Komatsu PC15R-8 Hydraulic Excavator Shop Manual WEBM002800

$40.00

- Type Of Manual: Shop Manual

- Manual ID: WEBM002800

- Format: PDF

- Size: 19.3MB

- Number of Pages: 236

Category: Komatsu Shop Manual PDF

-

Model List:

- PC15R-8 Hydraulic Excavator

- 1. MAIN MENU

- 2. COVER

- 3. FOREWARD

- 3.1. HOW TO READ THE SHOP MANUAL

- 3.2. HOISTING INSTRUCTIONS

- 3.3. STANDARD TIGHTENING TORQUE

- 3.4. COATING MATERIALS

- 3.5. WEIGHT TABLE

- 3.6. TABLE OF OIL AND COOLANT QUANTIES

- 4. CONTENTS

- 5. STRUCTURE AND FUNCTION

- 5.1. POWER TRAIN

- 5.2. SWING CIRCLE

- 5.3. SWING MOTOR

- 5.4. FINAL DRIVE

- 5.5. TRACK FRAME AND RECOIL SPRING

- 5.6. CARRIER ROLLER

- 5.7. STEEL SHOE

- 5.8. HYDRAULIC SYSTEM

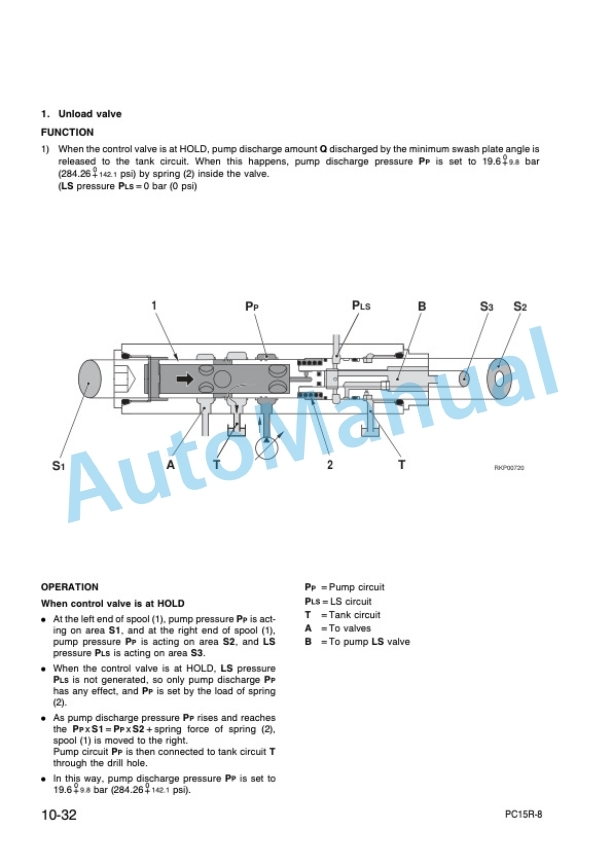

- 5.9. HYDRAULIC CIRCUIT DIAGRAM

- 5.10. SOLENOID VALVE

- 5.11. CUTTING SHOVEL CONTROL VALVE

- 5.12. ELECTRICAL CIRCUIT DIAGRAM

- 6. TESTING AND ADJUSTING

- 6.1. NORMAL OR STANDARD TECHNICAL DATA

- 6.2. SPECIAL TOOLS

- 6.3. CHECKING THE ENGINE SPEED

- 6.4. ADJUSTMENT OF VALVE CLEARANCE

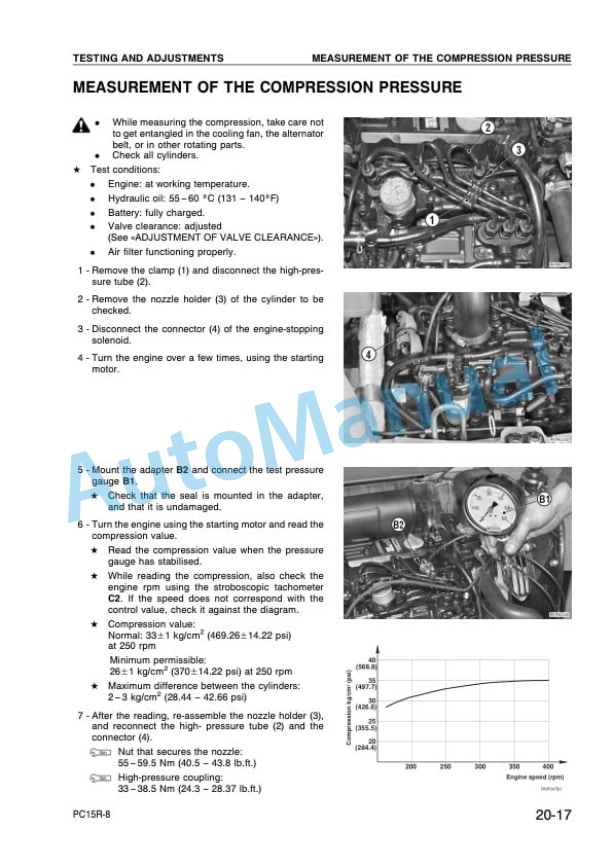

- 6.5. MEASUREMENT OF THE COMPRESSOR PRESSURE

- 6.6. CONTROL AND ADJUSTMENT OF THE TENSION OF THE FAN BELT

- 6.7. CONTROL AND ADJUSTMENT OF THE INJECTION TIMING

- 6.8. CONTROL AND ADJUSTMENT OF THE ACCELERATOR STROKE

- 6.9. ADJUSTMENTOF THE STROKE OF THE BLADE COMMAND LEVER

- 6.10. CONTROL AND ADJUSTMENT OF THE STROKE OF THE TRAVEL LEVER

- 6.11. CENTERING ADJUSTMENT OF THE BOOM SWING COMMAND PEDAL

- 6.12. ADJUSTMENT OF THE PPC VALVE CLEARANCES

- 6.13. ADJUSTMENT OF THE RUBBER PAD AND SAFETY MICROSWITCH FOR SERVOCONTROL ENGAGEMENT

- 6.14. CONTROL AND ADJUSTMENTOF THE STROKE OF THE TRACKSHOE TENSION

- 6.15. CONTROL AND REGULATION OF THE PREEURES IN THE HYDRAULIC CIRCUTIS

- 6.16. CONTROL AND REGULATION OF THE LS DIFFERENTIAL PRESSURE AND ADJUSTMENT OF THE LS VALVE

- 6.17. REGULATION OF THE PC VALVE

- 6.18. CONTROL AND REGULATION O THE SERVOCONTROL POWER SUPPLY

- 6.19. ELIMINATION OF RESIDUAL PRESSURES PRESSURISATION OF THE TANK

- 6.20. BLEEDING AIR FROM THE HYDRAULIC CIRCUITS

- 6.21. CONTROL OF HYDRAULIC DRIFTS ANALYSIS OF THE CAUSES OF A DRIFT

- 6.22. CHECKING FOR ANY LEAKAGES INSIDE THE WORKING EQUIPMENT CYLINDERS

- 6.23. CHECKING FOR ANY LEAKAGES INSIDE THE SWING MOTOR

- 6.24. METHODS FOR TESTING FOR LEAKAGES INSIDE THE SWIVEL JOINT

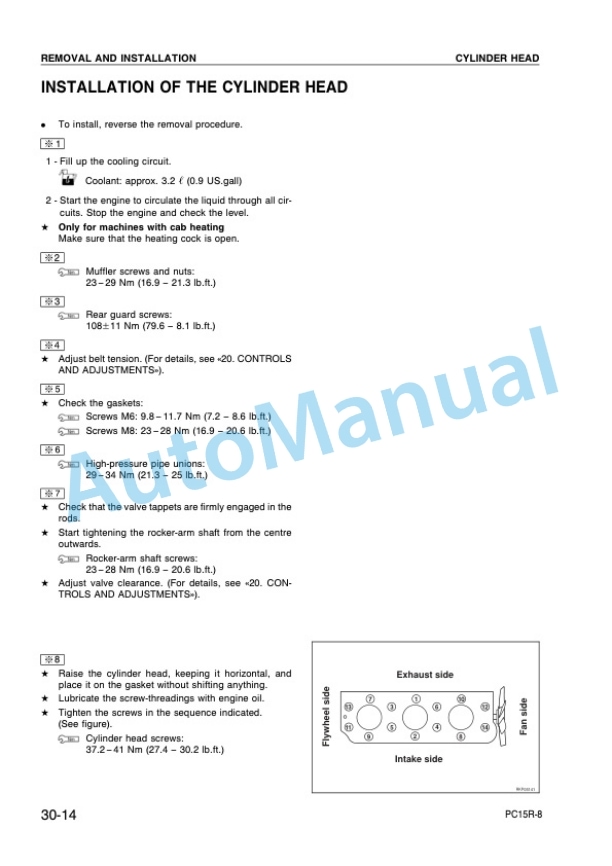

- 7. REMOVAL AND INSTALLATION

- 7.1. HOW TO READ THE MANUAL

- 7.2. PRECAUTIONS TO BE TAKEN WHILE WORKING

- 7.3. INJECTION NOZZLES

- 7.4. REAR COUNTERWEIGHT

- 7.4.1. REMOVAL

- 7.4.2. INSTALLATION

- 7.5. TOP COVER AND SIDE PANELS

- 7.5.1. REMOVAL

- 7.5.2. INSTALLATION

- 7.6. HYDRAULIC OIL TANK

- 7.7. ENGINEPUMP GROUP

- 7.8. ENGINEPUMP COUPLING

- 7.9. RIGHTHAND PPC VALVE

- 7.9.1. REMOVAL

- 7.9.2. INSTALLATION

- 7.10. LEFTHAND PPC VALVE

- 7.10.1. REMOVAL

- 7.10.2. INSTALLATION

- 7.11. SERVOCONTROL SOLENNIOD GROUP (PC12R)

- 7.11.1. REMOVAL

- 7.11.2. INSTALLATION

- 7.12. SERVOCONTROL SOLENNIOD GROUP (PC12R WITH TRAVEL INCREMENT PC15R)

- 7.12.1. REMOVAL

- 7.12.2. INSTALLATION

- 7.13. REVOLVING FRAME

- 7.14. RUBBER TRACKSHOES

- 7.15. COMPLETE FINAL DRIVE

- 7.16. IDLER AND RECOIL SPRING ASSEMBLY

- 7.17. SPRING RECOIL AND THRUST CYLINDER GROUPS

- 7.18. BUCKET CYLINDER

- 7.18.1. REMOVAL

- 7.18.2. INSTALLATION

- 7.19. BOOM SWING CYLINDER

- 7.20. WORKING EQUIPMENT CYLINDERS

- 7.20.1. DISASSEMBLY

- 7.20.2. ASSEMBLY

- 7.21. UPPER WORKING EQUIPMENT

- 7.22. BOOM SWING SUPPORT

- 8. MAINTENANCE STANDARD

- 8.1. SWING CIRCLE

- 8.2. TRACK FRAME AND RECOIL SPRING

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00