Komatsu PC200LL-6, PC220LL-6 Hydraulic Excavator Operation and Maintenance Manual CEAM008401

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM008401

- Format: PDF

- Size: 2.8MB

- Number of Pages: 218

-

Model List:

- PC200LL-6 Hydraulic Excavator

- PC220LL-6 Hydraulic Excavator

- 1. INTRODUCTION

- 1.1. FOREWORD

- 1.2. SAFETY INFORMATION

- 1.3. INTRODUCTION

- 1.3.1. INTENDED USE

- 1.3.2. FEATURES

- 1.3.3. BREAKING IN THE MACHINE

- 1.4. LOCATION OF PLATES, TABLE TO ENTER P.I.N. AND DISTRIBUTOR

- 1.4.1. PLATE LOCATION

- 1.4.2. ENGINE SERIAL NO. PLATE LOCATION

- 1.4.3. TABLE TO ENTER NUMBERS AND DISTRIBUTOR

- 1.5. TABLE OF CONTENTS

- 2. SAFETY

- 2.1. WARNING LABELS

- 2.2. GENERAL PRECAUTIONS

- 2.2.1. SAFETY RULES

- 2.2.2. SAFETY FEATURES

- 2.2.3. UNAUTHORIZED MODIFICATION

- 2.2.4. INSIDE OPERATORS COMPARTMENT

- 2.2.5. CLOTHING AND PERSONAL PROTECTIVE ITEMS

- 2.2.6. ALWAYS APPLY LOCK WHEN LEAVING OPERATORS SEAT

- 2.2.7. MOUNTING AND DISMOUNTING

- 2.2.8. INJURY FROM WORK EQUIPMENT

- 2.2.9. FIRE PREVENTION FOR FUEL AND OIL

- 2.2.10. PRECAUTIONS AT HIGH TEMPERATURES

- 2.2.11. ASBESTOS DUST HAZARD PREVENTION

- 2.2.12. FIRE EXTINGUISHER AND FIRST AID KIT

- 2.2.13. CAB GLASS

- 2.2.14. WINDOW WASHER FLUID

- 2.2.15. ESCAPE FROM FIRE

- 2.2.16. PROTECTION AGAINST FALLING OR FLYING OBJECTS

- 2.2.17. MACHINES WITH ACCUMULATOR

- 2.2.18. PRECAUTIONS FOR ATTACHMENTS

- 2.2.19. INDOOR VENTILATION

- 2.2.20. EMERGENCY EXIT FROM OPERATORS CAB

- 2.3. PRECAUTIONS DURING OPERATION

- 2.3.1. BEFORE STARTING ENGINE

- 2.3.2. OPERATING MACHINE

- 2.3.3. TRANSPORTATION

- 2.3.4. BATTERY

- 2.3.5. TOWING

- 2.4. PRECAUTIONS FOR MAINTENANCE

- 2.4.1. BEFORE CARRYING OUT MAINTENANCE

- 2.4.2. DURING MAINTENANCE

- 3. OPERATION

- 3.1. GENERAL

- 3.1.1. VIEW OF MACHINE

- 3.1.2. GENERAL VIEW OF OPERATORS COMPARTMENT

- 3.1.3. GENERAL VIEW OF MONITOR PANEL

- 3.2. EXPLANATION OF COMPONENTS

- 3.2.1. MACHINE MONITOR

- 3.2.2. SWITCHES

- 3.2.3. CONTROL LEVERS AND PEDALS

- 3.2.4. OPERATORS SEAT AND SEAT BELT

- 3.2.5. MONITOR PANEL

- 3.2.6. DOOR LOCK

- 3.2.7. CAP, COVER WITH LOCK

- 3.2.8. OPERATOR EASE

- 3.2.9. AIR CONDITIONER

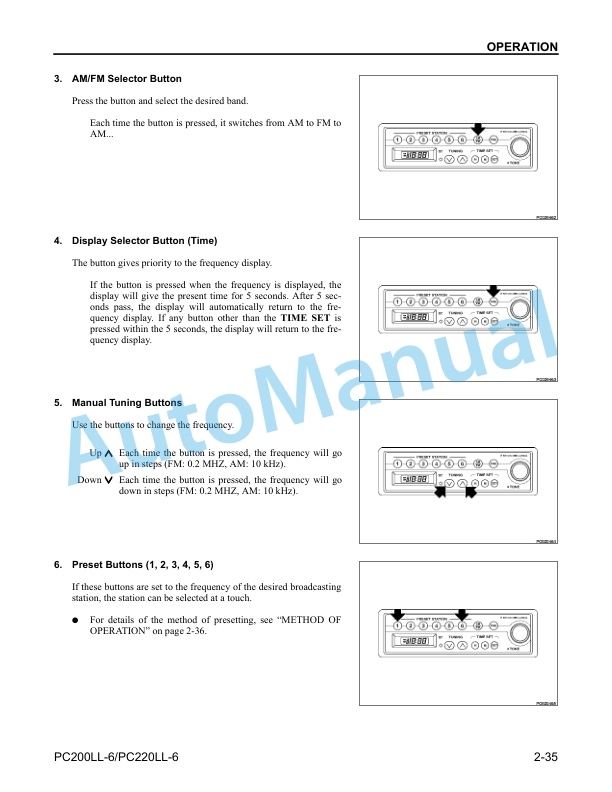

- 3.2.10. AM/FM RADIO

- 3.2.11. FUSE

- 3.2.12. FUSIBLE LINK

- 3.2.13. CONTROLLERS

- 3.2.14. TOOL BOX

- 3.2.15. GREASE GUN HOLDER

- 3.2.16. HANDLING ACCUMULATOR

- 3.3. OPERATION

- 3.3.1. CHECK BEFORE STARTING ENGINE

- 3.3.2. STARTING ENGINE

- 3.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 3.3.4. MOVING MACHINE

- 3.3.5. STEERING MACHINE

- 3.3.6. STOPPING MACHINE

- 3.3.7. SWINGING

- 3.3.8. OPERATION OF WORK EQUIPMENT

- 3.3.9. ACTIVE MODE

- 3.3.10. WORKING MODES

- 3.3.11. PRECAUTIONS FOR OPERATION

- 3.3.12. PRECAUTIONS WHEN TRAVELING ON HILLS

- 3.3.13. HOW TO ESCAPE FROM MUD

- 3.3.14. PARKING MACHINE

- 3.3.15. CHECK AFTER FINISHING WORK

- 3.3.16. STOPPING ENGINE

- 3.3.17. CHECK AFTER STOPPING ENGINE

- 3.3.18. LOCKING

- 3.4. TRANSPORTATION

- 3.4.1. TRANSPORTATION PROCEDURE

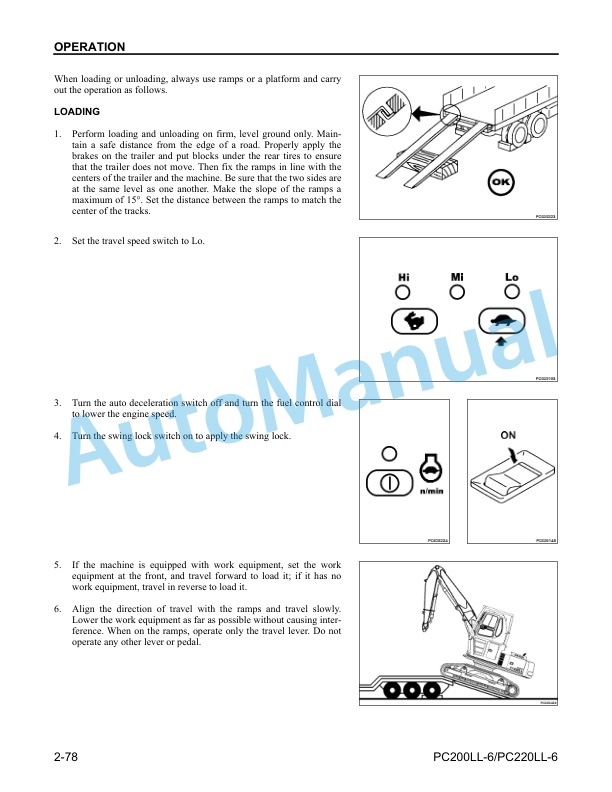

- 3.4.2. LOADING, UNLOADING WORK ON TRAILERS

- 3.5. COLD WEATHER OPERATION

- 3.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 3.5.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 3.5.3. AFTER COLD WEATHER

- 3.6. LONG TERM STORAGE

- 3.6.1. BEFORE STORAGE

- 3.6.2. DURING STORAGE

- 3.6.3. AFTER STORAGE

- 3.6.4. MACHINE START AFTER LONG TERM STORAGE

- 3.7. TROUBLESHOOTING

- 3.7.1. PHENOMENA THAT ARE NOT FAILURES

- 3.7.2. METHOD OF TOWING DISABLED MACHINE

- 3.7.3. USING MACHINE FOR LIGHT WEIGHT TOWING

- 3.7.4. PRECAUTIONS ON PARTICULAR JOB SITES

- 3.7.5. DISCHARGED BATTERY

- 3.7.6. OTHER TROUBLE

- 4. MAINTENANCE

- 4.1. GUIDES TO MAINTENANCE

- 4.2. OUTLINES OF SERVICE

- 4.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 4.2.2. OUTLINE OF HYDRAULIC SYSTEM

- 4.3. WEAR PARTS LIST

- 4.4. USE OF FUEL, COOLANT AND LUBRICANTS

- 4.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 4.4.2. ENGINE OIL SPECIFICATIONS

- 4.4.3. DAMPER CASE, SWING MACHINERY CASE, TRACK FRONT IDLERS, TRACK ROLLERS, TOP CARRIER ROLLERS AND HYD…

- 4.4.4. FINAL DRIVE OIL SPECIFICATIONS

- 4.5. STANDARD TIGHTENING TORQUES

- 4.5.1. INTRODUCTION OF NECESSARY TOOLS

- 4.5.2. BOLT IDENTIFICATION CHART

- 4.6. PERIODIC REPLACEMENT OF CRITICAL PARTS

- 4.7. MAINTENANCE SCHEDULE CHART

- 4.8. SERVICE PROCEDURE

- 4.8.1. INITIAL 250 HOURS SERVICE

- 4.8.2. WHEN REQUIRED

- 4.8.3. CHECK BEFORE STARTING

- 4.8.4. EVERY 100 HOURS SERVICE

- 4.8.5. EVERY 250 HOURS SERVICE

- 4.8.6. EVERY 500 HOURS SERVICE

- 4.8.7. EVERY 1000 HOURS SERVICE

- 4.8.8. EVERY 2000 HOURS SERVICE

- 4.8.9. EVERY 4000 HOURS SERVICE

- 4.8.10. EVERY 5000 HOURS SERVICE

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS AND DIMENSIONS

- 5.1.1. SPECIFICATIONS

- 5.1.2. DIMENSIONS

- 6. OPTIONS, ATTACHMENTS

- 6.1. GENERAL PRECAUTIONS

- 6.1.1. PRECAUTIONS RELATED TO SAFETY

- 6.1.2. SELECTION OF TRACK SHOES

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001