Komatsu PC228US-3E0, PC228USLC-3E0 Hydraulic Excavator Shop Manual TEN00161-04

$40.00

- Type Of Manual: Shop Manual

- Manual ID: TEN00161-04

- Format: PDF

- Size: 8.2MB

- Number of Pages: 337

Category: Komatsu Shop Manual PDF

-

Model List:

- PC228US-3E0 Hydraulic Excavator

- PC228USLC-3E0 Hydraulic Excavator

- 1. COVER

- 2. FOREWORD

- 2.1. BEFORE READING THIS MANUAL

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. USE OF MACHINE

- 2.3.2. DIRECTIONS OF MACHINE

- 2.4. PRODUCT INFORMATION

- 2.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 2.4.2. EPA REGULATIONS, ENGINE NUMBER PLATE

- 2.4.3. SERVICE METER LOCATION

- 2.4.4. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 2.5. CONTENTS

- 3. SAFETY

- 3.1. SAFETY

- 3.2. SAFETY LABELS

- 3.2.1. LOCATION OF SAFETY LABELS

- 3.2.2. SAFETY LABELS

- 3.3. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 3.3.1. PRECAUTIONS BEFORE STARTING OPERATION

- 3.3.2. PREPARATIONS FOR SAFE OPERATION

- 3.3.3. FIRE PREVENTION

- 3.3.4. PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

- 3.3.5. DO NOT GET CAUGHT IN WORK EQUIPMENT

- 3.3.6. PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES

- 3.3.7. PROTECTION AGAINST FALLING, FLYING, INTRUDING OBJECTS

- 3.3.8. UNAUTHORIZED MODIFICATION

- 3.3.9. PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

- 3.3.10. PRECAUTIONS RELATED TO CAB GLASS

- 3.3.11. PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING

- 3.4. PRECAUTIONS FOR OPERATION

- 3.4.1. PRECAUTIONS FOR JOBSITE

- 3.4.2. STARTING ENGINE

- 3.4.3. OPERATION

- 3.4.4. TRANSPORTATION

- 3.4.5. TOWING

- 3.4.6. LIFTING OBJECTS WITH BUCKET

- 3.5. PRECAUTIONS FOR MAINTENANCE

- 3.5.1. PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE

- 3.5.2. PRECAUTIONS FOR INSPECTION AND MAINTENANCE

- 4. OPERATION

- 4.1. MACHINE VIEW ILLUSTRATIONS

- 4.1.1. OVERALL MACHINE VIEW

- 4.1.2. CONTROLS AND GAUGES

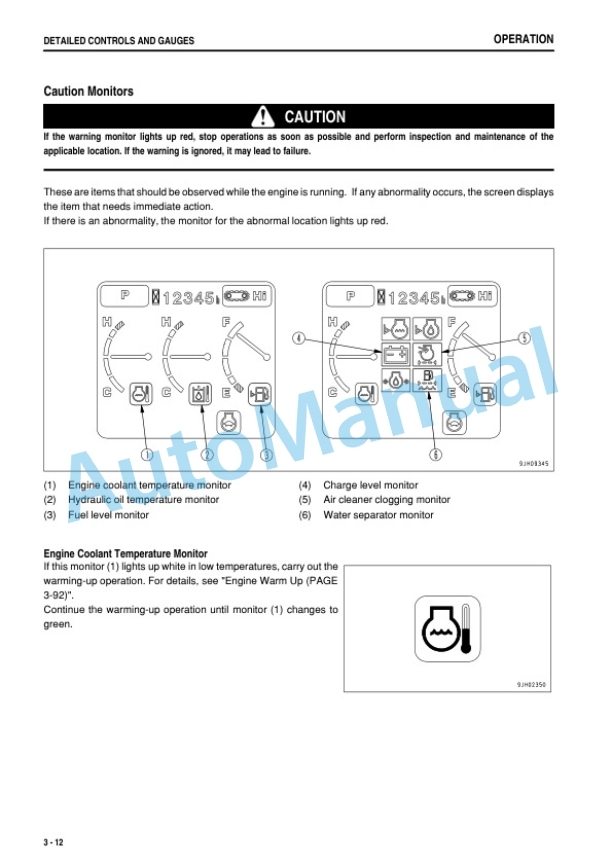

- 4.2. DETAILED CONTROLS AND GAUGES

- 4.2.1. MONITORING SYSTEM

- 4.2.2. SWITCHES

- 4.2.3. CONTROL LEVERS AND PEDALS

- 4.2.4. SUN ROOF

- 4.2.5. WINDSHIELD

- 4.2.6. SLIDING DOOR

- 4.2.7. EMERGENCY ESCAPE HAMMER

- 4.2.8. CAP WITH LOCK

- 4.2.9. HOT AND COOL BOX

- 4.2.10. MAGAZINE BOX

- 4.2.11. ASHTRAY

- 4.2.12. AIR CONDITIONER CONTROLS

- 4.2.13. AUTO AIR CONDITIONER CONTROLS

- 4.2.14. RADIO

- 4.2.15. AUXILIARY ELECTRIC POWER

- 4.2.16. FUSE

- 4.2.17. FUSIBLE LINK

- 4.2.18. CONTROLLER

- 4.2.19. TOOL BOX

- 4.2.20. GREASE PUMP HOLDER

- 4.3. MACHINE OPERATIONS AND CONTROLS

- 4.3.1. BEFORE STARTING ENGINE

- 4.3.2. STARTING ENGINE

- 4.3.3. AFTER STARTING ENGINE

- 4.3.4. STOPPING THE ENGINE

- 4.3.5. MACHINE OPERATION

- 4.3.6. STEERING THE MACHINE

- 4.3.7. SWINGING

- 4.3.8. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 4.3.9. WORKING MODE

- 4.3.10. PROHIBITED OPERATIONS

- 4.3.11. GENERAL OPERATION INFORMATION

- 4.3.12. TRAVELING ON SLOPES

- 4.3.13. ESCAPE FROM MUD

- 4.3.14. RECOMMENDED APPLICATIONS

- 4.3.15. BUCKET REPLACEMENT AND INVERSION

- 4.3.16. PARKING MACHINE

- 4.3.17. MACHINE INSPECTION AFTER DAILY WORK

- 4.3.18. LOCKING

- 4.4. TRANSPORTATION

- 4.4.1. TRANSPORTATION PROCEDURE

- 4.4.2. LOADING AND UNLOADING WITH TRAILER

- 4.4.3. LIFTING MACHINE

- 4.5. COLD WEATHER OPERATION

- 4.5.1. COLD WEATHER OPERATION INFORMATION

- 4.5.2. AFTER DAILY WORK COMPLETION

- 4.5.3. AFTER COLD WEATHER SEASON

- 4.6. LONG TERM STORAGE

- 4.6.1. BEFORE STORAGE

- 4.6.2. DURING STORAGE

- 4.6.3. AFTER STORAGE

- 4.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

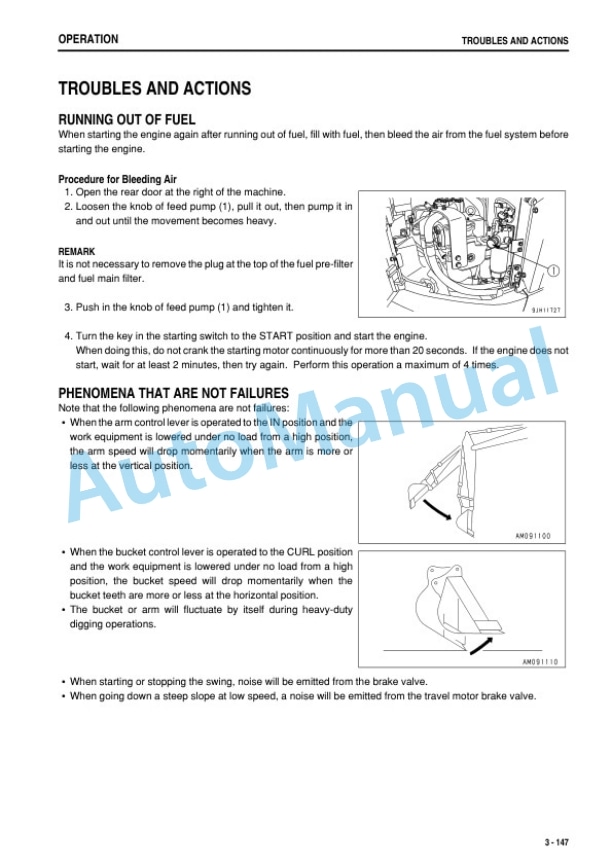

- 4.7. TROUBLES AND ACTIONS

- 4.7.1. RUNNING OUT OF FUEL

- 4.7.2. PHENOMENA THAT ARE NOT FAILURES

- 4.7.3. TOWING THE MACHINE

- 4.7.4. LIGHTWEIGHT TOWING HOLE

- 4.7.5. SEVERE JOB CONDITION

- 4.7.6. DISCHARGED BATTERY

- 4.7.7. OTHER TROUBLE

- 5. MAINTENANCE

- 5.1. MAINTENANCE INFORMATION

- 5.2. OUTLINE OF SERVICE

- 5.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 5.2.2. ELECTRIC SYSTEM MAINTENANCE

- 5.3. WEAR PARTS

- 5.3.1. WEAR PARTS LIST

- 5.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 5.4.1. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 5.5. TIGHTENING TORQUE SPECIFICATIONS

- 5.5.1. TIGHTENING TORQUE LIST

- 5.6. SAFETY CRITICAL PARTS

- 5.6.1. SAFETY CRITICAL PARTS LIST

- 5.7. MAINTENANCE SCHEDULE

- 5.7.1. MAINTENANCE SCHEDULE CHART

- 5.7.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

- 5.8. MAINTENANCE PROCEDURE

- 5.8.1. INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

- 5.8.2. INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)

- 5.8.3. WHEN REQUIRED

- 5.8.4. CHECK BEFORE STARTING

- 5.8.5. EVERY 100 HOURS MAINTENANCE

- 5.8.6. EVERY 250 HOURS MAINTENANCE

- 5.8.7. EVERY 500 HOURS MAINTENANCE

- 5.8.8. EVERY 1000 HOURS MAINTENANCE

- 5.8.9. EVERY 2000 HOURS MAINTENANCE

- 5.8.10. EVERY 4000 HOURS MAINTENANCE

- 5.8.11. EVERY 5000 HOURS MAINTENANCE

- 5.8.12. EVERY 8000 HOURS MAINTENANCE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 7. ATTACHMENTS, OPTIONS

- 7.1. GENERAL PRECAUTIONS FOR SAFETY

- 7.1.1. PRECAUTIONS WHEN SELECTING

- 7.1.2. READ THE INSTRUCTION MANUAL THOROUGHLY

- 7.1.3. PRECAUTIONS WHEN REMOVING OR INSTALLING

- 7.1.4. PRECAUTIONS WHEN USING

- 7.2. BUCKET WITH HOOK

- 7.2.1. HOOK CONDITION

- 7.2.2. PROHIBITED OPERATIONS

- 7.3. MACHINE READY FOR ATTACHMENT

- 7.3.1. LOCATIONS

- 7.3.2. HYDRAULIC CIRCUIT

- 7.3.3. ATTACHMENT REMOVAL AND INSTALLATION

- 7.3.4. ATTACHMENT OPERATIONS

- 7.3.5. LONG TERM STORAGE

- 7.3.6. SPECIFICATIONS

- 7.4. ATTACHMENT GUIDE

- 7.4.1. ATTACHMENT COMBINATIONS

- 7.4.2. TRACK SHOES SELECTION

- 7.4.3. BUCKET TEETH SELECTION

- 7.5. RECOMMENDED ATTACHMENT OPERATIONS

- 7.5.1. HYDRAULIC BREAKER

- 7.6. BLADE

- 7.6.1. DETAILED CONTROLS

- 7.6.2. BLADE CONTROL AND OPERATION

- 7.6.3. PROHIBITED OPERATIONS

- 7.6.4. GENERAL OPERATION INFORMATION

- 7.6.5. EVERY 100 HOURS MAINTENANCE

- 7.7. HANDLING MACHINES EQUIPPED WITH KOMTRAX

- 7.7.1. BASIC PRECAUTIONS

- 8. INDEX

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00