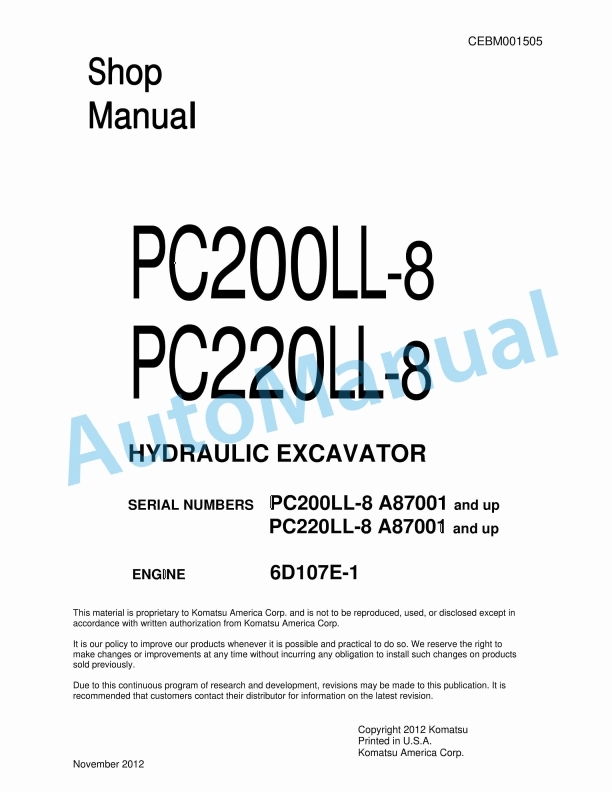

Komatsu PC200LL-8, PC220LL-8 Hydraulic Excavator Shop Manual CEBM001505

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM001505

- Format: PDF

- Size: 187.7MB

- Number of Pages: 1316

Category: Komatsu Shop Manual PDF

-

Model List:

- PC200LL-8 Hydraulic Excavator

- PC220LL-8 Hydraulic Excavator

- 1. COVER PC200LL/220LL8

- 1.1. CONTENTS

- 1.2. FOREWORD

- 1.2.1. SAFETY

- 1.2.2. GENERAL

- 1.2.3. HOW TO READ THE SHOP MANUAL

- 1.2.4. HOISTING INSTRUCTIONS

- 1.2.5. HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENTS

- 1.2.6. PUSH PULL COUPLER

- 1.2.7. EXPLANATION OF MAINTENANCE STANDARD TERMS

- 1.2.8. STANDARD TIGHTENING TORQUE

- 1.2.9. ELECTRIC WIRE CODE

- 1.2.10. CONVERSION TABLES

- 1.2.11. COATING MATERIALS

- 1.3. GENERAL

- 1.3.1. SPECIFICATIONS

- 1.3.2. WEIGHT TABLE

- 1.3.3. FUEL, COOLANT, AND LUBRICANTS

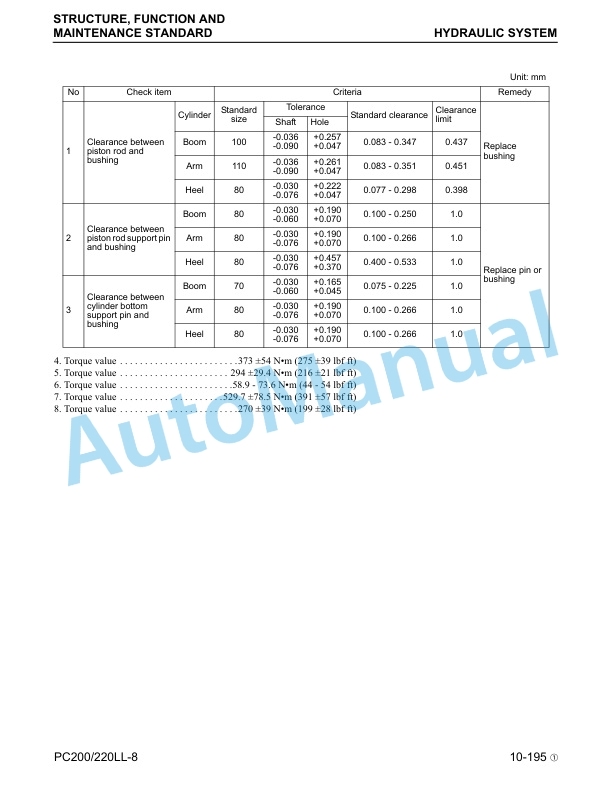

- 1.4. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 1.4.1. ENGINE AND COOLING SYSTEM

- 1.4.2. SWING MACHINERY

- 1.4.3. UNDERCARRIAGE AND FRAME

- 1.4.4. TRACK AND CARRIER ROLLER

- 1.4.5. TRACK SHOES

- 1.4.6. HYDRAULIC SYSTEM

- 1.4.7. WORK EQUIPMENT

- 1.4.8. CAB AND ITS ATTACHMENTS

- 1.4.9. ELECTRICAL SYSTEM

- 1.4.10. ELECTRICAL CONTROL SYSTEM

- 1.4.11. MONITOR SYSTEM

- 1.4.12. SENSORS

- 1.4.13. KOMTRAX TERMINAL SYSTEM

- 1.5. STANDARD VALUE TABLES

- 1.5.1. STANDARD SERVICE VALUE TABLE

- 1.5.2. MACHINE POSTURE

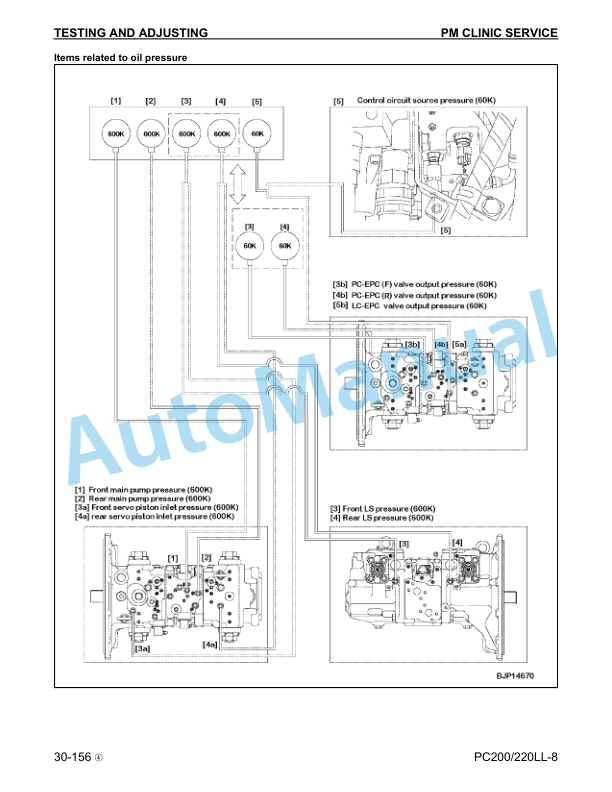

- 1.6. TESTING AND ADJUSTING

- 1.6.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 1.6.2. ENGINE COMPONENTS

- 1.6.3. AIR CONDITIONER COMPRESSOR BELT TENSION

- 1.6.4. FAN BELT

- 1.6.5. SWING CIRCLE BEARING CLEARANCE

- 1.6.6. TRACK CHAIN TENSION

- 1.6.7. OIL PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS

- 1.6.8. CONTROL CIRCUIT BASIC PRESSURE

- 1.6.9. OIL PRESSURE IN PUMP PC CONTROL CIRCUIT

- 1.6.10. OIL PRESSURE IN PUMP LS CONTROL CIRCUIT

- 1.6.11. SOLENOID VALVE OUTPUT PRESSURE

- 1.6.12. ATTACHMENT SOLENOID VALVE OUTPUT PRESSURE

- 1.6.13. PPC VALVE OUTPUT PRESSURE

- 1.6.14. SOFT SWING ADJUSTMENTS (IF EQUIPPED)

- 1.6.15. PLAY OF WORK EQUIPMENT AND SWING PPC VALVES

- 1.6.16. HYDRAULIC DRIFT OF WORK EQUIPMENT

- 1.6.17. RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

- 1.6.18. OIL LEAKAGE

- 1.6.19. BLEEDING AIR FROM EACH PART

- 1.6.20. ADJUSTING MIRRORS

- 1.6.21. SPECIAL FUNCTIONS OF MACHINE MONITOR

- 1.6.22. HANDLING VOLTAGE CIRCUIT OF ENGINE CONTROLLER

- 1.6.23. PREPARATION FOR ELECTRICAL SYSTEM TROUBLESHOOTING

- 1.6.24. PROCEDURE FOR TESTING DIODES

- 1.6.25. PM CLINIC SERVICE

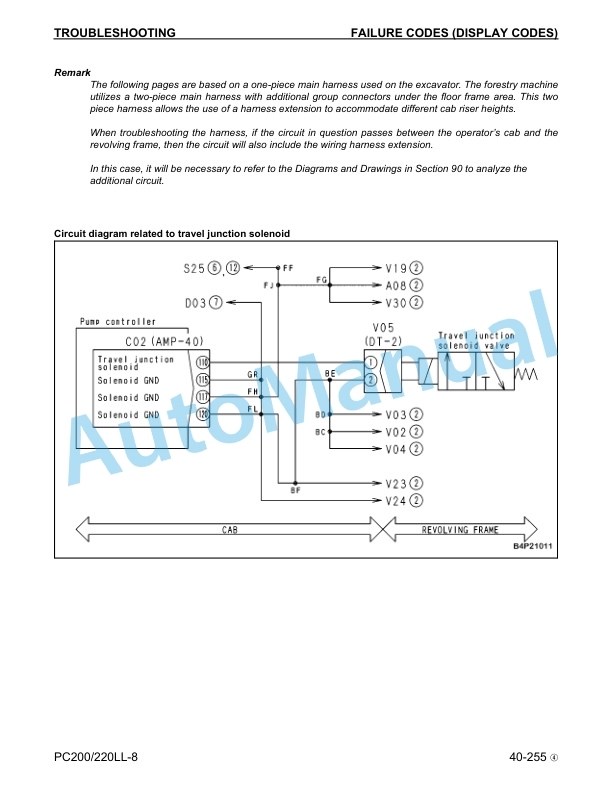

- 1.7. TROUBLESHOOTING

- 1.7.1. GENERAL INFORMATION

- 1.7.2. ELECTRIC WIRE CODE

- 1.7.3. HOW TO READ ELECTRIC WIRE CODE

- 1.7.4. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 1.7.5. TADAPTER TABLE

- 1.7.6. FAILURE CODES (DISPLAY CODES)

- 1.7.7. ELECTRICAL SYSTEM (EMODE)

- 1.7.8. HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 1.8. DISASSEMBLY AND ASSEMBLY

- 1.8.1. HOW TO READ THIS MANUAL

- 1.8.2. SPECIAL TOOLS LIST

- 1.8.3. SKETCHES OF SPECIAL TOOLS

- 1.8.4. CONNECTOR REPAIR PROCEDURES

- 1.8.5. PRECAUTIONS DURING OPERATION

- 1.8.6. LIST OF ADHESIVES

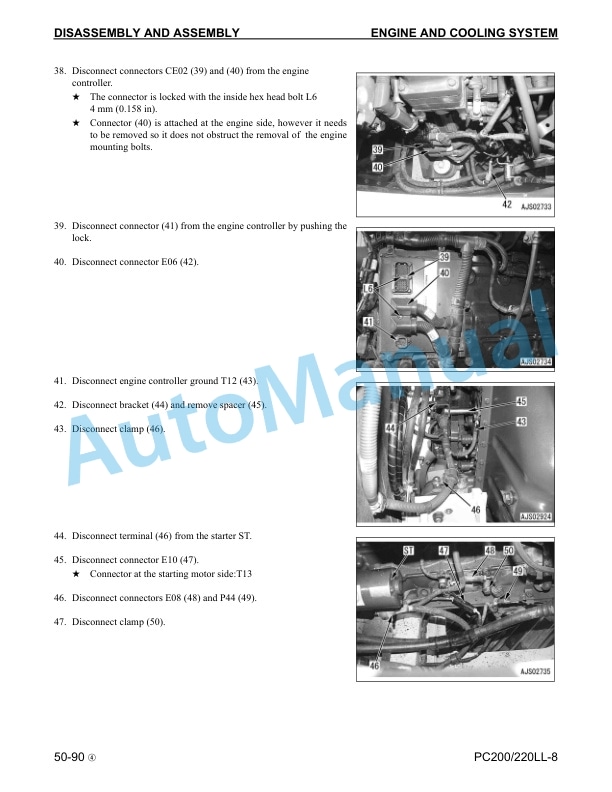

- 1.8.7. ENGINE AND COOLING SYSTEM

- 1.8.8. POWER TRAIN

- 1.8.9. UNDERCARRIAGE AND FRAME

- 1.8.10. HYDRAULIC SYSTEM

- 1.8.11. WORK EQUIPMENT

- 1.8.12. CAB AND ITS ATTACHMENTS

- 1.8.13. ELECTRICAL SYSTEM

- 1.9. AIR CONDITIONER

- 1.9.1. STRUCTURE AND FUNCTION

- 1.9.2. TESTING AND ADJUSTING

- 1.9.3. TROUBLESHOOTING

- 1.10. DIAGRAMS AND DRAWINGS

- 1.10.1. HYDRAULIC DIAGRAMS AND DRAWINGS

- 1.10.2. ELECTRICAL DIAGRAMS AND DRAWINGS

Rate this product

You may also like