Komatsu PC18MR-5 Compact Hydraulic Excavator Operation and Maintenance Manual PEN01296-05

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: PEN01296-05

- Format: PDF

- Size: 8.5MB

- Number of Pages: 295

-

Model List:

- PC18MR-5 Compact Hydraulic Excavator

- 1. COVER

- 2. FOREWORD

- 2.1. CONTENTS

- 2.2. FOREWORD

- 2.3. SAFETY INFORMATION

- 2.4. INTRODUCTION

- 2.5. MACHINE INFORMATION

- 2.5.1. LOCATION OF PRODUCT IDENTIFICATION NUMBER (PIN) AND MACHINE SERIAL NO. PLATE

- 2.5.2. LOCATION OF ENGINE NUMBER

- 2.5.3. SERVICE METER LOCATION

- 2.5.4. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 2.6. ABBREVIATION LIST

- 3. SAFETY

- 3.1. SAFETY LABELS

- 3.2. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 3.2.1. PRECAUTIONS BEFORE STARTING OPERATION

- 3.2.2. PREPARATIONS FOR SAFE OPERATION

- 3.2.3. ACTIONS IF FIRE OCCURS

- 3.2.4. PRECAUTIONS TO PREVENT FIRE

- 3.2.5. PRECAUTIONS WHEN YOU GET ON OR OFF MACHINE

- 3.2.6. PRECAUTIONS FOR MACHINE AND JOBSITE

- 3.3. PRECAUTIONS FOR OPERATION

- 3.3.1. PRECAUTIONS FOR JOBSITE

- 3.3.2. START ENGINE

- 3.3.3. PRECAUTIONS FOR OPERATION

- 3.3.4. PRECAUTIONS FOR TRANSPORTATION

- 3.3.5. TOWING AND BEING TOWED

- 3.3.6. LIFTING OPERATION BY BUCKET WITH HOOK

- 3.4. PRECAUTIONS FOR MAINTENANCE

- 3.4.1. PRECAUTIONS BEFORE YOU START INSPECTION AND MAINTENANCE

- 3.4.2. PRECAUTIONS FOR CHECK AND MAINTENANCE

- 4. OPERATION

- 4.1. GENERAL VIEW

- 4.1.1. MACHINE EQUIPMENT NAME

- 4.1.2. CONTROLS AND GAUGES NAMES

- 4.1.3. MACHINE MONITOR EQUIPMENT NAME

- 4.1.4. NAMES OF OTHER EQUIPMENT

- 4.2. EXPLANATION OF COMPONENTS

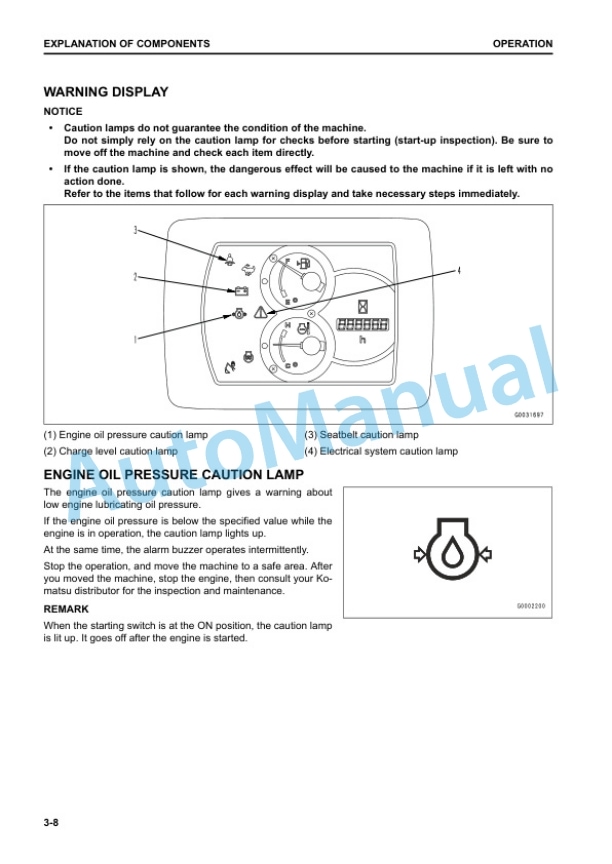

- 4.2.1. MACHINE MONITOR EQUIPMENT

- 4.2.2. NAMES OF SWITCH PANEL EQUIPMENT

- 4.2.3. NAMES OF CONTROL LEVERS AND PEDALS

- 4.2.4. OTHER EQUIPMENT

- 4.2.5. KOMTRAX

- 4.3. MACHINE OPERATIONS AND CONTROLS

- 4.3.1. CHECKS AND ADJUSTMENT BEFORE YOU START ENGINE

- 4.3.2. START ENGINE

- 4.3.3. OPERATIONS AND CHECKS AFTER YOU START ENGINE

- 4.3.4. STOP ENGINE

- 4.3.5. START MACHINE (TRAVEL FORWARD AND REVERSE) AND STOP MACHINE

- 4.3.6. STEER MACHINE

- 4.3.7. SWING MACHINE

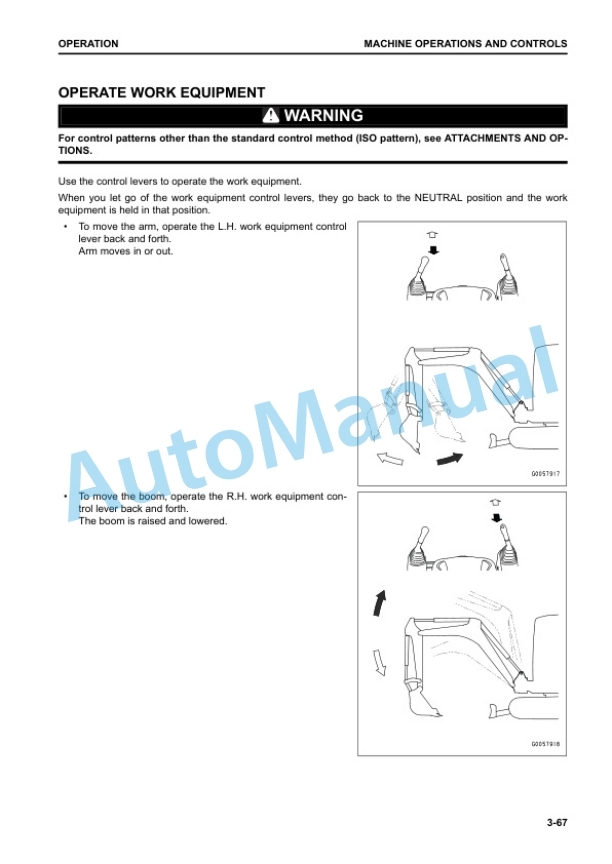

- 4.3.8. OPERATE WORK EQUIPMENT

- 4.3.9. OPERATE VARIABLE GAUGE

- 4.3.10. PROHIBITED OPERATIONS

- 4.3.11. WORK PRECAUTIONS

- 4.3.12. PRECAUTIONS WHEN YOU WORK ON SLOPE

- 4.3.13. ESCAPE FROM SOFT GROUND

- 4.3.14. RECOMMENDED APPLICATIONS

- 4.3.15. REPLACE BUCKET

- 4.3.16. PARK MACHINE

- 4.3.17. CHECK AFTER YOU FINISH WORK

- 4.3.18. LOCK

- 4.4. HANDLE RUBBER SHOES

- 4.4.1. RUBBER SHOES

- 4.5. TRANSPORTATION

- 4.5.1. LOAD AND UNLOAD A TRAILER

- 4.5.2. LIFT MACHINE

- 4.6. COLD WEATHER OPERATION

- 4.6.1. COLD WEATHER INFORMATION

- 4.6.2. FUEL AND LUBRICANTS

- 4.6.3. COOLANT

- 4.6.4. BATTERY

- 4.6.5. PRECAUTIONS AFTER DAILY WORK COMPLETION IN COLD WEATHER

- 4.6.6. AFTER COLD WEATHER SEASON

- 4.7. LONGTERM STORAGE PRECAUTIONS

- 4.7.1. PREPARATION FOR LONGTERM STORAGE

- 4.7.2. MAINTENANCE DURING LONGTERM STORAGE

- 4.7.3. START MACHINE AFTER LONGTERM STORAGE

- 4.8. TROUBLES AND ACTIONS

- 4.8.1. ACTIONS WHEN YOU RUN OUT OF FUEL

- 4.8.2. PHENOMENA THAT ARE NOT FAILURES

- 4.8.3. PRECAUTIONS FOR TOWING MACHINE

- 4.8.4. PRECAUTIONS FOR SEVERE JOB CONDITION

- 4.8.5. ACTIONS WHEN BATTERY IS DISCHARGED

- 4.8.6. OTHER TROUBLE

- 5. MAINTENANCE

- 5.1. PRECAUTIONS FOR MAINTENANCE

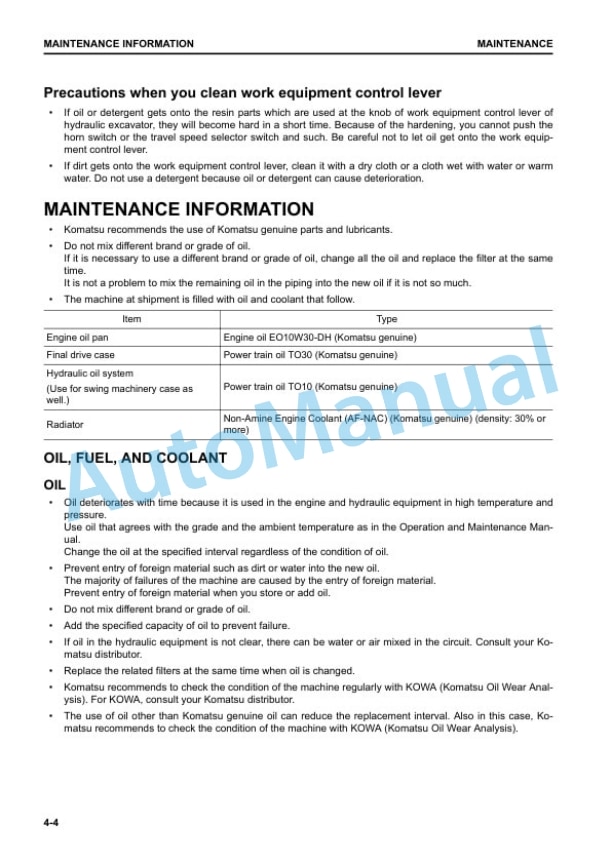

- 5.2. MAINTENANCE INFORMATION

- 5.2.1. OIL, FUEL, AND COOLANT

- 5.2.2. ELECTRICAL COMPONENTS

- 5.2.3. HYDRAULIC COMPONENTS

- 5.2.4. STANDARD TORQUE

- 5.3. MAINTENANCE SCHEDULE

- 5.3.1. MAINTENANCE INTERVAL TABLE

- 5.3.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

- 5.4. MAINTENANCE PROCEDURE

- 5.4.1. INITIAL 10 HOURS MAINTENANCE

- 5.4.2. WHEN REQUIRED

- 5.4.3. CHECK BEFORE YOU START OPERATION

- 5.4.4. EVERY 100 HOURS MAINTENANCE

- 5.4.5. EVERY 500 HOURS MAINTENANCE

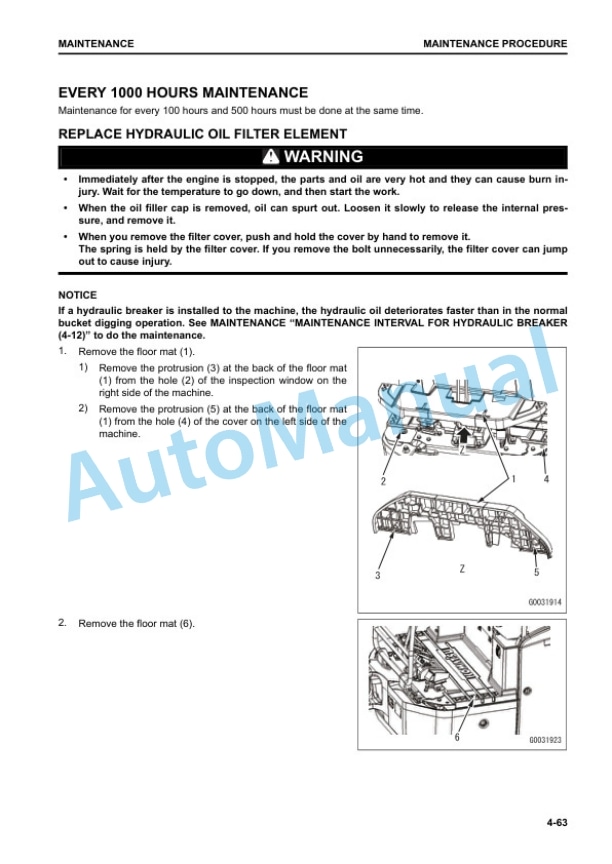

- 5.4.6. EVERY 1000 HOURS MAINTENANCE

- 5.4.7. EVERY 1500 HOURS MAINTENANCE

- 5.4.8. EVERY 2000 HOURS MAINTENANCE

- 5.4.9. EVERY 4000 HOURS MAINTENANCE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 7. ATTACHMENTS AND OPTIONS

- 7.1. PRECAUTIONS TO USE ATTACHMENTS AND OPTIONS SAFELY

- 7.2. HANDLE BUCKET WITH HOOK

- 7.2.1. WORK PRECAUTIONS

- 7.3. HANDLE MACHINE READY FOR INSTALLATION OF ATTACHMENT

- 7.3.1. EXPLANATION OF COMPONENTS ON MACHINES WITH ATTACHMENT

- 7.3.2. CONNECT HYDRAULIC CIRCUIT OF MACHINES READY FOR INSTALLATION OF ATTACHMENT

- 7.3.3. CHANGE OVER HYDRAULIC CIRCUIT OF MACHINES WITH ATTACHMENT

- 7.3.4. OPERATE ATTACHMENT

- 7.3.5. LONGTERM STORAGE

- 7.3.6. SPECIFICATIONS

- 7.4. BATTERY DISCONNECT SWITCH

- 7.4.1. SYSTEM OPERATING LAMP

- 7.5. CONTROL PATTERNS OTHER THAN STANDARD CONTROL PATTERN

- 7.5.1. CHANGE CONTROL PATTERN

- 7.6. ATTACHMENTS AND OPTIONS

- 7.6.1. INSTALL ATTACHMENT

- 7.7. RECOMMENDED ATTACHMENT OPERATIONS

- 7.7.1. HYDRAULIC BREAKER

- 7.7.2. BREAKERS

- 8. REPLACEMENT PARTS

- 8.1. DEFINED LIFE PARTS

- 8.1.1. DEFINED LIFE PARTS LIST

- 8.2. CONSUMABLE PARTS

- 8.2.1. CONSUMABLE PARTS LIST

- 8.3. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 8.3.1. LUBRICATION CHART

- 8.3.2. USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 8.3.3. RECOMMENDED BRANDS AND QUALITIES OTHER THAN KOMATSU GENUINE OILS

- 9. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702