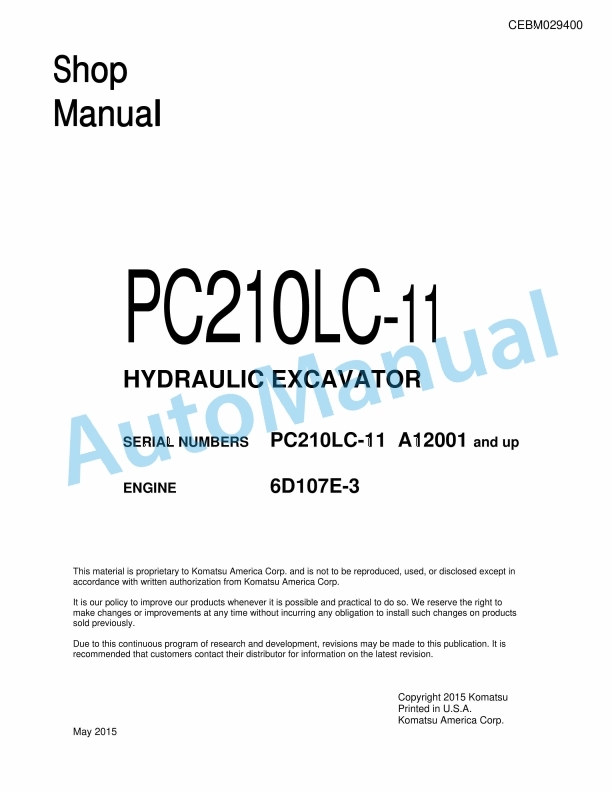

Komatsu PC210LC-11 Hydraulic Excavator Shop Manual CEBM029400

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM029400

- Format: PDF

- Size: 64.0MB

- Number of Pages: 2586

Category: Komatsu Shop Manual PDF

-

Model List:

- PC210LC-11 Hydraulic Excavator

- 1. PC210LC11 TITLE PAGE

- 1.1. INDEX AND FOREWORD

- 1.1.1. INDEX

- 1.1.2. FOREWORD, SAFETY, BASIC INFORMATION

- 1.2. SPECIFICATIONS

- 1.2.1. CONTENTS

- 1.2.2. SPECIFICATIONS

- 1.3. STRUCTURE AND FUNCTION

- 1.3.1. CONTENTS

- 1.3.2. UREA SCR SYSTEM

- 1.3.3. BOOTUP SYSTEM

- 1.3.4. ENGINE SYSTEM

- 1.3.5. COOLING SYSTEM

- 1.3.6. CONTROL SYSTEM

- 1.3.7. HYDRAULIC SYSTEM

- 1.3.8. WORK EQUIPMENT SYSTEM

- 1.3.9. SWING SYSTEM

- 1.3.10. TRAVEL SYSTEM

- 1.3.11. UNDERCARRIAGE AND FRAME

- 1.3.12. WORK EQUIPMENT

- 1.3.13. CAB AND ITS ATTACHMENTS

- 1.4. STANDARD VALUE TABLE

- 1.4.1. CONTENTS

- 1.4.2. STANDARD VALUE TABLE FOR ENGINE

- 1.4.3. STANDARD VALUE TABLE FOR MACHINE

- 1.4.4. STANDARD VALUE TABLE FOR ELECTRICAL

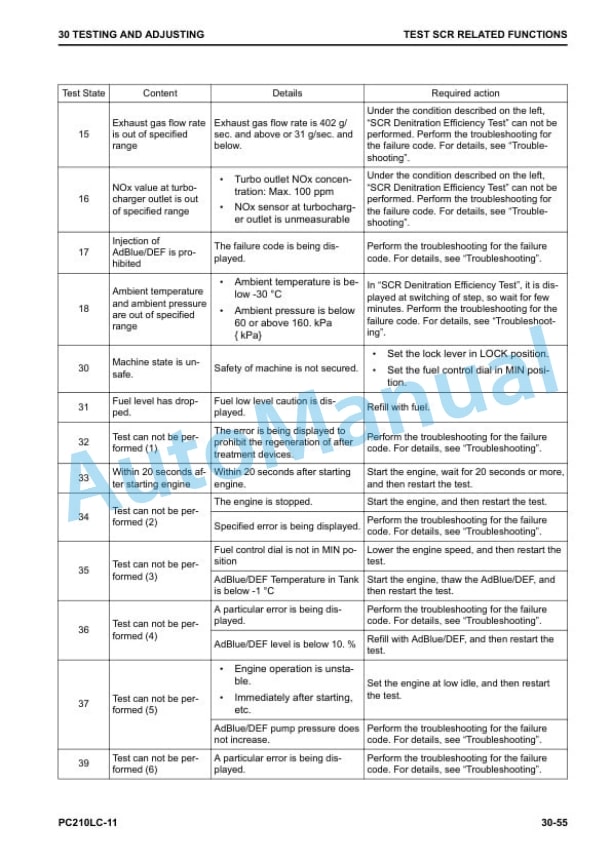

- 1.5. TESTING AND ADJUSTING

- 1.5.1. CONTENTS

- 1.5.2. RELATED INFORMATION ON TESTING AND ADJUSTING

- 1.5.3. ENGINE AND COOLING SYSTEM

- 1.5.4. POWER TRAIN

- 1.5.5. UNDERCARRIAGE AND FRAME

- 1.5.6. HYDRAULIC SYSTEM

- 1.5.7. CAB AND ITS ATTACHMENTS

- 1.5.8. ELECTRICAL SYSTEM

- 1.5.9. Pm CLINIC

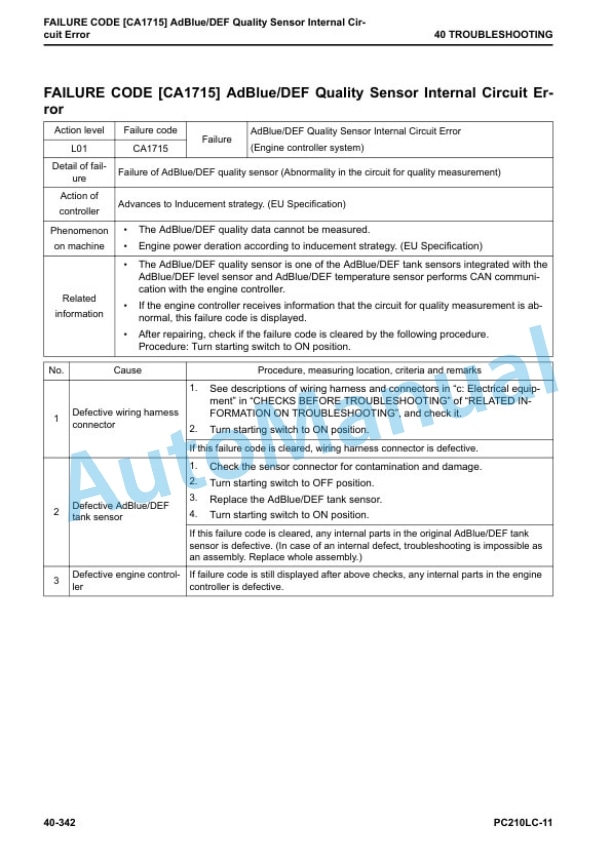

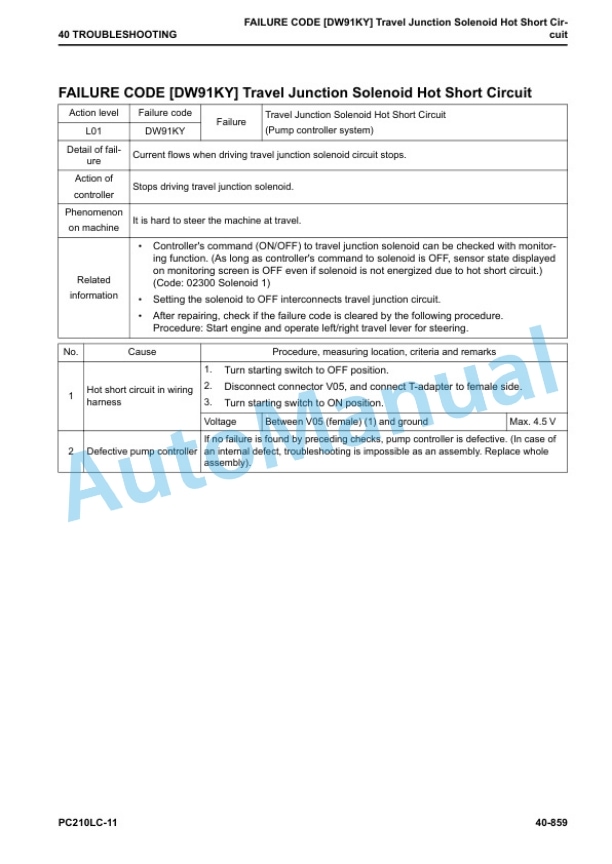

- 1.6. TROUBLESHOOTING

- 1.6.1. CONTENTS

- 1.6.2. RELATED INFORMATION ON TROUBLESHOOTING

- 1.6.3. TROUBLESHOOTING BY FAILURE CODE (DISPLAY OF CODE)

- 1.6.4. TROUBLESHOOTING OF ELECTRICAL SYSTEM (EMODE)

- 1.6.5. TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)

- 1.6.6. TROUBLESHOOTING OF ENGINE (SMODE)

- 1.7. DISASSEMBLY AND ASSEMBLY

- 1.7.1. CONTENTS

- 1.7.2. RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY

- 1.7.3. ENGINE AND COOLING SYSTEM

- 1.7.4. POWER TRAIN

- 1.7.5. UNDERCARRIAGE AND FRAME

- 1.7.6. HYDRAULIC SYSTEM

- 1.7.7. WORK EQUIPMENT

- 1.7.8. CAB AND ITS ATTACHMENTS

- 1.7.9. ELECTRICAL SYSTEM

- 1.8. MAINTENANCE STANDARD

- 1.8.1. CONTENTS

- 1.8.2. ENGINE AND COOLING SYSTEM

- 1.8.3. POWER TRAIN

- 1.8.4. UNDERCARRIAGE AND FRAME

- 1.8.5. HYDRAULIC SYSTEM

- 1.8.6. WORK EQUIPMENT

- 1.9. APPENDIX

- 1.9.1. CONTENTS

- 1.9.2. AIR CONDITIONER SYSTEM

- 1.9.3. COMPONENT PARTS OF AIR CONDITIONER SYSTEM

- 1.9.4. EXPLANATION OF PROCEDURE FOR TESTING AND TROUBLESHOOTING OF AIR CONDITIONER

- 1.9.5. CIRCUIT DIAGRAM AND ARRANGEMENT OF CONNECTOR PINS FOR AIR CONDITIONER

- 1.9.6. AIR CONDITIONER SYSTEM DIAGRAM

- 1.9.7. INSTALLATION LOCATIONS OF AIR CONDITIONER PARTS AND ARRANGEMENT OF CONNECTORS

- 1.9.8. TESTING AIR LEAKAGE (DUCT)

- 1.9.9. TESTING AIR CONDITIONER USING SELFDIAGNOSIS FUNCTION

- 1.9.10. HOW TO OPEN THE ELECTRICAL SYSTEM ABNORMALITY RECORD SCREEN IN SERVICE MODE OF THE MACHINE MONITOR

- 1.9.11. TEST VENT (MODE) CHANGEOVER

- 1.9.12. TESTING FRESH/RECIRC AIR CHANGEOVER

- 1.9.13. TEST SUNLIGHT SENSOR

- 1.9.14. TEST (DUAL) PRESSURE SWITCH FOR REFRIGERANT

- 1.9.15. TEST RELAYS

- 1.9.16. AIR CONDITIONER TROUBLESHOOTING CHART 1

- 1.9.17. AIR CONDITIONER TROUBLESHOOTING CHART 2

- 1.9.18. INFORMATION DESCRIBED IN TROUBLESHOOTING TABLE

- 1.9.19. FAILURE CODE 879AKA A/C Recirculation Air Temperature Sensor Open Circuit

- 1.9.20. FAILURE CODE 879AKB A/C Recirculation Air Temperature Sensor Short Circuit

- 1.9.21. FAILURE CODE 879BKA A/C Fresh Air Temperature Sensor Open Circuit

- 1.9.22. FAILURE CODE 879BKB A/C Fresh Air Temperature Sensor Short Circuit

- 1.9.23. FAILURE CODE 879CKA Ventilating Sensor Open Circuit

- 1.9.24. FAILURE CODE 879CKB Ventilating Sensor Short Circuit

- 1.9.25. FAILURE CODE 879DKZ Sunlight Sensor Open Circuit or Short Circuit

- 1.9.26. FAILURE CODE 879EMC Ventilation Damper Malfunction

- 1.9.27. FAILURE CODE 879FMC Air Mix Damper Malfunction

- 1.9.28. FAILURE CODE 879GKX Refrigerant Pressure Input Signal Out of Range

- 1.9.29. A1 TROUBLESHOOTING FOR POWER SUPPLY SYSTEM (AIR CONDITIONER DOES NOT OPERATE)

- 1.9.30. A2 TROUBLESHOOTING OF COMPRESSOR SYSTEM (AIR IS NOT COOLED)

- 1.9.31. A3 TROUBLESHOOTING FOR BLOWER MOTOR SYSTEM (NO AIR COMES OUT OR AIR FLOW IS ABNORMAL)

- 1.9.32. A4 TROUBLESHOOTING FOR FRESH/RECIRC AIR CHANGEOVER

- 1.9.33. TROUBLESHOOTING USING GAUGE PRESSURE

- 1.9.34. CONNECTION OF SERVICE TOOL

- 1.9.35. PRECAUTIONS FOR DISCONNECTING AND CONNECTING HOSES AND TUBES IN AIR CONDITIONER PIPINGS

- 1.9.36. HANDLE COMPRESSOR OIL

- 1.9.37. METHOD FOR REPLACING DESICCANT

- 1.10. CIRCUIT DIAGRAMS

- 1.10.1. CONTENTS

- 1.10.2. SYMBOLS USED IN HYDRAULIC CIRCUIT DIAGRAM

- 1.10.3. ELECTRICAL CIRCUIT DIAGRAM

- 1.11. INDEX

Rate this product

You may also like