Komatsu PC18MR-2 Compact Hydraulic Excavator Operation and Maintenance Manual TEN00052-03

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: TEN00052-03

- Format: PDF

- Size: 4.9MB

- Number of Pages: 241

-

Model List:

- PC18MR-2 Compact Hydraulic Excavator

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. DIRECTIONS OF MACHINE

- 2.4. PRODUCT INFORMATION

- 2.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 2.4.2. ENGINE SERIAL NUMBER PLATE AND ITS LOCATION

- 2.4.3. EPA NAMEPLATE

- 2.4.4. SERVICE METER LOCATION

- 2.4.5. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 3. CONTENTS

- 4. SAFETY

- 4.1. SAFETY

- 4.2. SAFETY LABELS

- 4.2.1. LOCATION OF SAFETY LABELS

- 4.2.2. SAFETY LABELS

- 4.3. GENERAL PRECAUTIONS

- 4.3.1. SAFETY RULES

- 4.3.2. IF PROBLEMS ARE FOUND

- 4.3.3. WORKING WEAR AND PERSONAL PROTECTIVE ITEMS

- 4.3.4. FIRE EXTINGUISHER AND FIRST AID KIT

- 4.3.5. SAFETY EQUIPMENT

- 4.3.6. KEEP MACHINE CLEAN

- 4.3.7. KEEP OPERATORS COMPARTMENT CLEAN

- 4.3.8. LEAVING OPERATORS SEAT WITH LOCK

- 4.3.9. HANDRAILS AND STEPS

- 4.3.10. MOUNTING AND DISMOUNTING

- 4.3.11. NO PERSONS ON ATTACHMENTS

- 4.3.12. BURN PREVENTION

- 4.3.13. FIRE PREVENTION AND EXPLOSION PREVENTION

- 4.3.14. ACTION IF FIRE OCCURS

- 4.3.15. FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION

- 4.3.16. CAUTIONS RELATED TO ROPS (ROLLOVER PROTECTION SYSTEM)

- 4.3.17. ATTACHMENT INSTALLATION

- 4.3.18. ATTACHMENT COMBINATIONS

- 4.3.19. UNAUTHORIZED MODIFICATIONS

- 4.3.20. SAFETY AT JOBSITE

- 4.3.21. WORKING ON LOOSE GROUND

- 4.3.22. DISTANCE TO HIGH VOLTAGE CABLES

- 4.3.23. ENSURE GOOD VISIBILITY

- 4.3.24. VENTILATION FOR ENCLOSED AREA

- 4.3.25. SIGNALMANS SIGNAL AND SIGNS

- 4.3.26. ASBESTOS DUST HAZARD PREVENTION

- 4.4. SAFETY MACHINE OPERATION

- 4.4.1. STARTING ENGINE

- 4.4.2. OPERATION

- 4.4.3. TRANSPORTATION

- 4.4.4. BATTERY

- 4.4.5. TOWING

- 4.4.6. LIFTING OBJECTS WITH BUCKET

- 4.5. SAFETY MAINTENANCE INFORMATION

- 4.5.1. WARNING TAG

- 4.5.2. KEEP WORK PLACE CLEAN AND TIDY

- 4.5.3. APPOINT LEADER WHEN WORKING WITH OTHERS

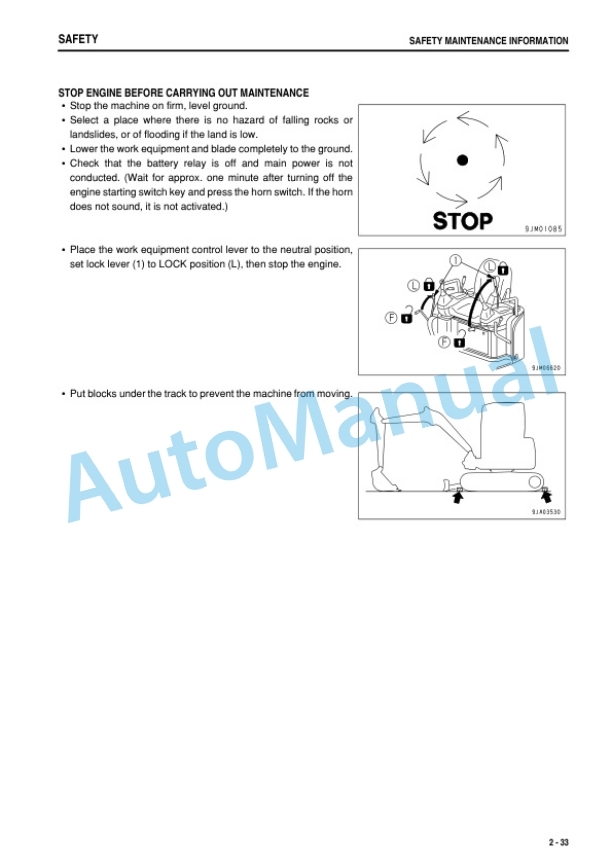

- 4.5.4. STOP ENGINE BEFORE CARRYING OUT MAINTENANCE

- 4.5.5. CAUTIONS FOR OPENING (TILTING) FLOOR

- 4.5.6. TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING

- 4.5.7. PROPER TOOLS

- 4.5.8. PERSONNEL

- 4.5.9. ATTACHMENTS

- 4.5.10. WORK UNDER THE MACHINE

- 4.5.11. NOISE

- 4.5.12. WHEN USING HAMMER

- 4.5.13. WELDING WORKS

- 4.5.14. REMOVING BATTERY TERMINALS

- 4.5.15. SAFETY FIRST WHEN USING HIGHPRESSURE GREASE TO ADJUST TRACK TENSION

- 4.5.16. DO NOT DISASSEMBLE RECOIL SPRINGS

- 4.5.17. SAFETY RULES FOR HIGHPRESSURE OIL

- 4.5.18. SAFETY HANDLING HIGHPRESSURE HOSES

- 4.5.19. WASTE MATERIALS

- 4.5.20. COMPRESSED AIR

- 4.5.21. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5. OPERATION

- 5.1. MACHINE VIEW ILLUSTRATIONS

- 5.1.1. OVERALL MACHINE VIEW

- 5.1.2. CONTROLS AND GAUGES

- 5.2. DETAILED CONTROLS AND GAUGES

- 5.2.1. MONITORING SYSTEM

- 5.2.2. SWITCHES

- 5.2.3. CONTROL LEVERS AND PEDALS

- 5.2.4. COVER WITH LOCK

- 5.2.5. ENGINE REAR COVER

- 5.2.6. COOLING COVER

- 5.2.7. BATTERY COVER

- 5.2.8. METHOD OF OPENING (TILTING) FLOOR

- 5.2.9. FUSE

- 5.2.10. BLOCK FUSE

- 5.2.11. OPERATION MANUAL STORAGE

- 5.2.12. TOOL BOX

- 5.3. MACHINE OPERATIONS AND CONTROLS

- 5.3.1. BEFORE STARTING ENGINE

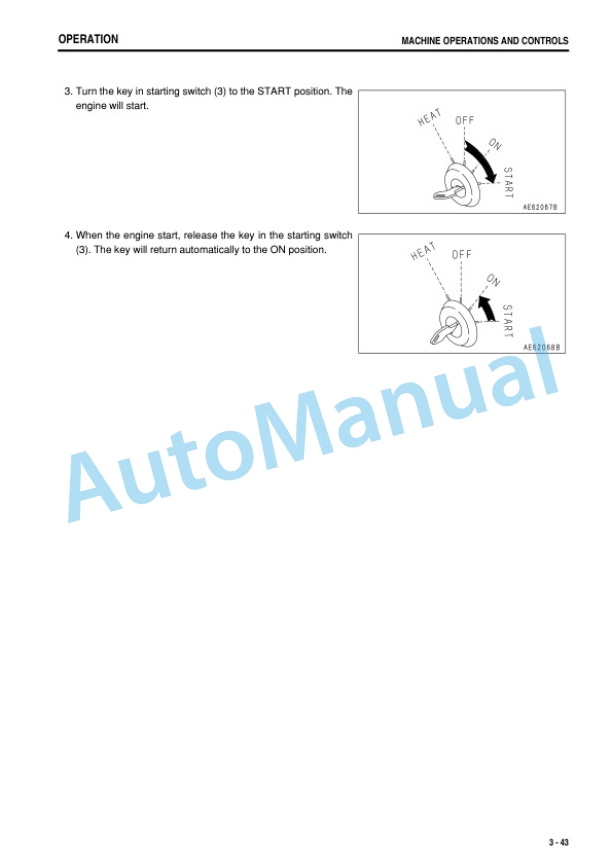

- 5.3.2. STARTING ENGINE

- 5.3.3. AFTER STARTING ENGINE

- 5.3.4. STOPPING THE ENGINE

- 5.3.5. MACHINE OPERATION

- 5.3.6. STEERING THE MACHINE

- 5.3.7. SWINGING

- 5.3.8. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 5.3.9. PROHIBITED OPERATIONS

- 5.3.10. GENERAL OPERATION INFORMATION

- 5.3.11. TRAVELING ON SLOPES

- 5.3.12. ESCAPE FROM MUD

- 5.3.13. WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR

- 5.3.14. BUCKET REPLACEMENT

- 5.3.15. PARKING MACHINE

- 5.3.16. MACHINE INSPECTION AFTER DAILY WORK

- 5.3.17. LOCKING

- 5.3.18. RUBBER SHOES (MACHINE WITH RUBBER SHOES ONLY)

- 5.4. TRANSPORTATION

- 5.4.1. TRANSPORTATION PROCEDURE

- 5.4.2. LOADING AND UNLOADING WITH TRAILER

- 5.4.3. LIFTING MACHINE

- 5.5. COLD WEATHER OPERATION

- 5.5.1. COLD WEATHER OPERATION INFORMATION

- 5.5.2. AFTER DAILY WORK COMPLETION

- 5.5.3. AFTER COLD WEATHER SEASON

- 5.6. LONG TERM STORAGE

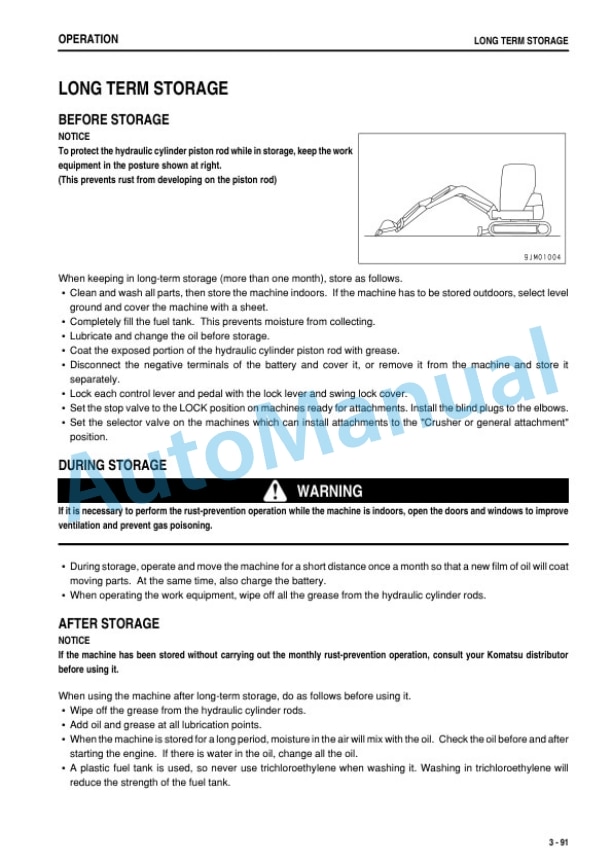

- 5.6.1. BEFORE STORAGE

- 5.6.2. DURING STORAGE

- 5.6.3. AFTER STORAGE

- 5.7. TROUBLES AND ACTIONS

- 5.7.1. RUNNING OUT OF FUEL

- 5.7.2. PHENOMENA THAT ARE NOT FAILURES

- 5.7.3. TOWING THE MACHINE

- 5.7.4. SEVERE JOB CONDITION

- 5.7.5. DISCHARGED BATTERY

- 5.7.6. OTHER TROUBLE

- 6. MAINTENANCE

- 6.1. MAINTENANCE INFORMATION

- 6.2. OUTLINE OF SERVICE

- 6.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 6.2.2. ELECTRIC SYSTEM MAINTENANCE

- 6.2.3. HANDLING HYDRAULIC SYSTEM

- 6.3. WEAR PARTS

- 6.3.1. WEAR PARTS LIST

- 6.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 6.4.1. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 6.5. TIGHTENING TORQUE SPECIFICATIONS

- 6.5.1. TIGHTENING TORQUE LIST

- 6.6. SAFETY CRITICAL PARTS

- 6.6.1. SAFETY CRITICAL PARTS LIST

- 6.7. MAINTENANCE SCHEDULE

- 6.7.1. MAINTENANCE SCHEDULE CHART

- 6.7.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

- 6.8. MAINTENANCE PROCEDURE

- 6.8.1. WHEN REQUIRED

- 6.8.2. CHECK BEFORE STARTING

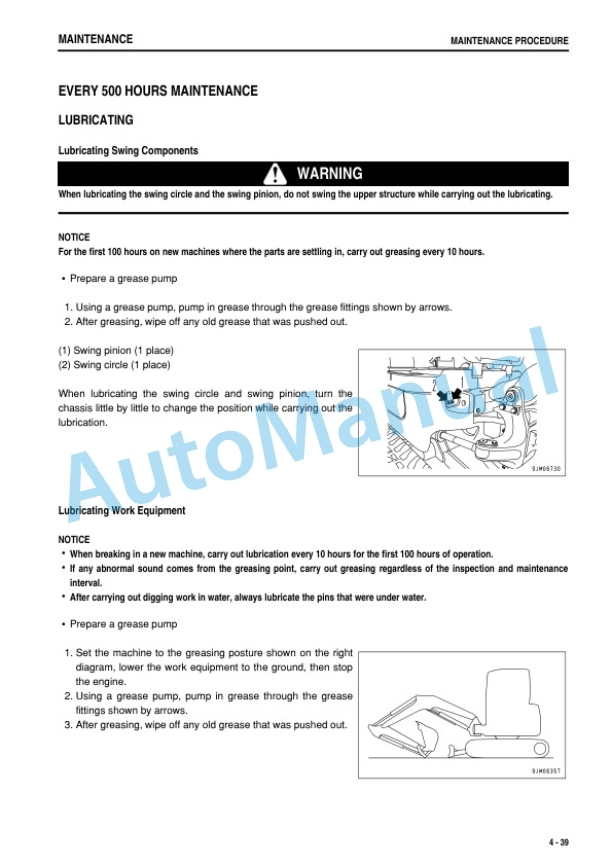

- 6.8.3. EVERY 500 HOURS MAINTENANCE

- 6.8.4. EVERY 1000 HOURS MAINTENANCE

- 6.8.5. EVERY 2000 HOURS MAINTENANCE

- 7. SPECIFICATIONS

- 7.1. SPECIFICATIONS

- 8. ATTACHMENTS, OPTIONS

- 8.1. ATTACHMENTS AND OPTIONS GENERAL INFORMATION

- 8.1.1. SAFETY FIRST

- 8.1.2. ATTACHMENT INSTALLATION

- 8.2. BUCKET WITH HOOK

- 8.2.1. PROHIBITED OPERATIONS

- 8.3. MACHINE READY FOR ATTACHMENT

- 8.3.1. LOCATIONS

- 8.3.2. HYDRAULIC CIRCUIT

- 8.3.3. ATTACHMENT OPERATIONS

- 8.3.4. LONG TERM STORAGE

- 8.3.5. SPECIFICATIONS

- 8.4. CHANGING MACHINE CONTROL PATTERN (IF PATTERN CHANGE VALVE EQUIPPED)

- 8.4.1. CONTROL PATTERN CHANGE PROCEDURE

- 8.4.2. MACHINE CONTROL PATTERNS

- 8.5. ATTACHMENT GUIDE

- 8.5.1. ATTACHMENT COMBINATIONS

- 8.6. HANDLING ARM WITH BUILTIN BREAKER

- 8.6.1. REMOVING AND INSTALLING CHISEL

- 8.6.2. PROCEDURE FOR BREAKER OPERATIONS

- 8.6.3. PRECAUTIONS WHEN CARRYING OUT BREAKER OPERATIONS

- 8.6.4. INSTALLATION OF BUCKET

- 8.6.5. PRECAUTIONS WHEN CARRYING OUT BUCKET OPERATIONS

- 8.6.6. STOWING CHISEL, DUMMY CHISEL

- 8.6.7. CHECK BEFORE STARTING

- 8.6.8. REPLACEMENT INTERVAL OF CONSUMABLE PARTS

- 8.6.9. SPECIFICATIONS

- 8.7. RECOMMENDED ATTACHMENT OPERATIONS

- 8.7.1. HYDRAULIC BREAKER

- 9. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1