Komatsu PC128UU-1, PC128US-1 Hydraulic Excavator Shop Manual SEBM009805

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM009805

- Format: PDF

- Size: 62.5MB

- Number of Pages: 794

Category: Komatsu Shop Manual PDF

-

Model List:

- PC128UU-1 Hydraulic Excavator

- PC128US-1 Hydraulic Excavator

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. LIST OF LUBRICANTS AND WATER

- 4. STRUCTURE AND FUNCTION

- 4.1. RADIATOR AND OIL COOLER

- 4.2. PTO (COUPLING)

- 4.3. ENGINE CONTROL

- 4.4. POWER TRAIN SYSTEM

- 4.5. SWING CIRCLE

- 4.6. SWING MACHINERY

- 4.7. TRACK FRAME

- 4.8. IDLER CUSHION

- 4.9. TRACK SHOE

- 4.10. HYDRAULIC PIPING DRAWING

- 4.11. HYDRAULIC CIRCUIT DIAGRAM

- 4.12. CENTER SWIVEL JOINT

- 4.13. VALVE CONTROL

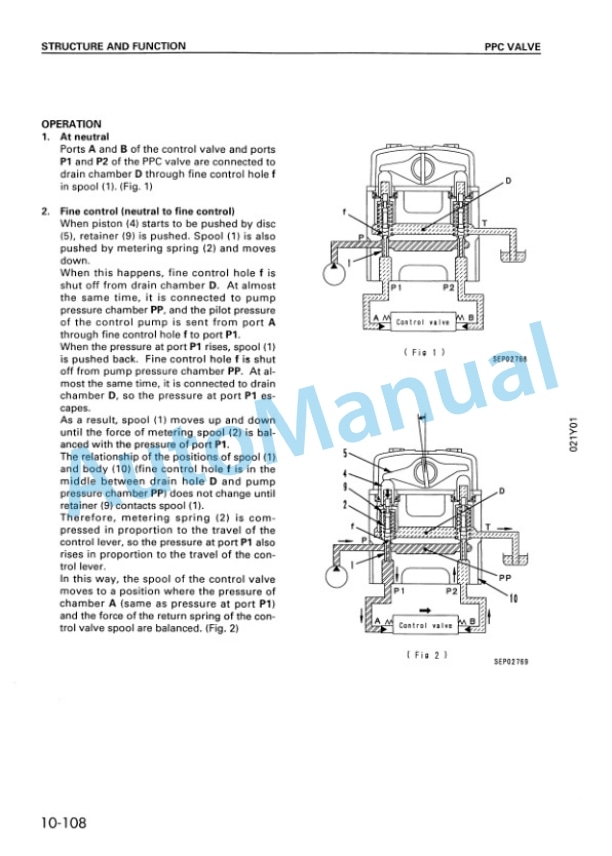

- 4.14. PPC VALVE

- 4.15. PPC SHUTTLE AND TRAVEL JUNCTION VALVE

- 4.16. EPC SOLENOID VALVE

- 4.17. BOOM HOLDING VALVE

- 4.18. WORK EQUIPMENT

- 4.19. AIR CONDITIONER

- 4.20. ACTUAL ELECTRICAL WIRING DIAGRAM

- 4.21. ELECTRONIC CIRCUIT DIAGRAM

- 4.22. ELECTRONIC CONTROL SYSTEM

- 4.23. MACHINE MONITORING SYSTEM

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 5.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL RELATED PARTS (EXCEPT AUTOMATIC HORIZONTAL DIGGING MACHINE)

- 5.4. STANDARD VALUE TABLE FOR ELECTRICAL RELATED PARTS

- 5.5. TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING

- 5.6. MEASURING ENGINE SPEED

- 5.7. MEASURING EXHAUST COLOR

- 5.8. ADJUSTMENT VALVE CLEARANCE

- 5.9. MEASUREMENT BLOWBY PRESSURE

- 5.10. MEASUREMENT ENGINE OIL PRESSURE

- 5.11. TESTING AND ADJUSTMENT OF FUEL INJECTION TIMING

- 5.12. TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION

- 5.13. ADJUSTING ENGINE SPEED SENSOR

- 5.14. ADJUSTING FUEL CONTROL CABLE

- 5.15. ADJUSTING FUEL CONTROL CABLE

- 5.16. ADJUSTING ENGINE STOP SOLENOID LINKAGE

- 5.17. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

- 5.18. TESTING AND ADJUSTING OUTPUT PRESSURE OF PC VALVE (SERVO PISTON INPUT PRESSURE)

- 5.19. TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE

- 5.20. TESTING AND ADJUSTING CONTROL PUNP CIRCUIT OIL PRESSURE

- 5.21. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 5.22. MEASURING PPC VALVE OUTPUT PRESSURE AND TESTING PPC SHUTTLE VALVE

- 5.23. ADJUSTING WORK EQUIPMENT, SEING PPC VALVE

- 5.24. TESTING AND ADJUSTING TRAVEL DEVIATION

- 5.25. CHECKING LOCATION OF CAUSE OF HYDRAULIC DRIFT OF WORK EQUIPMENT

- 5.26. MEASUREMENT OIL LEAKAGE OF SWING, TRAVEL MOTOR

- 5.27. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.28. TESTING CLEARANCE OF SWING CIRCLE BEARING

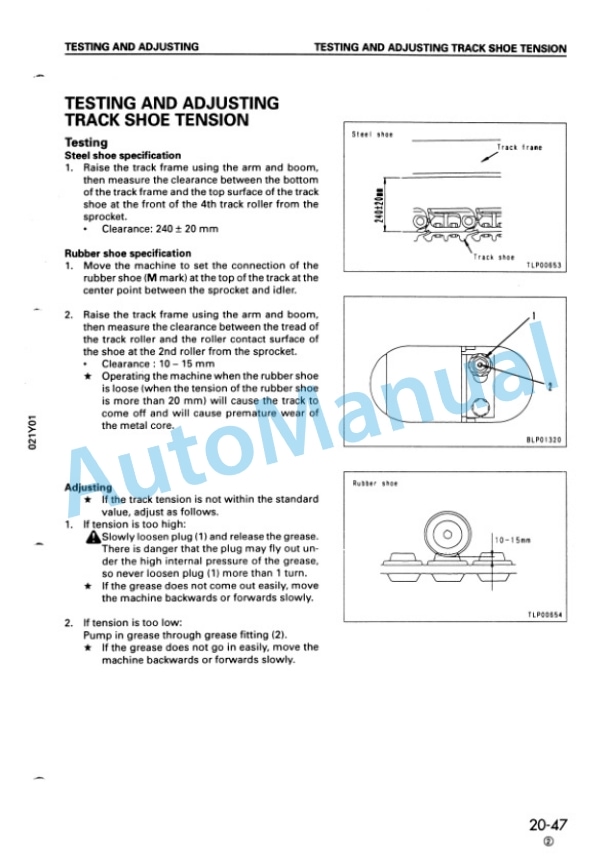

- 5.29. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.30. BLEEDING AIR

- 5.31. PROCEDURE FOR RESETTING ELECTRICAL SYSTEM AND CHECKING OPERATION

- 5.32. PROCEDURE FOR REPLACING POTENTIOMETER

- 5.33. PREOCEDURE FOR CHECKING DIODE

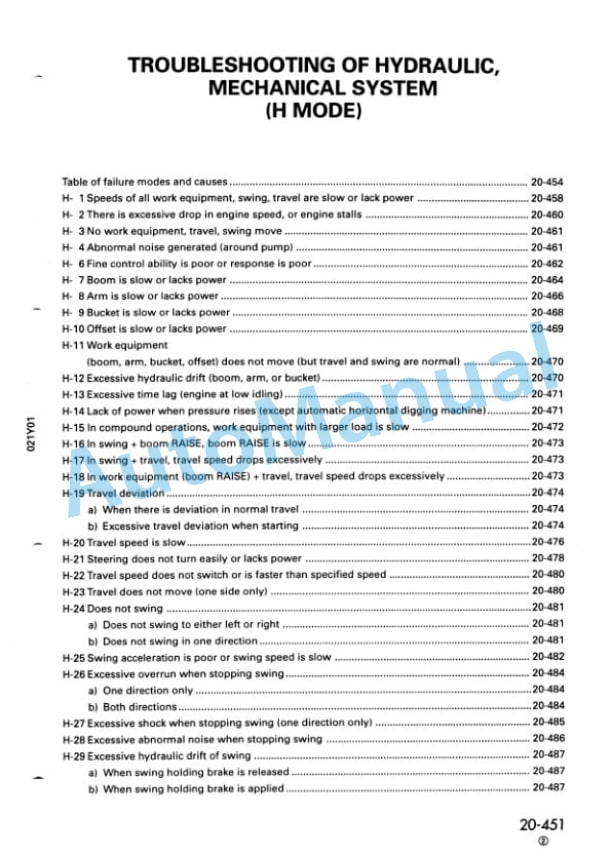

- 5.34. TROUBLESHOOTING

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SKECHES OF SPECIAL TOOLS

- 6.5. STARTING MOTOR

- 6.6. ALTERNATOR

- 6.7. ENGINE OIL COOLER

- 6.8. FUEL INJECTION PUMP

- 6.9. WATER PUMP

- 6.10. NOZZLE HOLDER

- 6.11. TURBOCHARGER

- 6.12. THERMOSTAT

- 6.13. CYLINDER HEAD

- 6.14. ENGINE, MAIN PUMP

- 6.15. RADIATOR, HYDRAULIC COOLER

- 6.16. FUEL TANK

- 6.17. CENTER SWIVEL JOINT

- 6.18. SPROCKET

- 6.19. TRAVEL MOTOR

- 6.20. SWING MOTOR, SWINMG MACHINERY

- 6.21. SWING MACHINERY

- 6.22. SWING MOROR

- 6.23. REVOLVING FRAME

- 6.24. SWING CIRCLE

- 6.25. IDLER, RECOIL SPRING

- 6.26. CARRIER ROLLER

- 6.27. SEEEL SHOE RUBBER PAD SHOE, LOAD LINER

- 6.28. INTEGRATED RUBBER SHOE

- 6.29. HYDRAULIC TANK

- 6.30. PCEPC, LSEPC VALVE

- 6.31. PC VALVE

- 6.32. LS VALVE

- 6.33. LS SELSECT VALVE

- 6.34. LS SHUTTLE VALVE

- 6.35. PRESSURE COMPENSATION VALVE

- 6.36. MAIN RELIEF VALVE

- 6.37. SOLENOID VALVE

- 6.38. WORK EQUIPMENT LH.PPC VALVE (ARM, SWING)

- 6.39. WORK EAUIPMENT R.H. PPC VALVE (BOOM, BUCKET)

- 6.40. WORK EQUIPMENT PPC VALVE (BOOM, BUCKET, ARM, SWING)

- 6.41. TRAVEL PPC VALVE

- 6.42. PPC VALVE FPR OFFSET CONTROL

- 6.43. BLADE PPC VALVE

- 6.44. BOOM LOCK VALVE

- 6.45. BUCKET CYLINDER

- 6.46. OFFSET CYLINDER

- 6.47. BLADE CYLINDER

- 6.48. HYDRAULIC CYLINDER

- 6.49. AIR CONDITIONER COMPRESSOR

- 6.50. AIR CONDENSER

- 6.51. COUNTERWEIGHT

- 6.52. CONTROLLER

- 6.53. MONITOR

- 6.54. CAR COOLER UNIT

- 7. MAINTENANCE STANDARD

- 7.1. SWING MACHINERY

- 7.2. CENTER SWIVEL JOINT

- 7.3. PPC VALVE

- 7.4. PPC SHUTTLETRAVEL JUNCTION VALVE

- 7.5. EPC SOLENOID VALVE

- 7.6. BOOM HOLDING VALVE

- 7.7. HYDRAULIC CYLINDER

- 7.8. WORK EQUIPMENT

- 7.9. DIMENSION OF WORK EQUIPMENT

- 8. OTHERS

- 8.1. HYDRAULIC PIPING DRAWING

- 8.2. MACHINE EQUIPMENT WITH AUTOMATIC HORIZONTAL EXCAVATION CONTROL (PC128UU1)

- 8.3. HYDRAUIC CIRCUIT DIAGRAM (PC128UU1)

- 8.4. MACHINE EQUIPMENT WITH AUTOMATIC HORIZONTAL EXCAVATION CONTROL (PC128UU1)

- 8.5. CLSS

- 8.6. ACTUAL ELECTRICAL WIRING DIAGRAM (PC128UU1)

- 8.7. ELECTRICAL CIRCUIT DIAGRAM (PC128UU1)

- 8.8. ELECTRONIC CONTRAL SYSTEM

- 8.9. HYDRAUIC CIRCUIT DIAGRAM (PC128US1)

- 8.10. ELECTRICAL CIRCUIT DIAGRAM (PC128US1)

- 8.11. CONNECTOR ARRANGEMENT DIAGRAM

Rate this product

You may also like