Komatsu PC18MR-2 Hydraulic Excavator Shop Manual SEBM038404

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM038404

- Format: PDF

- Size: 16.5MB

- Number of Pages: 391

Category: Komatsu Shop Manual PDF

-

Model List:

- PC18MR-2 Hydraulic Excavator

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DIMENSION DRAWING

- 3.2. WORKING RANGE DRAWING

- 3.3. SPECIFICATIONS

- 3.4. WEIGHT TABLE

- 3.5. LUBRICANTS,FUEL AND COOLANT SPECIFICATIONS

- 4. STRUCTURE,FUNCTION AND MAINTENANCE STANDARD

- 4.1. HYDRAULIC COMPONENTS LAYOUT DRAWING

- 4.2. HYDRAULIC TANK

- 4.3. CENTER SWIVEL JOINT

- 4.4. TRAVEL MOTOR

- 4.5. HYDRAULIC CYLINDER

- 4.6. SOLENOID VALVE

- 4.7. VARIABLE GAUGE VALVE

- 4.8. MULTICONTROL VALVE

- 4.9. HYDRAULIC PUMP

- 4.10. CONTROL VALVE

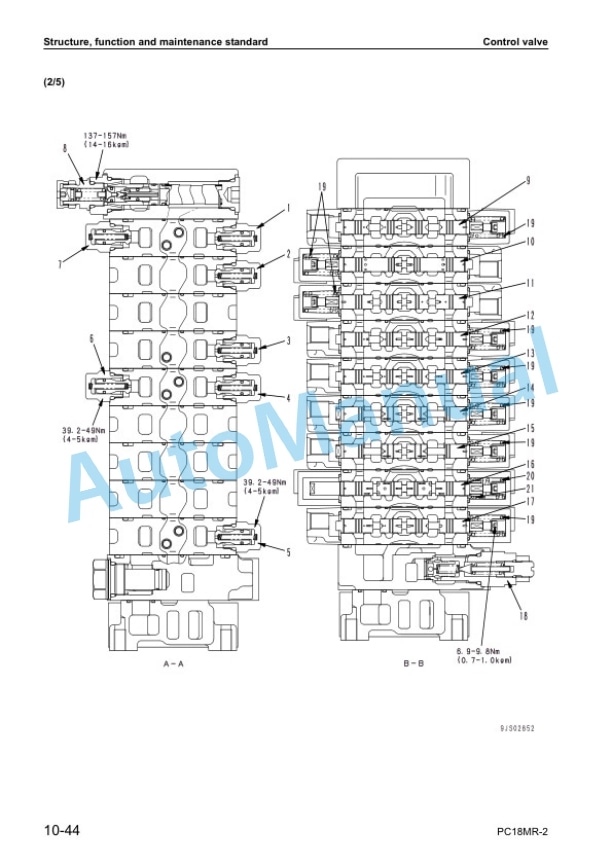

- 4.11. CLSS

- 4.12. OPERATION FOR EACH FUNCTION AND VALVE

- 4.13. SWING MOTOR

- 4.14. PPC VALVE

- 4.15. WORK EQUIPMENT

- 4.16. DIMENSIONS OF EACH PART OF WORK EQUIPMENT

- 4.17. FLOOR

- 4.18. ENGINE CONTROL

- 4.19. ELECTRIC CONTROL SYSTEM

- 4.20. COMPONENT PARTS OF SYSTEM

- 4.21. MONITOR SYSTEM

- 4.22. MONITOR PANEL

- 4.23. SENSORS

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGING RELATED PARTS

- 5.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 5.3. TESTING AND ADJUSTING

- 5.3.1. LIST OF TESTING, ADJUSTING,AND TROUBLESHOOTING TOOLS

- 5.3.2. MEASURING ENGINE SPEED

- 5.3.3. MEASURING OF EXHAUST GAS COLOR

- 5.3.4. ADJUSTING VALVE CLEARANCE

- 5.3.5. TESTING COMPRESSION PRESSURE

- 5.3.6. TESTING ENGINE OIL PRESSURE

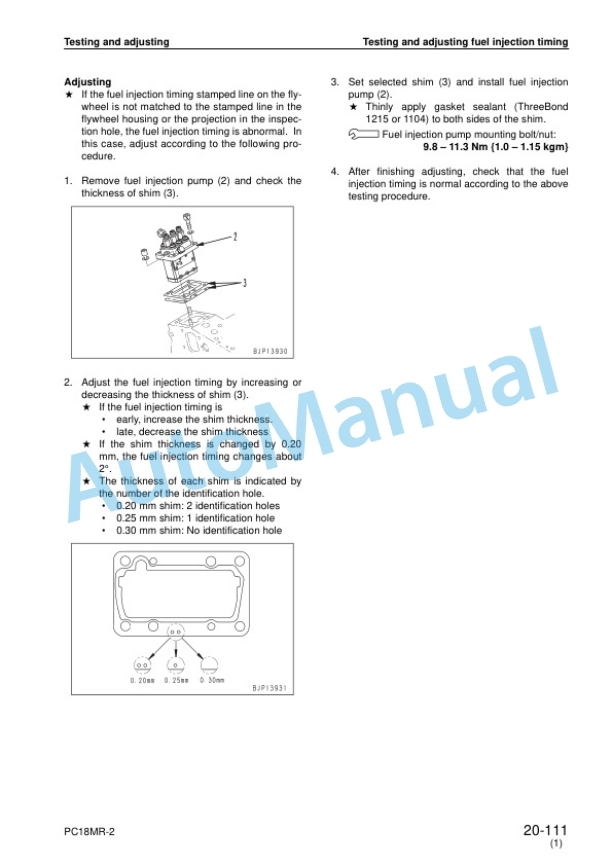

- 5.3.7. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.3.8. ADJUSTING ENGINE STOP SOLENOID

- 5.3.9. BLEEDING AIR FROM FUEL CIRCUIT

- 5.3.10. TESTING AND ADJUSTING FAN BELT TENSION

- 5.3.11. ADJUSTING FUEL CONTROL LEVER LINKAGE

- 5.3.12. MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

- 5.3.13. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.3.14. TESTING AND ADJUSTING OIL PRESSURES IN WORK EQUIPMENT,TRAVEL,SWING,AND BLADE CIRCUITS

- 5.3.15. TESTING AND ADJUSTING CONTROL CIRCUIT BASIC PRESSURE

- 5.3.16. TESTING AND ADJUSTING PUMP LS DIFFERENTIAL PRESSURE

- 5.3.17. MEASURING SOLENOID VALVE OUTPUT PRESSURE

- 5.3.18. MEASURING PPC VALVE OUTPUT PRESSURE

- 5.3.19. ADJUSTING PLAY OF WORK EQUIPMENT AND SWING PPC VALVES

- 5.3.20. MEASURING SWING HOLDING BRAKE RELEASE PRESSURE

- 5.3.21. TESTING OIL LEAKAGE FORM CYLINDER

- 5.3.22. RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

- 5.3.23. BLEEDING AIR FROM CYLINDER

- 5.3.24. PRESSURIZING HYDRAULIC TANK

- 5.3.25. HOW TO OPEN AND CLOSE(TILT) FLOOR

- 5.3.26. INSPECTION PROCEDURES FOR DIODE

- 5.4. TROUBLESHOOTING

- 5.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.4.4. CHECKS BEFORE TROUBLESHOOTING

- 5.4.5. CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING

- 5.4.6. CONNECTORS LIST AND CONNECTORS ARRANGEMENT STEREOGRAM

- 5.4.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.4.8. TADAPTERBOXES AND TADAPTER TABLE

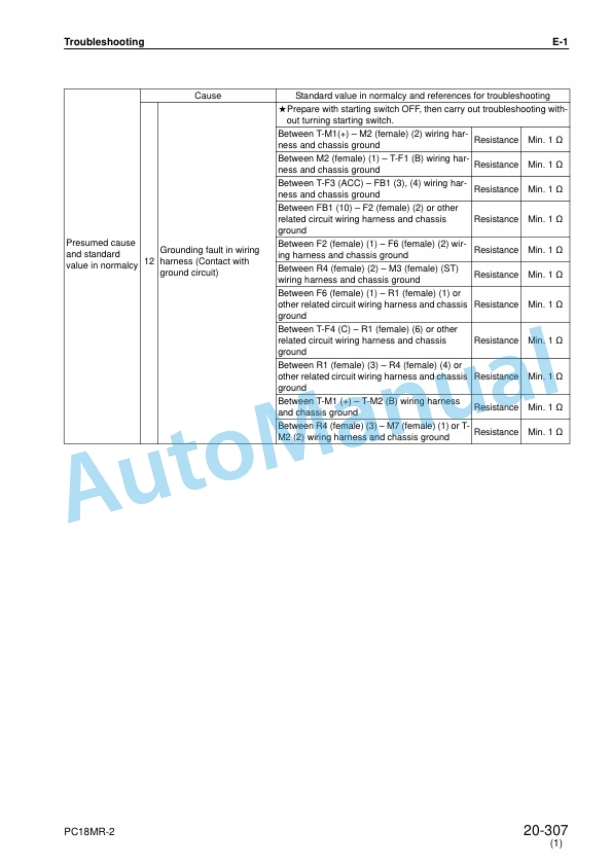

- 5.4.9. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 5.4.9.1. BEFORE CARRYING OUT TROUBLESHOOTING FOR ELECTRICAL SYSTEM(E MODE)

- 5.4.9.2. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 5.4.9.3. E1 ENGINE DOES NOT START

- 5.4.9.4. E2 ENGINE DOES NOT STOP

- 5.4.9.5. E3 ENGINE OIL PRESSURE MONITOR DOES NOT INDICATE NORMALLY

- 5.4.9.6. E4 CHARGE LEVEL MONITOR DOES NOT INDICATE NORMALLY

- 5.4.9.7. E5 FUEL LEVEL GAUGE DOES NOT INDICATE NORMALLY

- 5.4.9.8. E6 SERVICE METER DOES NOT OPERATE NORMALLY

- 5.4.9.9. E7 PREHEATING SYSTEM DOES NOT OPERATE NORMALLY

- 5.4.9.10. E8 TRAVEL SPEED SHIFTING SYSTEM DOES NOT OPERATE NORMALLY

- 5.4.9.11. E9 ENGINE COOLANT TEMPERATURE MONITOR DOES NOT INDICATE NORMALLY

- 5.4.9.12. E10 LOCK LEVER DOES NOT OPERATE NORMALLY

- 5.4.9.13. E11 BLADE/VARIABLE GAUGE SELECTOR SYSTEM DOES NOT OPERATE NORMALLY

- 5.4.9.14. E12 NIGHT LAMP OF MACHINE MONITOR AND WORKING LAMP DO NOT LIGHT UP

- 5.4.9.15. E13 TRAVEL ALARM DOES NOT SOUND OR DOES NOT SOUNDING

- 5.4.10. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 5.4.10.1. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 5.4.10.2. H1 SPEED OR POWER OF WHOLE WORK EQUIPMENT,TRAVEL,SWING,AND BLADE IS LOW

- 5.4.10.3. H2 ENGINE SPEED LOWERS EXTREMELY OR ENGINE STALLS

- 5.4.10.4. H3 WHOLE WORK EQUIPMENT,TRAVEL SYSTEM,SWING SYSTEM,AND BLADE DO NOT MOVE

- 5.4.10.5. H4 ABNORMAL SOUND COMES OUT FROM AROUND HYDRAULIC PUMP

- 5.4.10.6. H5 FINE CONTROL PERFORMANCE OR RESPONSE IS LOW

- 5.4.10.7. H6 SPEED OR POWER OF BOOM IS LOW

- 5.4.10.8. H7 SPEED OR POWER OF ARM IS LOW

- 5.4.10.9. H8 SPEED OR POWER OF BUCKET IS LOW

- 5.4.10.10. H9 SPEED OR POWER OF BOOM SWING IS LOW

- 5.4.10.11. H10 WORK EQUIPMENT DOES NOT MOVE SINGLY

- 5.4.10.12. H11 WORK EQUIPMENT HYDRAULIC DRIFT IS LARGE

- 5.4.10.13. H12 TIME LAG OF WORK EQUIPMENT IS LARGE

- 5.4.10.14. H13 IN COMPOUND OPERATION OF WORK EQUIPMENT,SPEED OF PART LOADED MORE IS LOW

- 5.4.10.15. H14 MACHINE DEVIATES DURING TRAVEL

- 5.4.10.16. H15 TRAVEL SPEED OR TRAVEL POWER IS LOW

- 5.4.10.17. H16 MACHINE IS NOT STEERED WELL OR STEERING POWER IS LOW

- 5.4.10.18. H17 TRAVEL SPEED DOES NOT CHANGE

- 5.4.10.19. H18 TRAVEL MOTOR DOES NOT WORK(ONE SIDE ONLY)

- 5.4.10.20. H19 SPEED OR POWER OF SWING IS LOW

- 5.4.10.21. H20 MACHINE DOES NOT SWING

- 5.4.10.22. H21 SWING ACCELERATION PERFORMANCE IS LOW

- 5.4.10.23. H22 MACHINE OVERRUNS WHEN IT STOPS SWINGING

- 5.4.10.24. H23 LARGE SHOCK IS MADE WHEN MACHINE STOPS SWINGING

- 5.4.10.25. H24 WHEN UPPER STRUCTURE STOPS SWINGING,IT MAKES LARGE SOUND

- 5.4.10.26. H25 HYDRAULIC DRIFT OF SWING IS LARGE

- 5.4.10.27. H26 SPEED OR POWER OF BLADE IS LOW

- 5.4.10.28. H27 BLADE DOES NOT MOVE

- 5.4.10.29. H28 HYDRAULIC DRIFT OF BLADE IS LARGE

- 5.4.10.30. H29 VARIABLE GAUGE DOES NOT MOVE

- 5.4.10.31. H30 TROUBLESHOOTING FOR HYDRAULIC BREAKER

- 5.4.11. TROUBLESHOOTING OF ENGINE(S MODE)

- 5.4.11.1. TROUBLESHOOTING CHART

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. HOW TO READ THIS MANUAL

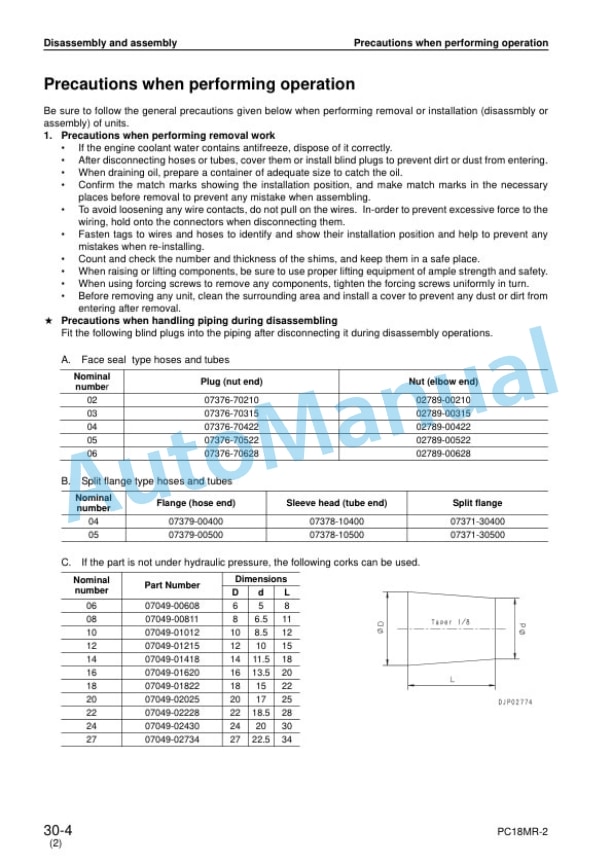

- 6.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCH OF SPECIAL TOOLS

- 6.5. REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

- 6.6. REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY

- 6.7. REMOVAL AND INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY

- 6.8. REMOVAL AND INSTALLATION OF ENGINE AND HYDRAULIC PUMP ASSEMBLY

- 6.9. REMOVAL AND INSTALLATION OF TRACK SHOE ASSEMBLY

- 6.10. DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY

- 6.11. DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING

- 6.12. DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 6.13. ASSEMBLY OF TRAVEL MOTOR ASSEMBLY

- 6.14. REMOVAL AND INSTALLATION OF FLOOR FRAME ASSEMBLY

- 6.15. REMOVAL AND INSTALLATION OF REVOLVING FRAME

- 6.16. REMOVAL AND INSTALLATION OF SWING CIRCLE ASSEMBLY

- 6.17. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC PUMP ASSEMBLY

- 6.18. DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY

- 6.19. REMOVAL AND INSTALLATION OF HYDRAULIC SYSTEM AND CENTER SWIVEL JOINT ASSEMBLY

- 6.20. DISASSEMBLY AND ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY

- 6.21. REMOVAL AND INSTALLATION OF SWING MOTOR ASSEMBLY

- 6.22. DISASSEMBLY AND ASSEMBLY OF SWING MOTOR ASSEMBLY

- 6.23. REMOVAL AND INSTALLATION OF WORK EQUIPMENT ASSEMBLY

- 6.24. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 6.25. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC BREAKER ASSEMBLY

- 7. OTHERS

- 7.1. HYDRAULIC CIRCUIT DIAGRAM

- 7.2. ELECTRICAL CIRCUIT DIAGRAM

Rate this product

You may also like