Komatsu PC22MR-3 Hydraulic Excavator Shop Manual WEN00038-00

$40.00

- Type Of Manual: Shop Manual

- Manual ID: WEN00038-00

- Format: PDF

- Size: 23.2MB

- Number of Pages: 400

Category: Komatsu Shop Manual PDF

-

Model List:

- PC22MR-3 Hydraulic Excavator

- 1. Index and foreword

- 1.1. Table of contents

- 1.2. Foreword and general information

- 1.3. Shop Manual

- 2. Specification

- 2.1. Contents

- 2.2. Specifications

- 2.3. Shop Manual

- 3. Structure and function

- 3.1. Hydraulic components layout drawing

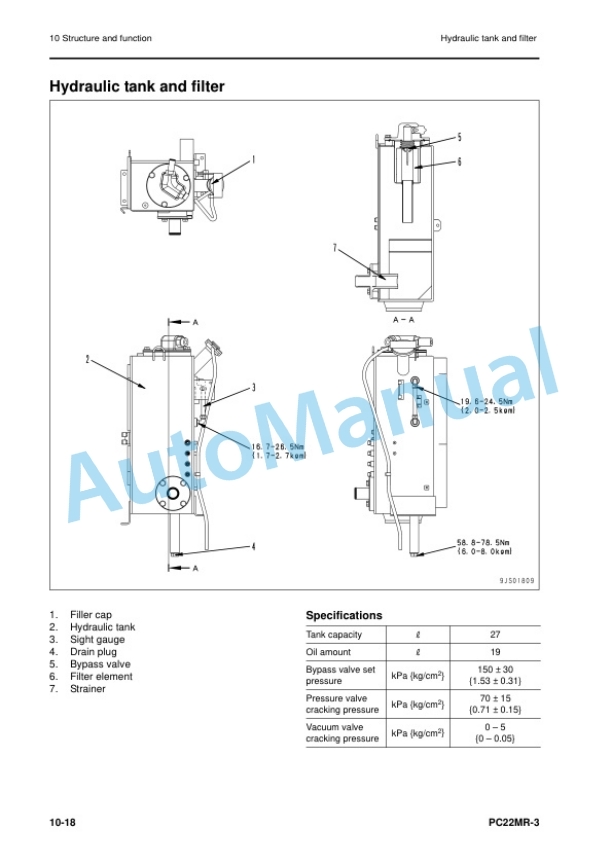

- 3.2. Hydraulic tank and filter

- 3.3. Center swivel joint

- 3.4. Travel motor

- 3.5. Hydraulic cylinder

- 3.6. Solenoid valve

- 3.7. Hydraulic pump

- 3.8. Control valve

- 3.9. CLSS

- 3.10. Swing motor

- 3.11. PPC valve

- 3.12. Work equipment

- 3.13. Floor

- 3.14. Shop Manual

- 4. Standard value table

- 4.1. Contents

- 4.2. Standard value table

- 5. Testing and adjusting

- 5.1. Contents

- 5.2. List of testing, adjusting, and troubleshooting tools

- 5.3. Measuring engine speed

- 5.4. Adjusting valve clearance

- 5.5. Measuring compression pressure

- 5.6. Measuring engine oil pressure

- 5.7. Testing and adjusting fuel injection timing

- 5.8. Bleeding air from fuel circuit

- 5.9. Testing and adjusting fan belt tension

- 5.10. Adjusting fuel control lever linkage

- 5.11. Measurement of clearance in swing circle bearings

- 5.12. Testing and adjusting track shoe tension

- 5.13. Testing and adjusting oil pressures in work equipment, travel, swing, and blade circuits

- 5.14. Measuring control circuit basic pressure

- 5.15. Testing and adjusting pump LS differential pressure

- 5.16. Measuring solenoid valve output pressure

- 5.17. Measuring PPC valve output pressure

- 5.18. Measuring swing holding brake release pressure

- 5.19. Measurement of oil leakage from cylinder

- 5.20. Releasing residual pressure from hydraulic circuit

- 5.21. Bleeding air from cylinder

- 5.22. Pressurizing hydraulic tank

- 5.23. How to open and close (tilt) floor

- 5.24. Inspection procedures for diode

- 5.25. How to start operation of KOMTRAX terminal

- 5.26. Lamp display of KOMTRAX terminal

- 5.27. Preparation work for troubleshooting of electrical system

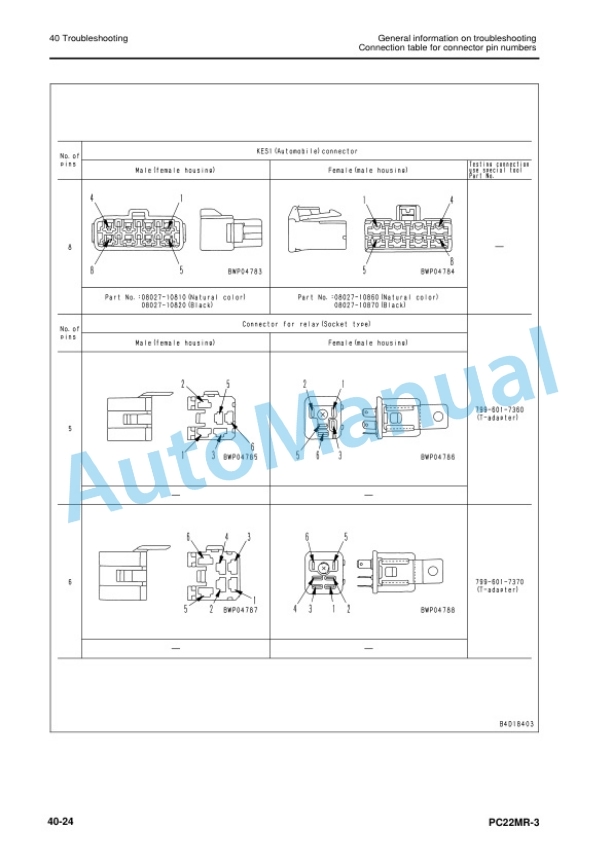

- 6. Troubleshooting

- 6.1. Contents

- 6.2. General information on troubleshooting

- 6.3. Troubleshooting of electrical system (Emode)

- 6.4. Troubleshooting of hydraulic and mechanical system (Hmode)

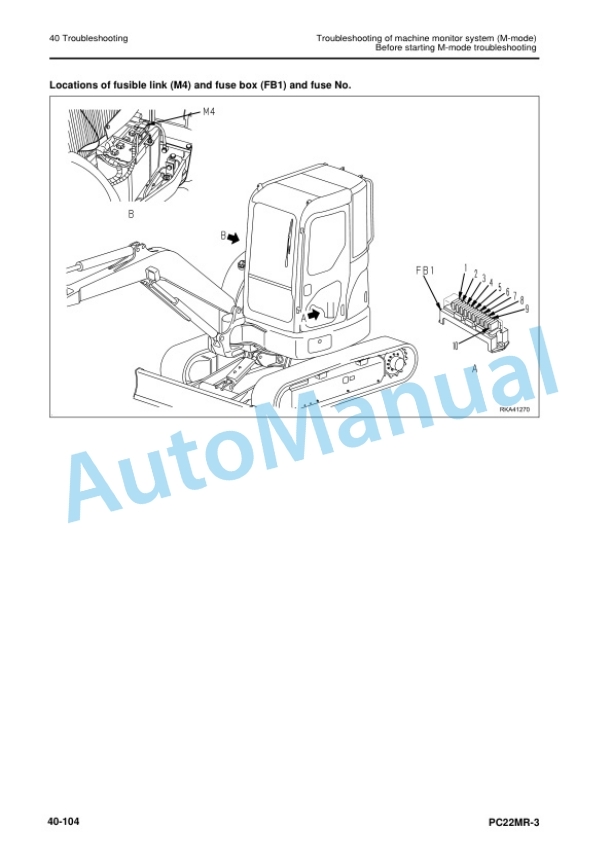

- 6.5. Troubleshooting of machine monitor system (Mmode)

- 7. Disassembly and assembly

- 7.1. Contents

- 7.2. How to read this manual

- 7.3. Coating materials list

- 7.4. Special tool list

- 7.5. Removal and installation of fuel injection pump assembly

- 7.6. Removal and installation of radiator and hydraulic oil cooler assembly

- 7.7. Removal and installation of engine and hydraulic pump assembly

- 7.8. Removal and installation of swing circle assembly

- 7.9. Removal and installation of track shoe assembly

- 7.10. Disassembly and assembly of idler assembly

- 7.11. Disassembly and assembly of recoil spring

- 7.12. Disassembly and assembly of track roller assembly

- 7.13. Removal and installation of floor frame assembly

- 7.14. Removal and installation of revolving frame assembly

- 7.15. Disassembly and assembly of control valve assembly

- 7.16. Removal and installation of center swivel joint assembly

- 7.17. Disassembly and assembly of center swivel joint assembly

- 7.18. Removal and installation of swing motor and swing machinery assembly

- 7.19. Disassembly and assembly of hydraulic cylinder assembly

- 7.20. Removal and installation of work equipment assembly

- 7.21. Removal and installation of KOMTRAX station (for canopy)

- 7.22. Removal and installation of KOMTRAX station (for cab)

- 8. Diagrams and drawings

- 8.1. Contents

- 8.2. Hydraulic diagram

- 8.3. Electrical diagram

Rate this product

You may also like