Komatsu PC1000-1, PC1000LC-1, PC1000SE-1, PC1000SP-1 Hydraulic Excavator Shop Manual SEBM021N0107

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM021N0107

- Format: PDF

- Size: 82.3MB

- Number of Pages: 750

Category: Komatsu Shop Manual PDF

-

Model List:

- PC1000-1 Hydraulic Excavator

- PC1000LC-1 Hydraulic Excavator

- PC1000SE-1 Hydraulic Excavator

- PC1000SP-1 Hydraulic Excavator

- 1. MAIN MENU

- 2. CONTENTS

- 3. LIST OF REVISED PAGES

- 4. SAFETY NOTICE

- 5. FOREWORD

- 5.1. HOW TO READ THE SHOP MANUAL

- 5.2. HOISTING INSTRUCTIONS

- 5.2.1. WIRE ROPES

- 5.3. COATING MATERIALS

- 5.4. STANDARD TIGHTENING TORQUE

- 5.4.1. STANDARD TIGHTENING TORQUES OF BOLTS AND NUTS

- 5.4.2. TIGHTENING TORQUE OF HOSE NUTS

- 5.4.3. TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

- 5.4.4. TIGHTENING TORQUE OF ORING BOSS CONNECTOR

- 5.4.5. TIGHTENING TORQUE OF ORING BOSS CONNECTOR

- 5.4.6. TIGHTENING TORQUES OF FLARE NUT

- 5.4.7. TIGHTENING TORQUE FOR 102 SERIES ENGINE (BOLT AND NUTS)

- 5.4.8. TIGHTENING TORQUE FOR 102 SERIES ENGINE (EYE JOINTS)

- 5.4.9. TIGHTENING TORQUE FOR 102 SERIES ENGINE (TAPERED SCREWS)

- 5.5. ELECTRIC WIRE CODE

- 5.5.1. CLASSIFICATION BY THICKNESS

- 5.5.2. CLASSIFICATION BY COLOR AND CODE

- 5.6. CONVERSION TABLE

- 5.6.1. METHOD OF USING THE CONVERSION TABLE

- 6. ENGINE

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. PTO (Power TakeOff)

- 6.1.2. PTO LUBRICATION SYSTEM

- 6.1.3. AUTODECELERATION SYSTEM

- 6.2. TESTING AND ADJUSTING

- 6.2.1. STANDARD FOR TESTING AND ADJUSTING

- 6.2.2. TESTING AND ADJUSTING TOOL LIST

- 6.2.3. ADJUSTING VALVE CLEARANCE

- 6.2.4. MEASURING COMPRESSION PRESSURE

- 6.2.5. MEASURING BLOWBY PRESSURE

- 6.2.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 6.2.7. ADJUSTING FUEL CONTROL LEVER

- 6.2.8. ADJUSTING AUTODECELERATION SYSTEM

- 6.2.9. MEASURING EXHAUST GAS COLOR

- 6.3. DISASSEMBLY AND ASSEMBLY

- 6.3.1. ENGINE OIL COOLER

- 6.3.2. WATER PUMP

- 6.3.3. FUEL INJECTION PUMP

- 6.3.4. HYDRAULIC OIL COOLER

- 6.3.5. RADIATOR

- 6.3.6. ENGINE, PTO, HYDRAULIC PUMP

- 6.3.7. AUTODECELERATION CYLINDER

- 6.4. MAINTENANCE STANDARD

- 6.4.1. PTO (Power TakeOff)

- 7. POWER TRAIN

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. POWER TRAIN

- 7.1.2. TRAVEL AND BRAKE SYSTEM

- 7.1.3. SWING SYSTEM

- 7.2. DISASSEMBLY AND ASSEMBLY

- 7.2.1. CENTER SWIVEL JOINT ASSEMBLY

- 7.2.2. TRAVEL MOTOR, BRAKE VALVE

- 7.2.3. TRAVEL MOTOR

- 7.2.4. FINAL DRIVE ASSEMBLY

- 7.2.5. CONC VALVE ASSEMBLY

- 7.2.6. SWING CONTROL VALVE

- 7.2.7. MAIN RELIEF VALVE

- 7.2.8. SWING CONTROL VALVE

- 7.2.9. FRONT SWING MOTOR

- 7.2.10. REAR SWING MOTOR

- 7.2.11. SWING MOTOR ASSEMBLY

- 7.2.12. REVOLVING FRAME

- 7.2.13. SWING CIRCLE

- 7.2.14. FRONT SWING MACHINERY

- 7.2.15. REAR SWING MACHINERY

- 7.2.16. SWING MACHINERY

- 7.2.17. SWING MACHINERY

- 7.3. MAINTENANCE STANDARD

- 7.3.1. TRAVEL MOTOR AND BRAKE VALVE

- 7.3.2. TRAVEL RELIEF VALVE

- 7.3.3. TRAVEL SHUTTLE VALVE

- 7.3.4. STRAIGHTTRAVEL VALVE

- 7.3.5. FINAL DRIVE

- 7.3.6. SWING CONTROL VALVE

- 7.3.7. JET SENSOR

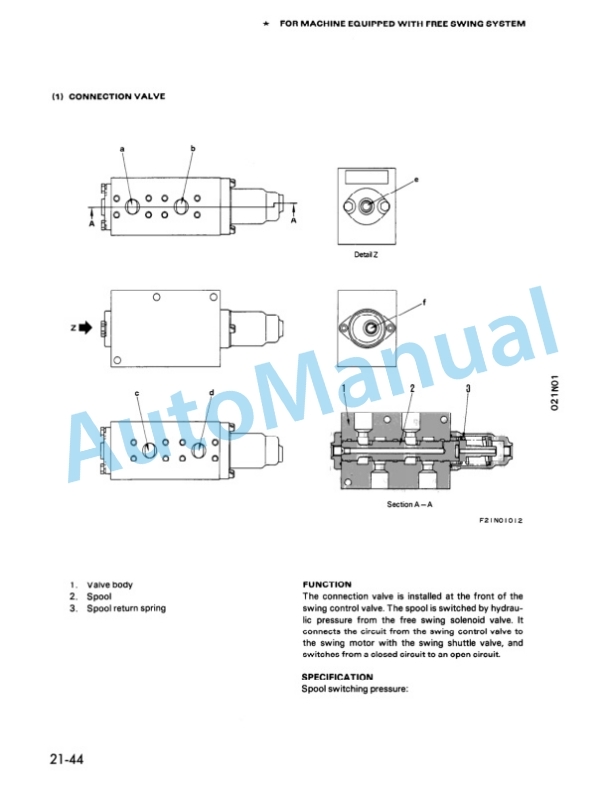

- 7.3.8. CONNECTION VALVE

- 7.3.9. SWING MOTOR

- 7.3.10. SWING MACHINERY

- 7.3.11. SWING CIRCLE

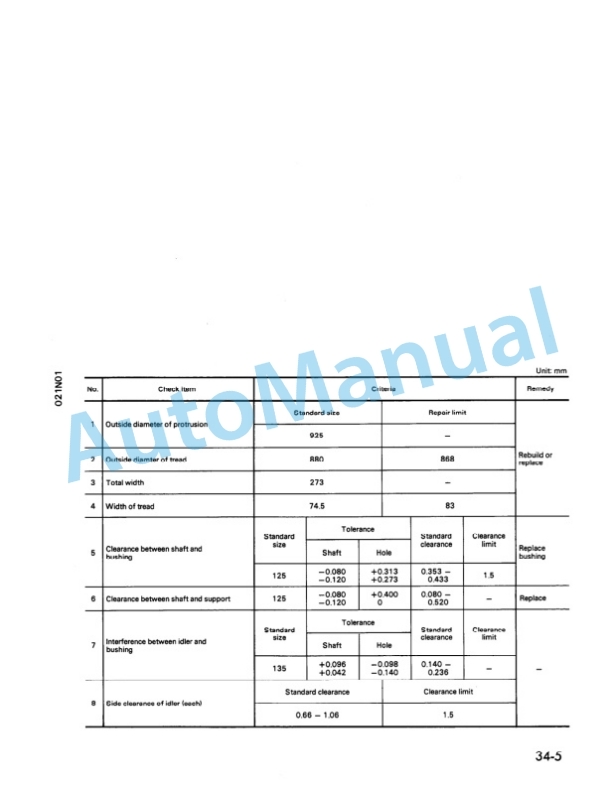

- 8. UNDERCARRIAGE

- 8.1. STRUCTURE AND FUNCTION

- 8.2. DISASSEMBLY AND ASSEMBLY

- 8.2.1. IDLER ADJUSTMENT CYLINDER

- 8.3. MAINTENANCE STANDARD

- 8.4. STRUCTURE AND FUNCTION

- 8.4.1. AIR PIPING

- 8.4.2. AIR CIRCUIT DIAGRAM

- 9. HYDRAULIC SYSTEM

- 9.1. STRUCTURE AND FUNCTION

- 9.1.1. HYDRAULIC SYSTEM LOCATION

- 9.1.2. HYDRAULIC CIRCUIT DIAGRAM

- 9.1.3. WORK EQUIPMENT CONTROL

- 9.1.4. ELECTRONIC AUTOMATIC WORK EQUIPMENT CONTROL SYSTEM

- 9.1.5. HYDRAULIC TANK

- 9.1.6. MAIN PUMP

- 9.1.7. CHARGING AND PTO LUBRICATING PUMP

- 9.1.8. HYDRAULIC OIL FILTER

- 9.1.9. STAGE AND 3STAGE MODE SELECTOR OLSS (Open center Load Sensing System)

- 9.1.10. HYDRAULIC CONTROL VALVE

- 9.1.11. PPC VALVE

- 9.1.12. PPC ACCUMULATOR

- 9.1.13. PPC SHUTTLE VALVE

- 9.1.14. PILOT RELIEF VALVE

- 9.1.15. SAFETY LOCK VALVE

- 9.1.16. HYDRAULIC CYLINDER

- 9.1.17. WORK EQUIPMENT

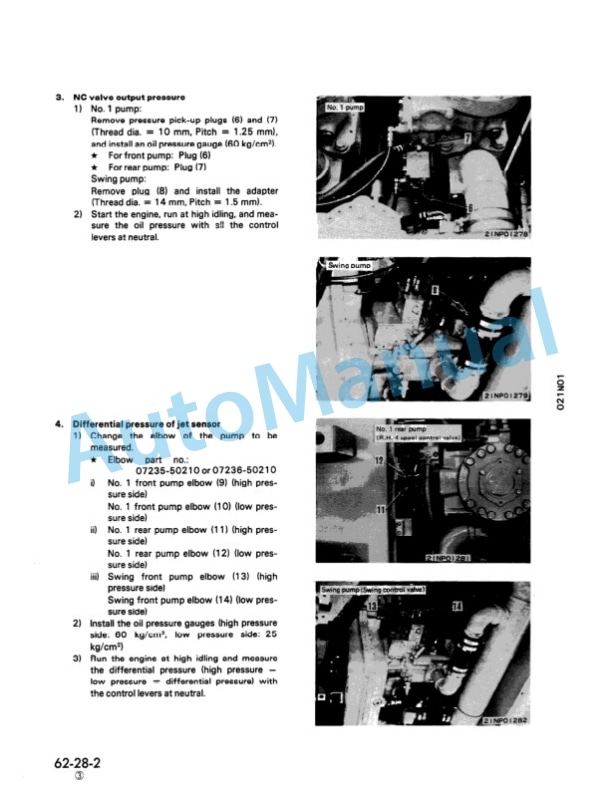

- 9.2. TESTING AND ADJUSTING

- 9.2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 9.2.2. TABLE OF JUDGEMENT STANDARD VALVE (FOR MACHINES EQUIPPED WITH 3STAGE MODE SELECTOR OLSS)

- 9.2.3. TABLE OF ELECTRICAL JUDGEMENT STANDARD VALUE

- 9.2.4. TESTING AND ADJUSTING TOOL LIST

- 9.2.5. TESTING AND ADJUSTMENT OF RELIEF PRESSURE

- 9.2.6. TESTING AND ADJUSTMENT OF CONTROL CIRCUIT PRESSURE

- 9.2.7. BLEEDING AIR AND RELEASING PRESSURE

- 9.2.8. CHARGING ACCUMULATOR WITH GAS

- 9.2.9. CHECKING SWIVEL JOINT

- 9.2.10. TESTING AND ADJUSTING OF TRAVEL CONTROL LEVER AND ROD

- 9.2.11. ADJUSTMENT OF WORK EQUIPMENT POTENTIOMETER (LOADING SHOVEL)

- 9.2.12. ADJUSTMENT OF WORK EQUIPMENT CONTROL BOX (LOADING SHOVEL)

- 9.2.13. TROUBLESHOOTING

- 9.3. DISASSEMBLY AND ASSEMBLY

- 9.3.1. CONC VALVE ASSEMBLY (for No. 1 front pump)

- 9.3.2. CONC VALVE ASSEMBLY (for No. 1 rear pump with TVC valve)

- 9.3.3. TVC VALVE (for No. 1 rear pump)

- 9.3.4. SERVO VALVE (for No. 1 front pump)

- 9.3.5. SERVO VALVE (for No 1 rear pump)

- 9.3.6. SERVO VALVE (for No. 2 front pump)

- 9.3.7. SERVO VALVE (for No. 2 rear pump)

- 9.3.8. SPOOL CONTROL VALVE

- 9.3.9. SPOOL CONTROL VALVE ASSEMBLY

- 9.3.10. CONTROL VALVE

- 9.3.11. MAIN RELIEF VALVE (for 4, 5SPOOL CONTROL VALVE)

- 9.3.12. PILOT RELIEF VALVE

- 9.3.13. PPC VALVE ASSEMBLY (for work equipment and swing)

- 9.3.14. BOOM CYLINDER (BACKHOE)

- 9.3.15. ARM CYLINDER (BACKHOE)

- 9.3.16. BUCKET CYLINDER ASSEMBLY (BACKHOE)

- 9.3.17. BOOM CYLINDER ASSEMBLY (LOADING SHOVEL)

- 9.3.18. ARM CYLINDER ASSEMLBY (LOADING SHOVEL)

- 9.3.19. BUCKET CYLINDER ASSEMBLY (LOADING SHOVEL)

- 9.3.20. BOTTOM DUMP CYLINDER ASSEMBLY (LOADING SHOVEL)

- 9.3.21. HYDRAULIC CYLINDER

- 9.3.22. BUCKET ASSEMBLY (BACKHOE)

- 9.3.23. BUCKET AND ARM (BACKHOE)

- 9.3.24. WORK EQUIPMENT (BACKHOE)

- 9.3.25. BUCKET (LOADING SHOVEL)

- 9.3.26. ARM (LOADING SHOVEL)

- 9.3.27. BOOM (LOADING SHOVEL)

- 9.3.28. WORK EQUIPMENT (LOADING SHOVEL)

- 9.3.29. POTENTIOMETER (LOADING SHOVEL)

- 9.3.30. COUNTERWEIGHT

- 9.4. MAINTENANCE STANDARD

- 9.4.1. CHARGING AND PTO LUBRICATION PUMP

- 9.4.2. PILOT RELIEF VALE

- 9.4.3. SPOOL CONTROL VALVE

- 9.4.4. SPOOL CONTROL VALVE

- 9.4.5. PPC VALVE

- 9.4.6. PPC SHUTTLE VALVE

- 9.4.7. WORK EQUIPMENT SAFETY VALVE

- 9.4.8. HYDRAULIC CYLINDER

- 9.4.9. WORK EQUIPMENT

- 10. ELECTRIC AND ELECTRONIC SYSTEM

- 10.1. TESTING AND ADJUSTING

- 10.1.1. ELECTRICAL CIRCUIT DIAGRAM

- 10.1.2. POSITION OF CONNECTORS FOR TROUBLESHOOTING

- 10.1.3. M MODE TROUBLESHOOTING

- 10.1.4. P MODE TROUBLESHOOTING

Rate this product

You may also like