Komatsu PC160LC-7K, PC180LC-7K Hydraulic Excavator Shop Manual UEBM002200

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEBM002200

- Format: PDF

- Size: 28.0MB

- Number of Pages: 676

Category: Komatsu Shop Manual PDF

-

Model List:

- PC160LC-7K Hydraulic Excavator

- PC180LC-7K Hydraulic Excavator

- 1. Sec 00.pdf

- 1.1. SAFETY

- 1.2. GENERAL

- 1.3. HOW TO READ THE SHOP MANUAL

- 1.4. HOISTING INSTRUCTIONS

- 1.5. PUSHPULL TYPE COUPLERS

- 1.6. COATING MATERIALS

- 1.7. STANDARD TIGHTENING TORQUE

- 1.8. ELECTRIC WIRE CODE

- 1.9. CONVERSION TABLES

- 1.10. UNITS

- 2. .pdf

- 2.1. GENERAL

- 3. .pdf

- 3.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 3.2. TESTING AND ADJUSTING

- 4. .pdf

- 4.1. TOOLS for testing, adjusting and troubleshooting

- 4.2. INSPECTION AND ADJUSTMENT OF ENGINE RPM

- 4.3. MEASUREMENT OF EXHAUST GAS COLOR

- 4.4. ADJUSTMENT OF VALVE CLEARANCE

- 4.5. MEASUREMENT OF COMPRESSION PRESSURE

- 4.6. MEASUREMENT OF BLOWBY PRESSURE

- 4.7. INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

- 4.8. MEASUREMENT OF ENGINE OIL PRESSURE

- 4.9. ADJUSTMENT OF ENGINE SPEED SENSOR

- 4.10. INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

- 4.11. MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

- 4.12. INSPECTION AND ADJUSTMENT OF TRACK SHOE TENSION

- 4.13. Inspection and adjustment oil pressure in work equipment, swing, and travel circuits

- 4.14. INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

- 4.15. INSPECTION AND ADJUSTMENT OF PUMP PC CONTROL CIRCUIT OIL PRESSURE

- 4.16. Inspection and adjustment pump LS control circuit oil pressure

- 4.17. Measurement of solenoid valve output pressure

- 4.18. MEASUREMENT OF PPC VALVE OUTPUT PRESSURE

- 4.19. ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE

- 4.20. INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

- 4.21. TESTING AND ADJUSTING TRAVEL DEVIATION

- 4.22. Release of residual pressure from hydraulic circuit

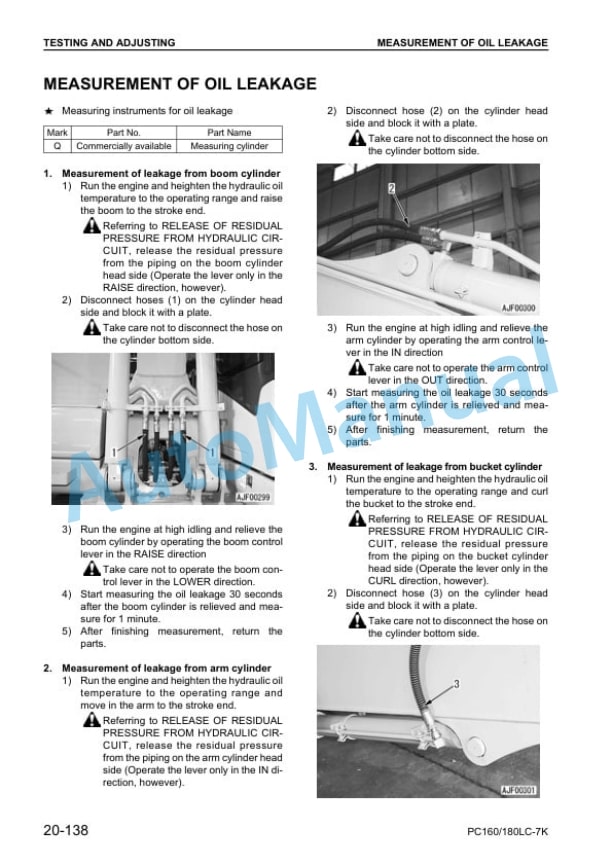

- 4.23. Measurement of oil leakage

- 4.24. Bleeding air from each part

- 4.25. INSPECTION PROCEDURES FOR DIODE

- 5. .pdf

- 5.1. PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

- 5.2. SPECIAL FUNCTION OF MONITOR PANEL

- 6. .pdf

- 6.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 6.2. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 6.3. CHECKS BEFORE TROUBLESHOOTING

- 6.4. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

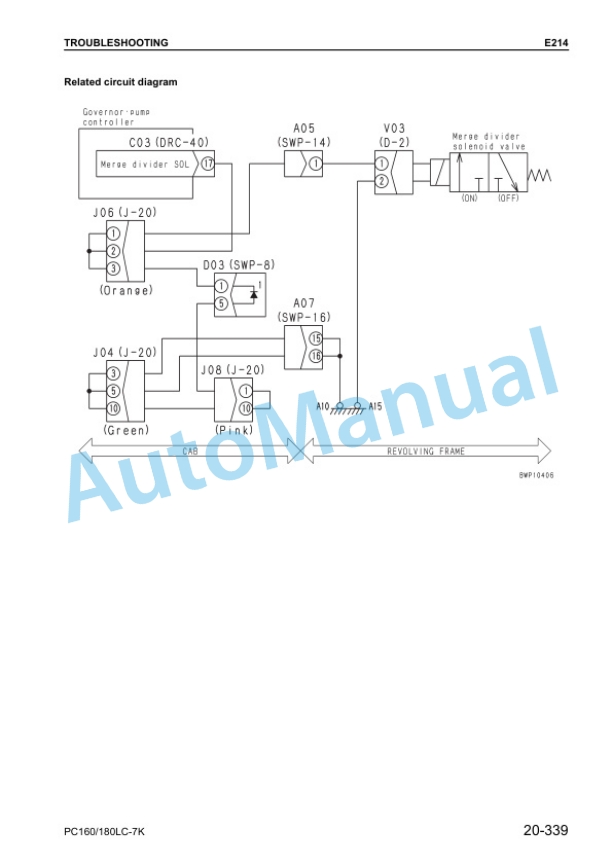

- 6.5. CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

- 6.6. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 6.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 6.8. Tadapter boxes and Tadapter table

- 7. .pdf

- 7.1. Before troubleshooting for displayed code

- 7.2. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 8. .pdf

- 8.1. Failure Code in Mechanical System (Abnormally lowered radiator water level)

- 8.2. Failure Code in Mechanical System (Hydraulic oil overheating)

- 8.3. Error Code in Electrical System (Abnormality in pressure sensor power source)

- 8.4. Error Code in Electrical System (Abnormality in engine rotation sensor)

- 8.5. Error Code in Electrical System (Shortcircuiting in attachment return switching relay)

- 8.6. Error Code in Electrical System (Shortcircuiting in PCEPC solenoid)

- 8.7. Error Code in Electrical System (Disconnection in PCEPC solenoid)

- 8.8. Error Code in Electrical System (Disconnection in attachment return switching relay)

- 8.9. Error Code in Electrical Equipment (Shortcircuiting in attachment oil flow rate adjusting EPC so…

- 8.10. Error Code in Electrical System (Disconnection in attachment oil flow rate adjusting EPC solenoid)

- 8.11. Error Code in Electrical System (Abnormality in governor potentiometer)

- 8.12. Error Code in Electrical System (Abnormality in fuel dial)

- 8.13. Error Code in Electrical System (Shortcircuiting in cold starting solenoid relay)

- 8.14. Error Code in Electrical System (Disconnection in cold starting solenoid relay)

- 8.15. Error Code in Electrical System (Shortcircuiting in battery relay)

- 8.16. Error Code in Electrical System (Stepout in governor motor)

- 8.17. Error Code in Electrical System (Disconnection in governor motor Phase A and B)

- 8.18. Error Code in Electrical System (Shortcircuiting in governor motor Phase A and Phase B)

- 8.19. Failure Code in Mechanical System (Outofrate engine rotation at high idling)

- 8.20. Failure Code in Mechanical System A000N2 (Outofrate engine rotation at low idling)

- 8.21. Failure Code in Mechanical System (Air cleaner clogging)

- 8.22. Failure Code in Mechanical System (Abnormally lowered charging voltage)

- 8.23. Failure Code in Mechanical System (Abnormally lowered engine oil pressure)

- 8.24. Failure Code in Mechanical System (Abnormally lowered engine oil level)

- 8.25. Failure Code in Mechanical System (Engine cooling water overheating)

- 9. .pdf

- 9.1. Before conducting Emode troubleshooting

- 9.2. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 10. .pdf

- 10.1. H1 Speed or power of all work equipment, swing, and travel are low

- 10.2. H2 Engine speed sharply drops or engine stalls

- 10.3. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 10.4. SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS

- 11. )complete.pdf

- 11.1. Removal and installation of fuel injection pump assembly

- 11.2. DISASSEMBLY AND ASSEMBLY

- 12. PC1607_Sec90.pdf

- 12.1. This page left intentionally blank

- 13. PC1607_Sec90_Body.pdf

- 13.1. HYDRAULIC diagram (1/1)

- 13.2. electrical circuit diagram (1/4)

- 13.3. electrical circuit diagram (2/4)

- 13.4. electrical circuit diagram (3/4)

- 13.5. electrical circuit diagram (4/4)

- 13.6. electrical circuit diagram for air conditioner

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00