Komatsu PC15R-8 Deluxe Hydraulic Excavator Operation and Maintenance Manual WEAM003001

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: WEAM003001

- Format: PDF

- Size: 13.0MB

- Number of Pages: 201

-

Model List:

- PC15R-8 Deluxe Hydraulic Excavator

- 1. MAIN MENU

- 2. COVER

- 3. FOREWARD

- 4. INFORMATION ON SAFETY

- 5. INTRODUCTION

- 5.1. INTENDED USES

- 5.2. IMPROPER OR UNAUTHORIZED USES

- 5.3. MAIN CHARACTERISTICS

- 5.4. RUNNINGIN

- 6. PRODUCT IDENTIFICATION

- 6.1. MACHINE SERIAL NUMBER

- 6.2. MACHINE IDENTIFICATION PLATE

- 6.3. ENGINE SERIAL NUMBER AND EMISSION LABEL

- 6.4. TRAVEL REDUCTION GEAR SERIAL NUMBER

- 6.5. SWING REDUCTION GEAR SERIAL NUMBER

- 6.6. CAB SERIAL NUMBER

- 6.7. SERIAL NUMBERS AND DEALERS ADDRESS

- 7. CONTENTS

- 8. SAFETY AND ACCIDENT PREVENTION

- 8.1. SAFETY PLATES

- 8.1.1. POSITION OF THE SAFETY PLATES

- 8.1.2. POSITION OF THE PICTOGRAMS

- 8.1.3. PICTOGRAMS AND RELEVANT MEANINGS

- 8.1.4. VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED

- 8.2. GENERAL PRECAUTIONS

- 8.2.1. GENERAL SAFETY RULES

- 8.2.2. SAFETY DEVICES AND GUARDS

- 8.2.3. CLOTHING AND PERSONAL PROTECTION ITEMS

- 8.2.4. UNAUTHORIZED MODIFICATIONS

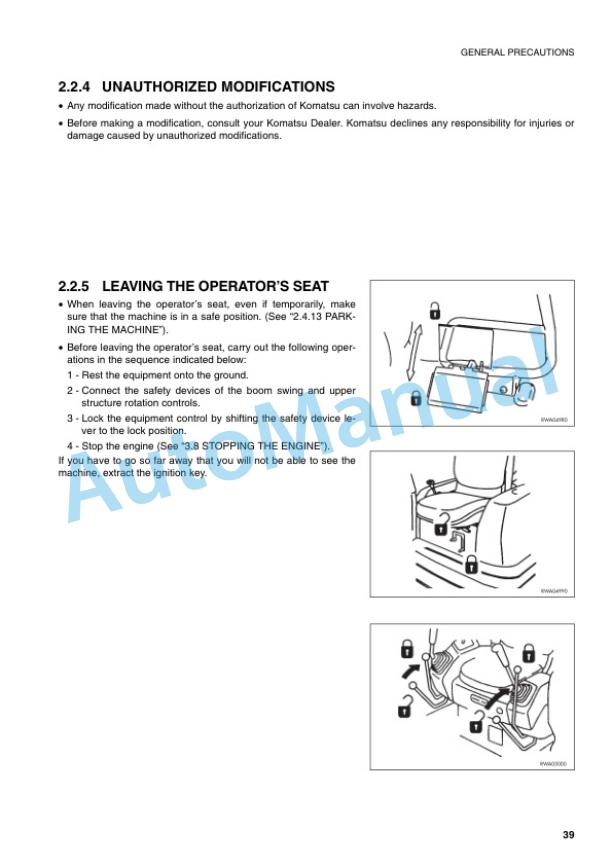

- 8.2.5. LEAVING THE OPERATORS SEAT

- 8.2.6. GETTING ON AND OFF THE MACHINE

- 8.2.7. PREVENTING FIRES DUE TO FUEL AND OIL

- 8.2.8. PREVENTING BURNS

- 8.2.9. PREVENTING DAMAGE DUE TO ASBESTOS POWDER

- 8.2.10. PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT

- 8.2.11. FIRE EXTINGUISHERS AND FIRST AID KIT

- 8.2.12. PRECAUTIONS CONCERNING THE CAB STRUCTURE

- 8.2.13. PRECAUTIONS CONCERNING THE EQUIPMENT

- 8.3. PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE

- 8.3.1. SAFETY ON THE WORK SITE

- 8.3.2. FIRE PREVENTION

- 8.3.3. PRECAUTIONS TO BE TAKEN FOR THE OPERATORS CAB

- 8.3.4. ROOM VENTILATION

- 8.3.5. PRECAUTIONS TO BE TAKEN FOR THE LIGHTS

- 8.3.6. CLEANING THE WINDOWS CHECKING THE WINDSHIELD WIPER BLADES

- 8.4. PRECAUTIONS TO BE TAKEN WHEN WORKING

- 8.4.1. STARTING THE ENGINE

- 8.4.2. CHECK THE DIRECTION BEFORE STARTING THE MACHINE

- 8.4.3. CHECKS FOR TRAVELLING IN REVERSE

- 8.4.4. MOVING THE MACHINE

- 8.4.5. MOVING ON SLOPES

- 8.4.6. WORKING ON SLOPES

- 8.4.7. UNAUTHORIZED OPERATIONS

- 8.4.8. PREVENTING ELECTROCUTION

- 8.4.9. VISIBILITY

- 8.4.10. WORKING ON ICY OR SNOWCOVERED SURFACES

- 8.4.11. PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT

- 8.4.12. WORKING ON LOOSE GROUND

- 8.4.13. PARKING THE MACHINE

- 8.5. TRANSPORTING THE MACHINE ON OTHER VEHICLES

- 8.5.1. LOADING AND UNLOADING

- 8.5.2. TRANSPORT

- 8.6. BATTERY

- 8.6.1. PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY

- 8.6.2. STARTING WITH THE BOOSTER CABLES

- 8.7. PRECAUTIONS FOR EMERGENCY RECOVERY

- 8.8. PRECAUTIONS TO BE TAKEN DURING MAINTENANCE

- 8.8.1. WARNING PLATES

- 8.8.2. TOOLS

- 8.8.3. PERSONNEL

- 8.8.4. EQUIPMENT

- 8.8.5. WORKING UNDER THE MACHINE

- 8.8.6. CLEANING THE MACHINE

- 8.8.7. USE OF THE ENGINE DURING MAINTENANCE OPERATIONS

- 8.8.8. PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY

- 8.8.9. STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION

- 8.8.10. RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP

- 8.8.11. CHECKING THE COOLANT LEVEL IN THE RADIATOR

- 8.8.12. USING LAMPS

- 8.8.13. PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR

- 8.8.14. PRECAUTIONS CONCERNING THE STARTER

- 8.8.15. HANDLING HIGHPRESSURE PIPES

- 8.8.16. PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGHPRESSURE OIL

- 8.8.17. PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE

- 8.8.18. COOLING FAN AND BELT

- 8.8.19. WASTE MATERIALS

- 8.8.20. PRECAUTIONS FOR THE USE OF THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES

- 9. THE MACHINE AND ITS OPERATIONS

- 9.1. SAFETY LOCKS

- 9.1.1. MACHINE LOCKS

- 9.2. GENERAL VIEWS

- 9.2.1. GENERAL VIEW OF THE MACHINE WITH CAB (OPTIONAL)

- 9.2.2. GENERAL VIEW OF THE MACHINE WITH CANOPY

- 9.2.3. GENERAL VIEW OF THE DRIVERS SEAT

- 9.3. INSTRUMENTS AND CONTROLS

- 9.3.1. INSTRUMENTS

- 9.3.2. WARNING LIGHTS

- 9.3.3. SWITCHES AND PUSH BUTTONS

- 9.3.4. ELECTRICAL ACCESSORIES

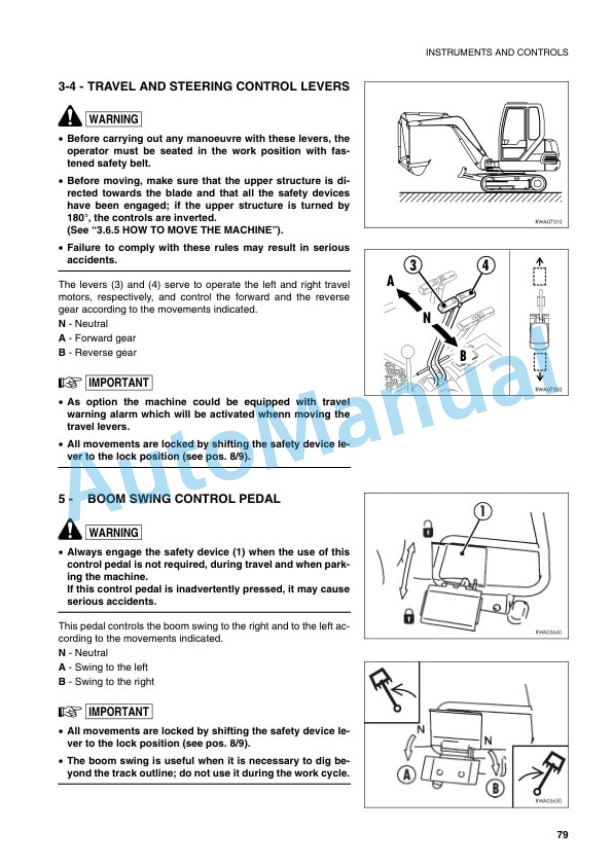

- 9.3.5. MACHINE CONTROLS

- 9.4. FUSES AND RELAYS

- 9.4.1. FUSES

- 9.4.2. RELAYS

- 9.5. GUARDS AND DRIVERS SEAT

- 9.5.1. ENGINE HOOD

- 9.5.2. CANOPY

- 9.5.3. CAB (OPTIONAL)

- 9.5.4. VENTILATION AND HEATING (ONLY ON MACHINES WITH CAB)

- 9.5.5. SEAT

- 9.5.6. SAFETY BELT

- 9.5.7. EMERGENCY EXIT (ONLY ON MACHINES WITH CAB)

- 9.5.8. TECHNICAL DOCUMENTATION CASE

- 9.5.9. FIRE EXTINGUISHER

- 9.5.10. FIRST AID KIT

- 9.6. USE OF THE MACHINE

- 9.6.1. CHECKS BEFORE STARTING MACHINE

- 9.6.2. STARTING THE ENGINE

- 9.6.3. WARMING THE ENGINE

- 9.6.4. HEATING THE HYDRAULIC OIL

- 9.6.5. HOW TO MOVE THE MACHINE

- 9.7. PARKING THE MACHINE

- 9.7.1. PARKING ON LEVEL GROUND

- 9.7.2. PARKING ON SLOPES

- 9.8. STOPPING THE ENGINE

- 9.9. TRANSPORTING THE MACHINE ON OTHER VEHICLES

- 9.9.1. LOADING AND UNLOADING THE MACHINE

- 9.9.2. TRANSPORT

- 9.10. LIFTING THE MACHINE

- 9.11. PRECAUTIONS TO BE TAKEN IN THE COLD SEASON

- 9.11.1. FUEL AND LUBRICANTS

- 9.11.2. COOLANT

- 9.11.3. BATTERY

- 9.11.4. OTHER PRECAUTIONS

- 9.11.5. PRECAUTIONS TO BE TAKEN AT THE END OF WORK

- 9.12. PRECAUTIONS TO BE TAKEN IN THE WARM SEASON

- 9.13. USING THE WORK EQUIPMENT

- 9.13.1. ORGANIZING THE WORK AREA

- 9.13.2. POSITIONING THE MACHINE FOR DIGGING OPERATIONS

- 9.13.3. DIGGING METHOD

- 9.13.4. CHANGING THE BUCKET

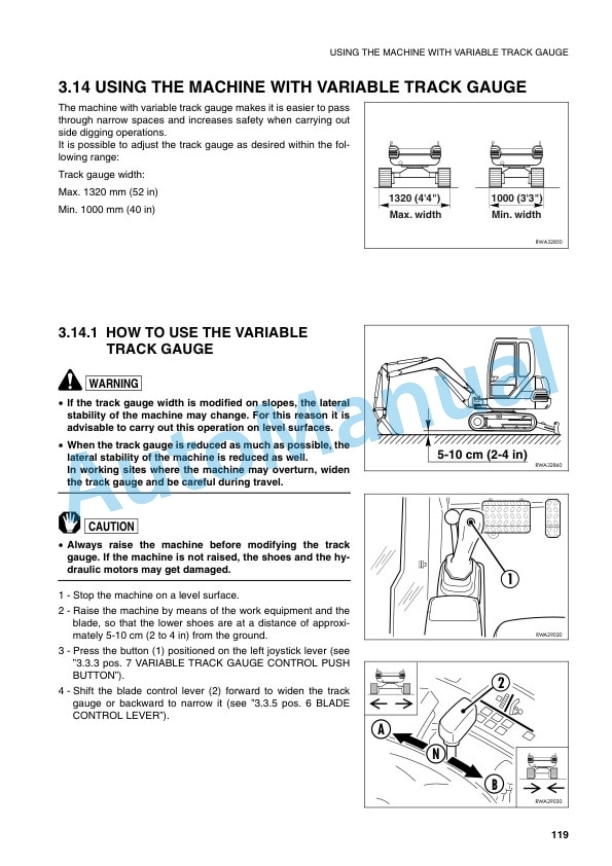

- 9.14. USING THE MACHINE WITH VARIABLE TRACK GUAGE

- 9.14.1. HOW TO USE THE VARIABLE TRACK GUAGE

- 9.14.2. ADJUSTING THE BLADE

- 9.15. LONG PERIODS OF INACTIVITY

- 9.15.1. BEFORE THE PERIOD OF INACTIVITY

- 9.15.2. DURING THE PERIOD OF INACTIVITY

- 9.15.3. AFTER THE PERIOD OF INACTIVITY

- 9.16. TROUBLESHOOTING

- 9.16.1. OCCURENCES THAT ARE NOT FAILURES

- 9.16.2. HOW TO REMOVE THE MACHINE

- 9.16.3. AFTER THE FUEL HAS RUN OUT

- 9.16.4. IF THE BATTERY IS DOWN

- 9.16.5. OTHER TROUBLES

- 10. MAINTENANCE

- 10.1. GUIDE TO MAINTENANCE

- 10.2. MAINTENANCE NOTES

- 10.2.1. NOTES REGARDING THE ENGINE

- 10.2.2. NOTES REGARDING THE HYDRAULIC SYSTEM

- 10.2.3. NOTES REGARDING THE ELECTRICAL SYSTEM

- 10.2.4. NOTES REGARDING LUBRICATION

- 10.2.5. PARTS SUBJEST TO WEAR THAT PERIODICALLY NEED CHANGING

- 10.3. FUEL, COOLANT AND LUBRICANTS

- 10.3.1. HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS

- 10.4. NUT AND BOLT TIGHTENING TORQUES

- 10.4.1. STANDARD TIGHTENING TORQUES

- 10.4.2. SPECIFIC TIGHTENING TORQUES

- 10.5. LUBRICATION

- 10.5.1. LUBRICATION DIAGRAM

- 10.5.2. LUBRICATION DIAGRAM (VARIABLE TRACK GUAGE)

- 10.6. PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY

- 10.6.1. CRITICAL PARTS FOR SAFETY

- 10.7. MAINTENANCE PLAN

- 10.7.1. WHEN REQUIRED

- 10.7.2. MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER)

- 10.7.3. CHECKS BEFORE STARTING

- 10.7.4. MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (ONLY FOR MACHINES IN WHICH THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES

- 10.7.5. MAINTENANCE EVERY 100 HOURS OF OPERATION

- 10.7.6. MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION

- 10.7.7. MAINTENANCE EVERY 250 HOURS OF OPERATION

- 10.7.8. MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (ONLY FOR MACHINE IN WHICH THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES

- 10.7.9. MAINTENANCE EVERY 500 HOURS OF OPERATION

- 10.7.10. MAINTENANCE EVERY 1000 HOURS OF OPERATION

- 10.7.11. MAINTENANCE EVERY 2000 HOURS OF OPERATION

- 11. TECHNICAL SPECIFICATIONS

- 11.1. TECHNICAL DATA

- 11.1.1. STANDARD OVERALL DIMENSIONS

- 11.1.2. TECHNICAL CHARACTERISTICS

- 11.1.3. OVERALL DIMENSIONS (ONLY

VERSION) - 11.1.4. TECHNICAL CHARACTERISTICS (ONLY

VERSION) - 11.1.5. LIFTING CAPACITY

- 11.1.6. LIFTING CAPACITY (ONLY

VERISON) - 12. AUTHORIZED OPTIONAL EQUIPMENT

- 12.1. AUTHORIZED OPTIONAL EQUIPMENT

- 12.1.1. PRECAUTIONS REGARDING SAFETY

- 12.1.2. PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT

- 12.1.3. CHARACTERISTICS OF THE OPTIONAL EQUIPMENT

- 12.2. ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER)

- 12.2.1. DESCRIPTION AND CONTROL

- 12.2.2. USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED

- 12.2.3. INSTALLING AND REMOVING THE DEMOLITION HAMMER

- 12.2.4. MAINTENANCE

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901