRCUIT)

- 3.3.9. ELECTRICAL CIRCUIT DIAGRAM FOR PANEL SYSTEMS (P CIRCUIT)

- 3.3.10. CONNECTOR TABLE FOR CONNECTOR PIN NUMBERS

- 3.3.11. TROUBLESHOOTING OF ELECTRICAL SYSTEM

- 3.3.11.1. INFORMATION IN TROUBLESHOOTING TABLE

- 3.3.11.2. E1 ENGINE DOES NOT START

- 3.3.11.3. E2 ENGINE DOES NOT STOP

- 3.3.11.4. E3 ENGINE OIL PRESSURE LAMP DOES NOT WORK PROPERLY

- 3.3.11.5. E4 ENGINE COOLING WATER TEMPERATURE LAMP DOES NOT WORK PROPERLY

- 3.3.11.6. E5 ENGINE PREHEATING SYSTEM DOES NOT WORK

- 3.3.11.7. E6 SERVICE METER DOES NOT ADVANCE

- 3.3.11.8. E7 HORN DOES NOT SOUND, OR DOES NOT STOP SOUNDING

- 3.3.11.9. E8 WORKING LAMP DOES NOT LIGHT UP, OR DOES NOT GO OFF

- 3.3.12. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)

- 3.3.12.1. METHOD OF USING TROUBLESHOOTING CHARTS

- 3.3.12.2. H1 ALL WORK EQUIPMENT, TRAVEL AND SWING SHOW SLOW SPEED OR LACK IN POWER

- 3.3.12.3. H2 ENGINE RUNNING SPEED DROPS SHARPLY OR ENGINE STALLS. MOREOVER, ALL WORK EQUIPMENT, TRAVEL AND SWING DO NOT MOVE AT ALL OR MOVE EXTREMELY SLOWLY

- 3.3.12.4. H3 THERE IS NOISE FROM AROUND HYDRAULIC PUMP

- 3.3.12.5. H4 CONTROL LEVERS AND PEDALS ARE HARD TO OPERATE

- 3.3.12.6. H5 BOOM MOVES SLOWLY, LACKS IN POWER, HAS LONG TIME LAG AND BIG HYDRAULIC DRIFT

- 3.3.12.7. H6 ARM MOVES SLOWLY, LACKS IN POWER, HAS LONG TIME LAG AND BIG HYDRAULIC DRIFT

- 3.3.12.8. H7 BUCKET MOVES SLOWLY, LACKS POWER, HAS LONG TIME LAG AND BIG HYDRAULIC DRIFT

- 3.3.12.9. H8 SWING IS SLOW, LACKS IN POWER AND HAS BIG HYDRAULIC DRIFT

- 3.3.12.10. H9 BLADE MOVES SLOWLY, LACKS IN POWER, HAS LONG TIME LAG AND BIG HYDRAULIC DRIFT

- 3.3.12.11. H10 MACHINE DEVIATES FROM TRAVEL PATH IN TRAVELING

- 3.3.12.11.1. THE MACHINE DEVIATES IN THE SAME DIRECTION BOTH IN FORWARD AND IN REVERSE DIRECTIONS

- 3.3.12.11.2. THE DEVIATION DIRECTION CHANGES DEPENDING ON FORWARD OR REVERSE TRAVEL

- 3.3.12.12. H11 NO POWER OR SLOW IN TRAVELING

- 3.3.12.13. H12 UNDERCARRIAGE DOES NOT MOVE (ONE SIDE ONLY)

- 3.3.12.14. H13 TRAVEL SPEED CANNOT BE CHANGED

- 3.3.12.15. H14 UPPER STRUCTURE DOES NOT SWING

- 3.3.12.16. H15 SWING SPEED IS SLOW OR ACCELERATION IS POOR

- 3.3.12.17. H16 OVERRUN WHEN STOPPING WING IS BIG

- 3.3.12.18. H17 THERE IS BIG SHOCK WHEN STOPPING SWING

- 3.3.12.19. H18 THERE IS BIG NOISE WHEN STOPPING SWING

- 3.3.12.20. H19 HYDRAULIC DRIFT OF SWING IS BIG

- 3.3.12.21. H20 TROUBLESHOOTING OF HYDRAULIC BREAKER

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. METHOD OF USING MANUAL

- 4.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 4.3. SPECIAL TOOL LIST

- 4.4. SWING MOTOR

- 4.4.1. REMOVAL AND INSTALLATION

- 4.5. CENTER SWIVEL JOINT

- 4.5.1. REMOVAL AND INSTALLATION

- 4.5.2. DISASSEMBLY AND ASSEMBLY

- 4.6. ENGINE AND HYDRAULIC PUMP

- 4.6.1. REMOVAL

- 4.6.2. INSTALLATION

- 4.7. REVOLVING FRAME

- 4.7.1. REMOVAL

- 4.7.2. INSTALLATION

- 4.8. SWING CIRCLE

- 4.8.1. REMOVAL AND INSTALLATION

- 4.8.2. REMOVAL AND INSTALLATION

- 4.9. CONTROL VALVE

- 4.9.1. ASSEMBLY

- 4.10. HYDRAULIC CYLINDER

- 4.10.1. ASSEMBLY

- 4.11. HYDRAULIC BREAKER

- 4.11.1. DISASSEMBLY

- 4.11.2. ASSEMBLY

- 5. OTHERS

- 5.1. HYDRAULIC CIRCUIT DIAGRAM

- 5.1.1. FIXED GAUGE TYPE (STD)

- 5.1.2. VARIABLE GAUGE TYPE (OPT)

- 5.2. ELECTRICAL CIRCUIT DIAGRAM

- 5.3. TRAVEL ALARM SPECIFICATION (IF EQUIPPED)

Rate this product

You may also like