Komatsu PC10-7, PC15-3, PC20-7 Hydraulic Excavator Shop Manual SEBM020P0703

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM020P0703

- Format: PDF

- Size: 12.4MB

- Number of Pages: 264

Category: Komatsu Shop Manual PDF

-

Model List:

- PC10-7 Hydraulic Excavator

- PC15-3 Hydraulic Excavator

- PC20-7 Hydraulic Excavator

- 1. COVER

- 2. CONTENTS

- 3. STRUCTURE AND FUNCTION

- 3.1. POWER TRAIN

- 3.2. SWING CIRCLE

- 3.3. SWING MACHINERY

- 3.4. TRACK FRAME AND RECOIL SPRING

- 3.5. HYDRAULIC PIPING

- 3.6. HYDRAULIC CIRCUIT DIAGRAM

- 3.7. HYDRAULIC TANK AND FUEL TANK

- 3.8. HYDRAULIC PUMP

- 3.9. SPOOL CONTROL VALVE

- 3.10. SPOOL CONTROL VALVE

- 3.11. SWING MOTOR

- 3.12. CENTER SWIVEL JOINT

- 3.13. TRAVEL MOTOR

- 3.14. HYDRAULIC CYLINDER

- 3.15. VALVE CONTROL

- 3.16. WORK EQUIPMENT

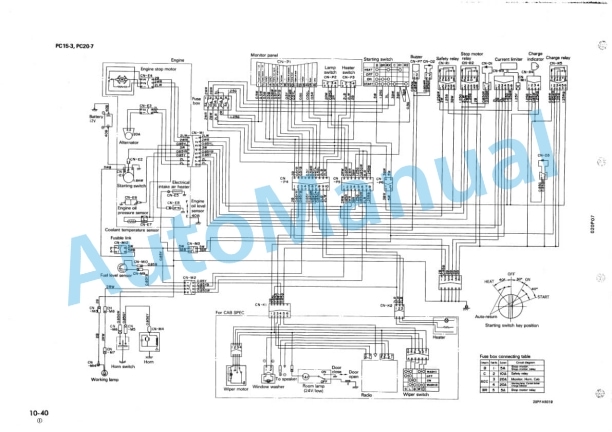

- 3.17. ELECTRICAL CIRCUIT DIAGRAM

- 3.18. MONITOR SYSTEM

- 4. TESTING AND ADJUSTING

- 4.1. TABLE OF JUDGEMENT STANDARD VALUE

- 4.2. STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM

- 4.3. TOOL FOR TESTING, ADJUSTING AND TROUBLESHOOTING

- 4.4. ADJUSTING VALVE CLEARANCE

- 4.5. MEASURING COMPRESSION PRESSURE

- 4.6. ADJUSTING FUEL INJECTION TIMING

- 4.7. ADJUSTING FUEL CONTROL LEVER

- 4.8. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

- 4.9. TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 4.10. BLEEDING AIR

- 4.11. TROUBLESHOOTING

- 4.11.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 4.11.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 4.11.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 4.11.4. CHECKS BEFORE TROUBLESHOOTING

- 4.11.5. ELECTRICAL CIRCUIT DIAGRAM

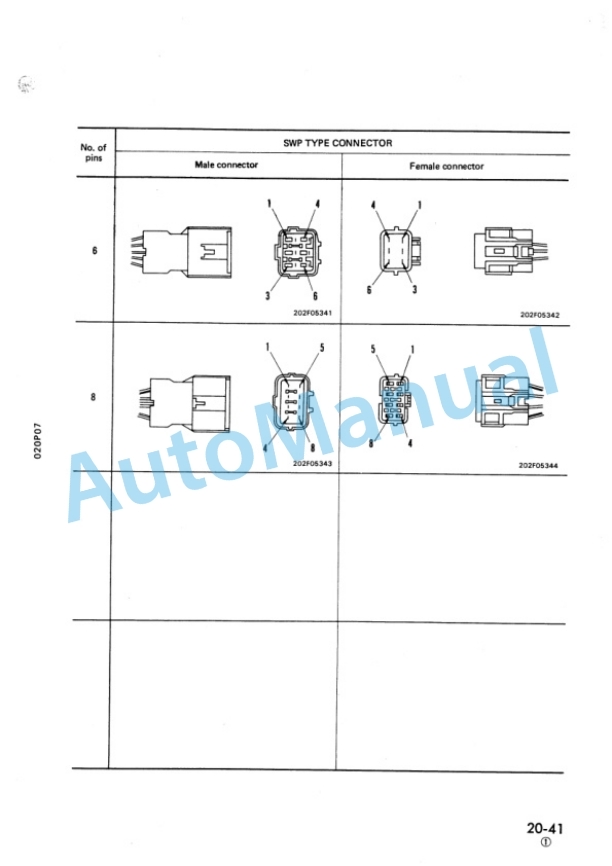

- 4.11.6. POSITION OF CONNECTORS FOR TROUBLESHOOTING

- 4.11.7. CONNECTION TABLE FOR CONNECTOR

- 4.11.8. HANDLING CONNECTORS

- 4.11.9. METHOD OF USING TROUBLESHOOTING CHARTS

- 4.11.10. TROUBLESHOOTING OF ELECTRICAL SYSTEM (C MODE)

- 4.11.10.1. C1. THIS ENGINE DOES NOT STOP WHEN THE STARTING SWITCH IS TURNED OFF

- 4.11.11. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 4.11.11.1. H1 SPEEDS OF WORK EQUIPMENT, TRAVEL SWING ARE ALL SLOW ALL WORK EQUIPMENT, TRAVEL, SWING LACK POWER

- 4.11.11.2. H2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS WORK EQUIPMENT, TRAVEL, SWING DO NOT MOVE, OR SPEED IN EXTREMELY SLOW

- 4.11.11.3. H3 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)

- 4.11.11.4. H4 CONTROL LEVER IS HEAVY

- 4.11.11.5. H5 WORK EQUIPMENT (BOOM, ARM, BUCKET) SPEED IS SLOW EXCESSIVE HYDRAULIC DRIFT

- 4.11.11.6. H6 WORK EQUIPMENT (BOOM, ARM, BUCKET) LACKS POWER

- 4.11.11.7. H7 EXCESSIVE TIME LAG

- 4.11.11.8. H8 WHEN MACHINE IS TRAVELING . IT DEVIATES NATURALLY TO ONE SIDE

- 4.11.11.8.1. DEVIATES IN SAME DIRECTION BOTH IN FORWARD AND REVERSE

- 4.11.11.8.2. DEVIATES IN DIFFERENT DIRECTION IN FORWARD AND REVERSE

- 4.11.11.9. H9 TRAVEL LACKS POWER (OR SPEED IS SLOW)

- 4.11.11.10. H10 MACHINE DOES NOT MOVE (ONE SIDE ONLY)

- 4.11.11.11. H11 DOES NOT SWING

- 4.11.11.12. H12 SWING SPEED IS SLOW OR ACCELERATION IS POOR

- 4.11.11.13. H13 EXCESSIVE OVERRUN WHEN STOPPING SWING

- 4.11.11.14. H14 EXCESSIVE SHOCK WHEN STOPPING SWING

- 4.11.11.15. H15 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING

- 4.11.11.16. H16 EXCESSIVE HYDRAULIC DRIFT OF SWING

- 4.11.11.17. H17 EXCESSIVE HYDRAULIC OF BOOM SWING

- 4.11.11.18. TABLE OF FAILURE MODES AND CAUSES

- 4.11.12. TROUBLESHOOTING OF MONITOR SYSTEM (P MODE)

- 4.11.12.1. P1 MONITOR PANEL DOES NOT WORK

- 4.11.12.2. P2 MONITOR PANEL CAUTION AND GAUGE LAMPS DO NOT LIGHT UP FOR 3 SECONDS AFTER STARTING SWITCHES TURNED ON, OR ALL LAMPS STAY LIGHTED UP

- 4.11.12.2.1. DO NOT LIGHT UP FOR 3 SECONDS

- 4.11.12.2.2. ALL LAMPS STAY LIGHTED UP

- 4.11.12.3. P3 (OIL PRESSURE CAUTION LAMP) DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED)

- 4.11.12.4. P4 (CHARGE CAUTION LAMP) DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED)

- 4.11.12.5. P5 (PREHEATING PILOT LAMP) DOES NOT LIGHT UP WHEN PREHEATING

- 4.11.12.6. P6 (ENGINE OIL LEVEL CAUTION LAMP) LIGHTS UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED) (ENGINE OIL LEVEL IS NORMAL)

- 4.11.12.7. P7 (ENGINE OIL PRESSURE CAUTION LAMP) LIGHTS UP WHEN ENGINE IS RUNNING (ENGINE OIL PRESSURE IS NORMAL)

- 4.11.12.8. P8 (CHARGE CAUTION LAMP) LIGHTS UP WHEN ENGINE IS RUNNING

- 4.11.12.9. P9 ABNORMALITY IN COOLANT TEMPERATURE GAUGE DISPLAY

- 4.11.12.9.1. AFTER ENGINE IS STARTED, GAUGE STAYS AT LOWEST LEVEL AND DOES NOT MOVE

- 4.11.12.9.2. AFTER ENGINE IS STARTED, LEVEL RISES IMMEDIATELY ENTERS TED RANGE EVEN WHEN ENGINE IS NOT OVERHEATING

- 4.11.12.10. P10 ABNORMALITY IN FUEL GAUGE DISPLAY

- 4.11.12.10.1. ALL SEGMENTS OF FUEL GAUGE GO OUT

- 4.11.12.10.2. FUEL LEVEL HAS GONE DOWN, BUT FUEL GAUGE STILL GIVES FULL DISPLAY, AND DOES NOT GO DOWN

- 4.11.12.10.3. FUEL GAUGE DOES NOT GIVE FULL DISPLAY EVEN WHEN FUEL TANK IS FILLED

- 4.11.12.11. P11 WHEN STARTING SWITCH IS TURNED ON, BUZZER DOES NOT SOUND FOR 1 SECOND

- 4.11.12.12. P12 ABNORMALITY IN SERVICE METER DISPLAY

- 4.11.12.12.1. SERVICE METER DOES NOT MOVE WHEN ENGINE IS RUNNING

- 4.11.12.12.2. SERVICE METER PILOT LAMP DOES NOT FLASH

- 4.11.12.13. P13 NIGHT LIGHTING DOES NOT LIGHT UP

- 4.11.12.13.1. WHEN LAMP SWITCH IS AT POSITION 1OR POSITION 2, INTERNAL LIGHTING OF MONITOR (GAUGE PORTION) DOES NOT LIGHT UP

- 4.11.12.13.2. WHEN LAMP SWITCH IS AT POSITION 2, WORKING LAMP DOES NOT LIGHT UP

- 4.11.12.14. P14 HEATER DOES NOT WORK WHEN HEATER SWITCH IS OPERATED (MACHINES WITH CAB SPECIFICATION)

- 5. DISASSEMBLY AND ASSEMBLY

- 5.1. METHOD OF USING MANUAL

- 5.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 5.3. SPECIAL TOOL LIST

- 5.4. FUEL INJECTION PUMP

- 5.5. ENGINE FRONT SEAL

- 5.5.1. REMOVAL

- 5.5.2. INSTALLATION

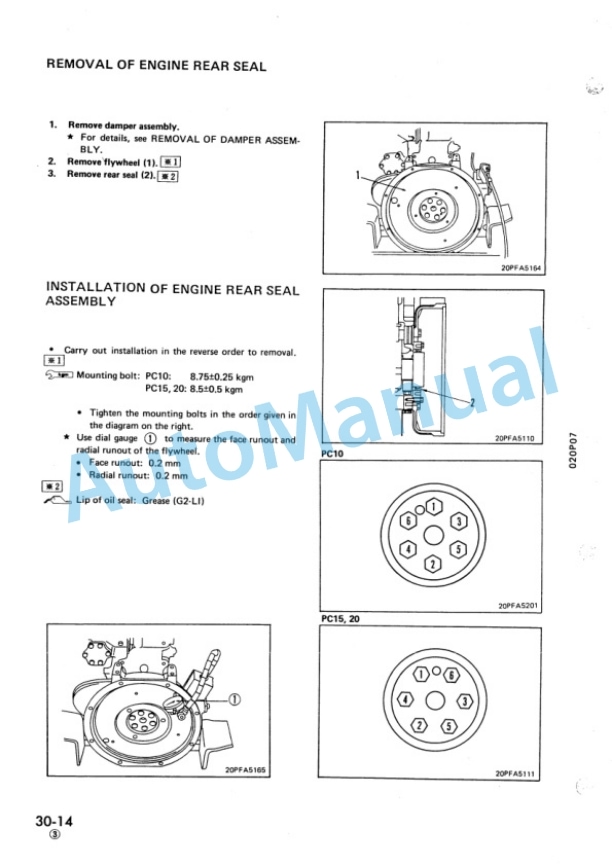

- 5.6. ENGINE REAR SEAL

- 5.7. RADIATOR AND OIL COOLER

- 5.7.1. REMOVAL

- 5.7.2. INSTALLATION

- 5.8. ENGINE AND HYDRAULIC PUMP

- 5.9. CENTER SWIVEL JOINT

- 5.10. SWING MOTOR AND SWING MACHINERY

- 5.11. SWING MACHINERY

- 5.11.1. DISASSEMBLY

- 5.11.2. ASSEMBLY

- 5.12. REVOLVING FRAME

- 5.13. IDLER AND RECOIL SPRING

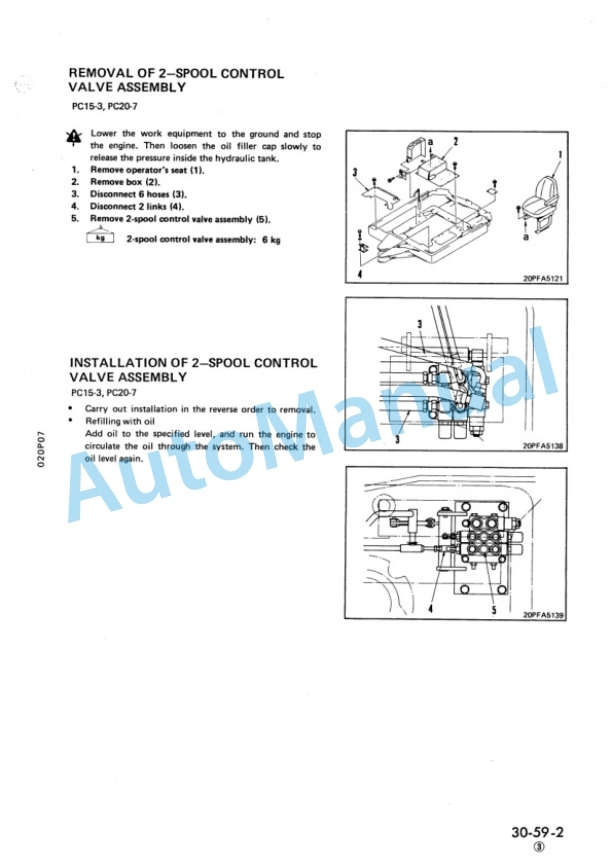

- 5.14. SPOOL CONTROL VALVE

- 5.14.1. REMOVAL

- 5.14.2. INSTALLATION

- 5.15. SPOOL CONTROL VALVE

- 5.15.1. REMOVAL

- 5.15.2. INSTALLATION

- 5.16. SPOOL CONTROL VALVE

- 5.16.1. DISASSEMBLY

- 5.16.2. ASSEMBLY

- 5.17. SPOOL CONTROL VALVE

- 5.18. BUCKET CYLINDER

- 5.18.1. REMOVAL

- 5.18.2. INSTALLATION

- 5.19. SWING CYLINDER

- 5.20. HYDRAULIC CYLINDER

- 6. MAINTENANCE STANDARD

- 6.1. SWING CIRCLE

- 6.2. SWING MACHINERY

- 6.3. TRACK FRAME AND RECOIL SPRING

- 6.4. SPOOL CONTROL VALVE

- 6.5. SPOOL CONTROL VALVE

- 6.6. SWING MOTOR

- 6.7. TRAVEL MOTOR

- 6.8. CENTER SWIVEL JOINT

- 6.9. HYDRAULIC CYLINDER

- 6.10. WORK EQUIPMENT

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00