Komatsu PC12R-8, PC12R-8HS, PC15R-8, PC15R-8HS Hydraulic Excavator Operation and Maintenance Manual WEAM002703

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: WEAM002703

- Format: PDF

- Size: 13.5MB

- Number of Pages: 210

-

Model List:

- PC12R-8 Hydraulic Excavator

- PC12R-8HS Hydraulic Excavator

- PC15R-8 Hydraulic Excavator

- PC15R-8HS Hydraulic Excavator

- 1. EAMPC12.PDF

- 1.1. FOREWORD

- 1.2. INFORMATION ON SAFETY

- 1.3. INTRODUCTION

- 1.3.1. INTENDED USES

- 1.3.2. IMPROPER OR UNAUTHORIZED USES

- 1.3.3. MAIN CHARACTERISTICS

- 1.3.4. RUNNINGIN

- 1.4. PRODUCT IDENTIFICATION

- 1.4.1. MACHINE SERIAL NUMBER

- 1.4.2. MACHINE IDENTIFICATION PLATE

- 1.4.3. ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE

- 1.4.4. TRAVEL REDUCTION GEAR SERIAL NUMBER

- 1.4.5. SWING REDUCTION GEAR SERIAL NUMBER

- 1.4.6. CAB SERIAL NUMBER

- 1.5. TABLE OF CONTENTS

- 1.5.1. SAFETY, NOISE AND VIBRATION PLATES

- 1.5.2. GENERAL PRECAUTIONS

- 1.5.3. PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE

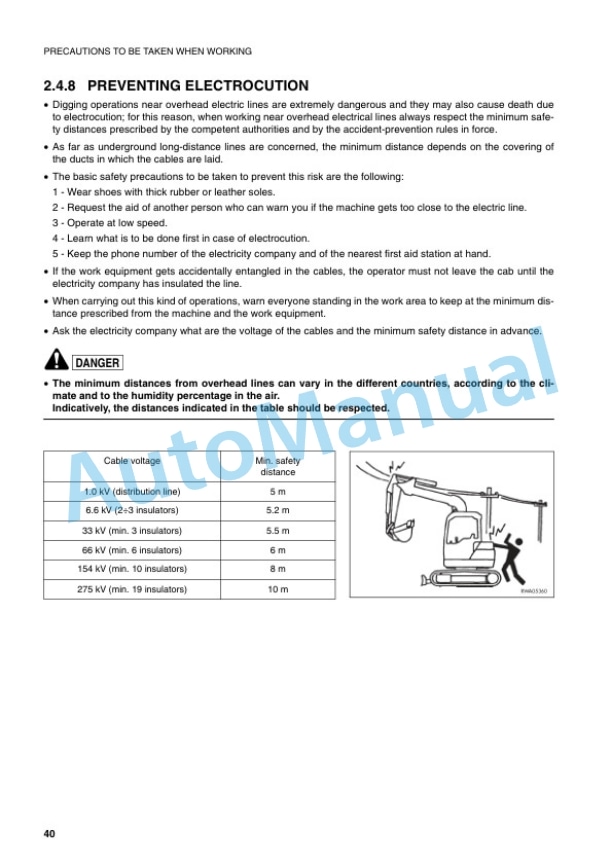

- 1.5.4. PRECAUTIONS TO BE TAKEN WHEN WORKING

- 1.5.5. TRANSPORTING THE MACHINE ON MOTOR VEHICLES

- 1.5.6. BATTERY

- 1.5.7. PRECAUTIONS FOR THE REMOVAL

- 1.5.8. PRECAUTIONS FOR MAINTENANCE

- 1.6. POSITION

- 1.7. COLOUR

- 1.8. CAPACITY (A)

- 1.9. INVOLVED CIRCUIT

- 1.9.1. USE OF THE MACHINE

- 1.9.2. PARKING THE MACHINE

- 1.9.3. STOPPING THE ENGINE

- 1.9.4. TRANSPORTING THE MACHINE ON MOTOR VEHICLES

- 1.9.5. LIFTING THE MACHINE

- 1.9.6. PRECAUTIONS TO BE TAKEN IN THE COLD SEASON

- 1.10. CHARGE PERCENTAGE

- 1.11. FLUID TEMPERATURE

- 1.11.1. OTHER PRECAUTIONS

- 1.11.2. PRECAUTIONS TO BE TAKEN AT THE END OF WORK

- 1.11.3. PRECAUTIONS TO BE TAKEN IN THE WARM SEASON

- 1.11.4. USING THE WORK EQUIPMENT

- 1.11.5. USING THE MACHINE WITH VARIABLE TRACK GAUGE

- 1.11.6. LONG PERIODS OF INACTIVITY

- 1.11.7. TROUBLESHOOTING

- 1.11.8. GUIDE TO MAINTENANCE

- 1.11.9. MAINTENANCE NOTES

- 1.12. Minimum ambient temperature (C)

- 1.13. Quantity of antifreeze (l)

- 1.14. Quantity of water (l)

- 1.14.1. NOTES REGARDING THE HYDRAULIC SYSTEM

- 1.14.2. NOTES REGARDING THE ELECTRICAL SYSTEM

- 1.14.3. NOTES REGARDING LUBRICATION

- 1.14.4. PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING

- 1.17. EVERY 250 HOURS

- 1.18. YM11930535150

- 1.20. EVERY 500 HOURS

- 1.21. YM12455055700

- 1.23. EVERY 500 HOURS

- 1.24. YM12905255630

- 1.26. EVERY 500 HOURS

- 1.27. YM11965512560

- 1.29. EVERY 500 HOURS

- 1.29.1. FUEL, COOLANT AND LUBRICANTS

- 1.30. WATER ANTIFREEZE

- 1.31. PERMANENT COOLANT

- 1.31.1. LUBRICATION WITH GREASE

- 1.32. NLGI 2

- 1.33. SUPPLIER

- 1.34. HEES SYNTHETIC BIODEGRADABLE OIL

- 1.34.1. DRIVING TORQUES FOR SCREWS AND NUTS

- 1.34.2. SPECIFIC DRIVING TORQUES

- 1.35. 0.5 5.5 0.5

- 1.36. 5 54 5

- 1.37. 0.5

- 1.38.1. LUBRICATION

- 1.38.2. PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY

- 1.43. Every 2 years or 4000 hours, whichever occurs first

- 1.43.1. MAINTENANCE PLAN

- 1.43.2. MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER)

- 1.45.1. CHECKS BEFORE STARTING

- 1.45.2. MAINTENANCE EVERY 100 HOURS OF OPERATION

- 1.45.3. MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION (Operations to be carried out together w…

- 1.47.1. MAINTENANCE EVERY 250 HOURS OF OPERATION

- 1.47.2. MAINTENANCE EVERY 500 HOURS OF OPERATION

- 1.47.3. MAINTENANCE EVERY 1000 HOURS OF OPERATION

- 1.48.1. MAINTENANCE EVERY 2000 HOURS OF OPERATION

- 1.48.2. WHEN REQUIRED

- 1.48.3. MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER)

- 1.48.4. MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which the synthetic…

- 1.48.5. MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION

- 1.48.6. MAINTENANCE EVERY 250 HOURS OF OPERATION

- 1.48.7. MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which the syntheti…

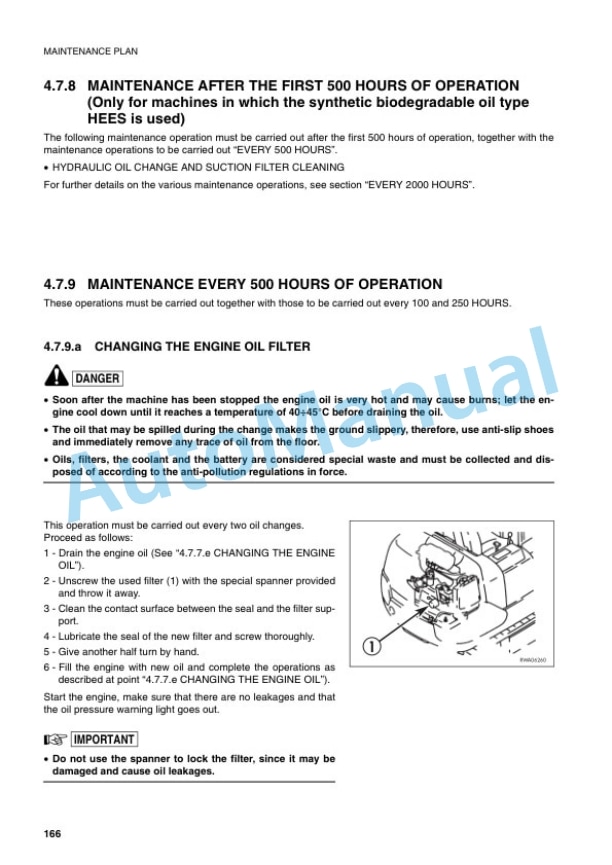

- 1.48.8. MAINTENANCE EVERY 500 HOURS OF OPERATION

- 1.48.9. MAINTENANCE EVERY 1000 HOURS OF OPERATION

- 1.48.10. MAINTENANCE EVERY 2000 HOURS OF OPERATION

- 1.49. TECHNICAL DATA

- 1.49.1. STANDARD OVERALL DIMENSIONS PC12R

- 1.49.2. TECHNICAL CHARACTERISTICS PC12R

- 1.49.3. TOTAL MASS

- 1.49.4. STANDARD BUCKET CAPACITY

- 1.49.5. ENGINE

- 1.49.6. ELECTRICAL SYSTEM

- 1.49.7. UPPER STRUCTURE ROTATION

- 1.49.8. SPEEDS

- 1.49.9. TOTAL MASS

- 1.49.10. STANDARD BUCKET CAPACITY

- 1.49.11. ENGINE

- 1.49.12. ELECTRICAL SYSTEM

- 1.49.13. UPPER STRUCTURE ROTATION

- 1.49.14. SPEEDS

- 1.49.15. TOTAL MASS

- 1.49.16. STANDARD BUCKET CAPACITY

- 1.49.17. ENGINE

- 1.49.18. ELECTRICAL SYSTEM

- 1.49.19. UPPER STRUCTURE ROTATION

- 1.49.20. SPEEDS

- 1.49.21. TOTAL MASS

- 1.49.22. STANDARD BUCKET CAPACITY

- 1.49.23. ENGINE

- 1.49.24. ELECTRICAL SYSTEM

- 1.49.25. UPPER STRUCTURE ROTATION

- 1.49.26. SPEEDS

- 1.49.27. AUTHORIZED OPTIONAL EQUIPMENT

- 1.49.28. (PC15RPC15R HS)

- 1.49.29. ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER)

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual